High-liquidity high-glossiness flame retardant toughened polypropylene material and preparation method thereof

A polypropylene material and high-flow technology, which is applied in the field of high-flow, high-gloss, flame-retardant and toughened polypropylene materials and their preparation, can solve the problems of unusability and reduce the mechanical properties and fluidity of the material, and achieve the reduction of total dosage, low price, and low cost. High flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

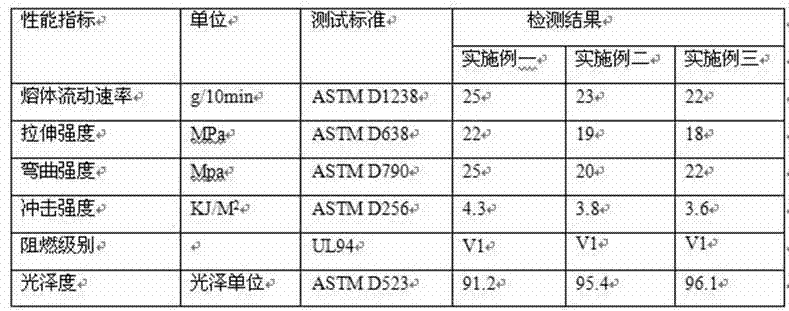

Embodiment 1

[0033] Embodiment 1: Accurately weigh each component by the following mass parts:

[0034] High melting point polypropylene K7726 100

[0035] Ethylene-octene copolymer 6

[0036] Odorless maleic anhydride grafted polypropylene 3

[0037] Ultra-fine high-gloss barium sulfate 10

[0038] Decabromodiphenylethane 12

[0040] Aryl phosphate salt nucleating agent TMP-6 0.1

[0041] Hindered phenolic antioxidant 1010 0.1

[0042] Phosphite lipid antioxidant 168 0.2

[0043] γ-Aminopropyltriethoxysilane 0.2

[0045] Distyryl bisbenzoxazole 0.03.

[0046] The material is prepared according to the following process:

[0047] Step 1: Mix 0.2 parts of γ-aminopropyltriethoxysilane, 0.3 parts of calcium stearate, 12 parts of decabromodiphenylethane, 6 parts of antimony trioxide, and 10 parts of superfine high-gloss barium sulfate at high speed Mix in a mixer for 4 minutes.

[0048] Step 2: 100 parts of high melting poin...

Embodiment 2

[0049] Embodiment 2: Accurately weigh each component by the following mass parts:

[0050] High melting point polypropylene K7726 100

[0051] Ethylene-octene copolymer 8

[0052] Odorless maleic anhydride grafted polypropylene 4

[0053] Ultra-fine high-gloss barium sulfate 15

[0054] Decabromodiphenylethane 12

[0056] Aryl phosphate salt nucleating agent TMP-6 0.15

[0057] Hindered phenolic antioxidant 1010 0.1

[0058] Phosphite lipid antioxidant 168 0.2

[0059] Stearic acid 0.3

[0061] Distyryl bisbenzoxazole 0.03.

[0062] The material is prepared according to the following process:

[0063] Step 1: Mix 0.3 parts of stearic acid, 0.4 parts of calcium stearate, 12 parts of decabromodiphenylethane, 6 parts of antimony trioxide, and 15 parts of superfine high-gloss barium sulfate in a high-speed mixer for 4 minutes.

[0064] Step 2: 100 parts of high melting point polypropylene K7726, 8 parts of ethylen...

Embodiment 3

[0065] Embodiment 3: Accurately weigh each component by the following mass parts:

[0066] High melting point polypropylene K7726 100

[0067] Ethylene-octene copolymer 10

[0068] Odorless maleic anhydride grafted polypropylene 4

[0069] Ultra-fine high-gloss barium sulfate 20

[0070] Decabromodiphenylethane 12

[0071] Antimony trioxide 6

[0072] Aryl phosphate salt nucleating agent TMP-6 0.2

[0073] Hindered amine antioxidant 1010 0.1

[0074] Phosphite lipid antioxidant 168 0.2

[0075] Stearic acid 0.4

[0076] Calcium stearate 0.5

[0077] Distyryl bisbenzoxazole 0.02.

[0078] The material is prepared according to the following process:

[0079] Step 1: Mix 0.4 parts of stearic acid, 0.5 parts of calcium stearate, 12 parts of decabromodiphenylethane, 6 parts of antimony trioxide, and 20 parts of superfine high-gloss barium sulfate in a high-speed mixer for 4 minutes.

[0080] Step 2: 100 parts of high melting point polypropylene K7726, 10 parts of ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com