Patents

Literature

97results about How to "Meet recycling requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical multiple-stage building rubbish crushing device

InactiveCN106807475ASimple structureReduce manufacturing costSievingScreeningConstruction wasteMultiple stages

Owner:殷晓晴

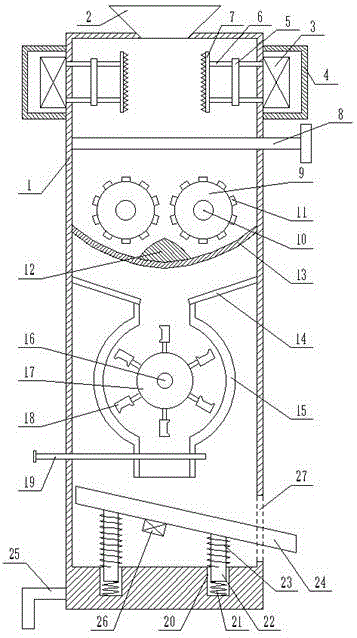

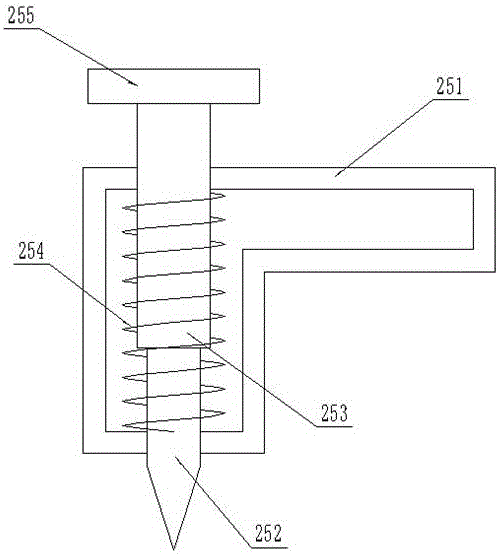

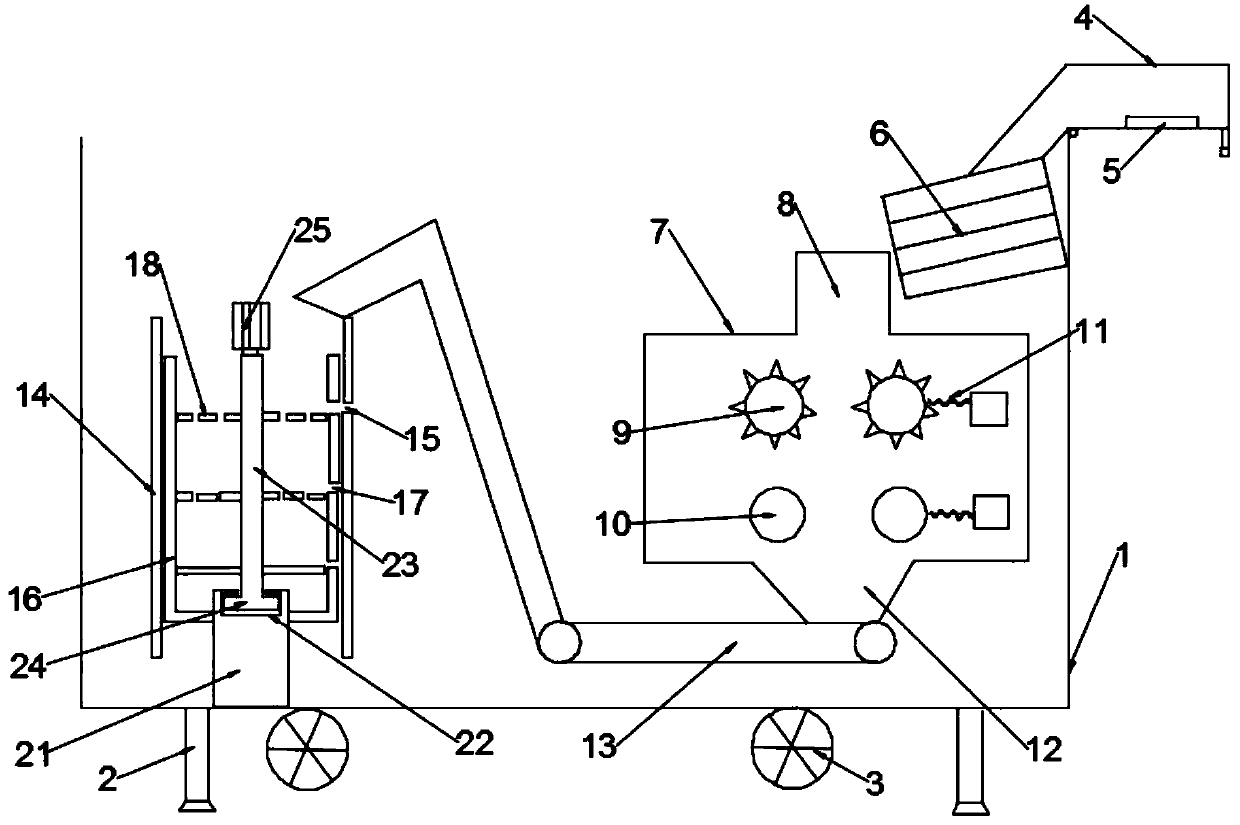

Construction waste treatment device with dual functions of crushing and screening

InactiveCN106824485ASimple structureReduce manufacturing costSievingScreeningMotor driveDual function

The invention discloses a construction waste treatment device with dual functions of crushing and screening. The construction waste treatment device has the advantages of being reasonable and simple in structure, low in production cost, convenient to install, good in crushing effect, convenient to use and the like. Multiple crushing is conducted on construction waste by a multi-level crushing device, the crushing effect is good, and the size of the construction waste after the crushing can meet the requirements of recycling and reusing; when the construction waste treatment device is in use, the construction waste is put into a lifting box and carried to a crushing chamber through a material net on a synchronous belt, firstly the construction waste is crushed through crushing blades and ground through grinding teeth, when the construction waste becomes thin and small particles, the particles are filtered by a first filtering net, when the particles are relatively large, grinding continues to be carried out, filtered particles enter a screening chamber through an oblique plate, a screening motor drives a screening plate, and the particles are screened on a screening net, fall into a transport chamber, and finally go to a transport vehicle to be collected.

Owner:徐勇

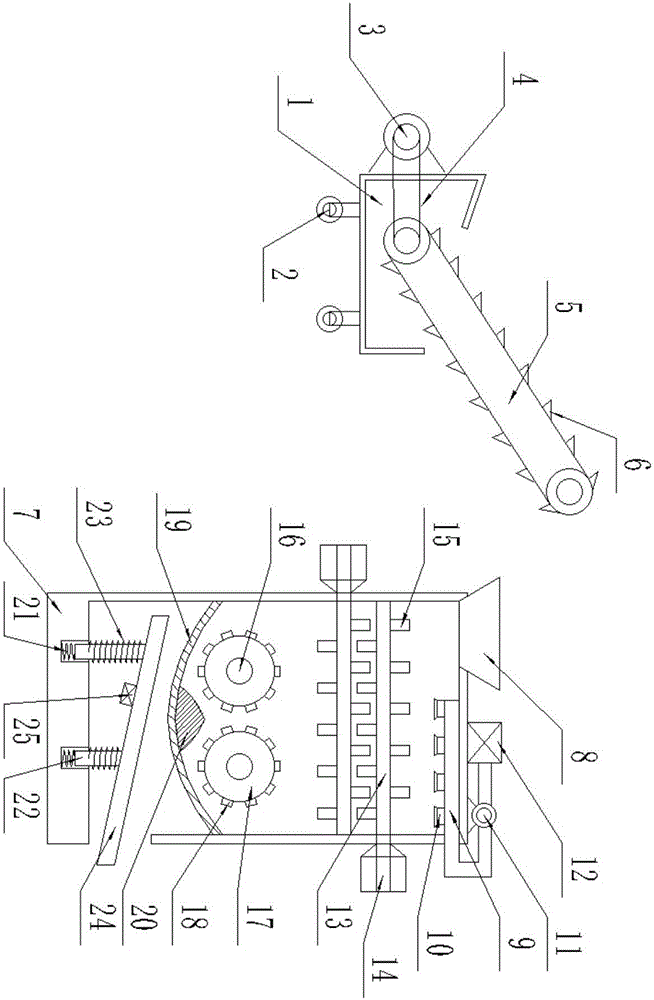

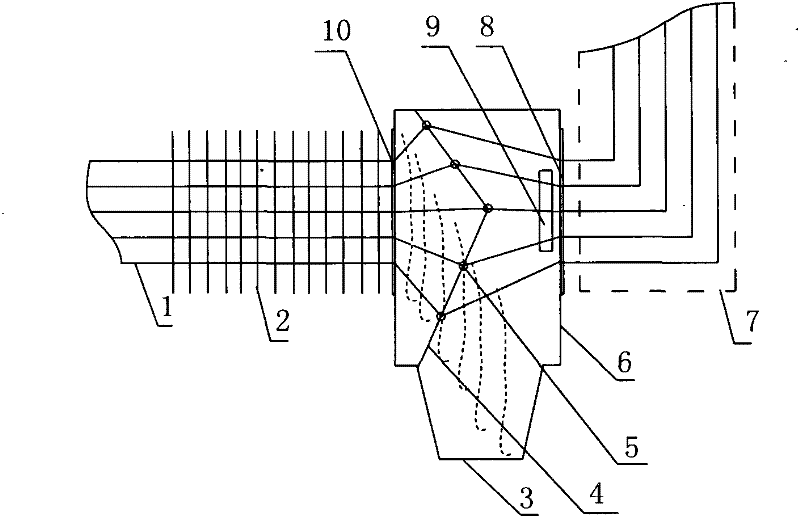

Clamp conveying type plastic film residue recycling machine with field straw chopping and returning function

InactiveCN103283408ASimple structureNot easy to tangleCrop conditionersMowersReturn functionPlastic film

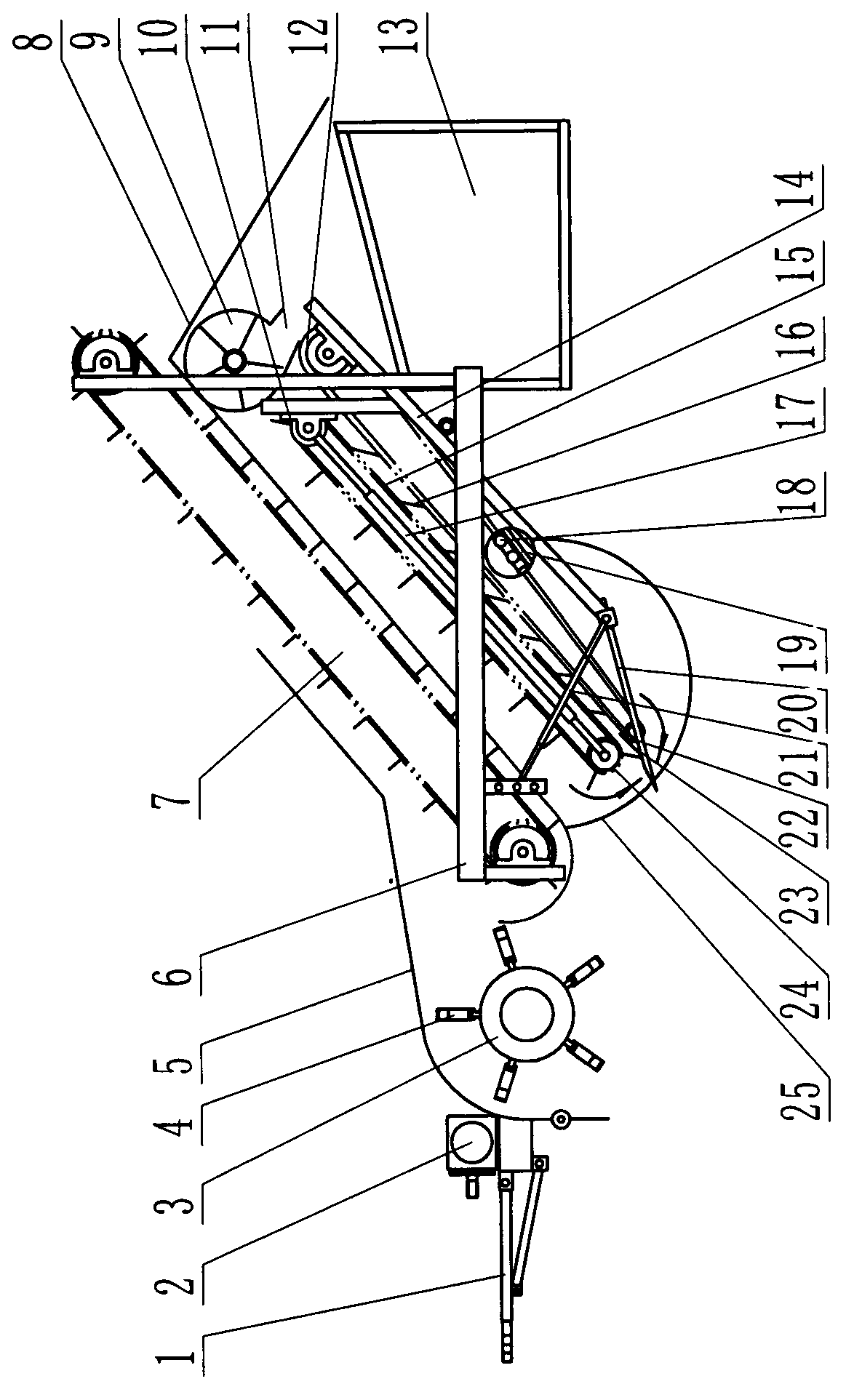

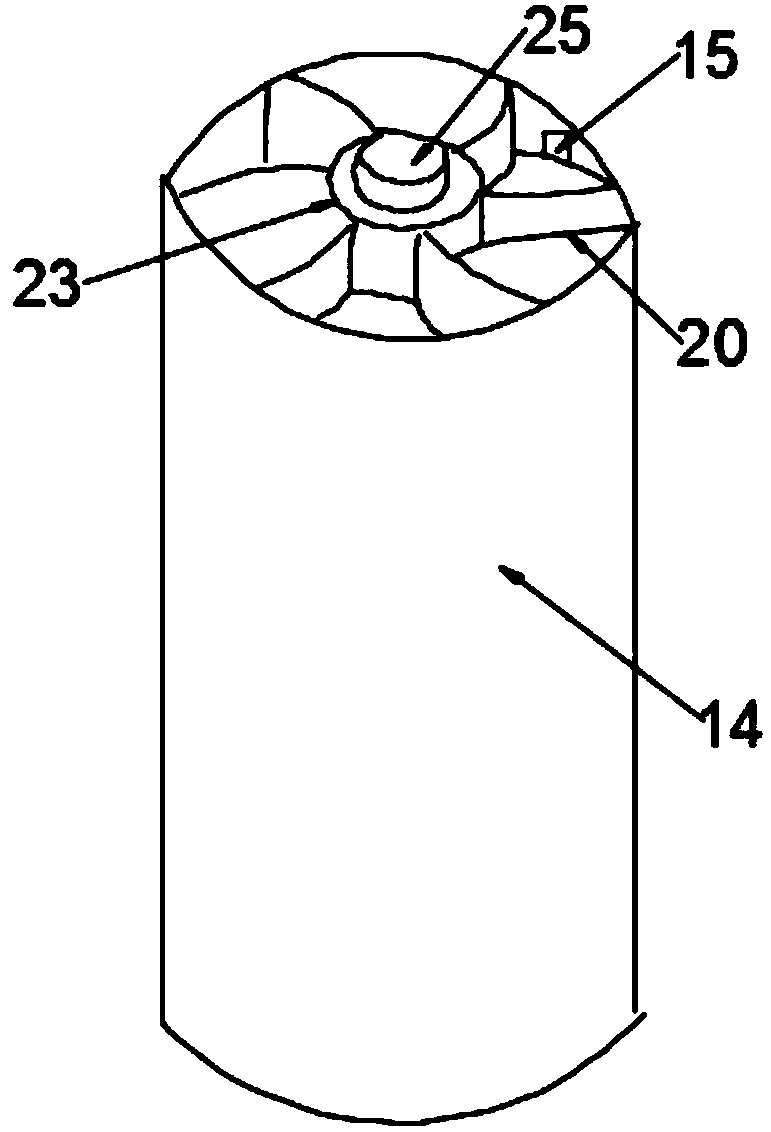

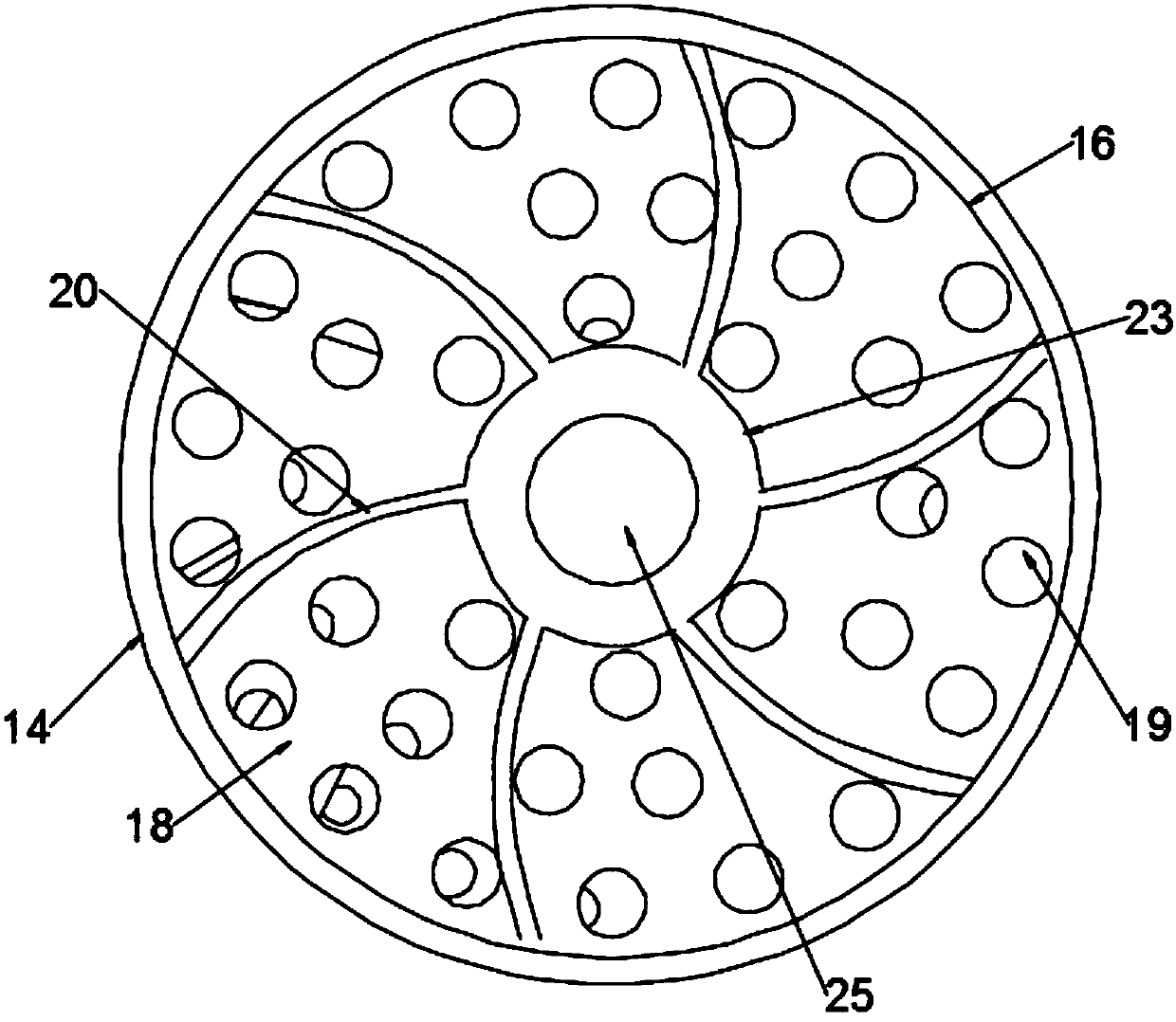

The invention relates to a clamp conveying type plastic film residue recycling machine with a field straw chopping and returning function. The clamp conveying type plastic film residue recycling machine with the field straw chopping and returning function comprises a hauling device (1), a driving system (2), a frame (6), a plastic film residue box (13), a travelling wheel (25), a straw chopping device, a straw conveying device (7), a plastic film residue recycling device and a film removing device, the hauling device (1) is arranged on the front side of the straw chopping device, the straw conveying device (7) is arranged on the rear side of the straw chopping device, a tail slide plate (8) is arranged on the rear side of the straw conveying device (7), the plastic film residue recycling device is arranged on the lower side of the straw conveying device (7), and the plastic film residue box (13) is arranged on the rear side of the plastic film residue recycling device which comprises a film lifting frame (14), a clamping plate chain (15), a clamping plate (16), a conveying belt chain (18), a conveying belt (19), a film lifting gear (20) and a soil retaining plate (23). The clamp conveying type plastic film residue recycling machine with the field straw chopping and returning function has the advantages of simple structure, high working efficiency, clean plastic film residue recycling, less proneness to plastic film residue twining, low impurity content in recycled plastic film residues and the like.

Owner:SHIHEZI UNIVERSITY

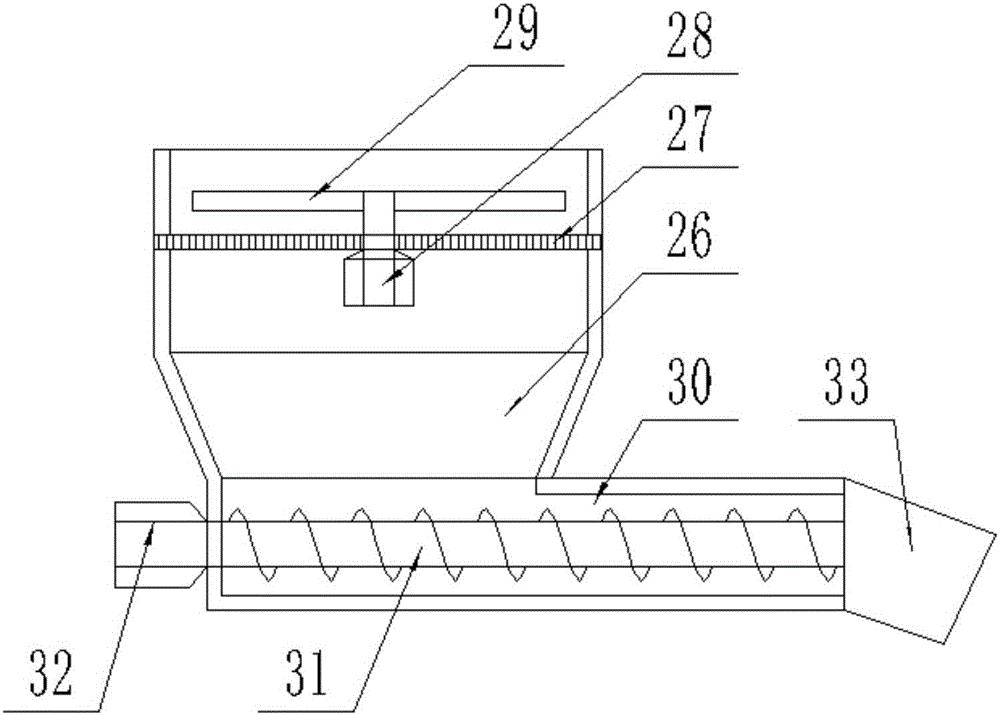

Novel straw smashing and film residue recycling machine

InactiveCN102726136ARecycle cleanNot easy to tangleCrop conditionersMowersMechanical engineeringImpurity

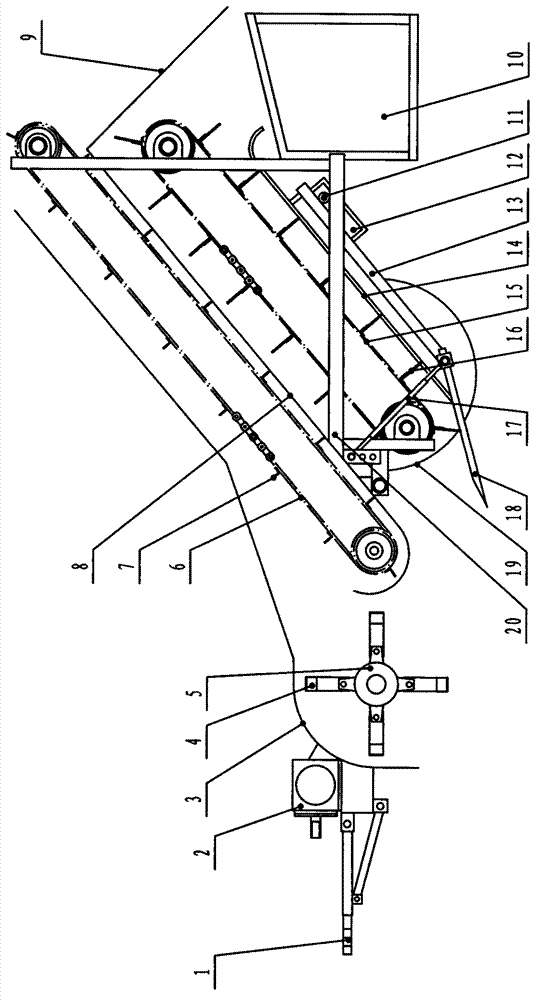

The invention relates to a novel straw smashing and film residue recycling machine comprising a traction device (1), a transmission system (2), a frame (20), a film residue box (10), a land wheel (19), a straw smashing device, a straw feeding device and a film residue recycling device, wherein the straw smashing device is composed of a cutter shaft (5), a blade (4) and a shield (3); the straw feeding device is composed of a straw conveying chain (6), a scraper (7), a base plate (8) and a tail plate (9); the film residue recycling device is composed of a film residue feeding chain (15), a film scraper (16), a film lifting rack and a suspension rod (17); and the film lifting rack is composed of a film lifting tooth (18), a grid bar (14), a frame (13) and a slide rail (12). The novel straw smashing and film residue recycling machine is simple in structure, high in operation speed, good in ground profiling capability, clean in film residue recycling, and low in impurity content in the recycled film residue; besides, the film residue is not easy to intertwine around a working component; and therefore, the machine is capable of meeting the requirements of straw smashing and film residue recycling.

Owner:SHIHEZI UNIVERSITY

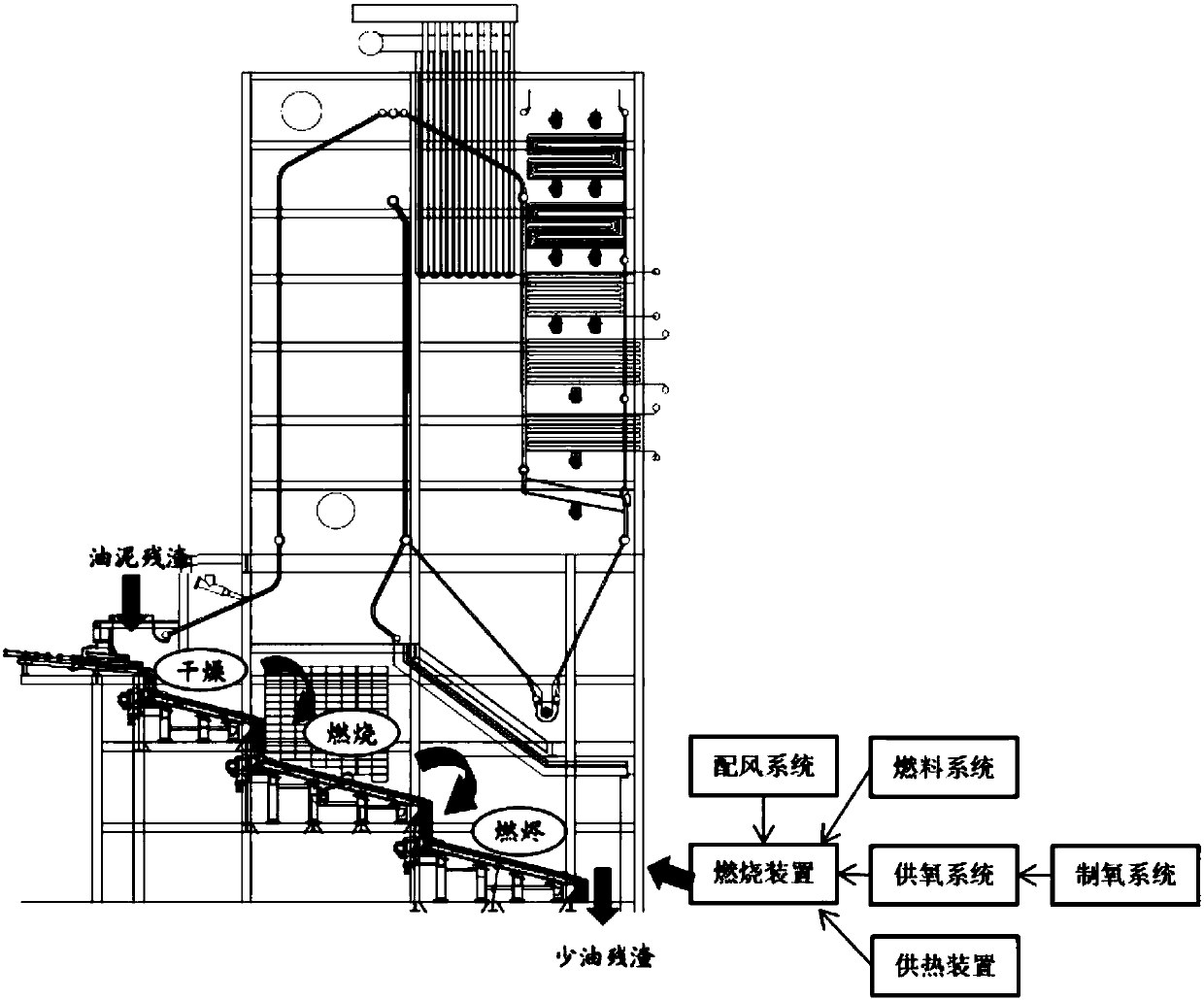

Harmless, recycling and integrated oil sludge treatment method

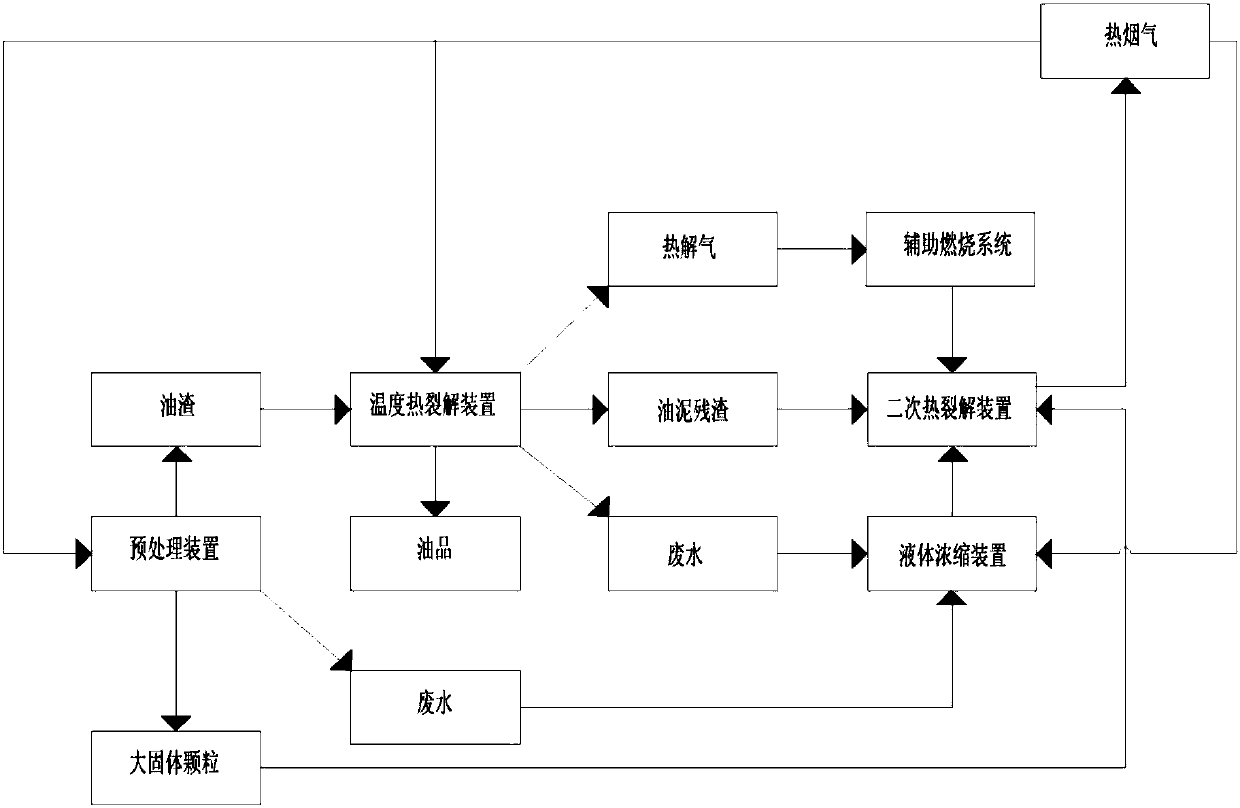

InactiveCN107777847AStable working conditionWorking conditions are easy to controlSludge treatment by pyrolysisByproduct vaporizationOil sludgePollution

The invention discloses a harmless, recycling and integrated oil sludge treatment method and belongs to the technical field of oil sludge treatment. The method is characterized by including: feeding oil sludge into a temperature thermal cracking device for preliminary cracking; feeding oil sludge residue after preliminary cracking into a secondary thermal cracking device for in-depth cracking; fully utilizing the secondary thermal cracking device to consume secondary pollutants generated in an upstream treatment process, and using smoke generated by the secondary thermal cracking device to optimize the upstream treatment process. On the basis of a burning method, the secondary thermal cracking device is added to recycle waste generated in the burning process. The method has the advantagesthat oil content of the oil sludge is reduced, and the whole process is free of secondary pollution.

Owner:CHONGQING FURAN TECH

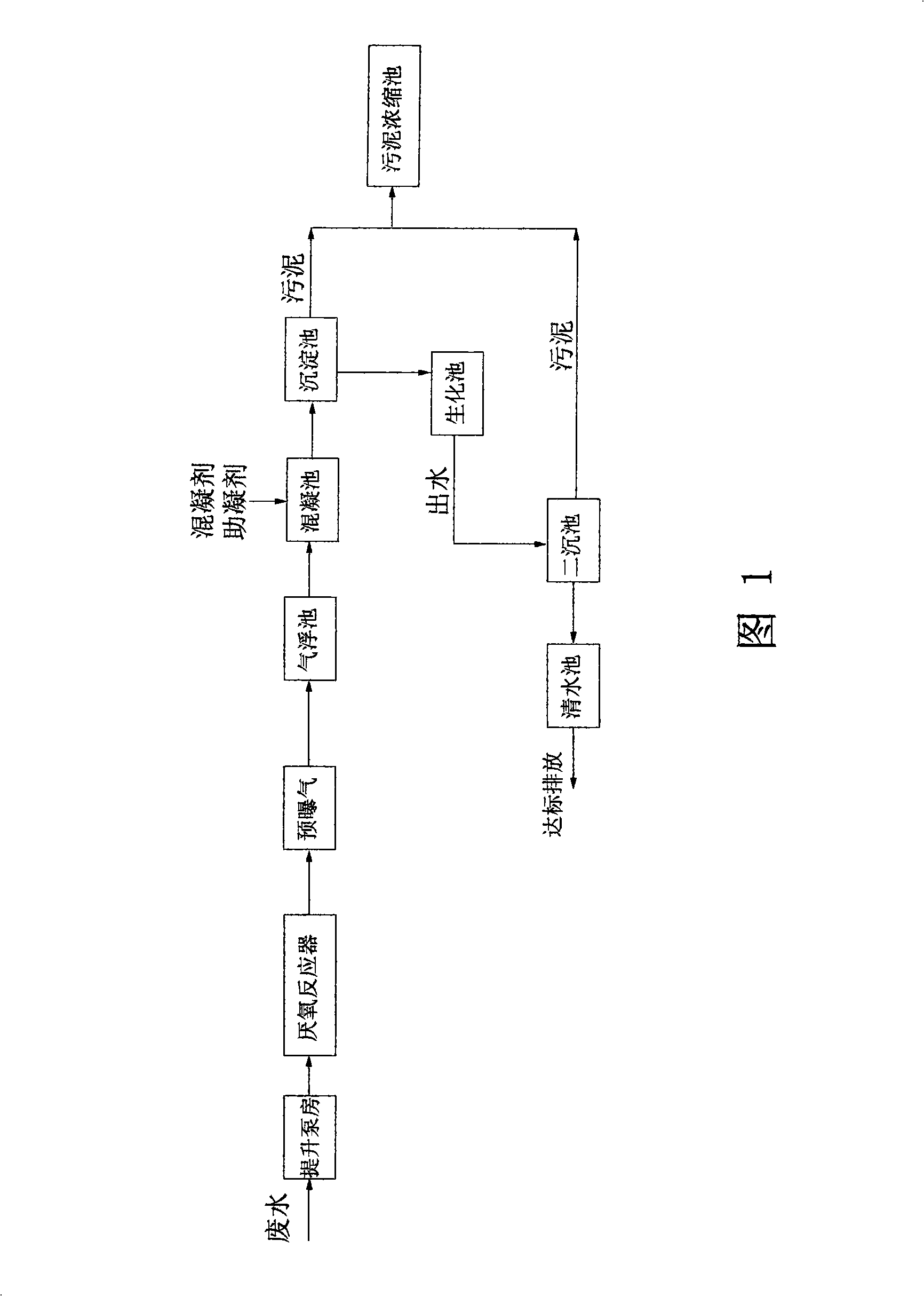

Pretreatment technique for decolorization of wastewater at middle plate of paper-making pulping

ActiveCN101343129AImprove biodegradabilityImprove cohesionWaste based fuelTreatment with anaerobic digestion processesTherapeutic effectAnaerobic reactor

The invention discloses a paper-making and pulping midcourse wastewater decolorizing pretreatment process, and the process comprises the following steps of: guiding the wastewater into an anaerobic reactor for anaerobic treatment, transforming part of organics having the biochemical ability in the wastewater into methane and carbon dioxide, and reducing lignin substances that have no biochemical ability in the wastewater; guiding the effluent water treated by the step (1) into a coagulation chamber, and adding a composite coagulant in the coagulation chamber to promote the condensation of lignin substances in the wastewater; and guiding the effluent water treated by the step (2) into a sedimentation tank for separating mud and water. The pretreatment process has advantages of simple process, good decolorizing effect, low cost, stable reaction process and good treatment effect, meanwhile, the adoption of the process can directly recycle water through the pretreatment and then advanced treatment to the wastewater.

Owner:HUATIAN ENG & TECH CORP MCC

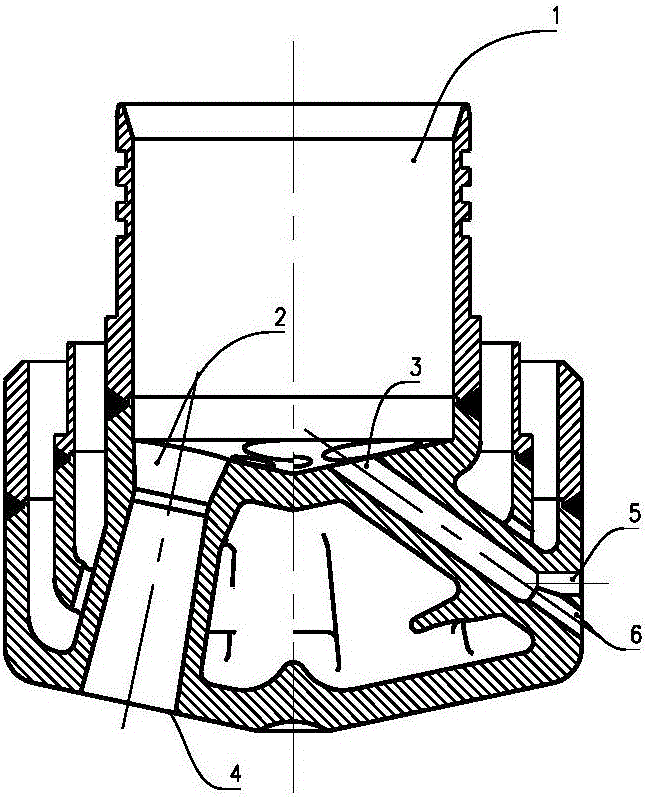

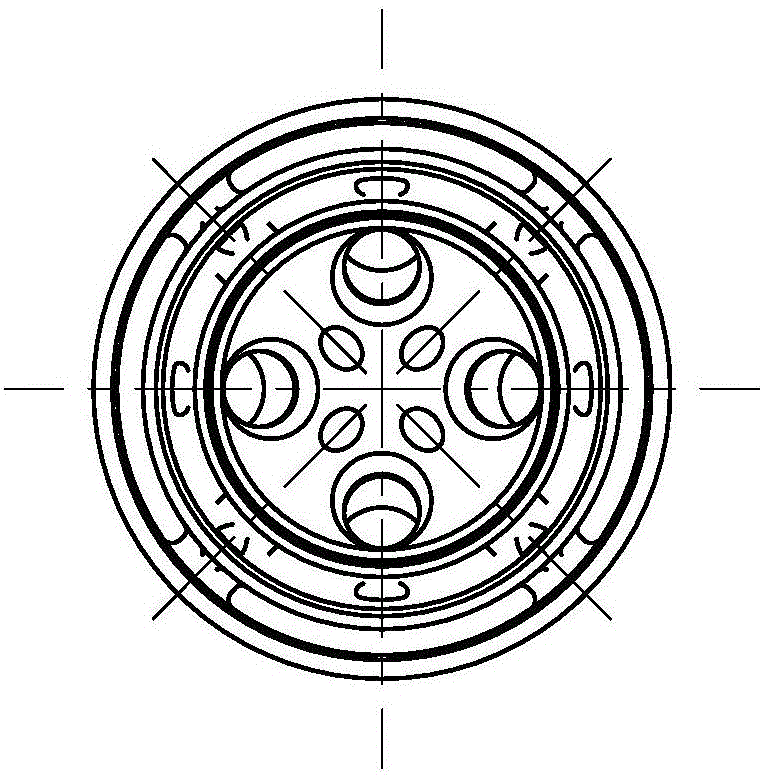

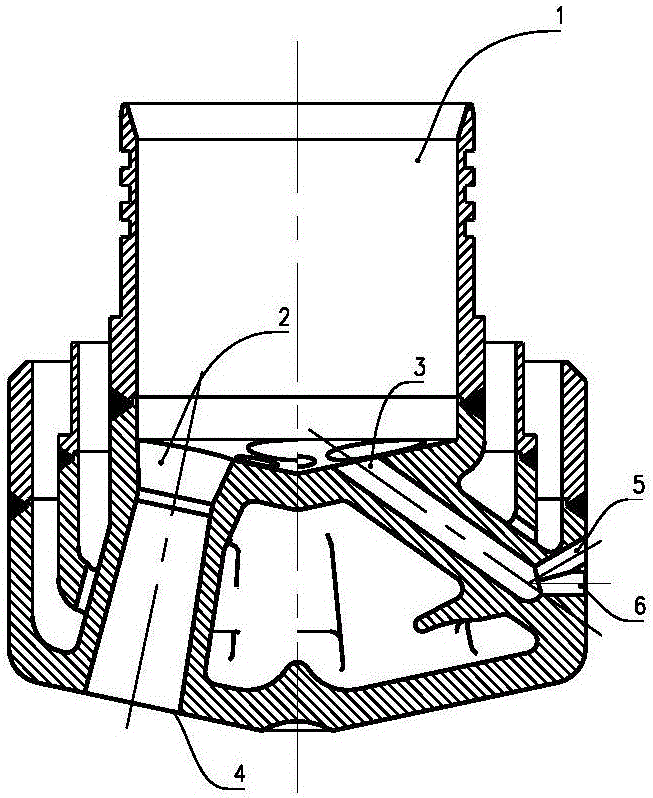

Double-flow oxygen gun and use method thereof

ActiveCN106282481AAdapt to recyclingAdapt to requirementsManufacturing convertersSputteringSteelmaking

The invention relates to a double-flow oxygen gun and a use method thereof, and belongs to the technical field of converter steelmaking. The double-flow oxygen gun has the advantages that a novel structure is used, and the converter steelmaking heat efficiency is improved, so that the converter cold material ratio, the slag melting effect and the terminal temperature hit rate are improved. Oxygen gun main holes and sub holes are formed in the spray head. The number of main holes and the number of sub holes at an oxygen inlet in the oxygen inlet direction of the spray head are identical; in the oxygen outlet direction of the spray head, the number of the main holes is unchanged, and the number of the sub holes at the outlet can be 1 to 3 times of the number of the sub holes at the inlet. The number of the main holes at the outlet of the spray head is 3 to 6, and the number of the sub holes is 6 to 15. The flow rate of the main holes accounts for more than 85 percent of the total flow rate; the flow rate of the sub holes accounts for less than 15 percent of the total oxygen supply. The outlet direction of the sub holes is not limited by the inlet direction of the sub holes, can be in various directions, and can be downward, horizontal and upward, so that the secondary combustion rate of a converter is sufficiently improved. During the oxygen gun operation, the blowing gun position is 100 to 200 mm higher than a conventional gun position; the slag sputtering gun position is 50 to 100mm higher than the conventional oxygen gun position.

Owner:CENT IRON & STEEL RES INST

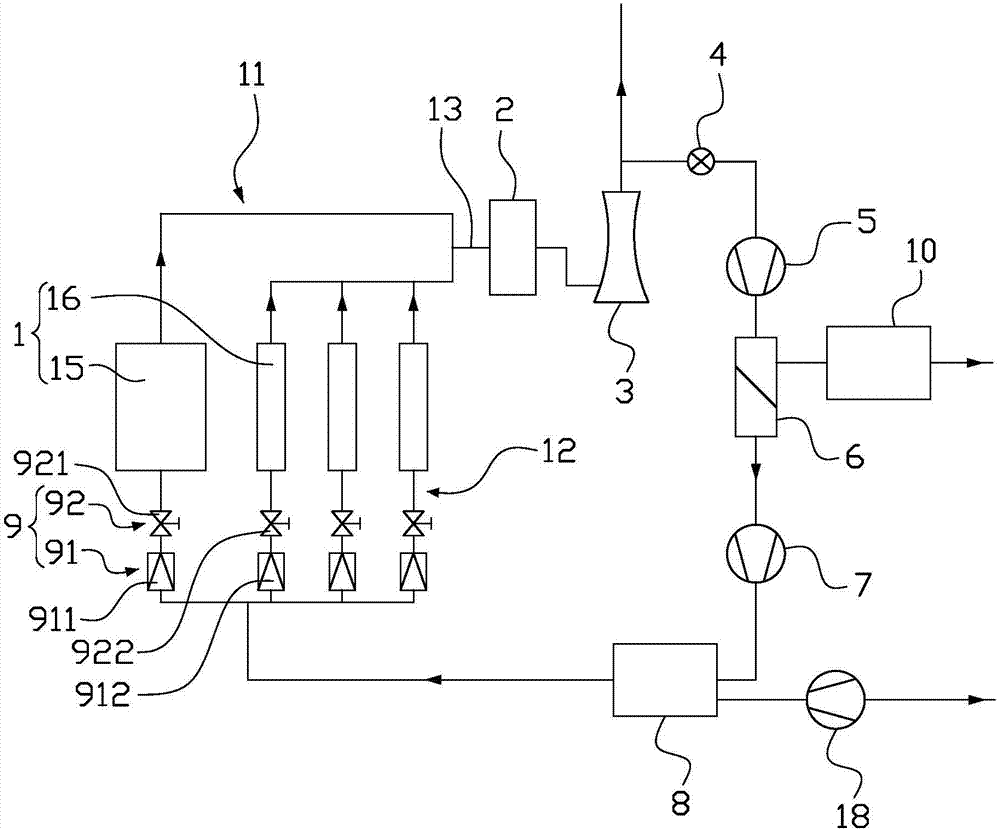

Desulfurization, denitrification and decarbonization integrated system for ship waste gas

ActiveCN106968760AMeet Recycling RequirementsReduce duplication of investmentInternal combustion piston enginesExhaust apparatusCo2 storageExhaust fumes

The invention discloses a desulfurization, denitrification and decarbonization integrated system for ship waste gas. The desulfurization, denitrification and decarbonization integrated system comprises a diesel engine, a heat exchanger, a desulfurization washing tower, a carbon dioxide film separator, a carbon dioxide storage tank and a gas inlet valve group, wherein a waste gas circulating pipeline is arranged between a gas exhaust end and a gas inlet end of the diesel engine; the heat exchanger, the desulfurization washing tower, the carbon dioxide film separator, the carbon dioxide storage tank and the gas inlet valve group are sequentially arranged in the waste gas circulating pipeline; waste gas exhausted from the gas exhaust end of the diesel engine enters the desulfurization washing tower to subject to desulfurization to obtain desulfurization waste gas after being cooled by the heat exchanger; the desulfurization waste gas enters the carbon dioxide film separator; carbon dioxide separated out by the carbon dioxide film separator is stored in the carbon dioxide storage tank; and carbon dioxide in the carbon dioxide storage tank is conveyed to the gas inlet end of the diesel engine through the gas inlet valve group. The desulfurization, denitrification and decarbonization integrated system for ship waste gas disclosed by the invention can simultaneously reduce discharge of NOX, SOX and CO2, and realizes integration of ship equipment.

Owner:SUNRUI MARINE ENVIRONMENT ENG

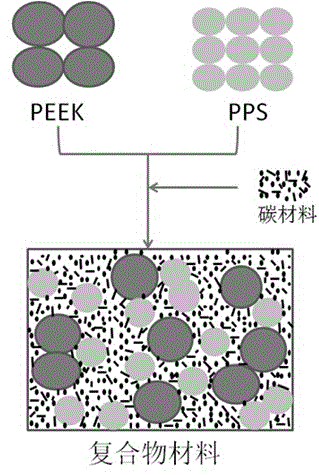

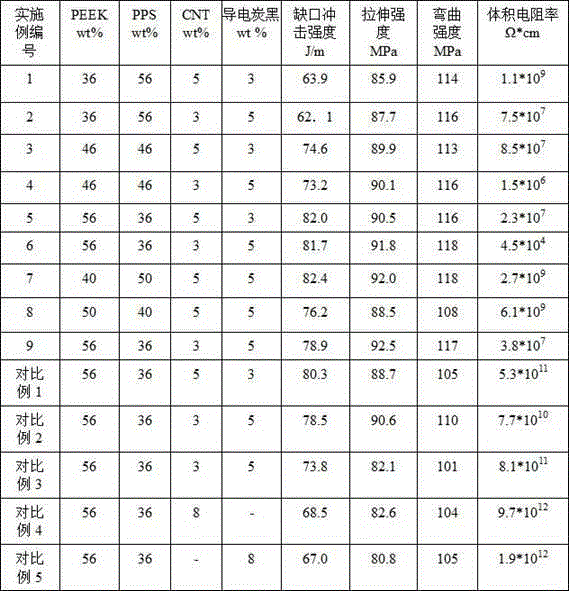

Heat-resistant antistatic conductive polymer composite material and preparation method therefor and application thereof

InactiveCN104987659AMeet Recycling RequirementsEasy to makePolymer scienceConductive polymer composite

The present invention provides a heat-resistant antistatic conductive polymer composite material and a preparation method therefor and application thereof. The composite material comprises the following compositions in percentage by mass: 30-60% of polyether-ether-ketone (PEEK); 30-60% of polyphenylene sulfide (PPS); 1-10% of carbon nanotubes (CNT); and 1-10% of conductive carbon black. According the present invention, the PEEK, PPS, CNT and conductive carbon black are optimally combined, and particles in different size stack together compactly to form an interlocked and controllable net structure, so the mechanical property can be guaranteed; the antistatic requirement of lower than 1012 ohm.cm is met with lower content of the conductive additive; the conductive requirement of 108 ohm.cm is met with appropriate carbon material content; and recycling and reuse of the PEEK material are implemented. According the invention, the physical blending-injection molding method used to obtain the composite material and is simpler and more adjustable than the melt blending-injection molding method in the prior art.

Owner:广州索润科技股份有限公司

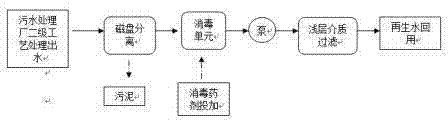

Method for producing regenerated water through combined process of magnetic separation and purification-shallow medium filtration

InactiveCN102757151ASmall footprintLow investment and operating costsMultistage water/sewage treatmentSeparation technologyFiltration

The invention belongs to a sewage treatment method in water treatment, and particularly relates to a method for producing regenerated water through the combined process of magnetic separation and purification-shallow medium filtration. Secondary effluent in a sewage treatment plant or water meeting the similar water quality standard is taken as raw water, and the raw water is subjected to magnetic separation and purification, disinfection and sand filtration and then is reused. Compared with the prior art, the method has the advantages that the magnetic disk separation technology can achieve the high-efficiency dephosphorization that cannot be achieved in the traditional advanced treatment process as well as the performance of heavy metal, the effluent effect reaches or is superior to that of the traditional advanced treatment process, and the reuse requirement of regenerated water can be met.

Owner:SCIMEE TECH & SCI CO LTD

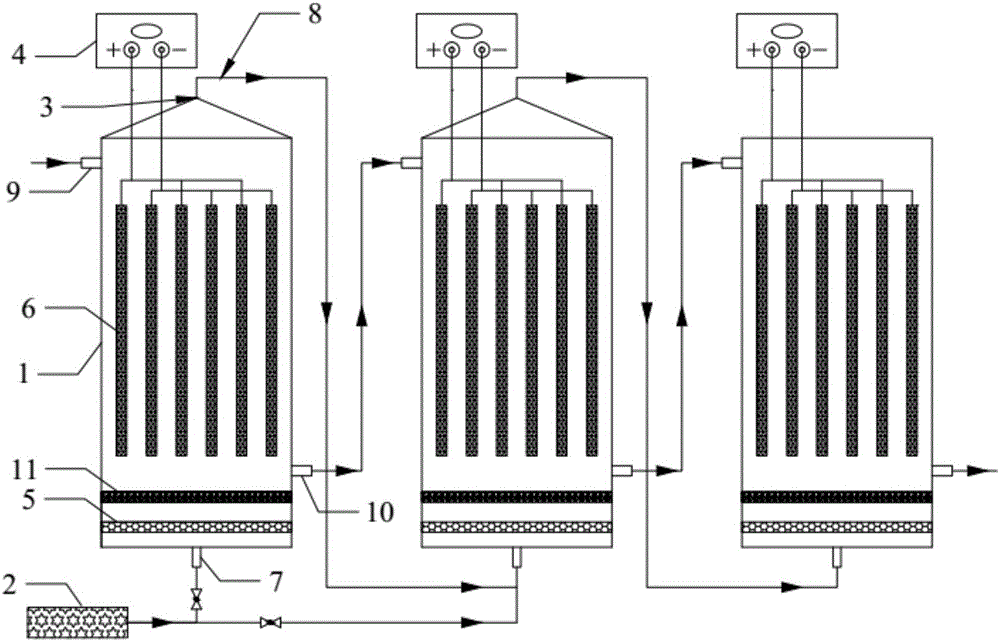

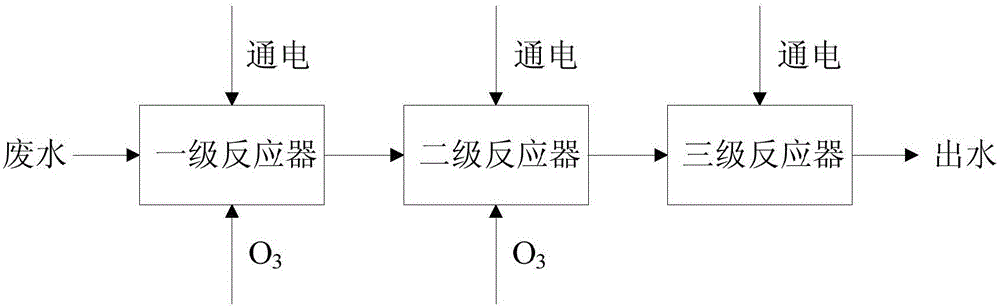

3D-EO three-dimensional peroxidation electrochemical device and application thereof

InactiveCN105800739AEasy to operateImprove automationWater contaminantsWater/sewage treatment by electrochemical methodsOzone generatorElectricity

The invention discloses a 3D-EO three-dimensional peroxidation electrochemical device and application thereof. This device comprises a reactor and an ozone generator in connection with the reactor, a three-dimensional electrochemical oxidation device and a nano aerating head are disposed in the reactor, the three-dimensional electrochemical oxidation device comprises a ceramic particle electrode and more than two evenly arranged electrode plates, and the electrode plates are arranged as positive electrodes and negative electrodes alternately. The device is simple to operate, easy to automate, convenient to maintain, mild in condition, high in processing speed and efficiency, free of adding any chemicals, substantially free of sludge, free of secondary pollution, and widely applicable to the treatment of organic wastewater.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

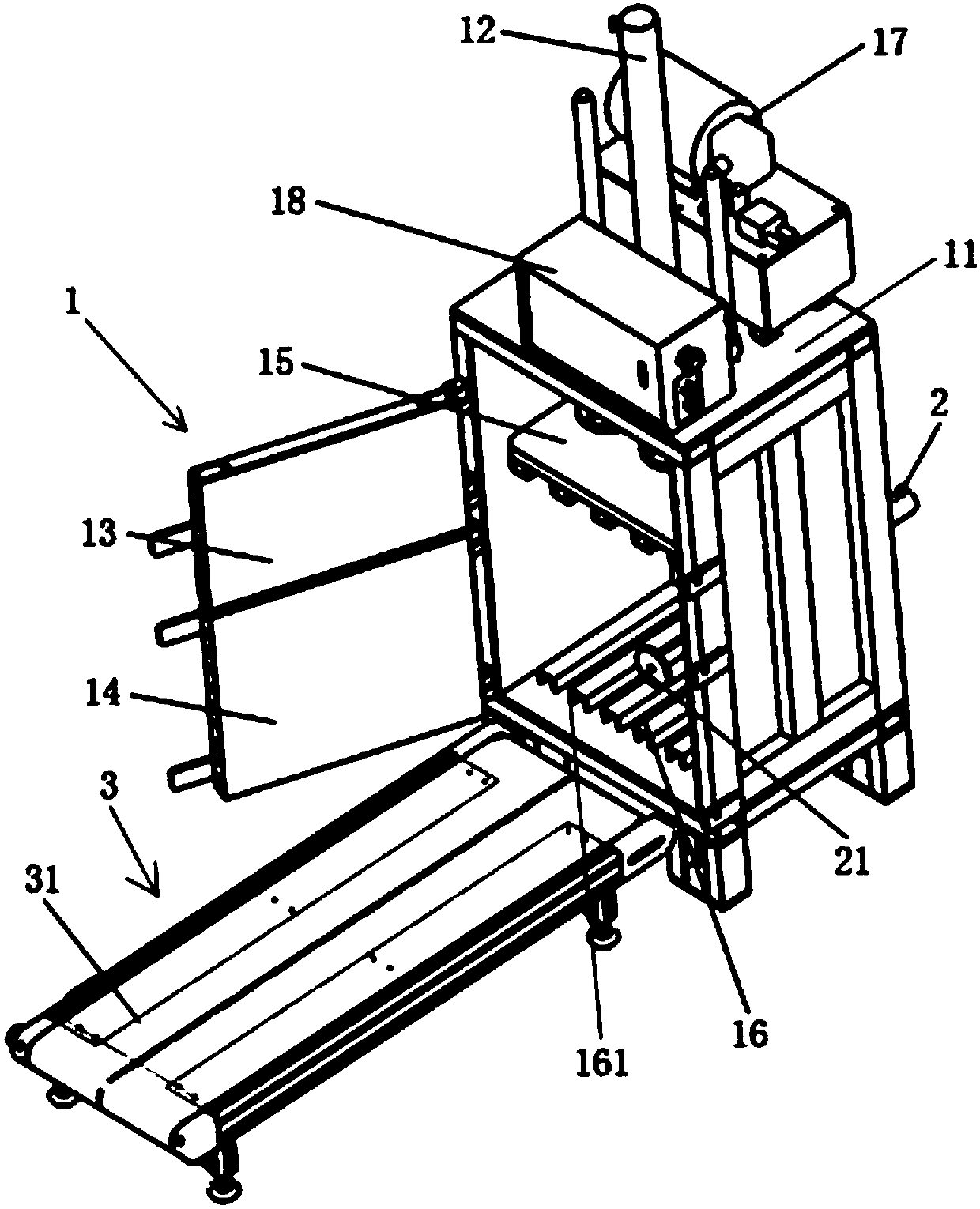

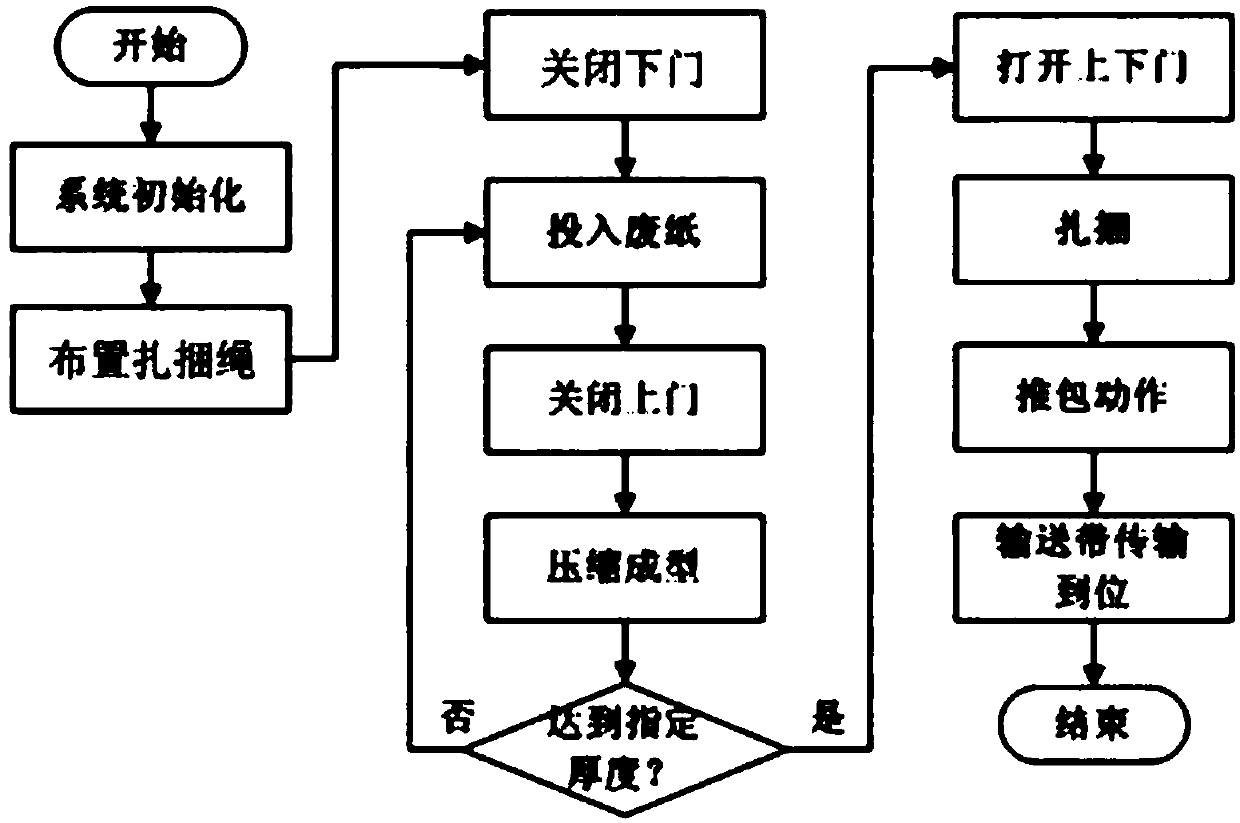

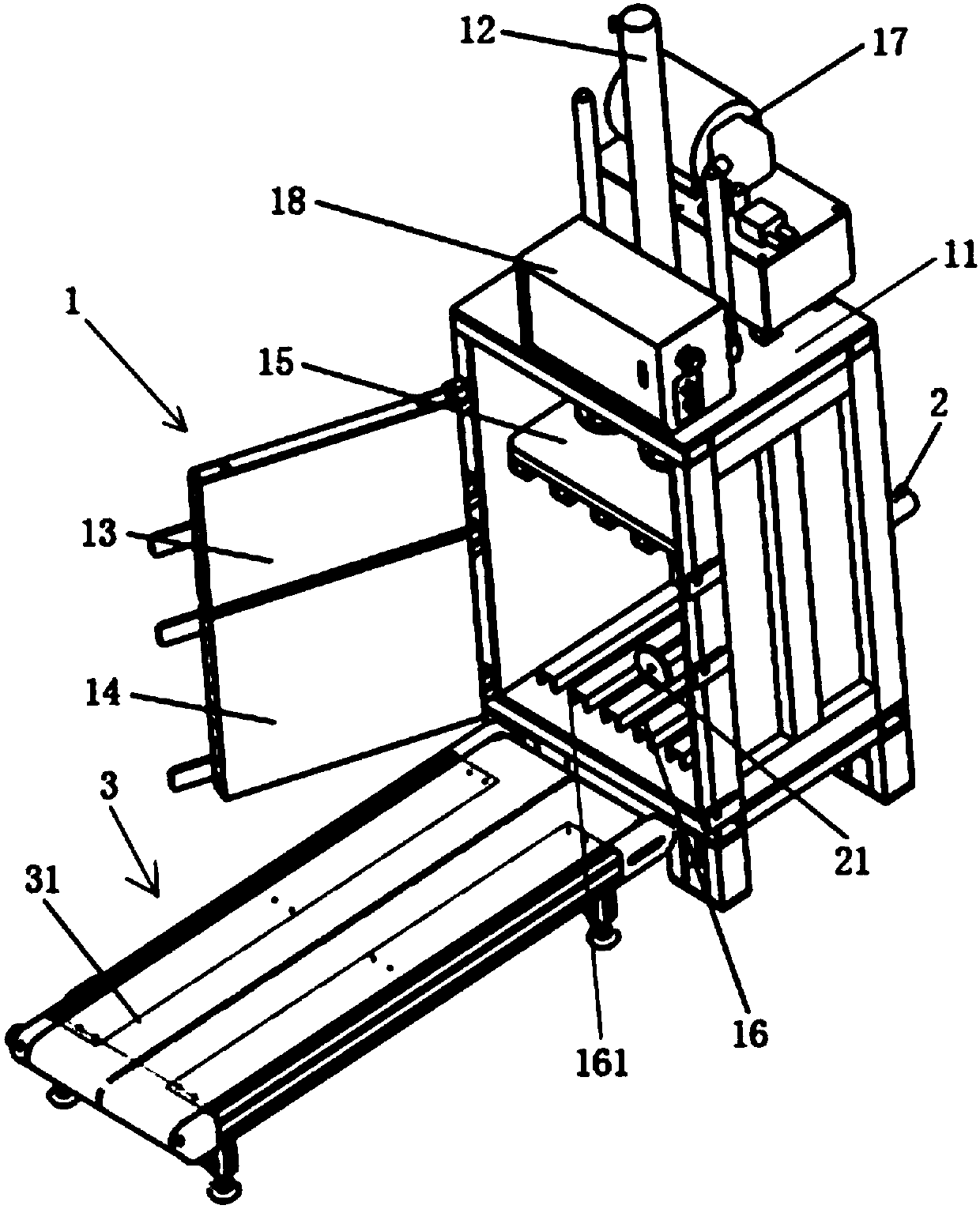

Multifunctional waste paper processing device

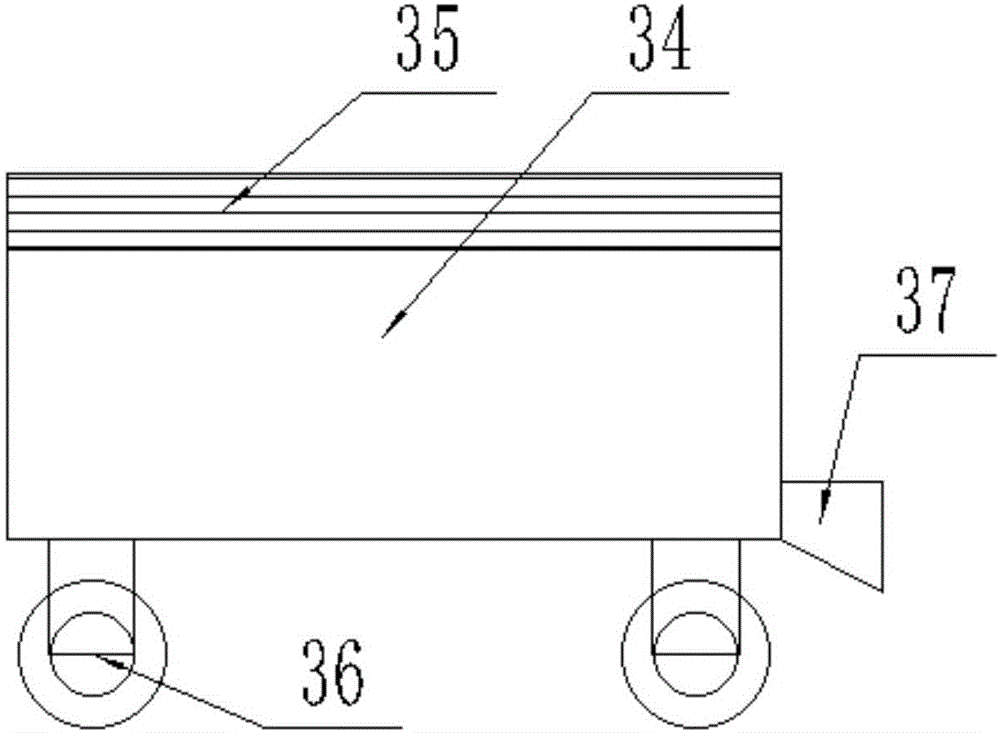

InactiveCN109956234ASmall footprintEasy to transportPaper recyclingRefuse receptaclesHydraulic cylinderCompression device

The invention discloses a multifunctional waste paper processing device, which includes a waste paper compression device, a paper package pushing device and a paper package conveying device. The wastepaper compression device includes a compression box and a compression hydraulic cylinder which is installed at the top end of the compression box, the paper package pushing device is installed at thebottom end of the compression box, and the paper package conveying device is installed at the front end of the compression box. The multifunctional waste paper processing device has the beneficial effects that through integration of the three functions of compression packaging, package pushing and transmission, the requirements of waste paper recovery processing are met, processed paper packagestake up little space and are convenient to transport, the efficiency in the working process is high, and the paper packages are in place; and in addition, through reasonable use of the multifunctionalwaste paper processing device, the logistics operation efficiency of waste recycling enterprises can be improved, and then the progress of the waste logistics domain related work is promoted, and positive significance for improving the degree of automation control, improving the working efficiency, more effectively using waste, and promoting environmental protection is achieved.

Owner:TIANJIN YOUCAI TECH DEV CO LTD

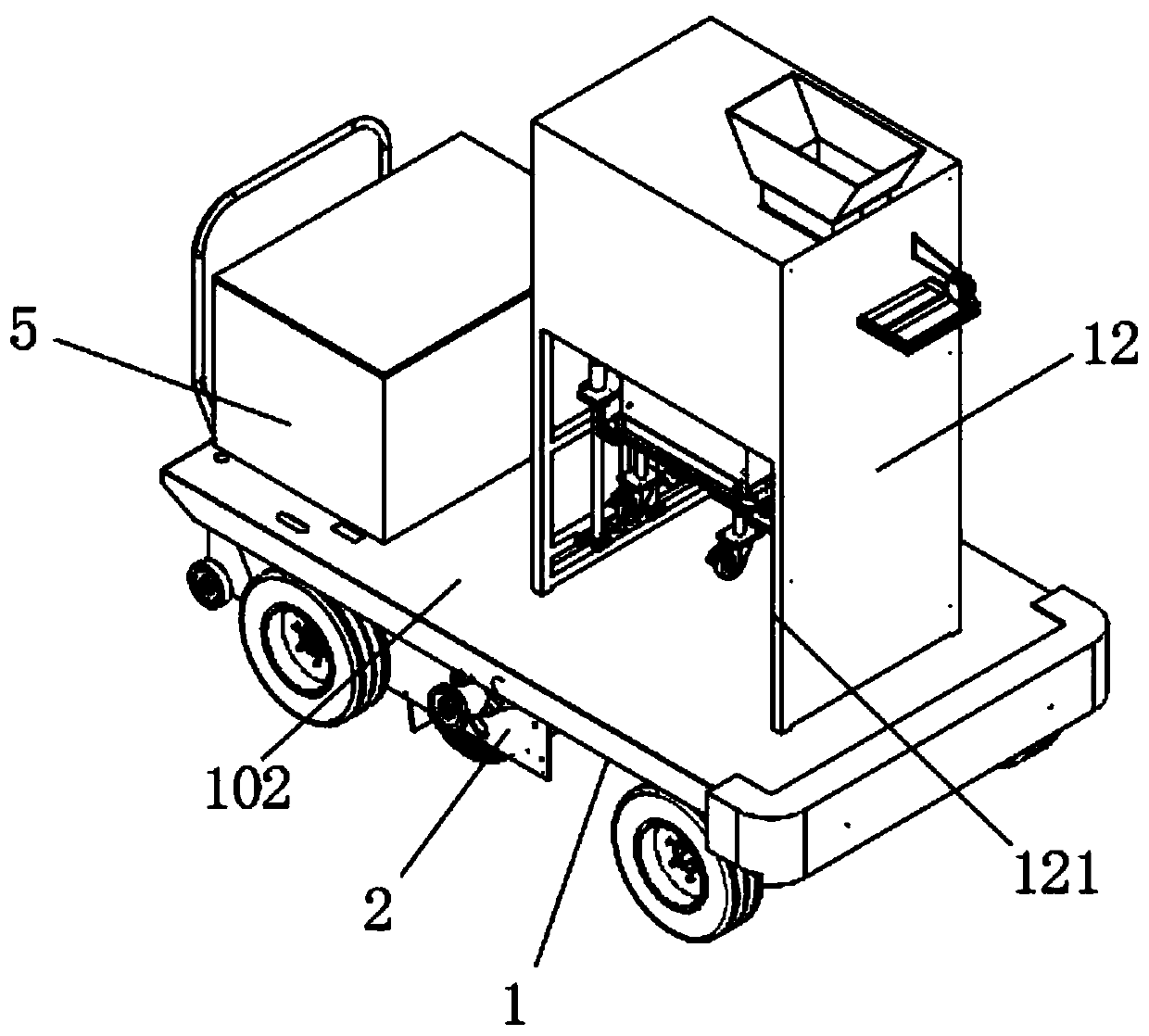

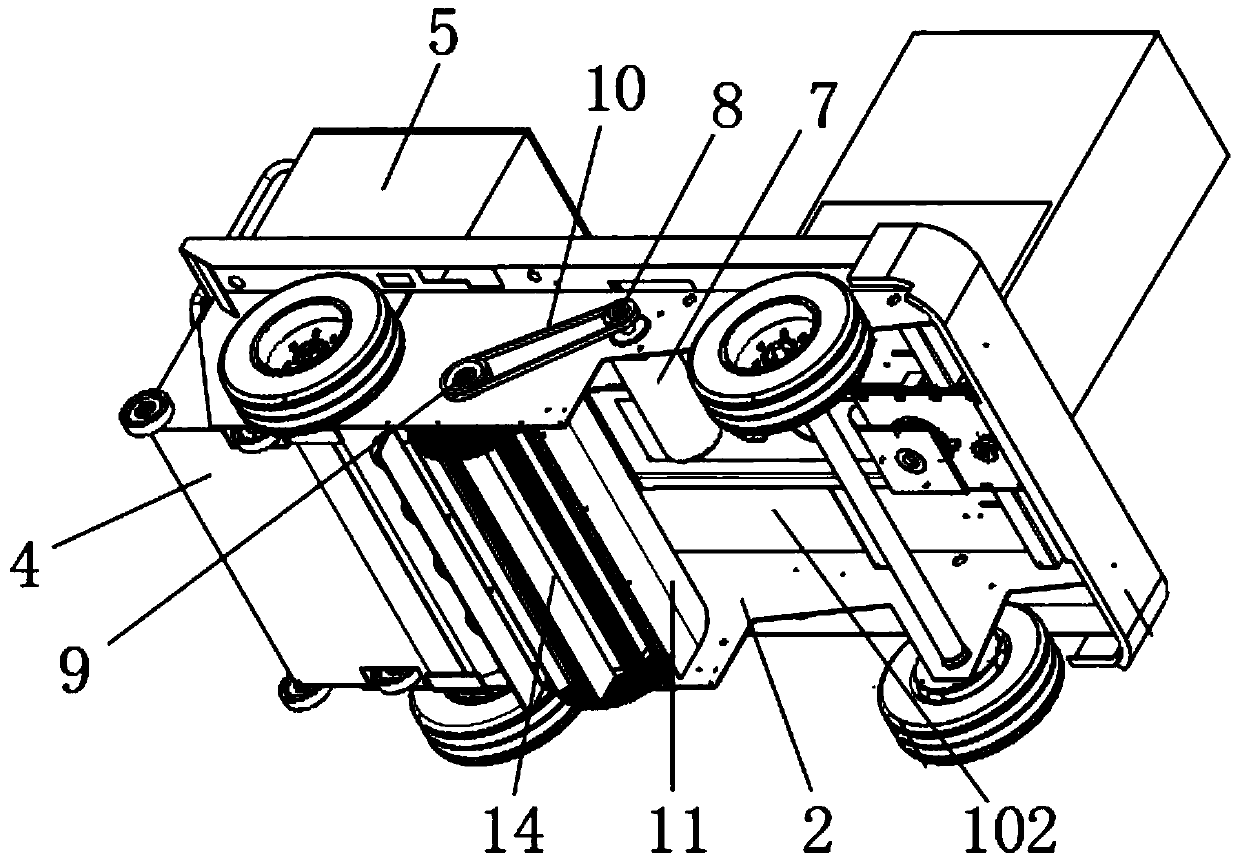

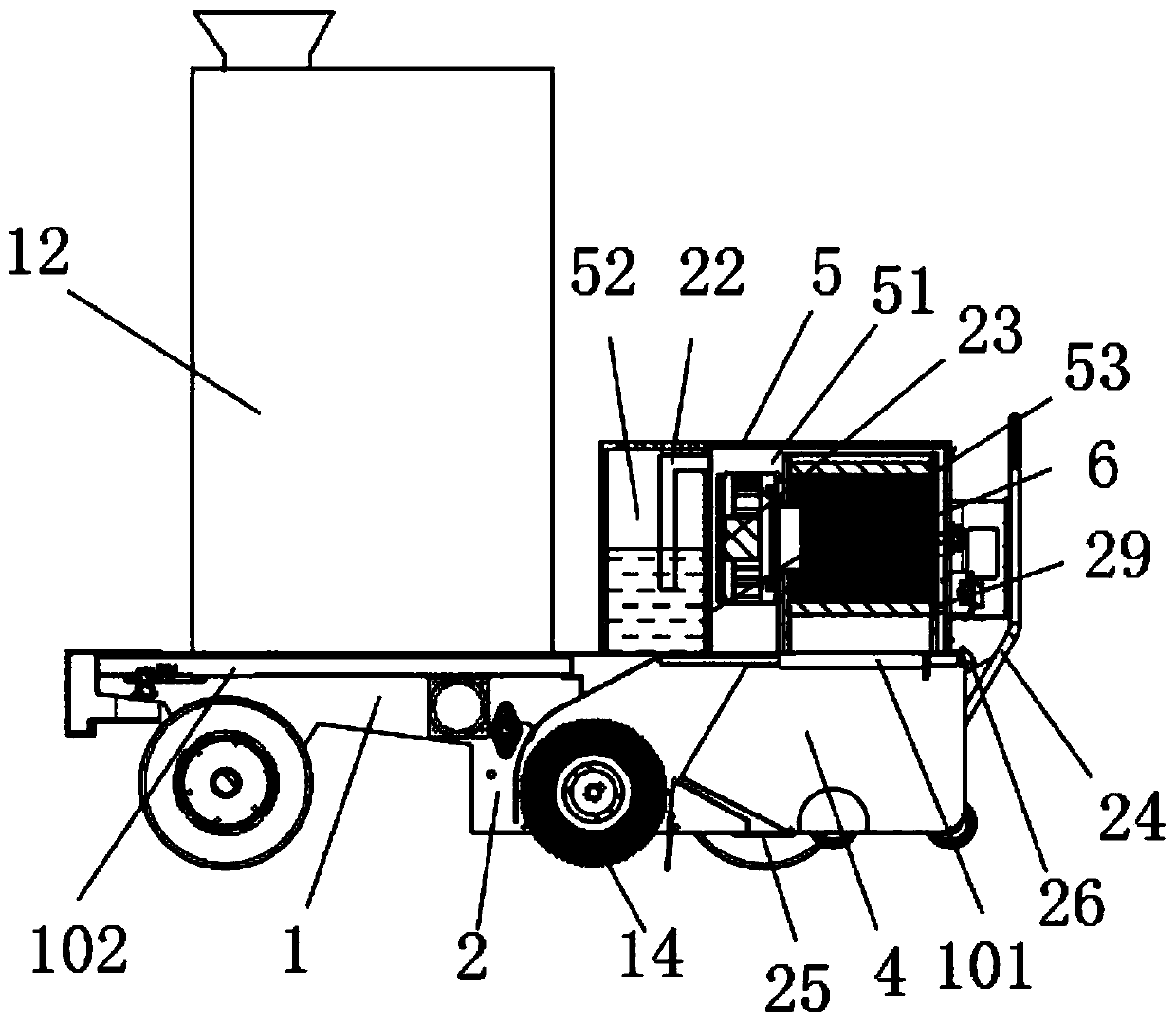

Movable construction waste crushing device

InactiveCN107684969AReasonable structural designEasy to useSievingScreeningVehicle frameArchitectural engineering

The invention discloses a movable construction waste crushing device. The movable construction waste crushing device comprises a frame, a feed pipe and wheels, wherein the wheels are mounted at the bottom of the frame; the feed pipe is mounted on the frame, and an electromagnet is mounted in the feed pipe; a rolling-type separator, a crusher, a chain bucket elevator and a separation cartridge aremounted in the frame; the crusher comprises a housing, a feed opening, toothed rollers, plain rollers and a crushing discharge opening; a sliding centrifugal sleeve, a centrifugal shaft and a slidingshaft are mounted in the separation cartridge; and the sliding centrifugal sleeve and the separation cartridge are in sliding fit in the axial direction. People only needs to place construction wasteinto the feed pipe to recover ferromagnetic substances in the construction waste, remove impurities and separate the construction waste according to granularity, so that recycling and reusing requirements are satisfied. The movable construction waste crushing device is good in mobility; people do not need to convey the construction waste to designated sites, so that convenience is brought for people; and small working noise is produced in the working process, so that use requirements of people are met.

Owner:吴步晨

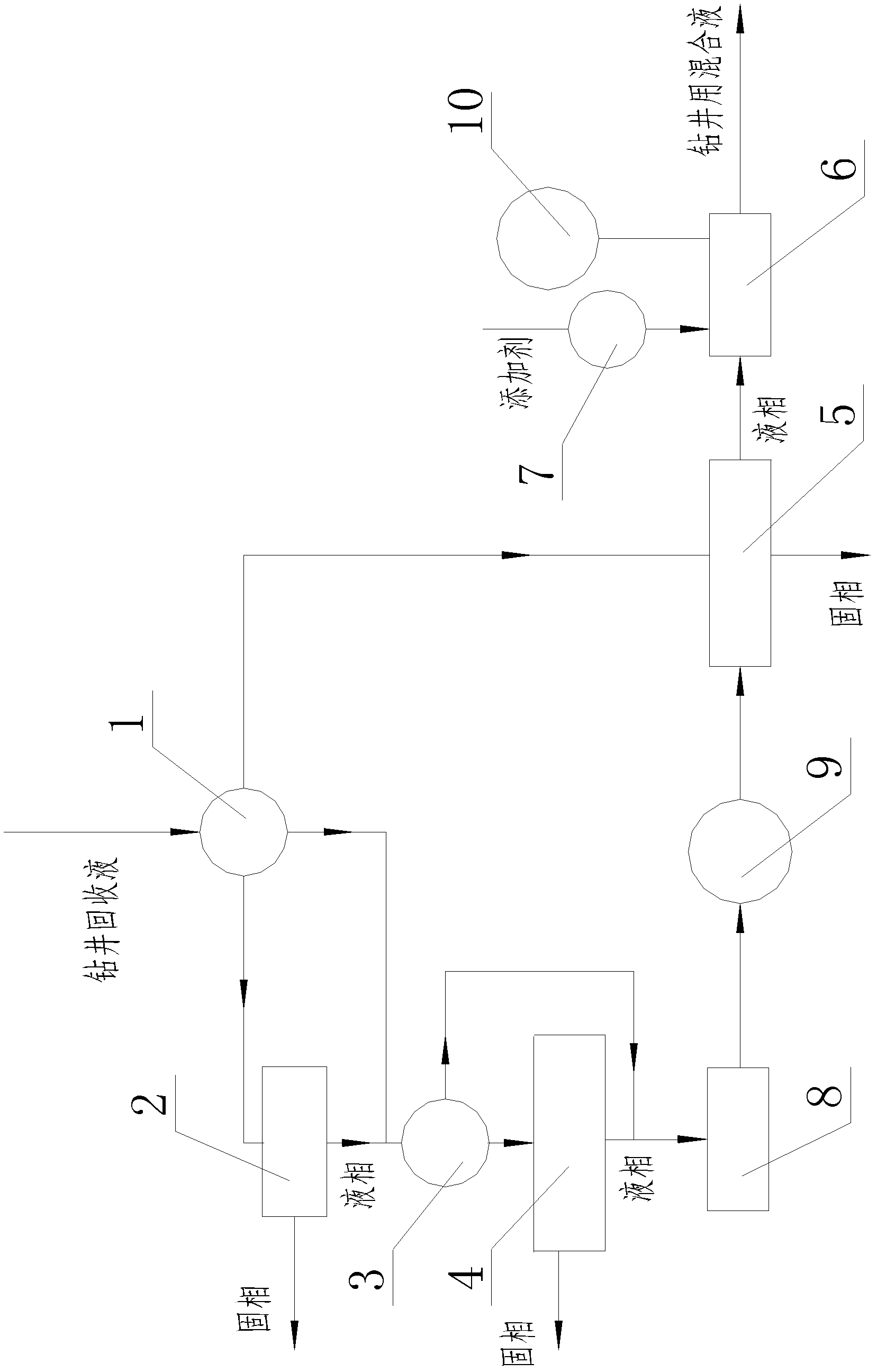

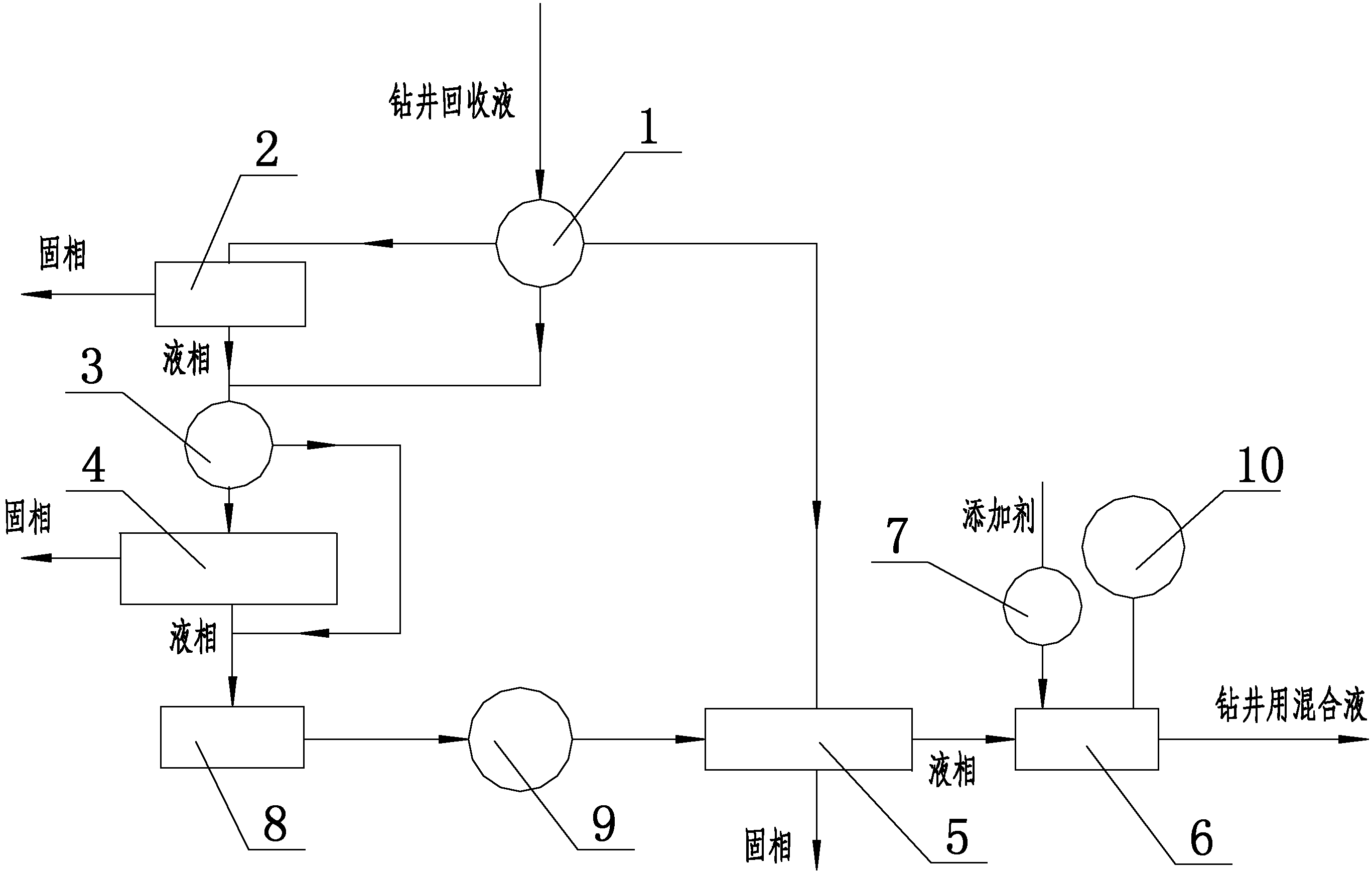

Recovery device of well drilling liquid

The invention discloses a recovery device of well drilling liquid, wherein the recovery device meets the solid-liquid separation of well drilling liquid with different concentrations and particle sizes. The recovery device comprises a first reversing valve, a vibration screen, a second reversing valve, a filtering centrifuge, a sedimentation centrifuge, a first liquid collecting groove and a chemical pump, wherein three outlets of the first reversing valve are respectively connected with an inlet of the vibration screen, an inlet of the second reversing valve and an inlet of the sedimentation centrifuge; an outlet of the vibration screen is also connected with the inlet of the second reversing valve; two outlets of the second reversing valve are respectively connected with an inlet of the filtering centrifuge and the inlet of the sedimentation centrifuge; an outlet of the filtering centrifuge is also connected with the inlet of the sedimentation centrifuge; an outlet of the sedimentation centrifuge is connected with the first liquid collecting groove; and the chemical pump is connected with the first liquid collecting groove. The recovery device has the advantages that: the vibration screen, the filtering centrifuge and the sedimentation centrifuge are arranged; and according to different solid phase concentrations of the well drilling liquid, the well drilling liquid is subjected to solid-liquid separation through different separation equipments by utilizing the reversing valve, so that the requirements of recovering the well drilling liquid with different concentrations are met.

Owner:JIANGSU HUADA CENTRIFUGE

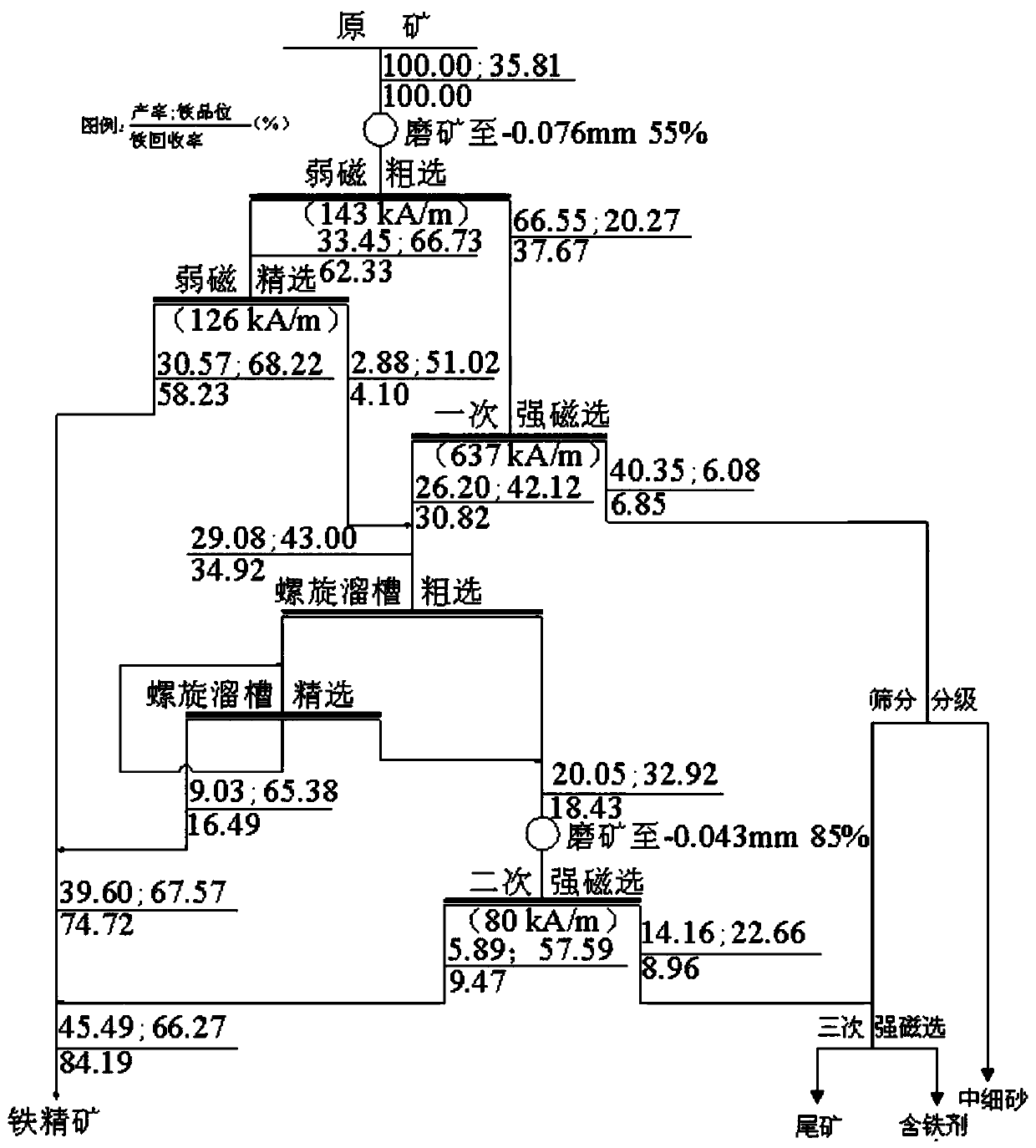

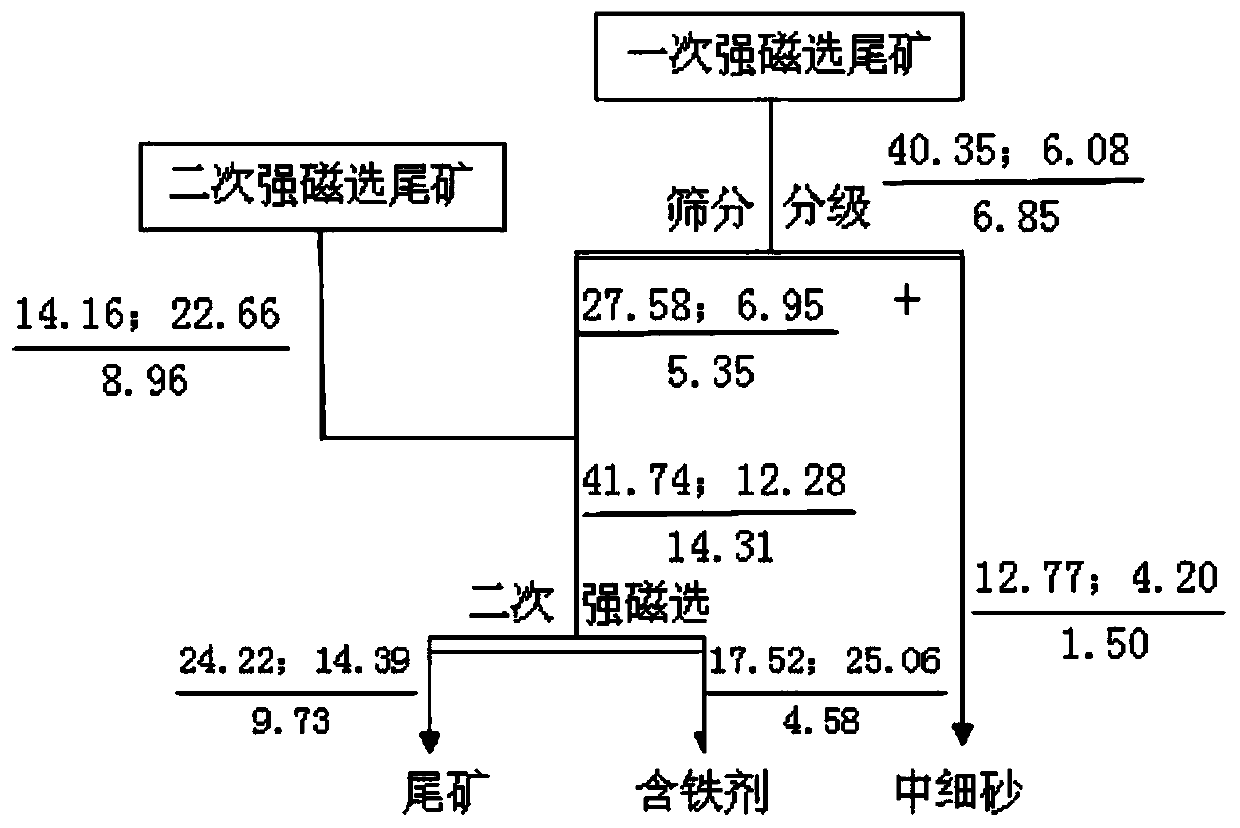

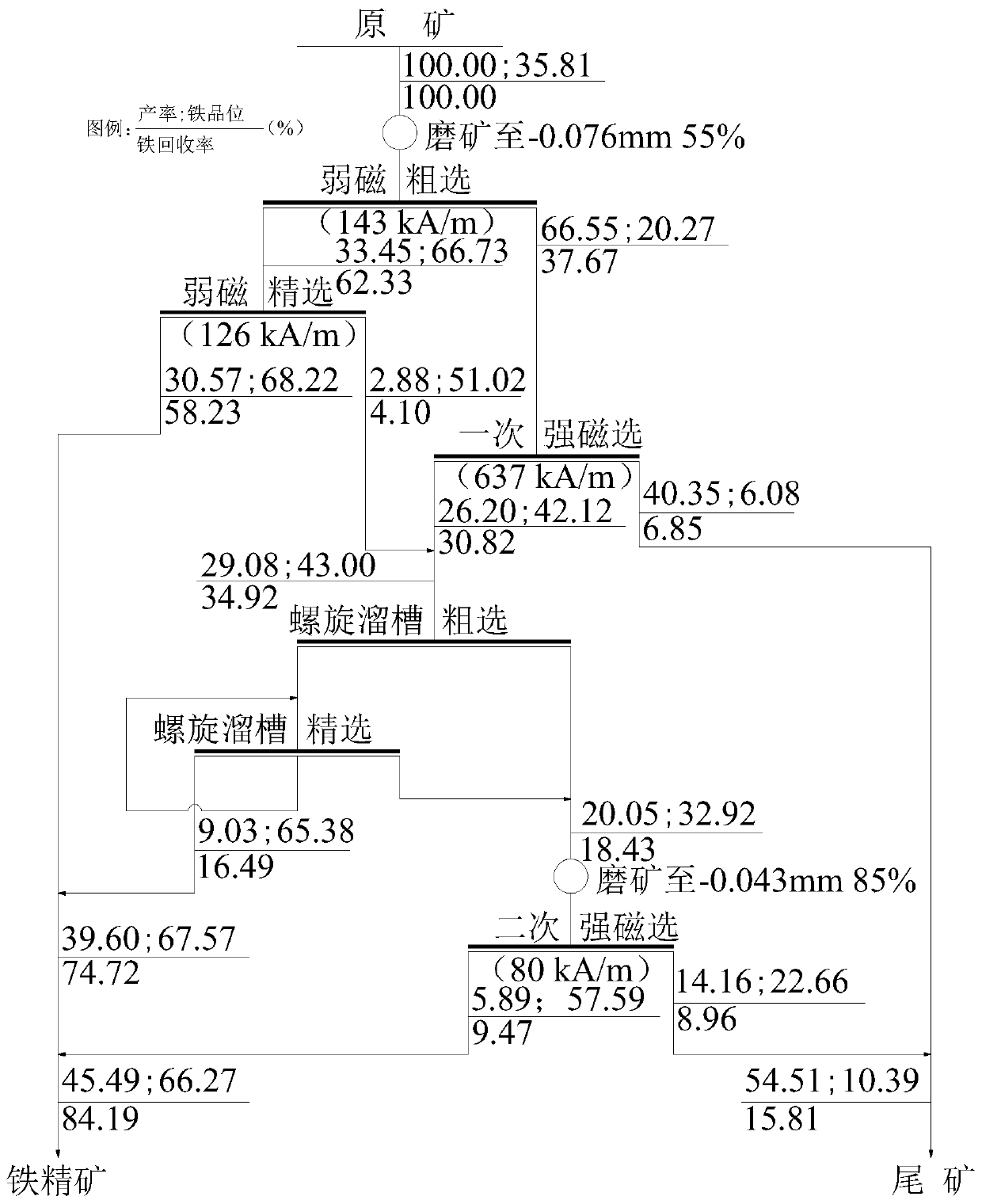

Magnetic-gravity separation method for magnetic-hematite mixed iron ore

ActiveCN109894267AGuaranteed Metal RecoverySimple process structureHigh gradient magnetic separatorsWet separationGravity separationMagnetic separation

The invention discloses a magnetic-gravity separation method for magnetic-hematite mixed iron ore. The method includes the following steps of: performing primary grinding on the magnetic-hematite mixed iron ore, and performing weak magnetic rough separation-weak magnetic fine separation on a primary grinding product to obtain a weak magnetic separation iron concentrate; performing primary strong magnetic separation on weak magnetic rough separation tailings; combining a primary strong magnetic separation concentrate and the weak magnetic fine separation tailings, and then performing spiral chute gravity separation to obtain a spiral chute gravity separation iron concentrate; performing secondary grinding on spiral chute gravity separation tailings, and performing secondary strong magneticseparation on a secondary grinding product to obtain a secondary strong magnetic separation iron concentrate; carrying out grinding-secondary strong magnetic separation on the gravity separation tailings; sieving and grading the primary strong magnetic separation tailings to obtain medium and fine sand products for construction, and discharging the sieved and graded fine tailings T1; and combiningthe secondary strong magnetic separation tailings and the sieved and graded fine tailings, and then performing tertiary strong magnetic separation to select an iron correcting agent for producing cement raw materials. The scheme of the invention has the advantages that the recovery rate of the iron concentrate is high, the secondary regrinding amount is small, energy conservation and consumptionreduction can be facilitated, environmental friendliness and simple process flow structures are realized, the water yield of the tailings is small, the index is stable, the field operation and management can be facilitated, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Process for manufacturing artificial turf

ActiveCN104060519AMeet recycling requirementsEnsure sustainable developmentGround pavingsFiberMolten state

The invention discloses a process for manufacturing artificial turf. The method comprises the steps that firstly, artificial turf fibers are arranged on a base fabric in a knitting and tufting mode; then, a thermoplastic material is heated to be of a molten state, is uniformly distributed on the back surface of the base fabric through the coating process or the heat sealing process, and forms a back adhesive layer after being cooled and solidified; the base fabric is separated from the back adhesive layer, the artificial turf fibers are fixed to the back adhesive layer in a bonding mode, and then the artificial turf capable of being wholly recycled is formed. The effect of bonding between the thermoplastic material serving as the back adhesive layer and the artificial turf fibers is excellent, but the effect of bonding between the thermoplastic material and the base fabric is poor or can not be achieved at all. The thermoplastic material serves as the back adhesive layer of the artificial turf, a base fabric structure of the finished product is omitted, the turf fibers and the back adhesive layer meet the requirement for wholly recycling the materials, and therefore the sustainable development of environment is maintained. The artificial turf is simple in structure, easy to manufacture and suitable for industrialization, saves the raw materials, lowers the cost and enables the resources to be recyclable.

Owner:TAISHAN SPORTS IND GRP +1

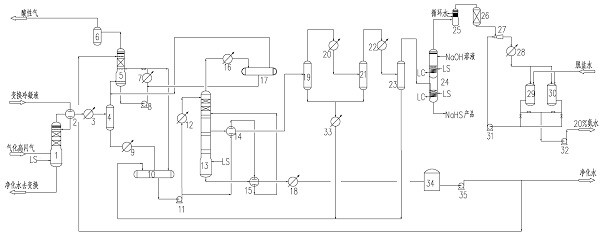

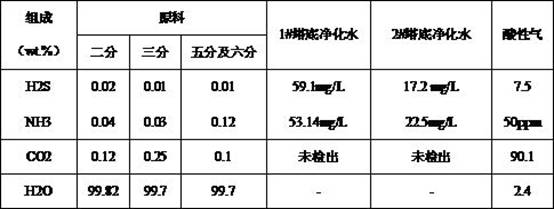

Comprehensive treatment process of conversion condensate

The invention discloses a comprehensive treatment process of conversion condensate. The method comprises the following steps: firstly, removing NH3, H2S and CO2 in conversion condensate and gasified high-flash gas by using a normal-pressure stripping tower, cooling a top gas phase, feeding a liquid phase into a pressurizing stripping tower, by a single-tower pressurizing belt side line extractionprocess, mixing the top gas phase with a gas phase of a normal-pressure stripping tower after condensation and liquid separation, removing ammonia in the gas through a water washing tower, then removing and recovering sulfur, discharging or recycling purified water at the bottom after being cooled, and producing sulfur-free ammonia water with the mass concentration of 20% is produced after hydrogen sulfide is removed through a multi-effect acidic tail gas purifier after three-stage condensation and liquid separation are carried out on middle side extraction. The method has the advantages of reasonable process design, stable device operation and high added value of products, has huge environmental protection benefits, and solves the problems that the ammonia water treated by the conversioncondensate contains sulfur and acidic gas carries ammonia.

Owner:WUHAN KELIN FINE CHEM

Printing and dyeing wastewater treating method

InactiveCN106395972ATroubleshoot complex handlersReach effluxWater treatment parameter controlSpecific water treatment objectivesChemical oxygen demandComplex problems

The invention provides a printing and dyeing wastewater treating method. The printing and dyeing wastewater treating method includes the step of mixing printing and dyeing wastewater with alkali resins with stirring for absorption, wherein the alkali resins are weak alkali resins or combinations of the weak alkali resins and strong alkali resins. The printing and dyeing wastewater treating method has the advantages that by adopting the strong alkali resins and / or the weak alkali resins to treat the printing and dyeing wastewater, COD (chemical oxygen demand) of outlet water can be controlled below 50mg / L, the problem of complexity in an existing low-concentration printing and dyeing wastewater treating process is solved, and the outlet water is enabled to satisfy the requirements of discharging or recycling.

Owner:SUZHOU QINGRAN ENVIRONMENTAL PROTECTION TECH

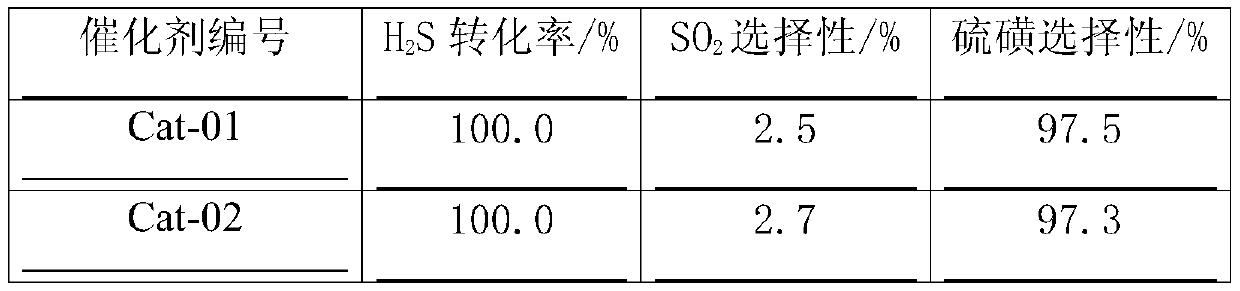

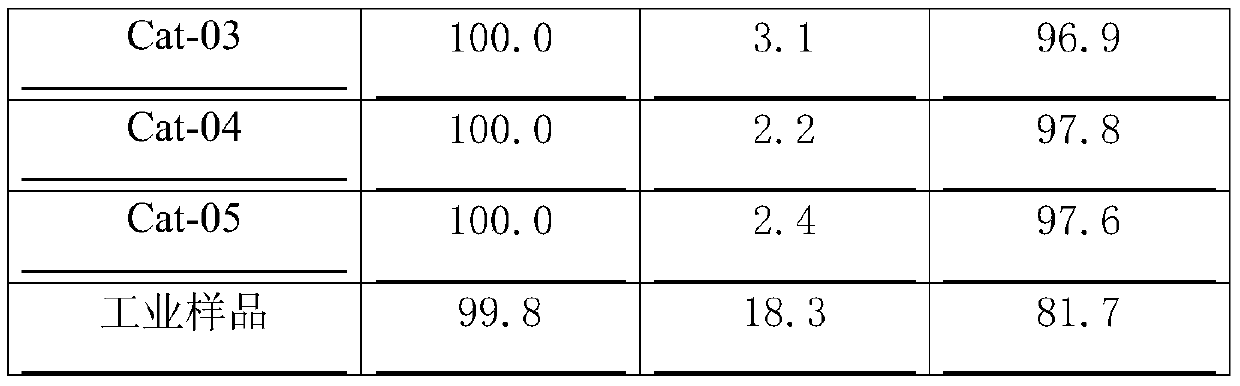

Catalyst for preparing sulfur by selective oxidation of hydrogen sulfide and preparation method thereof

InactiveCN110841641AMeet recycling requirementsStrong resistance to sulfationHeterogenous catalyst chemical elementsSulfur preparation/purificationPtru catalystPhysical chemistry

The invention provides a catalyst for preparing sulfur by selective oxidation of hydrogen sulfide and a preparation method of the catalyst. The catalyst is prepared by taking a titanium-silicon composite oxide as a carrier, taking ferric oxide or / and chromic oxide as an active component, and adding a certain amount of an active additive. The catalyst not only has high hydrogen sulfide conversion activity and sulfur generation selectivity, but also has sulfation resistance, oxygen content resistance and temperature fluctuation resistance, the stability and operability of the catalyst are improved, and the catalyst has a long service life.

Owner:青岛联信催化材料有限公司

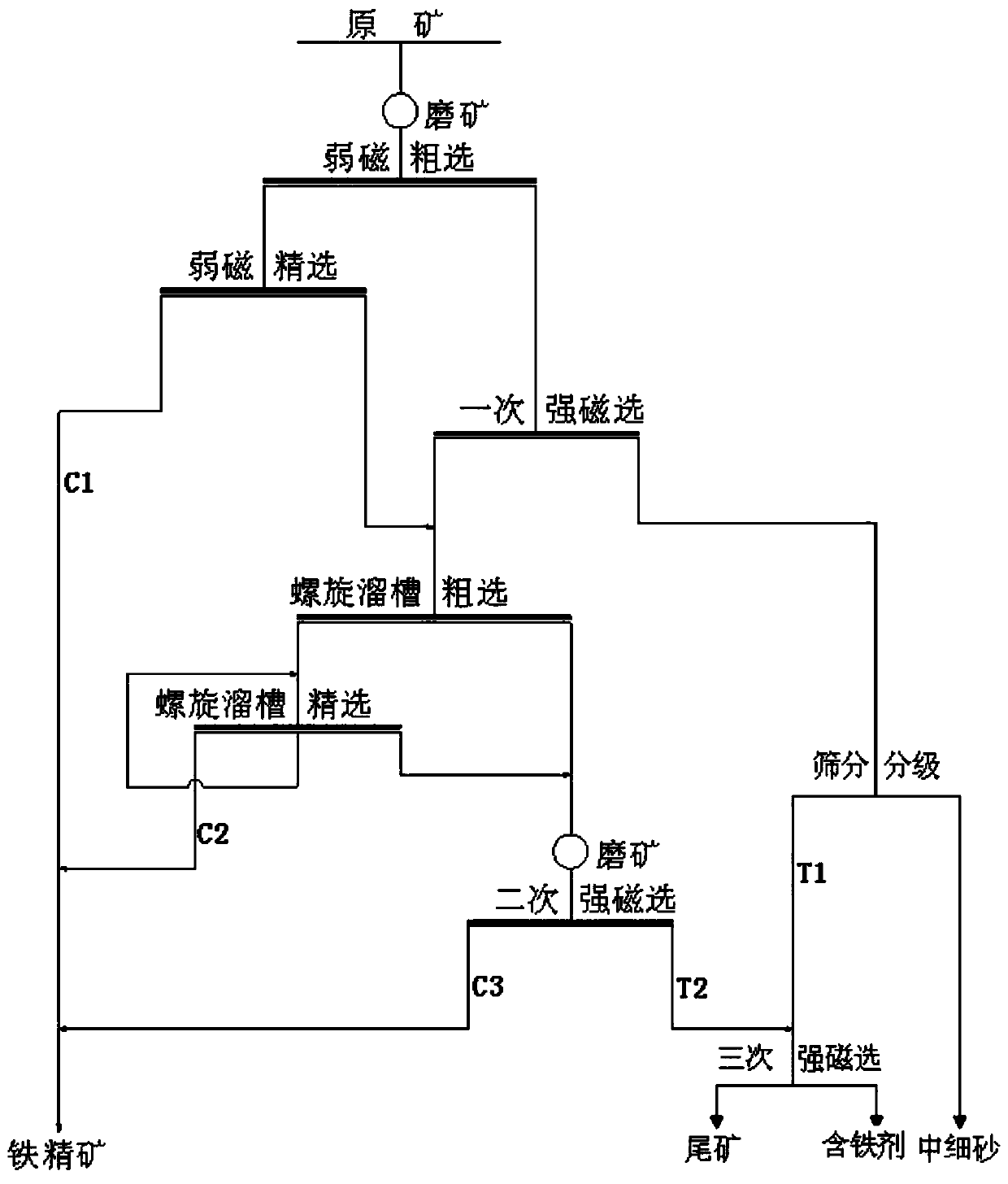

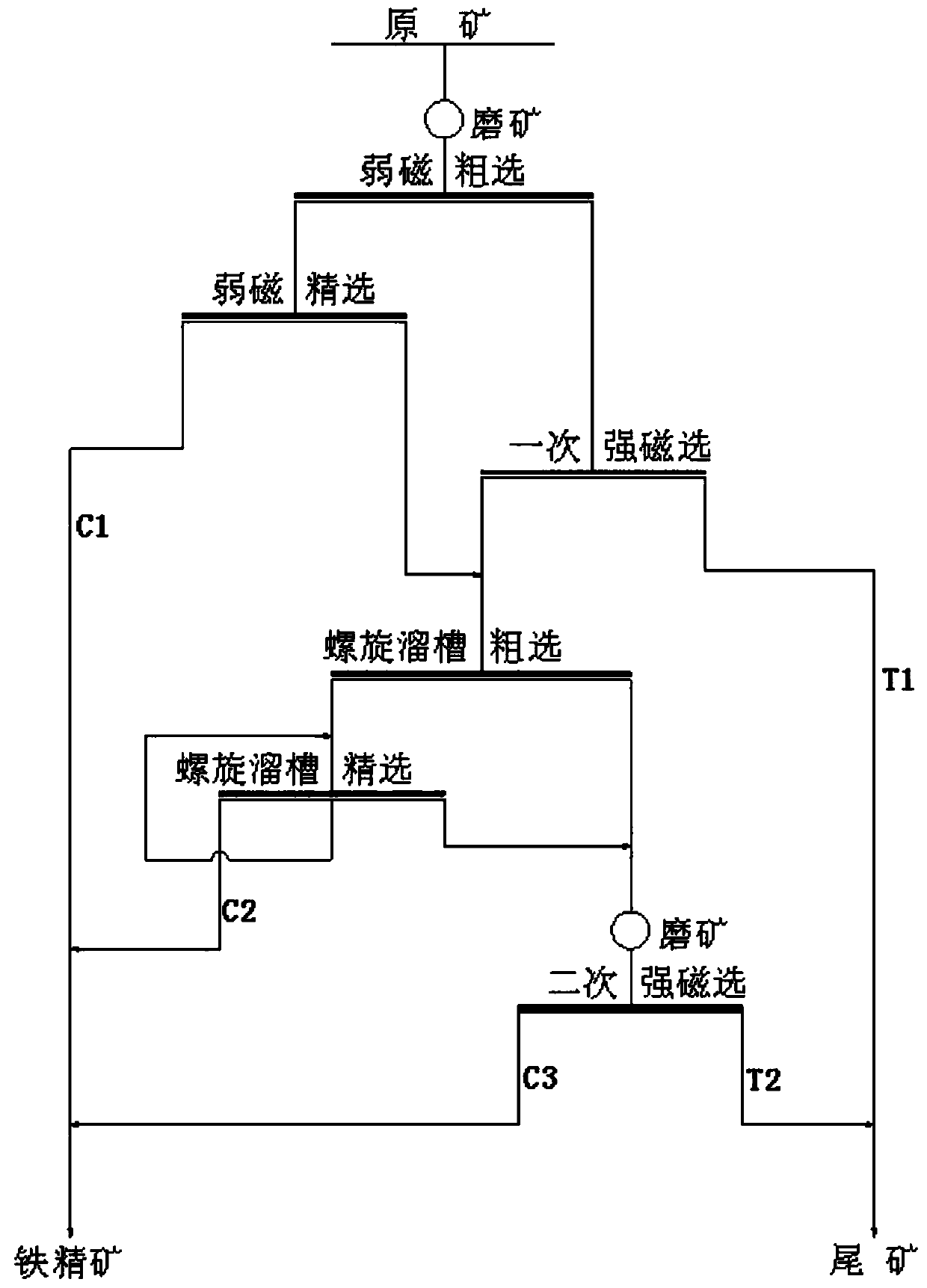

Non-flotation mineral processing method for magnetite-hematite mixed iron ore

ActiveCN109718946AGuaranteed RecoverySimple structureHigh gradient magnetic separatorsWet separationIronstoneHigh intensity

The invention discloses a non-flotation mineral processing method for magnetite-hematite mixed iron ore. The process adopted is as follows: carrying out first-stage grinding on magnetite-hematite mixed iron ore, and carrying out low-intensity magnetic rough separation and low-intensity magnetic fine selection on the first-stage grinding product to obtain low-intensity magnetic separation iron concentrate C1; carrying out primary high-intensity magnetic separation on the low-intensity magnetic rough separation tailings, discharging primary high-intensity magnetic separation concentrate, and discarding primary high-intensity magnetic separation tailings T1; combining the primary high-intensity magnetic separation concentrate and the low-intensity magnetic fine separation tailings, carrying out spiral chute gravity separation, discharging spiral chute gravity separation tailings, and obtaining spiral chute gravity separation iron concentrate C2; and carrying out second-stage grinding on the spiral chute gravity separation tailings, carrying out secondary high-intensity magnetic separation on the second-stage grinding product to obtain secondary high-intensity magnetic separation ironconcentrate C3, and discarding secondary high-intensity magnetic separation tailings T2. The non-flotation mineral processing method for magnetite-hematite mixed iron ore has the advantages of high recovery rate of iron concentrate, less second-stage regrinding, energy saving and consumption reducing, environment friendliness, simple process flow and structure, stable index, easy on-site operationand management, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Urban household garbage collecting device with excellent deodorizing effect

ActiveCN110685244ASolve the technical problems of poor deodorant effect and environmental protectionGuaranteed degree of crushingDispersed particle filtrationRoad cleaningRefuse collectionHazardous substance

The invention discloses an urban household garbage collecting device with an excellent deodorizing effect. The urban household garbage collecting device comprises a vehicle body, a first shell and a second shell. Both the first shell and the second shell are mounted on the vehicle body, a hairbrush roll is mounted between fixed plates, a garbage tank is arranged on one side of the hairbrush roll,a filter chamber and a clean water chamber are arranged on the inner side of the first shell, a lifting tank is arranged in the second shell, and a crushing assembly is arranged above the lifting tank. The garbage collecting device can recover garbage on the bottom surface automatically, and is high in work efficiency and convenient to use, so that the labor strength of people is reduced. The garbage collecting device filters gas in the garbage collected by the garbage tank for three times to remove impurities, harmful substances and odors in air, and is excellent in deodorizing effect and safe and environment-friendly. The lifting tank is conveniently detached, and rollers are arranged at the bottom of the lifting tank, so that the urban household garbage collecting device is convenient to move, can dispose the garbage quickly, and is high in work efficiency.

Owner:苏州科腾软件开发有限公司

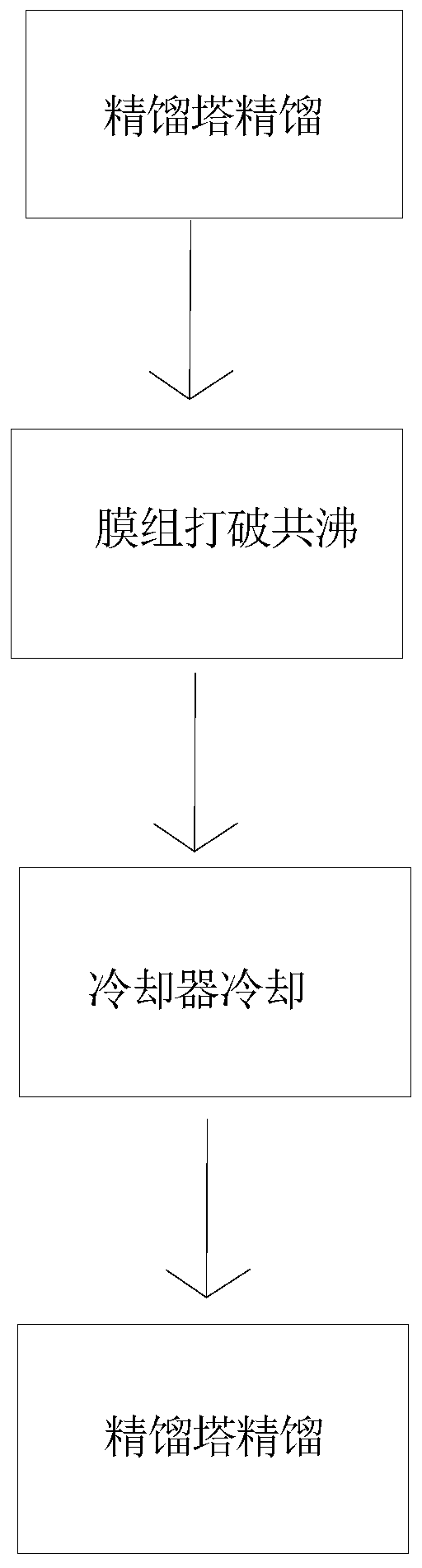

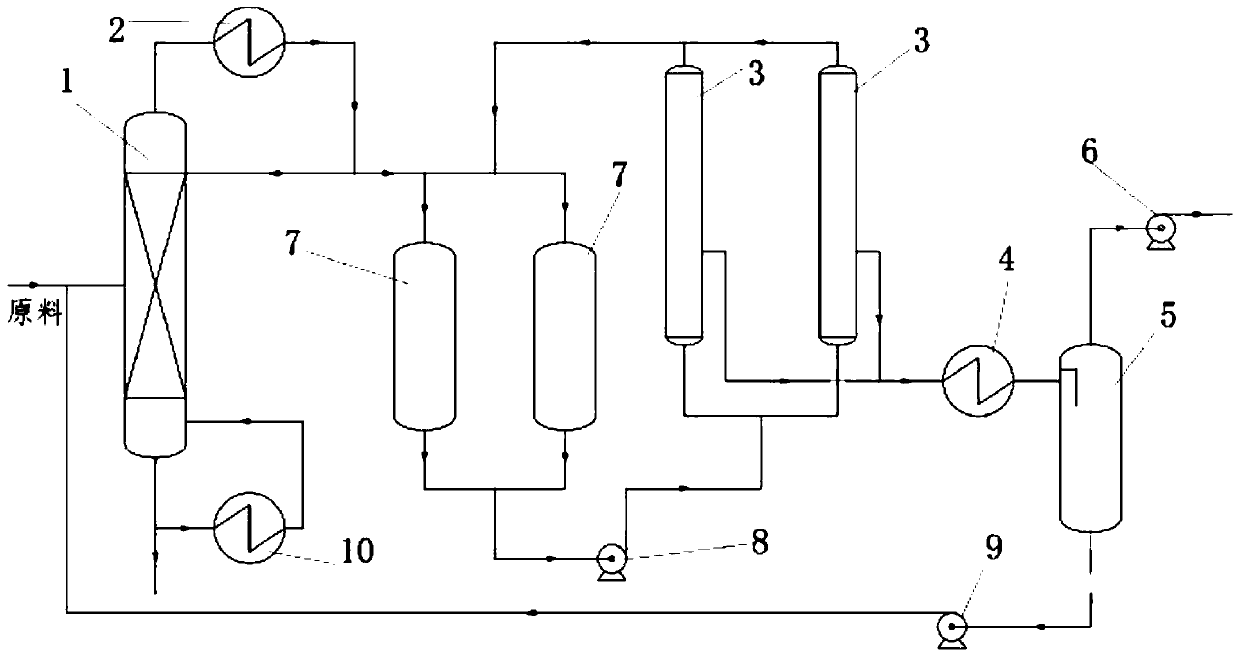

Method for separating methanol-containing organic solvent binary azeotrope

InactiveCN110105171AReduce condensation conditionsReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationChemical industryVapor liquid

The invention discloses a method for separating a methanol-containing organic solvent binary azeotrope. The method comprises the following steps: S1, rectifying a methanol-containing organic solvent solution by using a first rectification tower, and repeatedly heating and rectifying the solution to remove impurities and concentrate in order to obtain an methanol-containing azeotropic organic solvent A1; S2, heating the methanol-containing azeotropic organic solvent A1, performing repeated cycle purification by using pervaporation modules 3, heating the purified organic solvent A1 to a certaintemperature, separating a methanol vapor liquid A2 containing an extremely small amount of other organic solvents through a penetration side port under a vacuum condition under the action of pervaporation membranes, and cooling the methanol vapor liquid A2 by using a condenser to obtain a methanol solution A3 containing the extremely small amount of other organic solvents; and S3, rectifying the methanol solution A3 by using a second rectification tower to respectively obtain methanol and an azeotrope containing an extremely small amount of methanol. The method has the advantages of effectiveness in separation and recovery of the methanol-containing organic solvent binary azeotrope by using the modules and the rectification towers, low energy consumption, simplicity in operation of the whole system, simple process, solving of the difficulty in the separation of the methanol-containing azeotrope in the chemical industry, and saving of 30-60% of energy.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

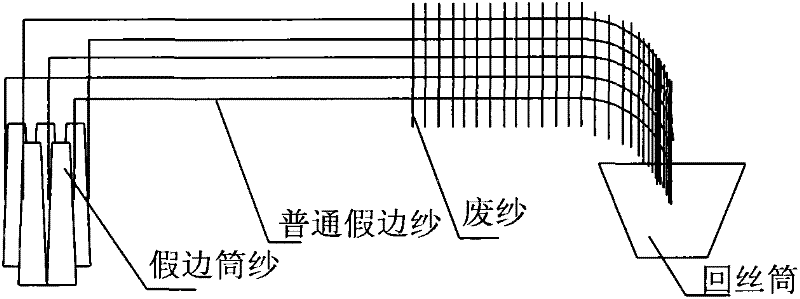

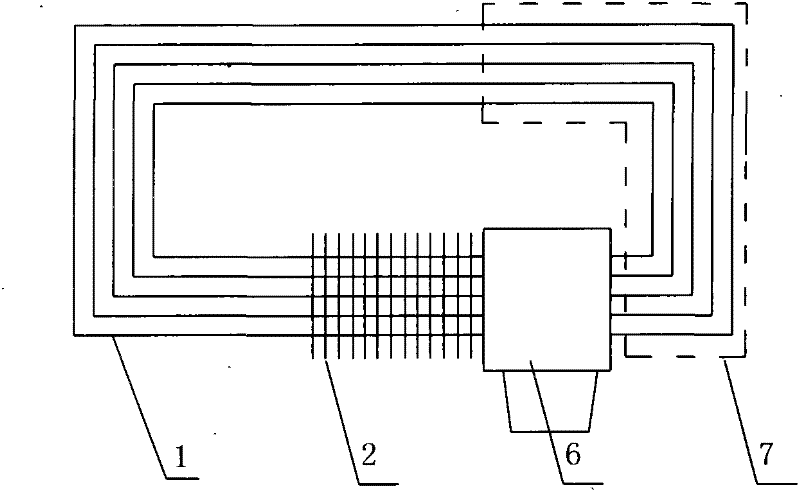

Method for recycling false selvedges of rapier loom

The invention provides a method for recycling false selvedges of a rapier loom, wherein annular false selvedges and a yarn separation box are arranged on the rapier loom; the silk separation box is arranged in the middles of the annular false selvedges; waste yarns are introduced into the silk separation box by weaving the annular false selvedges with the waste yarns; after the waste yarns are removed from the annular false selvedges by the silk separation box, the annular false selvedges are introduced into a false selvedge circulating channel of the rapier loom again to realize the recycling of the false selvedges; the silk separation box is internally provided with a silk separation plate and a draught fan; one side of the silk separation box is provided with an annular false selvedge inlet while the other side is provided with an annular false selvedge outlet; the annular false selvedge inlet and the annular false selvedge outlet are parallel to each other; the inner side of the annular false selvedge outlet is provided with the draught fan while the outer side of the annular false selvedge outlet is connected with the annular false selvedge circulating channel; silk separation holes for spacing the annular false selvedge are formed on the silk separation plate from top down; five annular false selvedges penetrate through the silk separation holes respectively; and the bottom of the silk separation plate is provided with a waste yarn collecting box.

Owner:山东如意毛纺服装集团股份有限公司

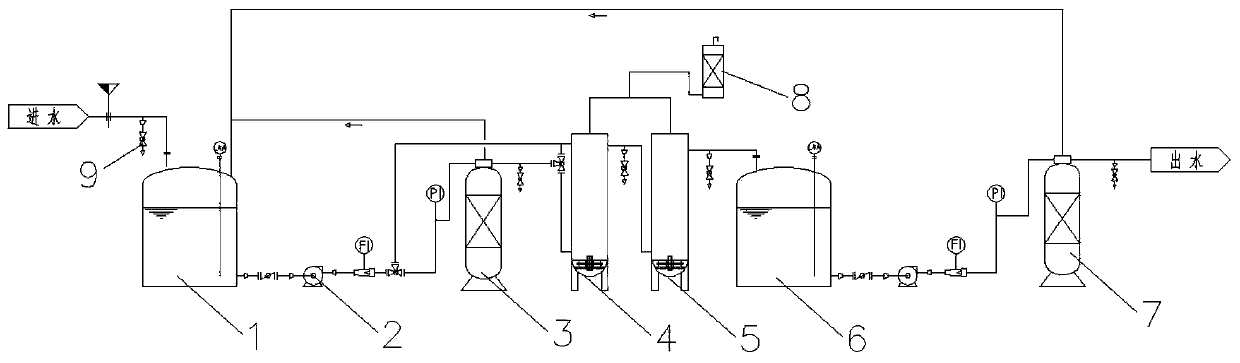

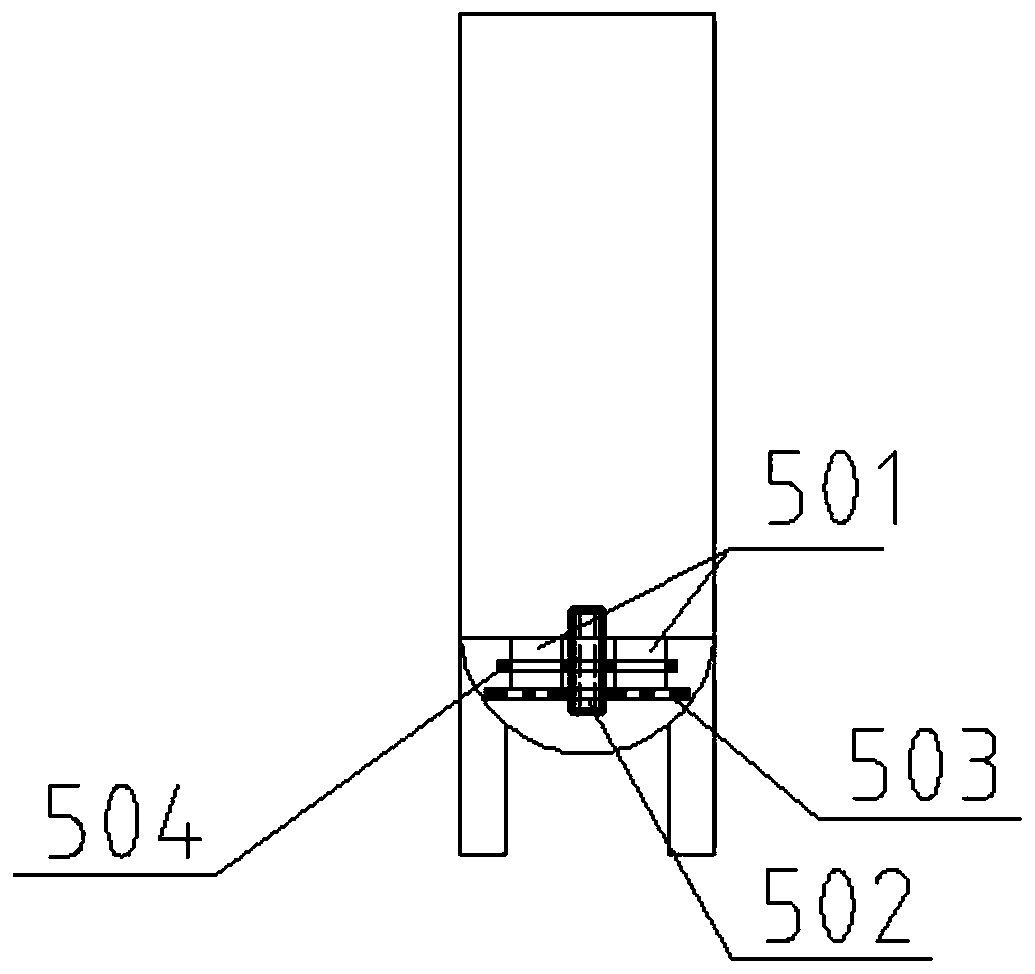

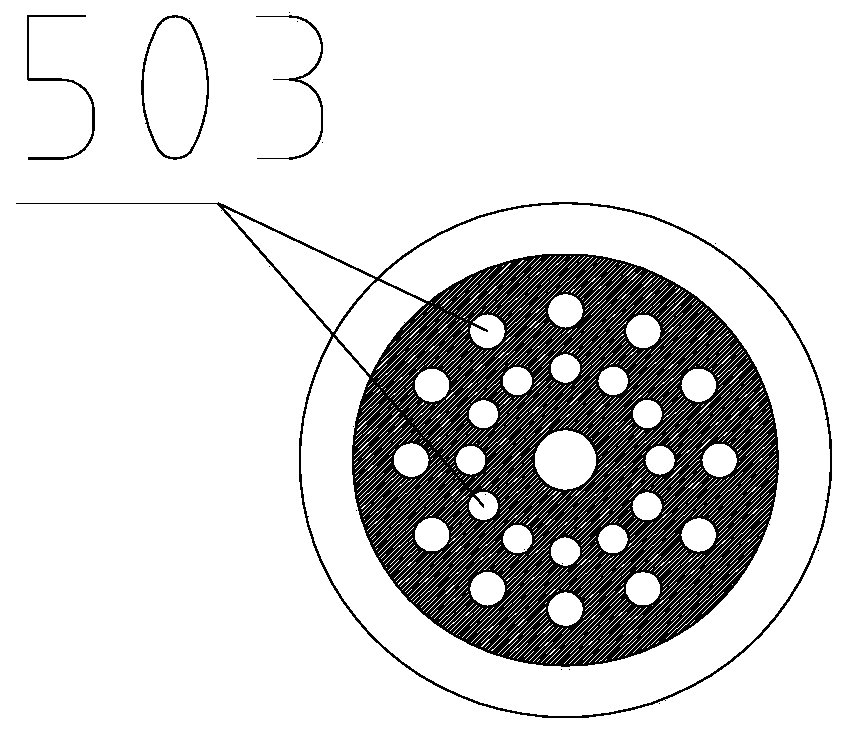

Method and device for processing sewage by virtue of multistage alternative microbial generator

InactiveCN103771590APrevention and control of secondary pollutionImprove removal effectBiological water/sewage treatmentSewage treatmentSewage

The invention discloses a method and device for processing sewage by virtue of a multistage alternative microbial generator. The method comprises the following steps: alternatively operating at least one-stage optimal three-stage microbial generation system, a biological generator group A and a biological generator group B, deriving step by step and logarithmically growing. The three-stage microbial generation system comprises an I-stage microbial generation system, a (img file='2014100613797100004dest-path-image001.TIF'wi='17'he='16' / )-stage microbial generation system and a (img file='559932dest-path-image002.TIF'wi=27'he='17' / )-stage microbial generation system. Each microbial generation system comprises a biological generator group A and a biological generator group B; the alternative operation of the biological generator group A and the biological generator group B comprises the processes of enabling the biological generator group B to have a rest for being needed again when the biological generator group A works normally; enabling the biological generator group A to have a rest for being needed again when the biological generator group B works normally. The step of deriving step by step comprises a process of taking a strain to simulate water temperature, climate, water quality and load in the I-stage microbial generation system, the (img file='2014100613797100004dest-path-image001.TIF'wi='17'he='16' / )-stage microbial generation system and the (img file='559932dest-path-image002.TIF'wi=27'he='17' / )-stage microbial generation system, then enabling microorganism to logarithmically grow in a special environment domestication and accelerating to generate microbial species. The method and the device for processing sewage through the multistage alternative microbial generator are good in processing effect and capable of greatly reducing sludge amount in the sewage treatment.

Owner:陈贤芳 +1

High-grade oxidization deep processing system of printing and dyeing wastewater C.E

PendingCN110066078AIncrease profitUniform and stable oxygen outputWater contaminantsTreatment involving filtrationElectrolysisActivated carbon filtration

The invention discloses a high-grade oxidization deep processing system of printing and dyeing wastewater C.E. The high-grade oxidization deep processing system comprises a raw water tank, a quartz sand filter, a C.E pre-electrolysis tank, a C.E electrolysis tank, a middle water tank and an active carbon filter which are sequentially communicated through a plurality of water inlet and outlet pipelines. The low-inlet and high-outlet mode is adopted for the water inlets and outlets of the C.E pre-electrolysis tank and the C.E electrolysis tank, and the tops of the C.E pre-electrolysis tank and the C.E electrolysis tank are both connected with the bottom of an active carbon adsorber; the C.E electrolysis tank comprises a plurality of electrode assemblies placed in electrode insertion groovesand an electrode assembly support, the electrode insertion grooves are evenly distributed in the electrode assembly support, each electrode assembly is an interlayer structure assembly composed of twonegative electrode plates, a built-in positive electrode plate, a plurality of screws, nuts and gaskets, and a plurality of flow guide holes are evenly distributed in the negative electrode plate andthe anode electrode plate. From the aspect of low energy consumption and low material consumption, the deep processing cost for making printing and dyeing wastewater reach the emission standard is reduced, meanwhile the recycling requirement is met, and energy conservation, emission reduction and recycling are realized.

Owner:SHANGHAI OCEAN UNIV

Agent for removing chloride ions in acidic wastewater, dechlorination method and application

ActiveCN111302469ATo achieve the purpose of removing chloride ions in polluted acid wastewaterMeet recycling requirementsWater contaminantsDispersed particle separationIndustrial waste waterChloride

The invention relates to an agent for removing chloride ions in waste acid wastewater and a dechlorination method and application, and belongs to the technical field of industrial wastewater treatmentand recycling. In order to solve the technical problems of limited dechlorination efficiency, large dosage and high cost of the existing dechlorination agent, the invention provides the agent for removing the chloride ions in the acidic wastewater, and the agent comprises bismuthate and / or bismuthate hydrate. The dechlorination agent provided by the invention is convenient to use and high in dechlorination efficiency, the highest dechlorination efficiency can reach 98.9%, and the dechlorination agent can be regenerated and recycled, so that the cost is relatively low, the problem of removal of chloride ions in the waste acid wastewater is solved, and resource recycling of the chloride ions in the waste acid wastewater is realized.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Stripping agent special for room-temperature vulcanized silicone rubber for insulator and stripping method

InactiveCN111440356AMeet recycling requirementsReduce wastePlastic recyclingPolymer scienceVulcanization

The invention discloses a stripping agent special for room-temperature vulcanized silicone rubber for an insulator and a stripping method. The stripping agent is prepared from, by mass, 50-70 parts ofsolvent butanone, 10-30 parts of cosolvent methyl alcohol, 10-20 parts of stripping auxiliary concentrated hydrochloric acid, 5-10 parts of functional auxiliary concentrated sulfuric acid and 2-5 parts of builder ethyl acetate. The stripping agent can effectively strip an RTV coating on the surface of the insulator (glass or ceramic insulator) coated with room temperature vulcanized silicone rubber (RTV) so that the surface of the insulator is recovered to be smooth and flat. Therefore, the effects of recycling and reducing pollution are achieved.

Owner:武汉疏能新材料有限公司

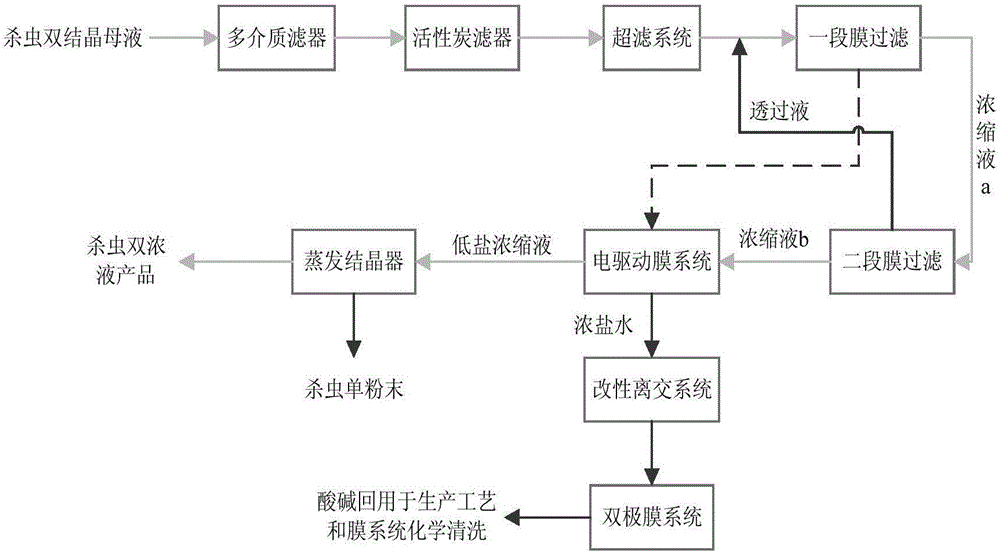

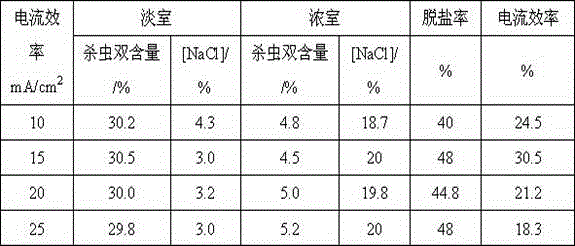

Bisultap mother liquor recycling system and process based on membrane treatment technology

ActiveCN106277521AReduce the amount of impuritiesHigh purityBiocideWater contaminantsHigh concentrationLiquid waste

The invention provides a bisultap mother liquor recycling system based on the membrane treatment technology. The bisultap mother liquor recycling system comprises filter equipment, an ultrafiltration system, a membrane filter system and an electric drive membrane system. The invention further provides a process used by the bisultap mother liquor recycling system based on the membrane treatment technology. The bisultap mother liquor recycling system and process have the advantages that product impurities are reduced evidently through multistage pretreatment, and product purity is increased; a monosultap product is obtained through evaporation crystallization, the mother liquor is still a high-concentration bisultap product after the crystallization, clean production is achieved while energy conservation and emission reduction are achieved, and good economic and environment benefits are achieved; the bipolar membrane system of the recycling system can perform electrolysis on desorbed salt to produce acid and alkali which can be reused in production, and waste liquid recycling is achieved; the recycling process of the bisultap mother liquor is promising in application prospect, comprehensive resource recycling is achieved, and high-value products are achieved.

Owner:SUNUP ENVIRONMENTAL TECH CO LTD

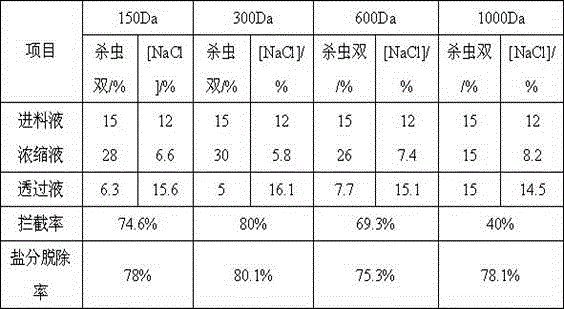

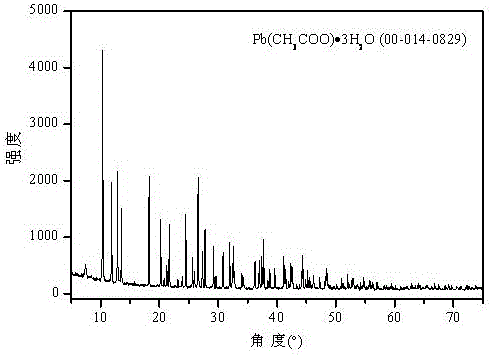

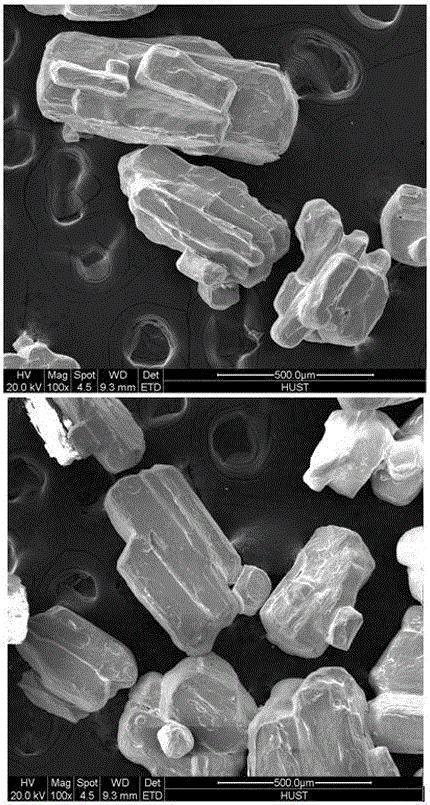

A method for preparing high-purity lead acetate and nanometer lead powder using waste lead paste

ActiveCN103880630BHigh purityNo pollution in the processNanotechnologyWaste accumulators reclaimingTube furnaceLead acetate

The invention relates to a preparation method of high-purity lead acetate and nanometer lead powder, in particular to a method for preparing high-purity lead acetate and nanometer lead powder by using waste lead paste of waste lead-acid batteries. The steps are as follows: adding waste lead plaster to a solution containing a desulfurizing agent for desulfurization and then performing solid-liquid separation to obtain desulfurized lead plaster; adding acetic acid solution and a solution as a reducing agent to the obtained desulfurized lead plaster to obtain soluble lead-containing acid Add the obtained soluble lead-containing acidic solution to glacial acetic acid for recrystallization and purification to obtain high-purity lead acetate trihydrate crystals and glacial acetic acid solution. The high-purity lead acetate crystals are roasted in a tube furnace or a muffle furnace to obtain nano lead powder. The preparation of lead acetate and nano-lead powder according to the method of the present invention has simple production process and low energy consumption, and its economic performance is better than that of traditional fire method or general wet method for preparing lead powder; the recovery rate of lead is high, no sulfur dioxide pollution is generated, and energy Realize the discharge of no pollutants, and the environmental pollution is extremely low.

Owner:湖北金洋冶金股份有限公司 +1

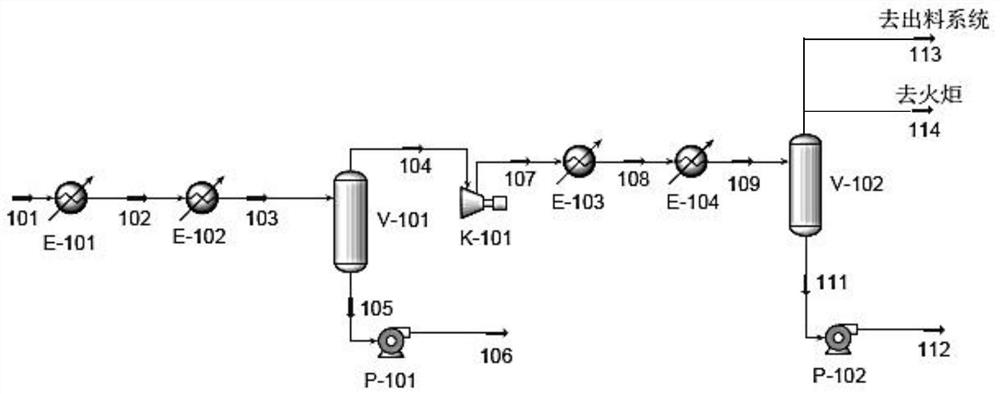

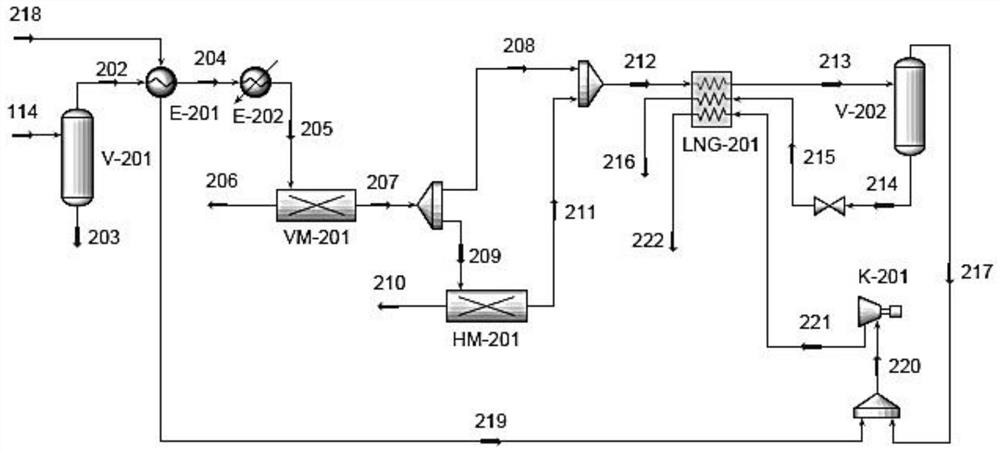

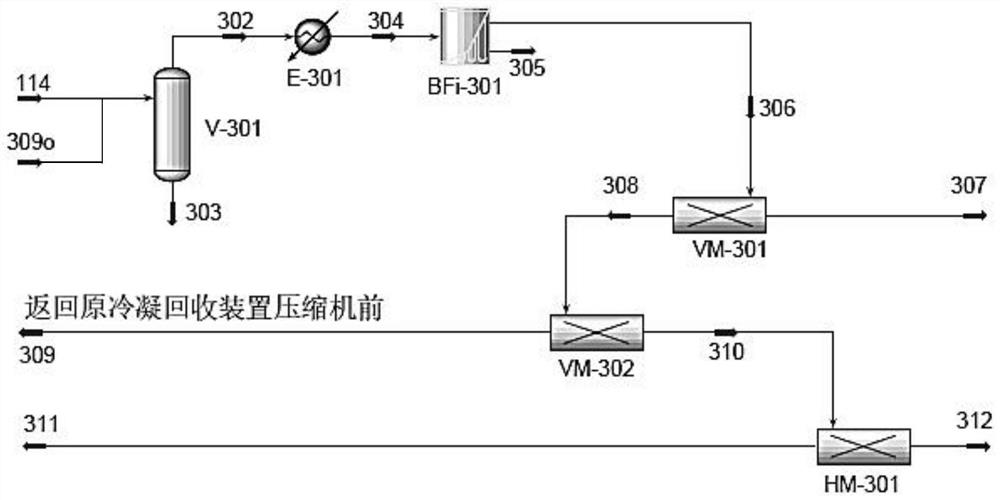

Method for recovering tail gas of gas-phase polyethylene device

ActiveCN112169549AHigh recovery rateLess investmentCombination devicesGas treatmentCondensation temperatureProcess engineering

The invention belongs to the technical field of VOCs recovery, and particularly relates to a method for recovering tail gas of a gas-phase polyethylene device. In a typical process of an exhaust gas recovery unit of a gas-phase polyethylene process, under the limitation of compression capacity and condensation temperature, a part of hydrocarbon gas still cannot be recycled and is directly discharged to a torch system, so that raw material waste and discharge pollution are caused. At present, an exhaust gas recovery system is modified by a part of built gas-phase polyethylene devices in China,common recovery technologies include membrane separation, cryogenic treatment, membrane and cryogenic treatment combination and the like, but the characteristics of high ethylene recovery rate, low investment cost and the like cannot be considered at the same time. The invention provides the method for recovering tail gas of a gas-phase polyethylene device, which not only can meet the recovery requirements of C4 <+> hydrocarbons, but also has the advantages of high ethylene recovery rate, lower investment cost, less dynamic equipment and the like.

Owner:DALIAN UNIV OF TECH PANJIN INST OF IND TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com