Pump and automatic putting system provided with same

A pump cavity and pump body technology, applied in the field of automatic feeding system, can solve the problems of increasing the difficulty of parts management, inconvenient installation, large volume, etc., and achieve the effect of convenient control program design, saving space and cost, and high degree of customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

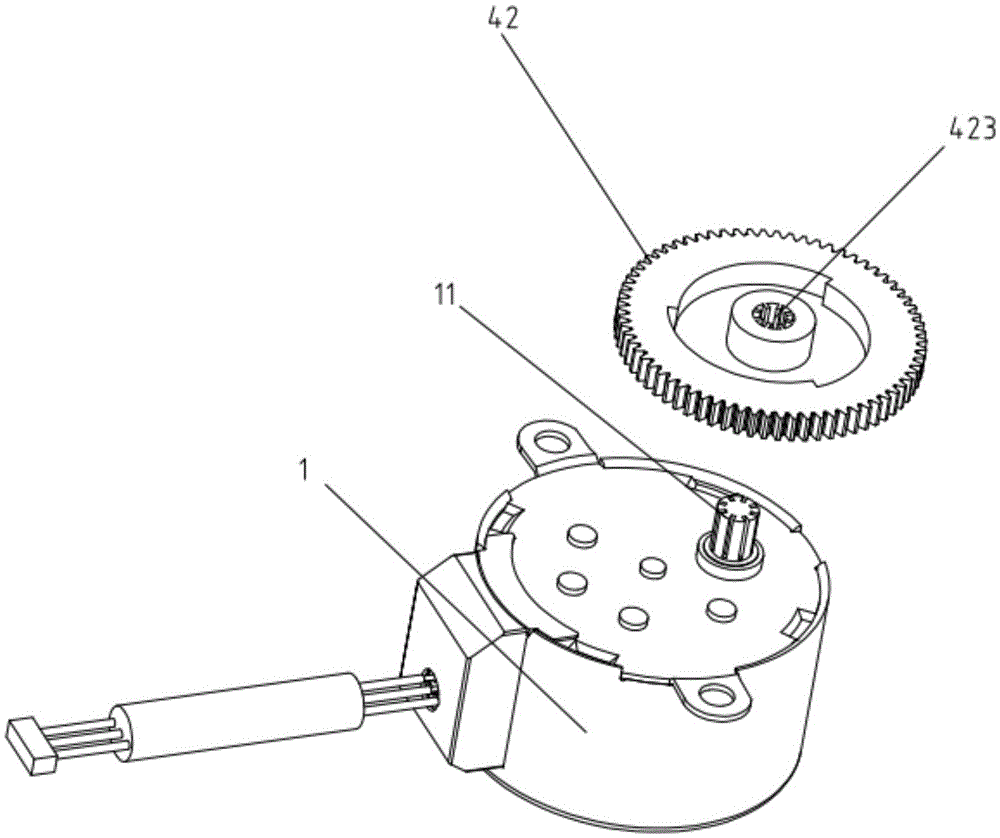

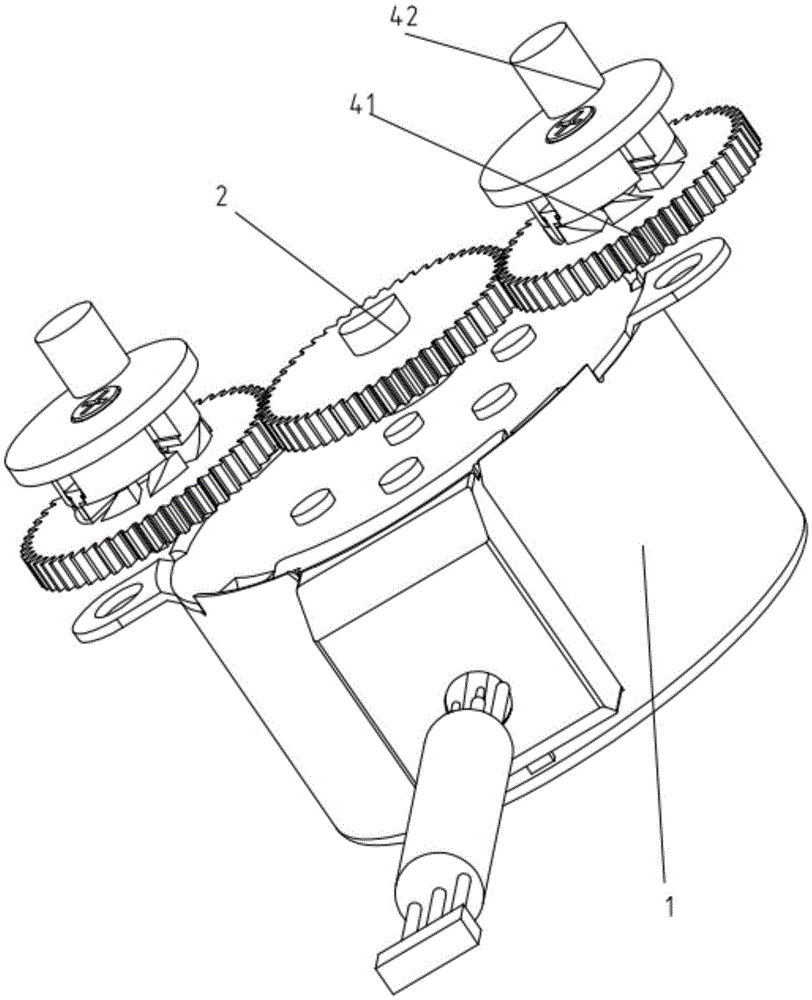

[0056] Such as Figure 1-7 , Shown in 14, a kind of pump, it comprises:

[0057] A power source 1 capable of forward and reverse power output; the power source 1 can be a motor;

[0058] A pump body 3, the pump body 3 has at least two pump chambers 31, and each pump chamber 31 is correspondingly provided with a pump chamber driving assembly 32;

[0059] At least two clutch mechanisms, the clutch mechanisms correspond to the pump chambers 31 one by one, and the clutch mechanisms are connected to the pump chamber driving components 32 of the corresponding pump chambers 31, when the power source 1 rotates forward to output power or when the power source 1 When the power output is reversed, at least one of the clutch mechanisms is in the power engagement state and at least one of the clutch mechanisms is in the power separation state, and the power source transmits power to the corresponding pump chamber drive assembly 32 through the clutch mechanism in the power engagement state...

Embodiment 2

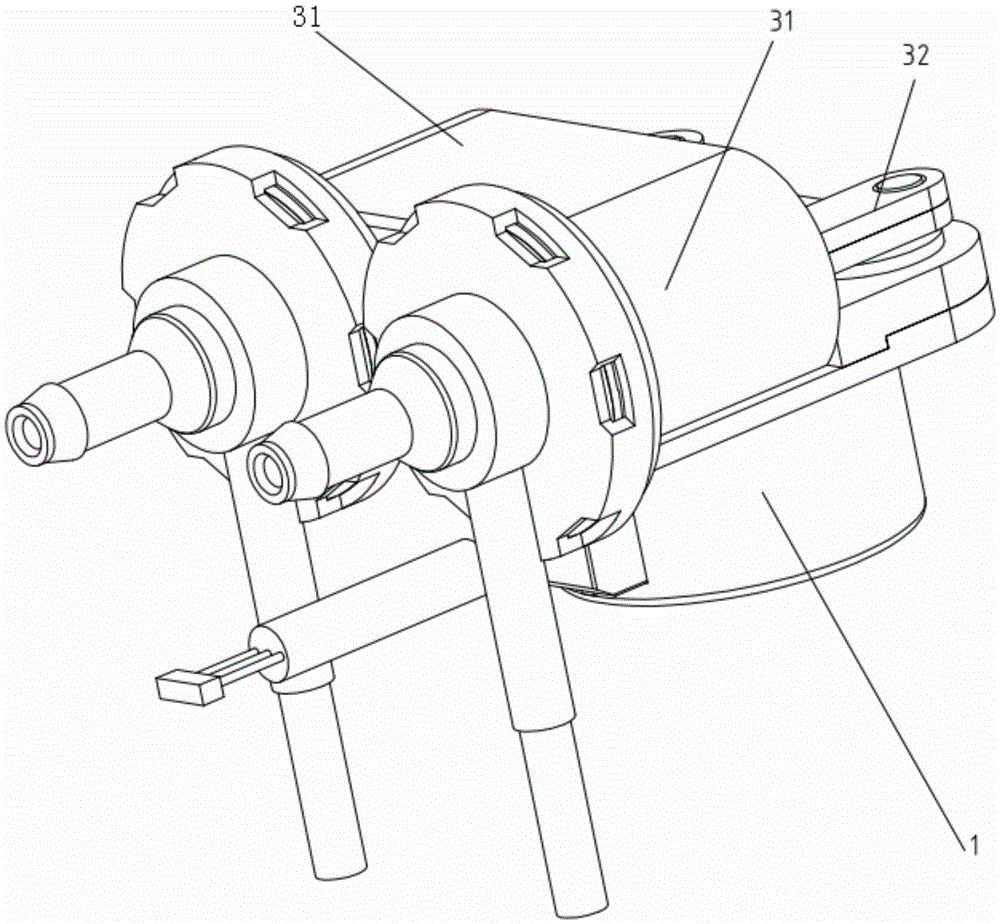

[0081] Such as Figures 9 to 17 Shown, a kind of pump, it comprises:

[0082] A power source 1 capable of forward and reverse power output; the power source 1 can be a motor;

[0083] The pump body 3, the pump body 3 has at least two pump chambers 31, and each pump chamber 31 is correspondingly provided with a pump chamber driving assembly 32; at least two clutch mechanisms, the clutch mechanisms correspond to the pump chambers 31 one by one, and the The above-mentioned clutch mechanism is connected with the pump chamber drive assembly 32 of the corresponding pump chamber 31, when the power source 1 rotates the power output in the forward direction or when the power source 1 reverses the power output, at least one of the clutch mechanisms is in the power engagement state and at least one The power separation of the clutch mechanism is in the power separation state, and the power source transmits power to the corresponding pump chamber drive assembly 32 through the clutch mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com