Bridge expansion joint device preventing extra large vertical rotation angle displacement

A technology for expansion joints and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as corner displacement, beam end upturning, expansion joint device damage, etc., to prevent breakage, avoid damage, and pass smoothly and safely Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

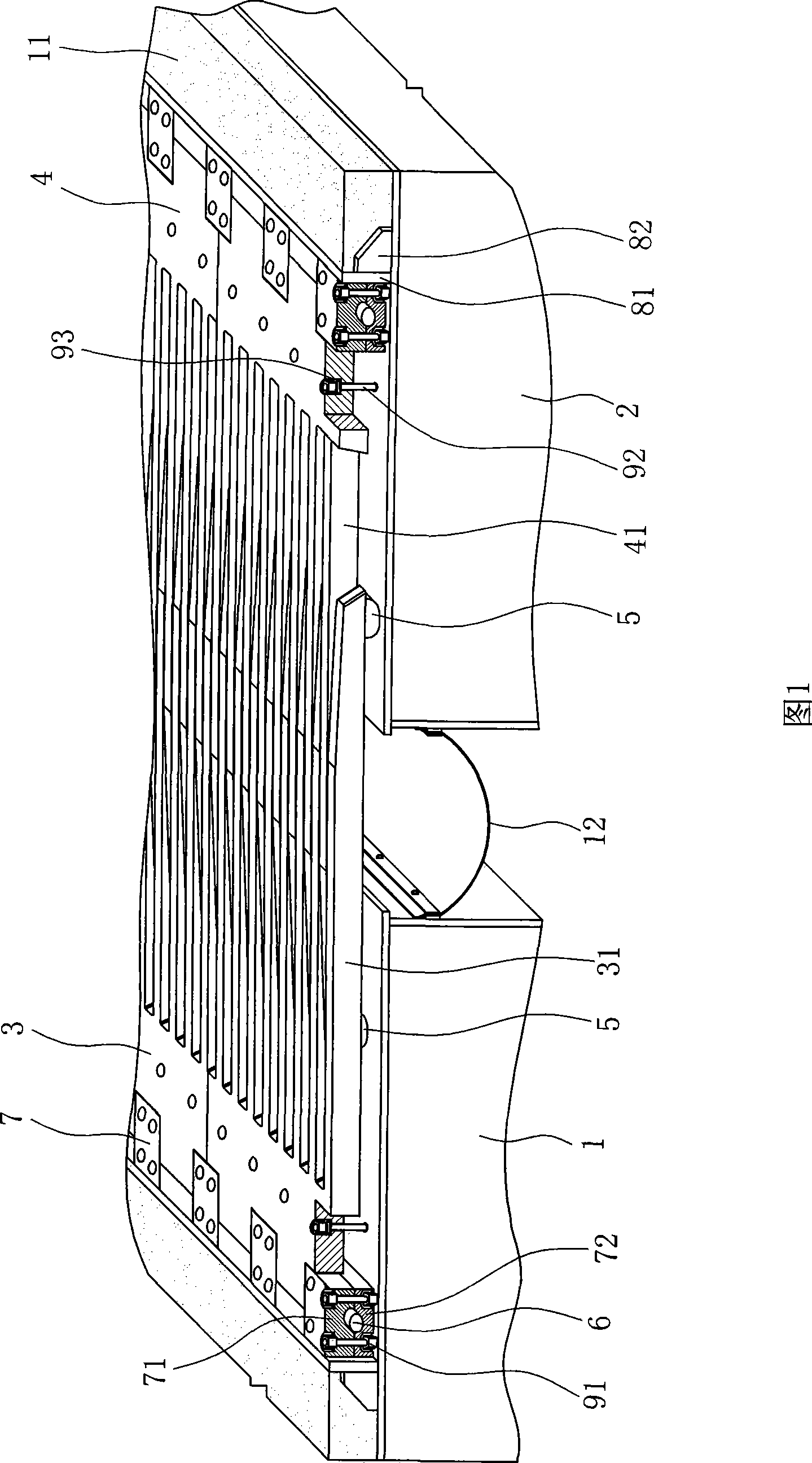

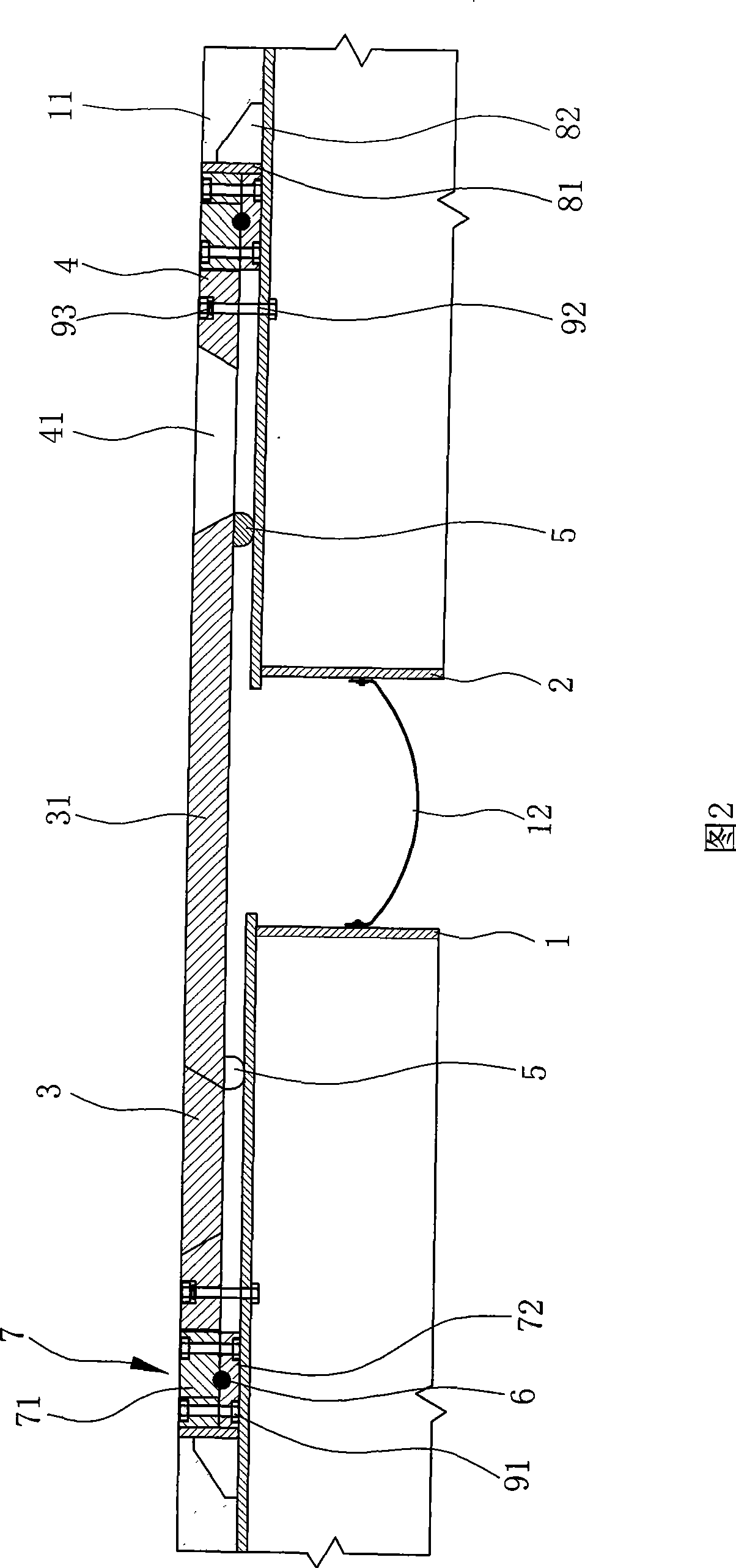

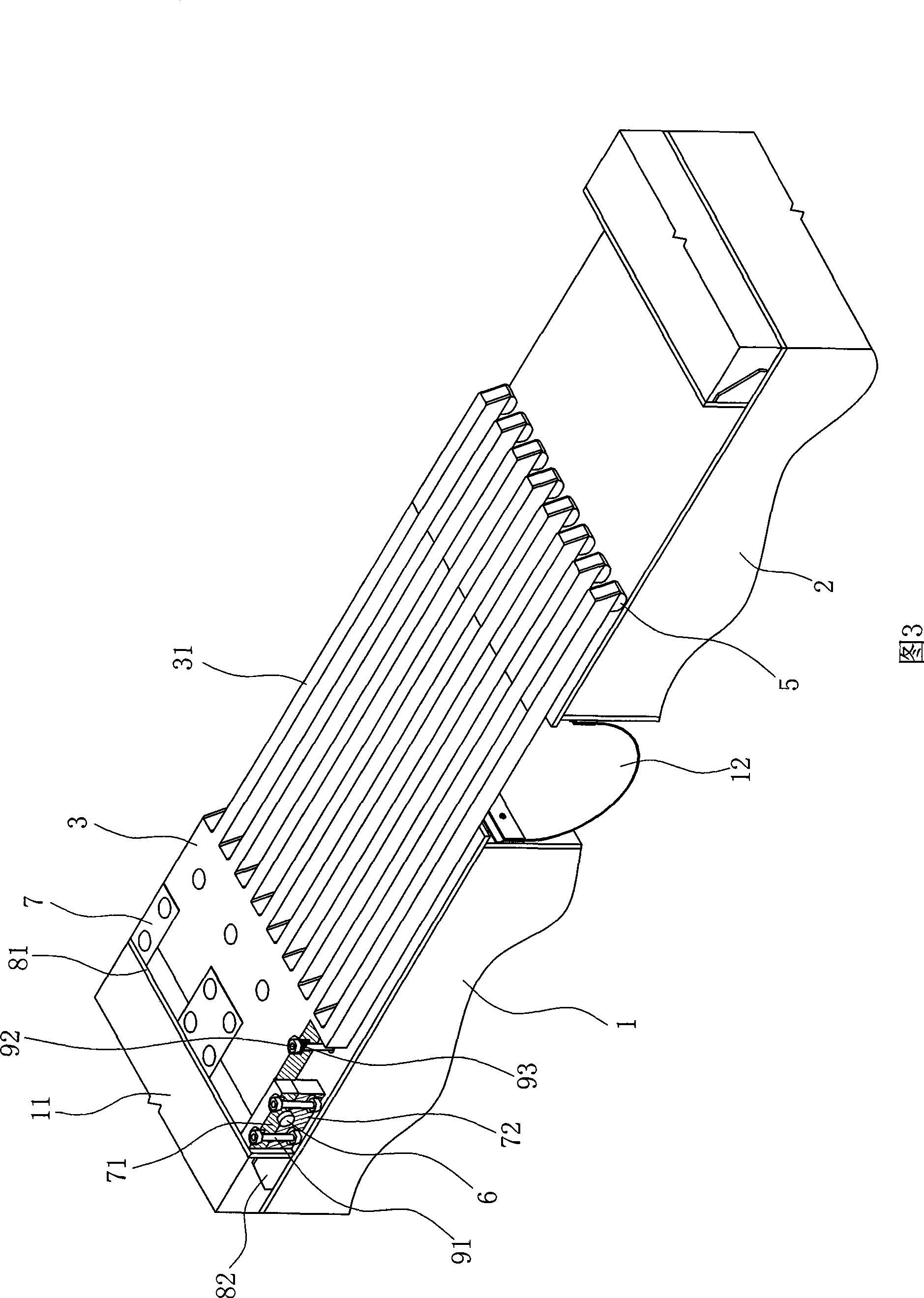

[0021] As shown in Figures 1 to 4, it is an embodiment in which the first and second girder bodies on both sides of the bridge expansion joint use steel box girders. The bridge expansion joint device that resists large vertical rotation angle displacement includes There are the first beam body 1 and the second beam body 2 located on both sides of the bridge expansion joint, the first movable comb plate 3 arranged on the first beam body 1 and the second movable comb plate arranged on the second beam body 2 Movable comb board 4;

[0022] Wherein, the first end of the first movable comb plate 3 is provided with comb teeth 31, and the first end of the second movable comb plate 4 also has comb teeth 41 and each comb tooth 31 of the first movable comb plate 3 interacts with each other. Interspersed intervals are arranged, and the comb teeth 31, 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com