Method for preparing aluminum trioxide-nickel oxide ceramic coating on nickel electrode surface

A technology of ceramic coating and alumina, which is applied in the direction of anodic oxidation, battery electrodes, alkaline battery electrodes, etc., can solve the problems of surface active substance powder loosening, battery capacity decline, battery failure, etc., to achieve enhanced adhesion, battery Capacity retention, the effect of alleviating the decline in battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

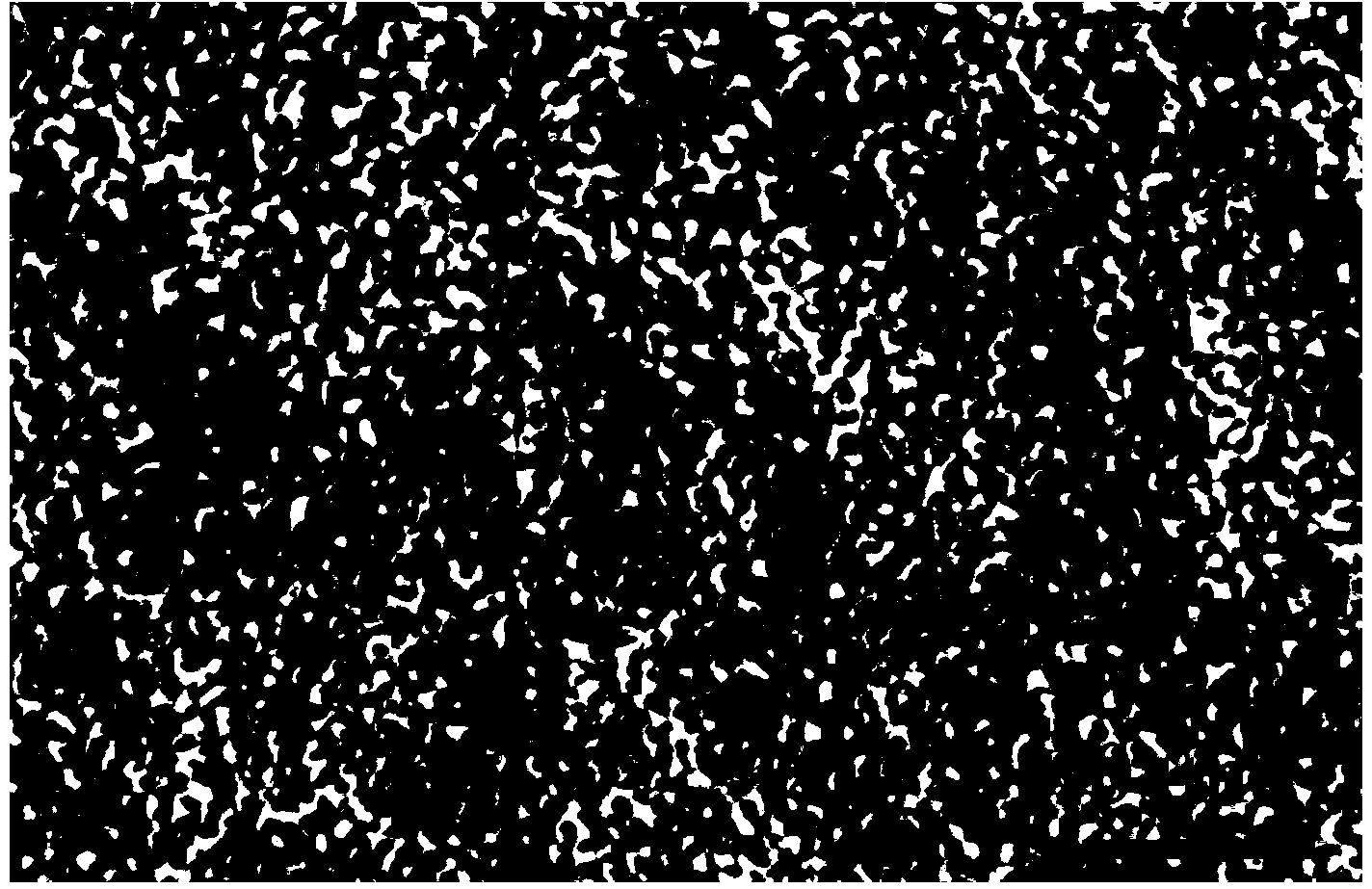

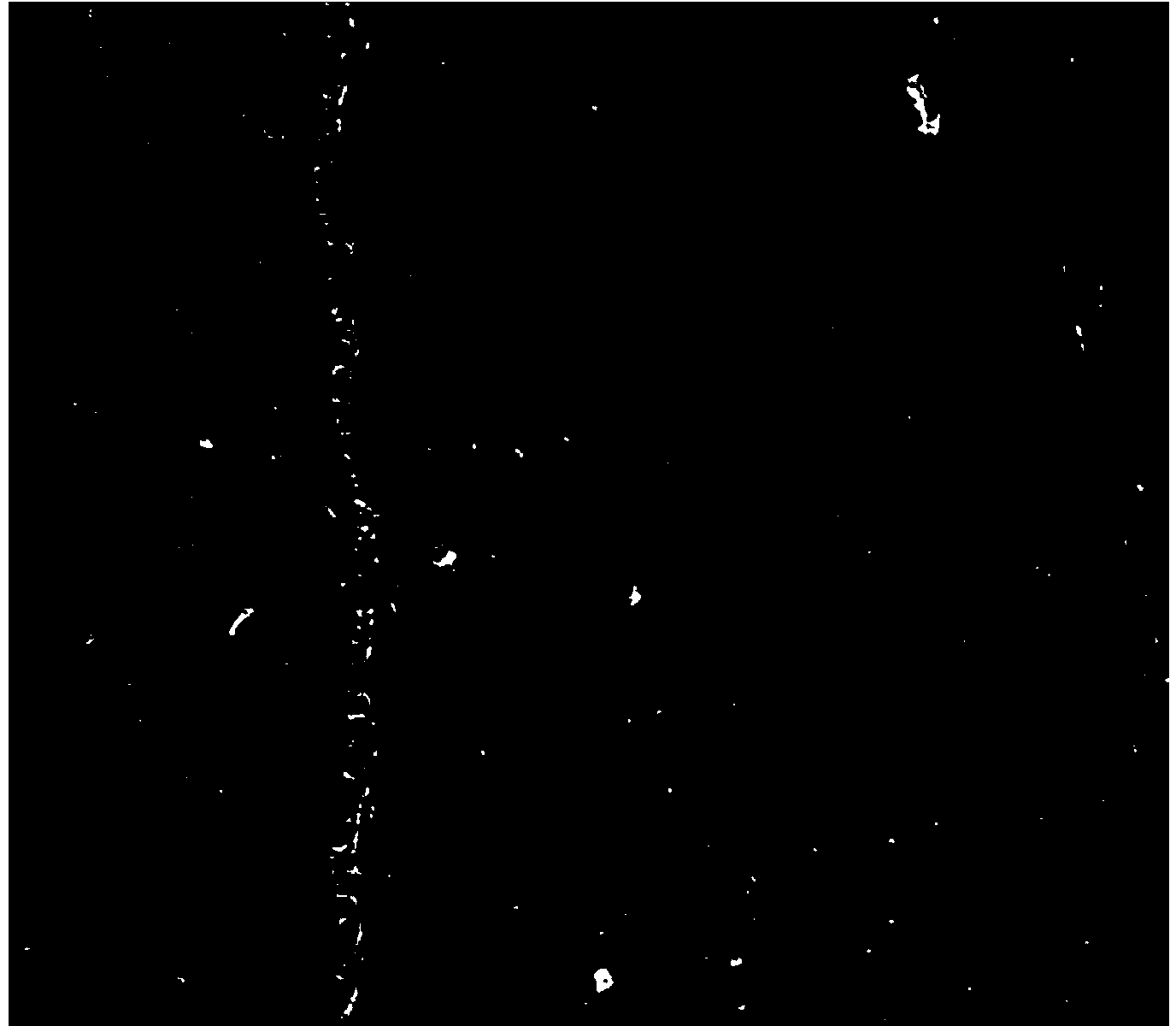

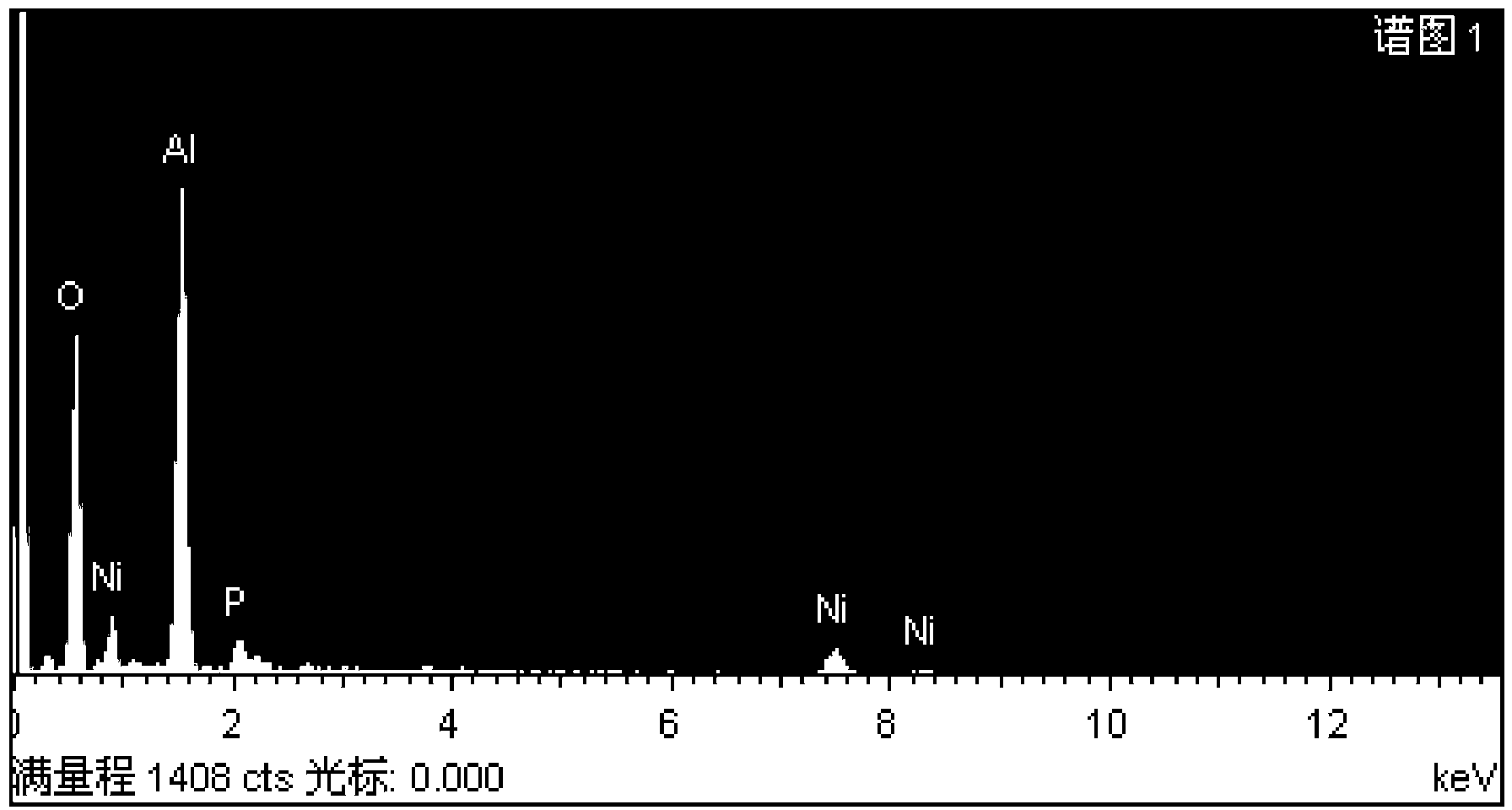

[0022] In this embodiment, the method for preparing aluminum oxide and nickel oxide ceramic coatings on the surface of the nickel electrode of the present invention includes the following steps: (1), first, the surface of the nickel electrode (pure nickel with a mass content of the nickel electrode greater than 99%) is coated with No. 2000 sandpaper was polished to remove the oxide layer on the surface, and then rinsed with distilled water; (2), weighed cerium chloride as 15g / L of cerium chloride, dissolved in distilled water, and prepared a solution; (3), the step (1 ) The treated nickel electrode is placed in the solution prepared in step (2), heated to 60°C in a water bath, and the treatment time is 8 hours, and a chemical conversion film is prepared on the surface of the nickel electrode; (4), according to the concentration of sodium aluminate Weigh sodium aluminate and sodium polyphosphate at a concentration of 15g / L and sodium polyphosphate at a concentration of 1g / L, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com