Quick connection joint for plastic pipeline

A quick-connection, plastic pipe technology, applied in the direction of pipe connection layout, pipe/pipe joint/pipe fittings, machinery and equipment, etc., can solve the problems that the pipe cannot be effectively fixed, the pipe joint is easy, and the pressure of the pipe is unstable. The disassembly is convenient and quick, the connection process is simple, and the effect of the pipe falling off is eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention can be explained in more detail through the following embodiments. The present invention is not limited to the following embodiments. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention;

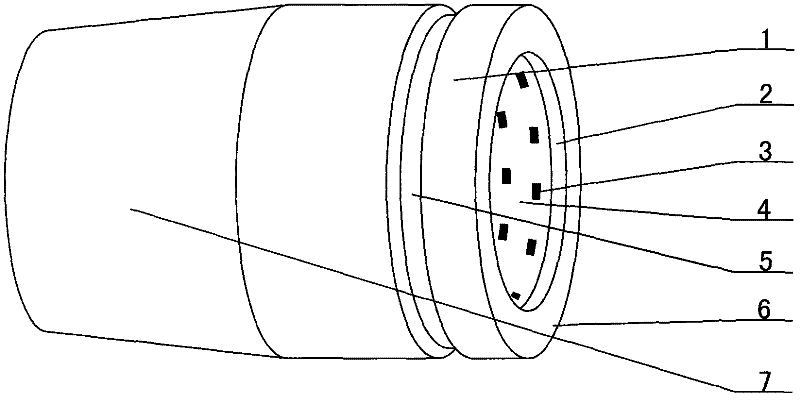

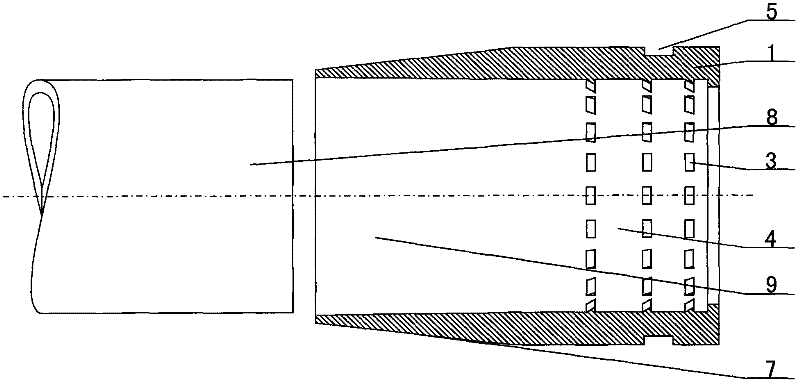

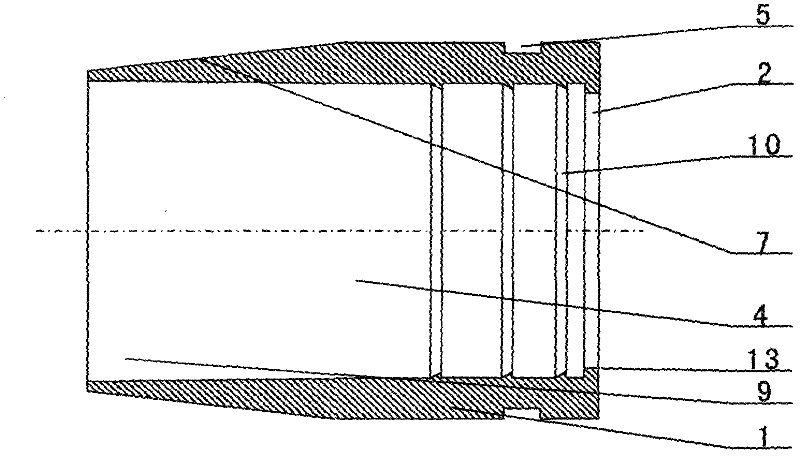

[0025] Attached Figure 1~6 For the quick connection joints of the plastic pipes described in the above, the connection joints are made of hard materials, that is, the hard materials used in the connection joints of the present invention are hard plastics and nylons, and the hard plastics are ABS, POM, PS, Any one of PMMA, PC, PET, PBT or PPO; any metal material of copper, aluminum alloy, cast iron, steel or stainless steel can also be used; the outer end to the middle of the connection joint is the connector 1, The other end to the middle of the outer edge surface of the connecting joint is a plug-in connector 7 with a small end diameter and a large middle diameter. A surrounding groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com