Supporting mechanism for underground weak engineering geological roadway and using method thereof

A technology of engineering geology and support mechanism, which is applied in the direction of earthwork drilling, pillars/brackets, temporary shields, etc. It can solve the problems of poor support effect, inability to contact and fit, and inability to act as active support, etc., to achieve simple structure , stable structure, and the effect of solving passive support defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

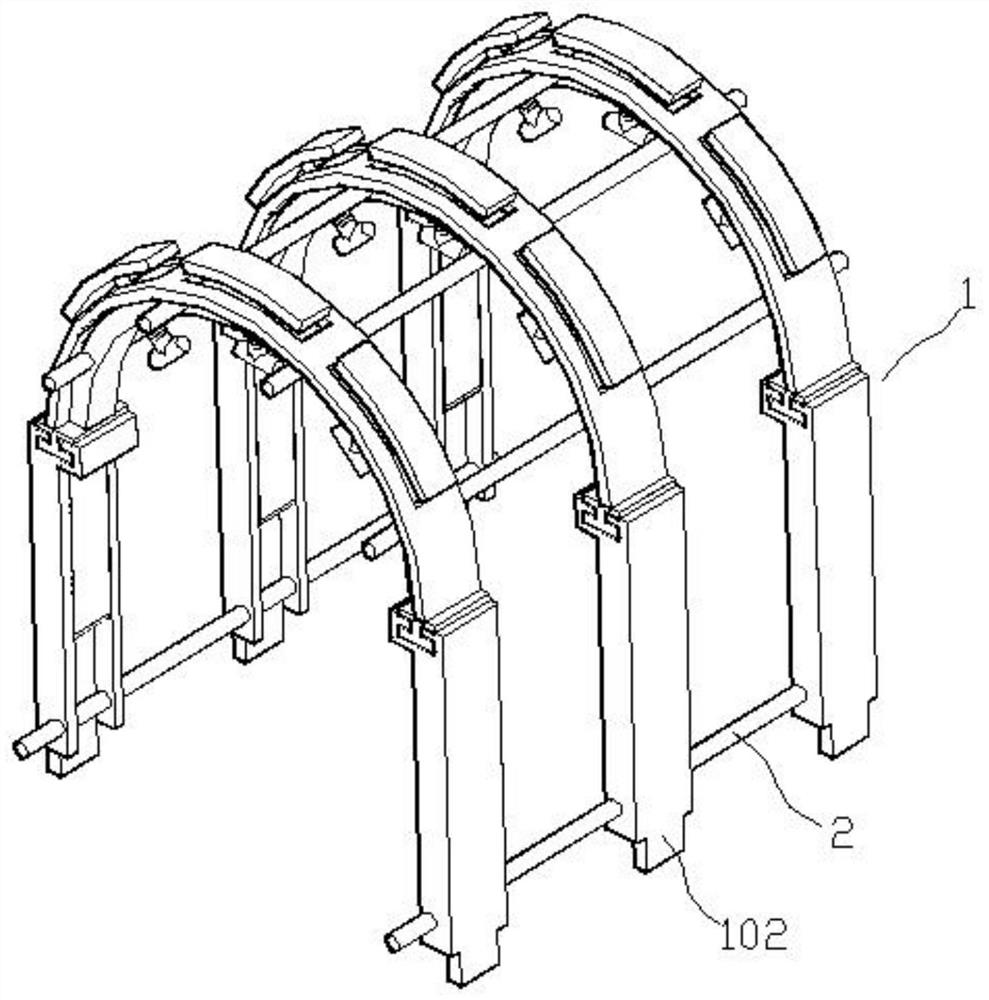

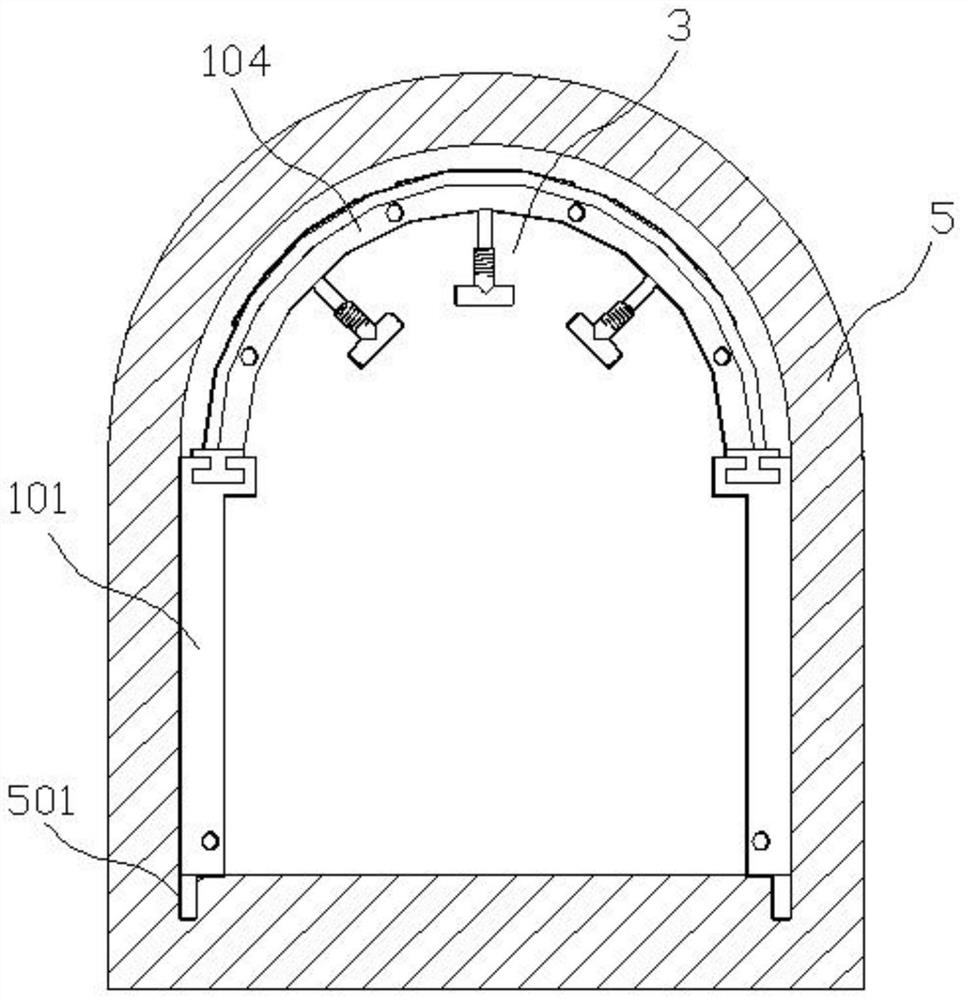

[0040] A support mechanism for underground weak engineering geological roadway, such as Figure 1-Figure 3As shown, it includes a plurality of support device units 1 and a connector for connecting the plurality of support device units 1 in series.

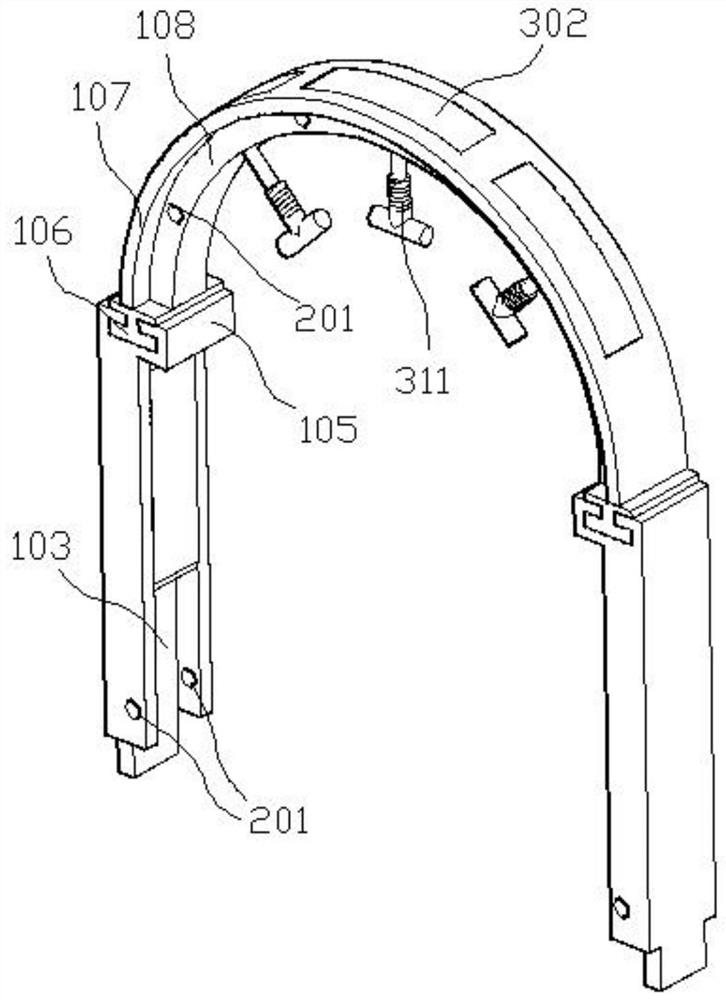

[0041] The supporting device unit 1 includes shaped steel pillars 101 symmetrically arranged on the left and right sides and an arc-shaped support 104 arranged above the shaped steel pillars 101. The shaped steel pillars 101 include a cylinder, a tenon 102 arranged at the bottom end of the cylinder, and a tenon 102 set on the cylinder. The cavity 103 on the side of the middle section and the boss 105 arranged on the top of the cylinder, and the boss 105 is provided with a groove 106, and the direction of the groove 106 is consistent with the direction in which the roadway 5 penetrates.

[0042] The arc bracket 104 includes a first arc frame 107 above and a second arc frame 108 below, the arc openings of the first arc frame 107 and ...

Embodiment approach

[0044] (I) if Figure 4 As shown, the above-mentioned block 109 is an "I"-shaped structure, the upper plate body of this type block 109 overlaps with the top of the boss 105, and the middle vertical plate and the lower plate body of the block 109 are mated and inserted into the groove 106. , a first positioning hole (not shown) is vertically opened in the upper plate body of the block 109, the boss 105 and the lower plate body of the block 109, and the first positioning pin 110 is arranged in the positioning hole, and the first positioning pin 110 is arranged in the positioning hole. The pin 110 is located at a front position or / and a rear position of the second arc-shaped frame 108 .

[0045] (Ⅱ) If Figure 5 As shown, the above-mentioned type block 109 is a "匸"-shaped structure, the upper plate body of this type block 109 is overlapped with the top of the boss 105, and the middle vertical plate and the lower plate body of the type block 109 are mated and inserted into the g...

Embodiment 2

[0051] The arc-shaped support 104 in the above-mentioned embodiment 1 is aimed at the geological roadway of the semi-circular arch type, and for roadways with other cross-sectional shapes, such as rectangular or trapezoidal roadways, the shape of the support is not arc-shaped, and can be changed and optimized into a corresponding shape. bracket structure.

[0052] Similarly, the shape of the support plate is not limited to arc shape, which is mainly based on the top structure of the roadway. When the cross section of the roadway is rectangular or trapezoidal, the shape of the support plate can also be straight strip shape, cross shape or other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com