Method for reducing mining vibration energy under hard rock stratum

A hard rock formation and energy technology, applied in the field of vibration energy control of coal mining under hard rock formations, can solve the problems of low recovery rate and efficiency, fracture, and failure to reduce stress concentration from the root cause, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

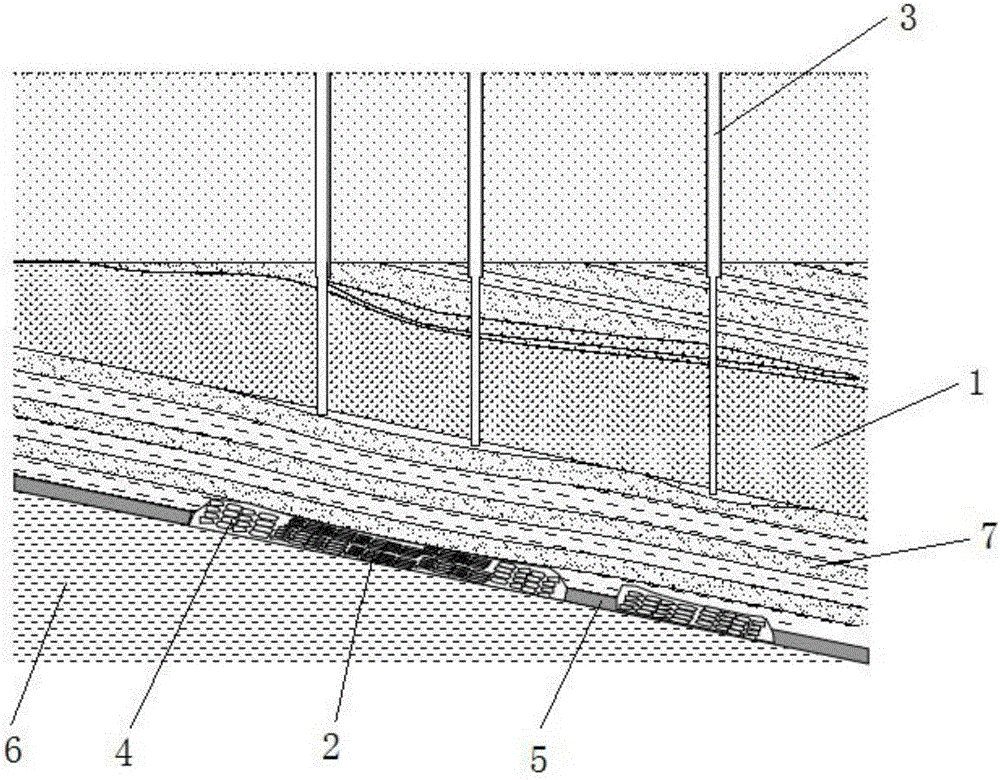

[0016] combine figure 1 , the specific embodiment of the present invention: a kind of method for reducing mining vibration energy under hard rock formation 1, comprises the following steps:

[0017] 1) Obtain the geological mining information of the mining area, and determine the maximum working face width allowed without breaking the hard rock layer 1 according to the mechanical parameters of the hard rock layer 1 and the distance between the hard rock layer 1 and the coal seam 6, and set aside 50-70m between the working faces Isolated coal pillar 5;

[0018] 2) Before mining at the coal mining face, several groups of drill holes 3 are constructed on the surface along the direction of the working face.

[0019] 3) During the mining process of the coal mining face, according to the distance between the coal mining face and each group of boreholes 3, each group of boreholes 3 is used to carry out grouting filling to the separation zone 7 under the hard rock layer 1, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com