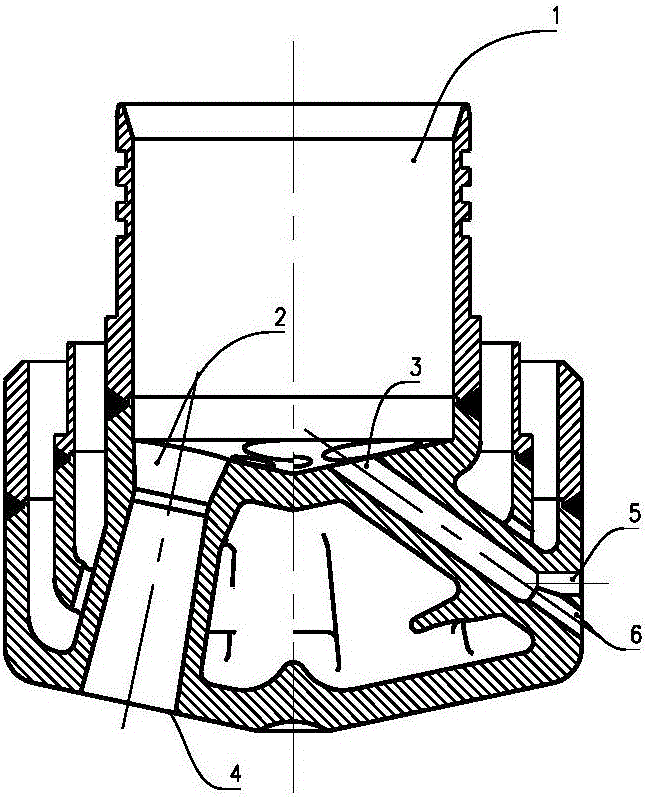

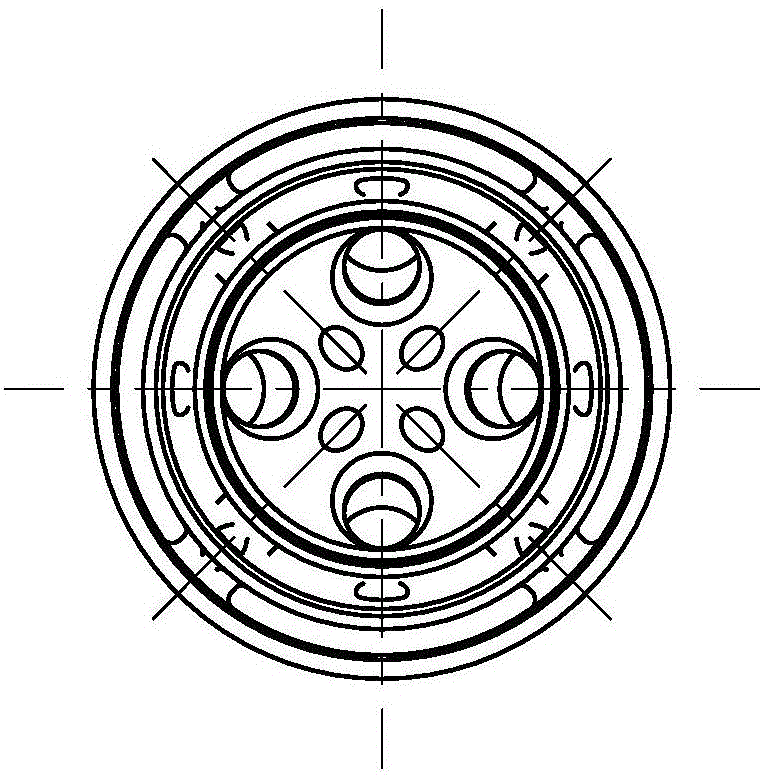

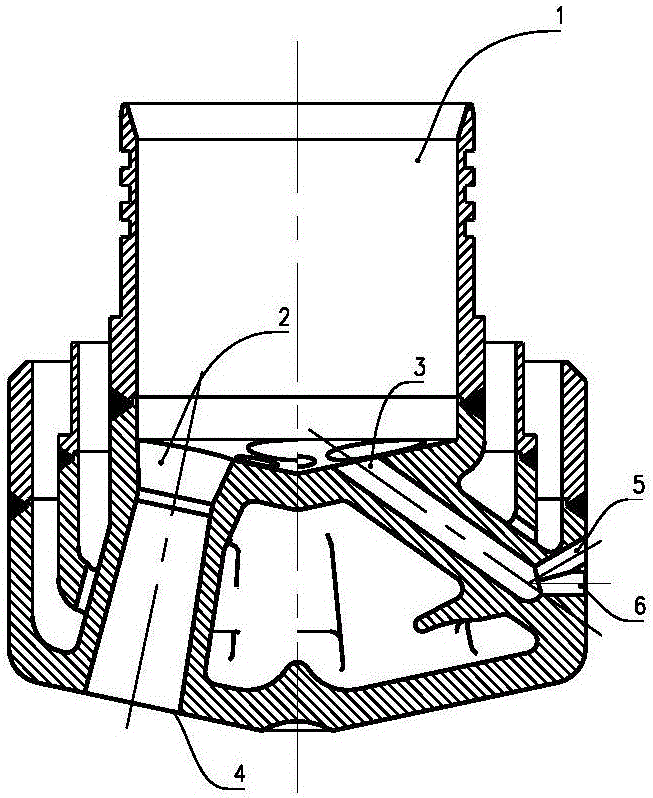

Double-flow oxygen gun and use method thereof

An oxygen lance and oxygen technology, applied in the direction of manufacturing converters, etc., can solve the problems of reducing the gas concentration of the converter, large water cooling space, reducing the service life of the nozzle, etc., to improve the end temperature of the converter, increase the temperature of the molten pool, and improve the application effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This implementation is aimed at the molten iron blowing and slag splashing effects of a 500kg induction furnace. Use nozzle I, add 200kg of pig iron, heat up the induction furnace to about 1350°C, and take molten iron sample 1. Lower the oxygen lance for oxygen blowing, the oxygen blowing intensity is 3.0Nm 3 / t.min, the gun position is controlled at 0.5-0.8m. Add 5kg of lime, 4kg of sintered ore, 3kg of dolomite during the oxygen blowing process, and the strength of bottom blowing argon is 0.03Nm 3 / t.min. After blowing oxygen for 14 minutes, take samples for temperature measurement 2. After blowing, the molten steel is poured out, leaving all the slag. For slag splashing to protect the furnace, the oxygen pressure of the slag splashing oxygen lance is 1.0Mpa, and the position of the slag splashing gun is 0.5-0.7m, so the slag splashing effect is better.

[0038] After the test, the samples were analyzed, and the results were: sample 1 [P] 0.099%, [Si] 0.3%, [C] 4...

Embodiment 2

[0040] This implementation is aimed at the molten iron blowing and slag splashing effects of a 500kg induction furnace. Using nozzle II, add 220kg of pig iron, heat up the induction furnace to about 1350°C, and take molten iron sample 1. Lower the oxygen lance for oxygen blowing, the oxygen blowing intensity is 3.0Nm 3 / t.min, the gun position is controlled at 0.5-0.8m. Add 5.2kg of lime, 4.1kg of sintered ore, 3.3kg of dolomite during the oxygen blowing process, and the strength of bottom blowing argon is 0.03Nm 3 / t.min. After blowing oxygen for 15 minutes, take samples for temperature measurement 2. After blowing, the molten steel is poured out, leaving all the slag. For slag splashing to protect the furnace, the oxygen pressure of the slag splashing oxygen lance is 1.0Mpa, and the position of the slag splashing gun is 0.5-0.7m, so the slag splashing effect is better.

[0041] After the test, the samples were analyzed and the results were: sample 1 [P] 0.097%, [Si] 0.33...

Embodiment 3

[0043] This implementation is aimed at the molten iron blowing and slag splashing effects of a 500kg induction furnace. Use nozzle III, add 200kg of pig iron, heat up the induction furnace to about 1350°C, and take molten iron sample 1. Lower the oxygen lance to blow oxygen, the strength of oxygen blowing is 3.2Nm 3 / t.min, the gun position is controlled at 0.5-0.8m. Add 4.9kg of lime, 3.6kg of sintered ore, 2.9kg of dolomite during the oxygen blowing process, and the intensity of bottom blowing argon is 0.03Nm 3 / t.min. After blowing oxygen for 14.5 minutes, take samples for temperature measurement 2. After blowing, the molten steel is poured out, leaving all the slag. For slag splashing to protect the furnace, the oxygen pressure of the slag splashing oxygen lance is 1.0Mpa, and the position of the slag splashing gun is 0.5-0.7m, so the slag splashing effect is better.

[0044] After the test, the samples were analyzed, and the results were: sample 1 [P] 0.12%, [Si] 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mach number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com