Patents

Literature

65results about How to "Good slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer special for high-quality high-yield southern citrus and preparation method thereof

The invention discloses a fertilizer special for high-quality high-yield southern citrus and a preparation method thereof and relates to the field of agricultural fertilizers. The fertilizer is formed by mixing and granulating the following components in parts by weight: 25-35 parts of organic matters, 17-23 parts of calcium, 16-20 parts of urea, 6-10 parts of monoammonium phosphate, 10-14 parts of potassium sulfate, 2-4 parts of talcum powder, 0.4-0.6 part of trace elements, 6-10 parts of humic acid, 0.4-0.6 part of microorganism and 1 part of coating cementing agent. The fertilizer provided by the invention has the characteristics that the fertilizer is green and environment-friendly, is suitable for being applied to the southern citrus and can promote the high quality and the high yield of the southern citrus. The fertilizer provided by the invention can be used as a basic fertilizer for the southern citrus in winter, and can also be used as a basic fertilizer for vegetables, flowers, melons and fruits, teas and other fruit trees in winter.

Owner:HUNAN ZHONGKE AGRI

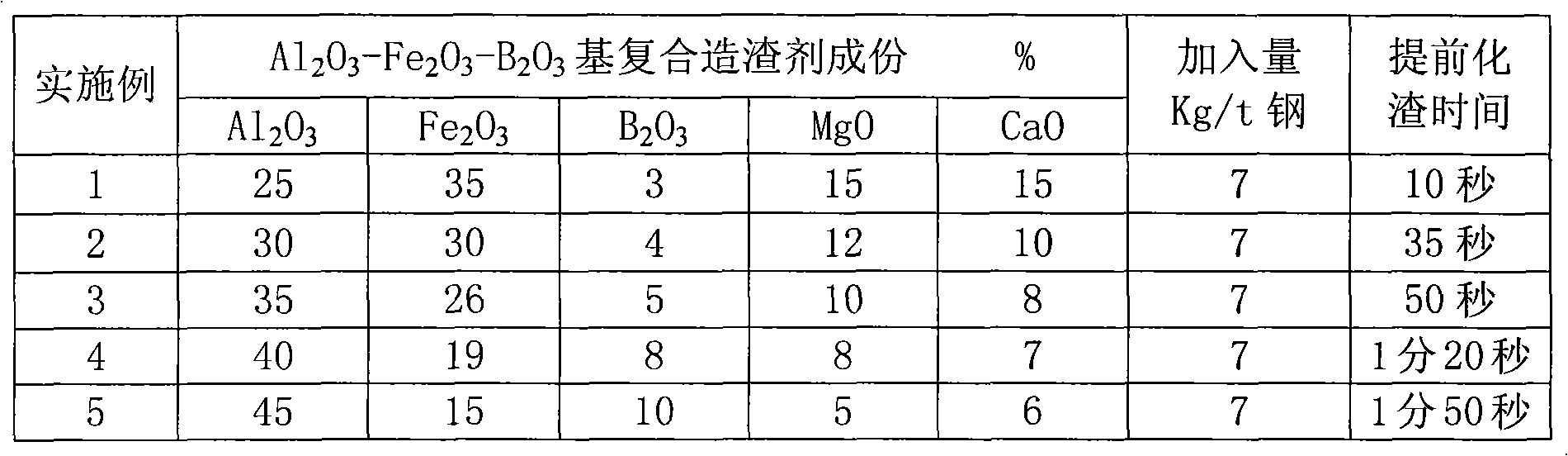

Converter steelmaking fluoride-free composite fluxing medium

InactiveCN102382926AAvoid pollutionHigh strengthManufacturing convertersProcess efficiency improvementSteelmakingForeign matter

The invention relates to a converter steelmaking fluoride-free composite fluxing medium, which belongs to the treatment of molten iron alloy by adopting a finishing agent to remove foreign matters. The invention particularly relates to a quick fluxing medium for converter smelting, which consists of the following ingredients in percentage by weight: aluminum oxide (Al2O3): 25 to 45 percent; ferric oxide (Fe2O3): 15 to 35 percent; boron oxide (B2O3): 3 to 10 percent; magnesium oxide (MgO): 5 to 15 percent; calcium oxide (CaO): 3 to 15 percent; and the balance of foreign matters and caking agent. The fluxing medium presents in granular pellets and are filled into a furnace in two times at the beginning of the converter smelting, and 6 to 8 kg of the fluxing medium is added per ton steel. Compared with the prior art, the converter steelmaking fluoride-free composite fluxing medium has the advantages that: no calcium fluoride (CaF2) is contained, so the pollution of the atmosphere and thewater resource caused by the fluoride-contained gas and the fluoride ion can be avoided; the resource of raw materials is abundant, and price of the raw materials is low; the strength of the pellets is high, and the stability is good; the slagging is fast, and the slagging time is advanced about one minute; the whole-process slagging is good, no slag is splashed, no slag is dried, and no slag is adhered onto a gun; and the consumption of the steel is reduced, the consumption of the fluxing material is reduced, and the economic benefit is remarkable.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

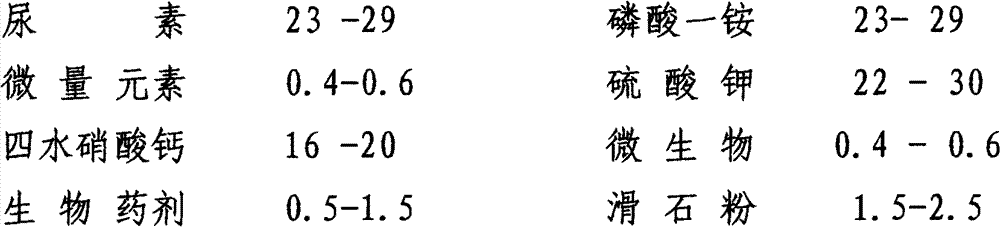

Novel citrus fertilizer for special purpose and its preparation method

InactiveCN102731220AHigh nutrient contentIncrease concentrationFertilizer mixturesFruit treeCalcium nitrate tetrahydrate

The invention relates to a novel citrus fertilizer for special purpose and its preparation method, and relates to the technical field of the agricultural fertilizer, the novel citrus fertilizer for special purpose of the invention is composed of 23-29 parts of urea, 23-29 parts of monoammonium phosphate, 0.4-0.6 parts of trace elements, 22-30 parts of potassium sulfate, 16-20 parts of calcium nitrate tetrahydrate, 0.4-0.6 parts of microbes, 0.5-1.5 parts of biopharmaceutical agent and 1.5-2.5 parts of talcum powder according to weight part; the citrus fertilizer for special purpose possesses the advantages of strong effect, obvious production enhancement effect, labor and time saving, environmental protection and the like, and can be used for spraying on leaves during the growth season of South citrus, and also can be used as a foliar-fertilizer for vegetables, flowers, fruits, tea leaves and other fruit trees.

Owner:HUNAN TIANJIN TECH

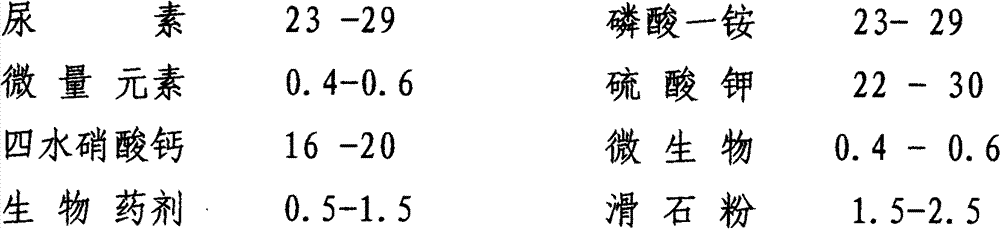

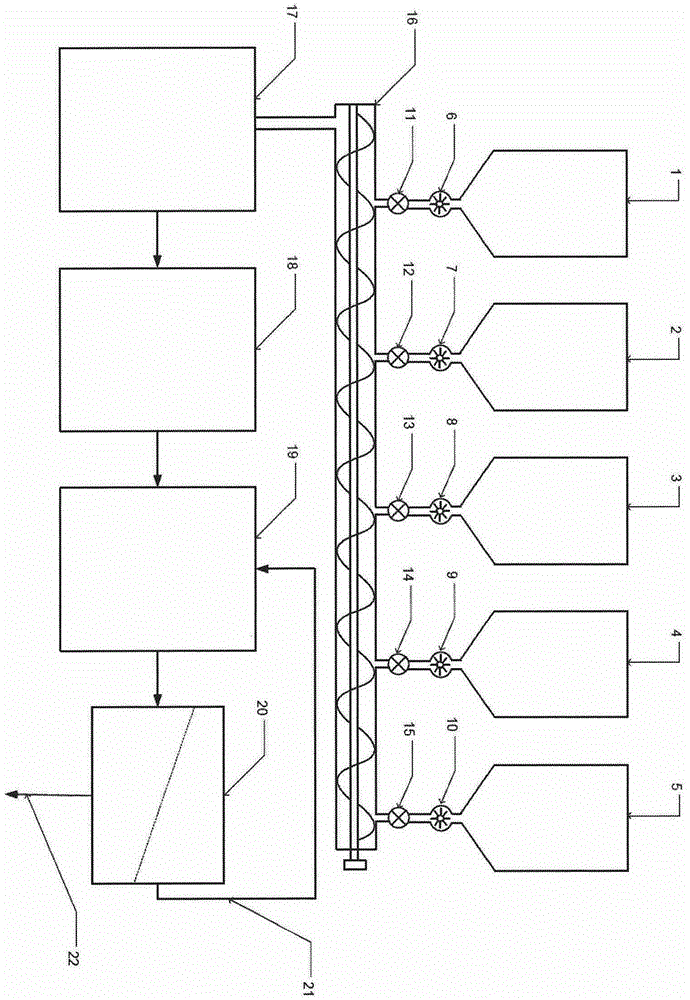

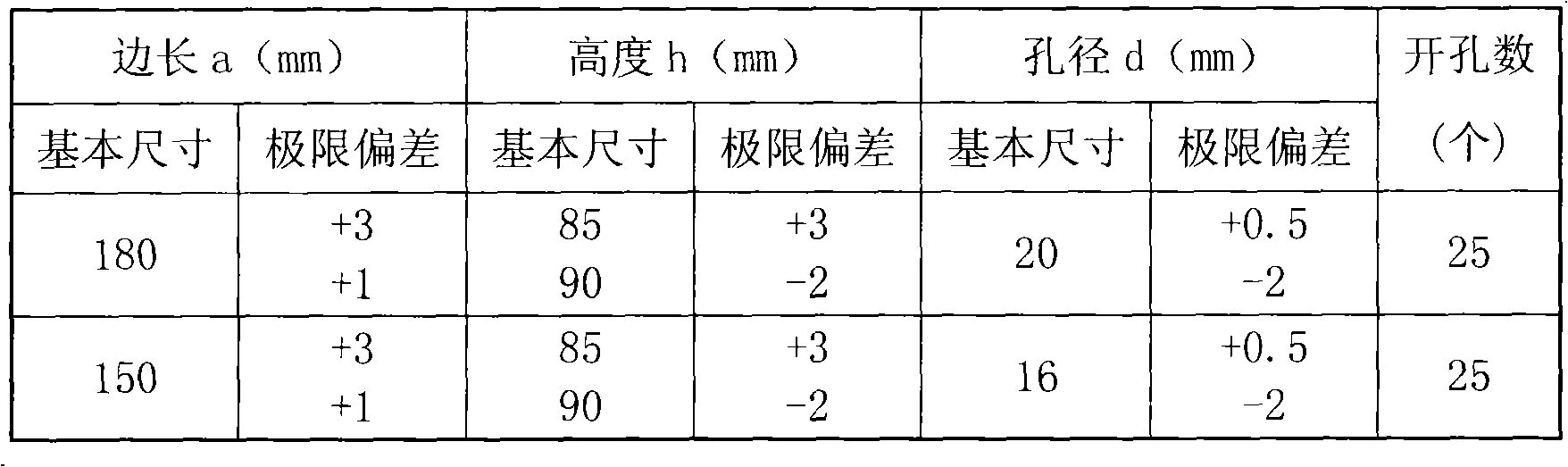

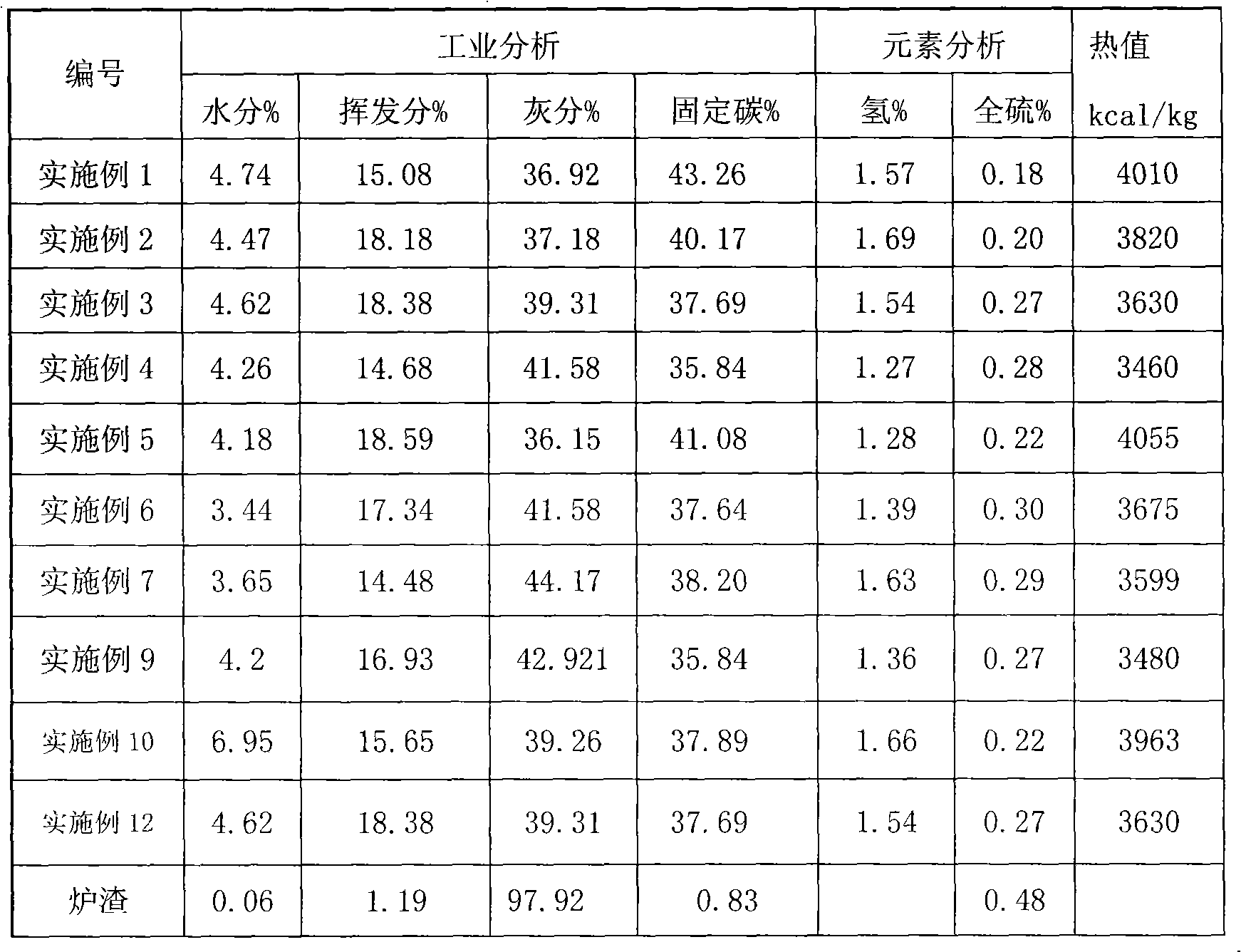

Gasification raw material, preparation method of the gasification raw material, and catalytic gasification method adopting the gasification raw material

The invention discloses a gasification raw material. The gasification raw material comprises a first carbon-containing material, an alkali metal catalyst loaded on the first carbon-containing material, a second carbon-containing material, and an alkaline-earth metal catalyst loaded on the second carbon-containing material, wherein the first carbon-containing material and the second carbon-containing material are same or different. The invention also discloses a preparation method of the gasification raw material and a catalytic gasification method adopting the gasification raw material.

Owner:ENN SCI & TECH DEV

Special bio-organic fertilizer for citrus and preparation method for bio-organic fertilizer

The present invention discloses a special bio-organic fertilizer for citrus and a preparation method for the bio-organic fertilizer, and relates to the technical field of agricultural fertilizer. The bio-organic fertilizer is prepared by mixing and pelletizing the following materials in parts by weight: 40-60 parts of organic matters, 20-40 parts of humic acid, 0.5-1.5 parts of microorganism, 0.5-1.5 parts of microelements, 1-3 parts of urea, 2-6 parts of monoammonium phosphate, 1-3 parts of potassium sulfate, 6-8 parts of calcium, 1-3 parts of talc powder, and 1-3 parts of an enveloped cementing agent. The bio-organic fertilizer has the characteristics of being green and environmental, suitable for being applied to southern citrus, and capable of promoting the high quality and yield of the southern citrus; the bio-organic fertilizer can be taken as ground fertilizer in winter for the southern citrus, as well as vegetables, flowers, fruits, tea leaves, and other fruit trees.

Owner:HUNAN ZHONGKE AGRI

Additive for improving Zhundong coal combustion and coking characteristics and use method thereof

The invention relates to a Zhundong coal additive and provides an additive for improving Zhundong coal combustion and coking characteristics and a use method thereof. The additive comprises, by mass, 20-36% of SiO2, 8-18% of Al2O3, 12-28% of MnO2, 6-23% of Fe2O3, 4-10% of KMnO4, 5-15% of Fe(NO3)3, 1-5% of TiO2 and 2-4% of a waterproof adhesive. The additive of Zhundong coal can be prepared by simple processes, has a low cost, can be transported, stored and used conveniently, can well improve Zhundong coal combustion, coking, slag-bonding and dust deposition characteristics, can effectively improve a blending combustion ratio of Zhundong coal, and has no side effect on fire coal equipment, no damage on the human body and no pollution on the environment.

Owner:浙江百能科技有限公司 +1

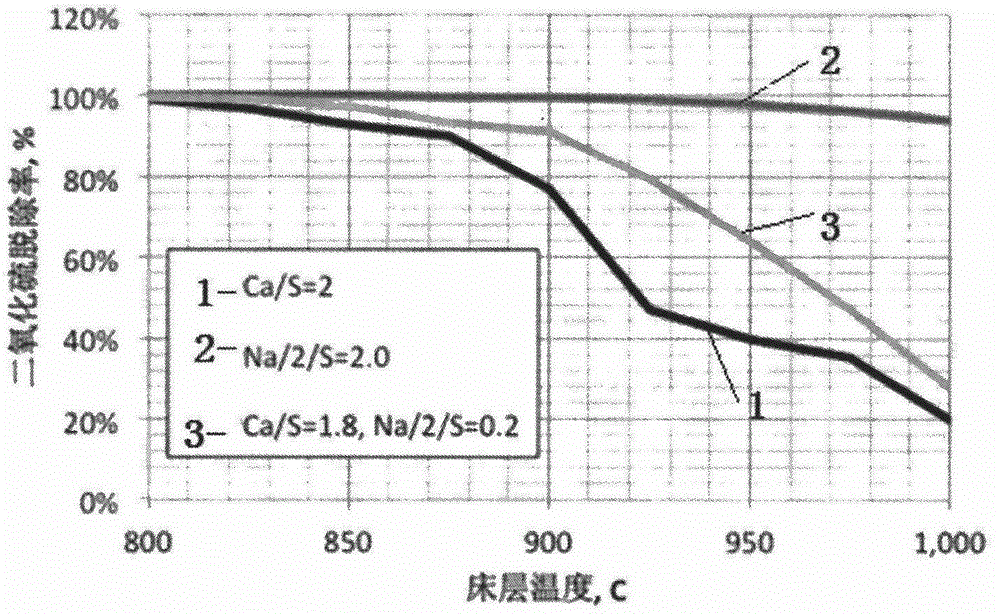

Composite additive

ActiveCN105567375AHigh activityIncrease the effective areaSolid fuelsFuel additivesInorganic compoundOrganic compound

Embodiments of the invention provide a composite additive, which comprises a calcium-based additive and a sodium-based additive, wherein the calcium-based additive comprises an inorganic calcium compound, an organic calcium compound or a combination of an inorganic calcium compound and an organic calcium compound, and the sodium-based additive comprises at least one selected from baking soda powder (NaHCO3), at least soda ash (Na2CO3) and caustic soda (NaOH). According to the present invention, the composite additive provided by the embodiments and coal are doped, and the obtained mixture is burned, such that SO2, HCL, HF, NOx and other toxic and harmful gases produced during the coal burning can be reduced, and the environmental pollution can be reduced.

Owner:YANKUANG GRP CO LTD +1

Biomass coal, preparation method and application thereof

The invention discloses a bio-briquette and a method for the same. The bio-briquette comprises following components in portion by weight percent: 0 to 20 portions of bituminous coal, 20 to 35 portions of anthracite coal, 30 to 60 portions of low-grade anthracite coal, 0 to 30 portions of biomass, 0 to 4 portions of sulfur-fixing agent and 0 to 10 portions of binding agent; the bio-briquette can also comprises 7 to 15 portions of water-proofing agent. In the bio-briquette of the invention, the addition amount of the biomass can reach a very high value, if materials are reasonably mixed and used, the consumption of the binding agent such as sienna is obviously reduced or the sienna is not used; the bio-briquette is excellent in the sulfur-fixing effect, high in strength and uneasy to loose and drop slag; moreover, while firing, the bio-briquette has bright flames and can be completely fired, and after firing, the slag shape is good, so that the bio-briquette can be applied to boilers or small sized burners for domestic use.

Owner:北京雄财清源低碳科技有限公司

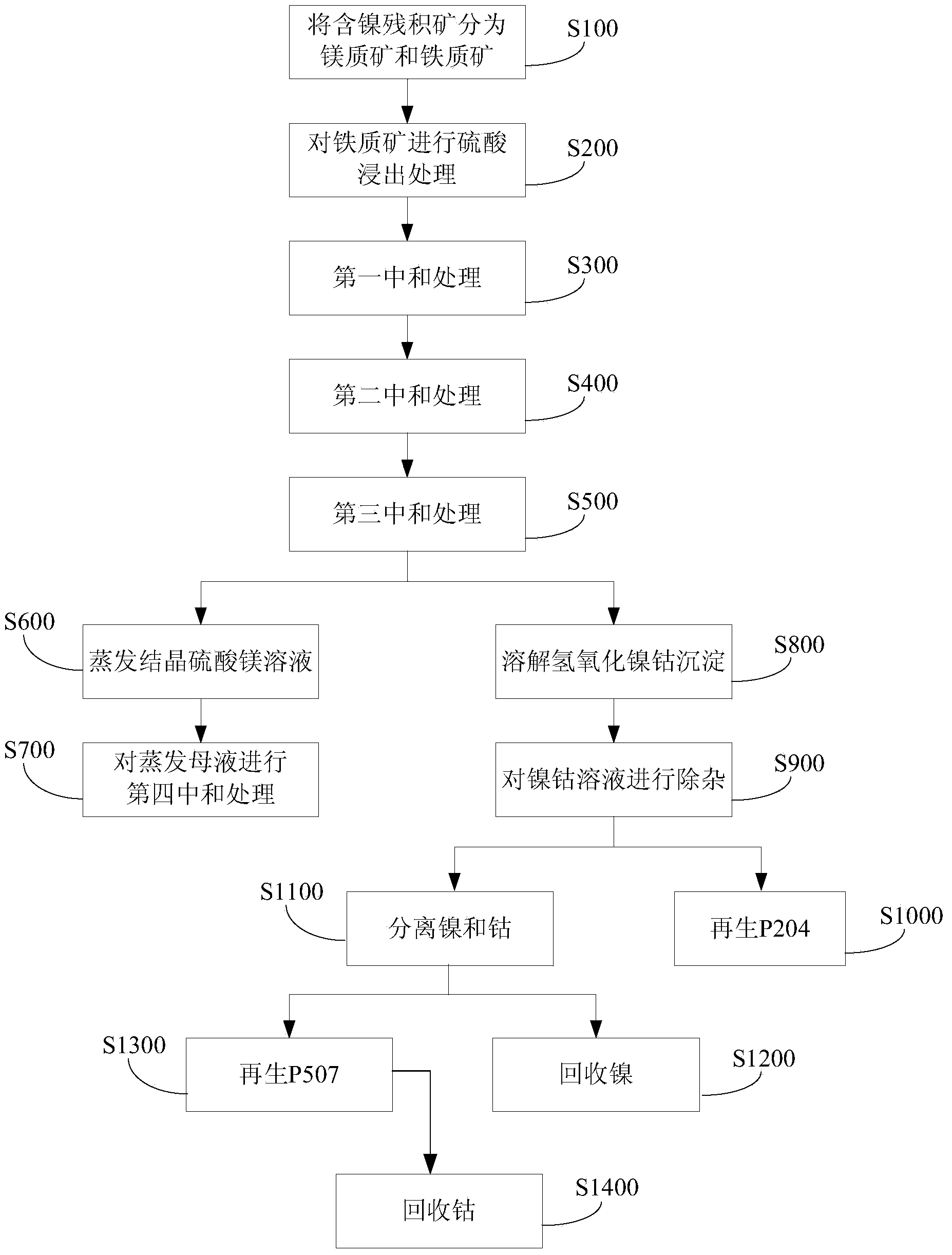

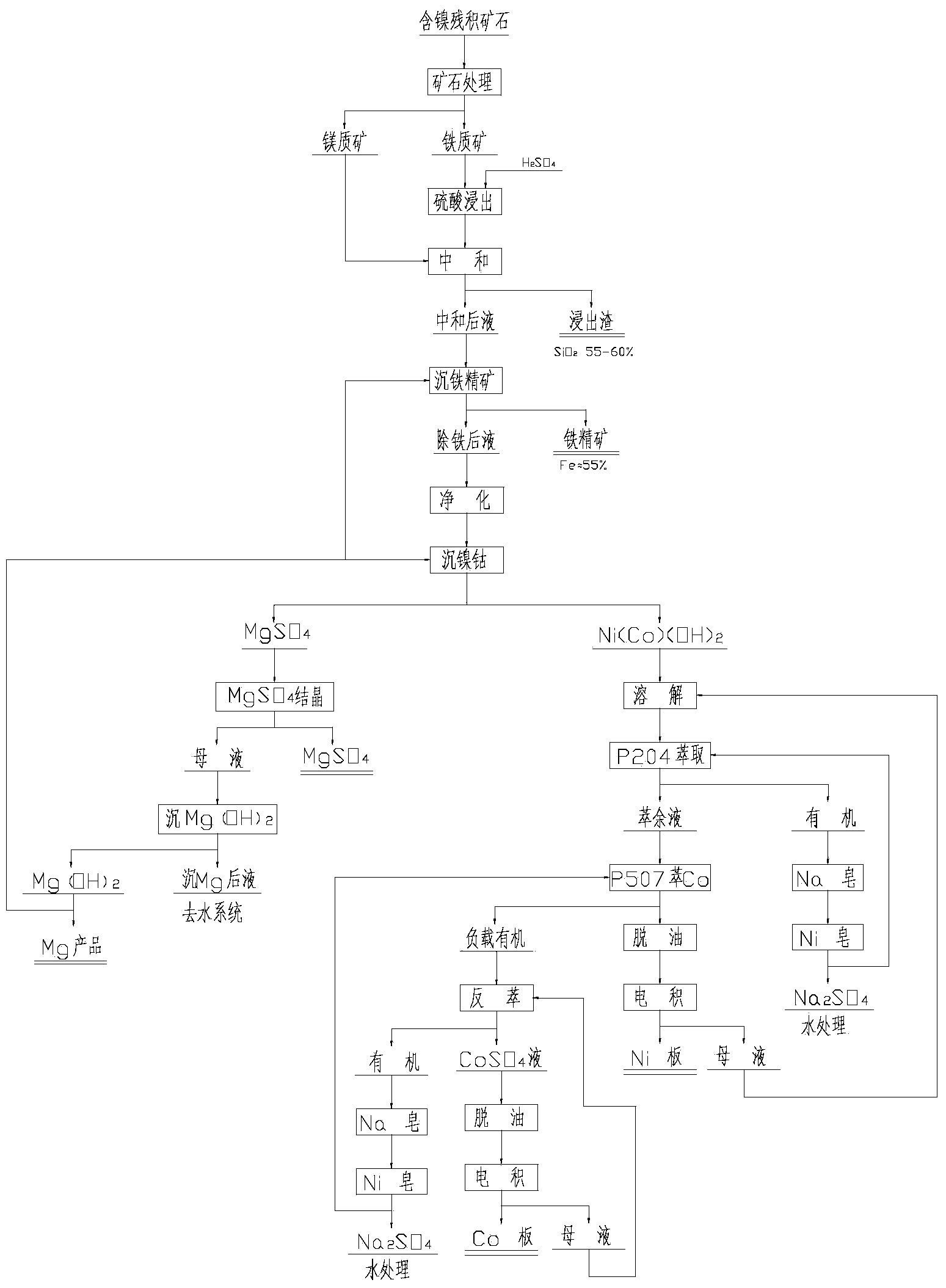

Treatment method of nickel-containing eluvial ores

ActiveCN103757260AEfficient removalGood slagPhotography auxillary processesProcess efficiency improvementFree acidCobalt hydroxide

The invention discloses a treatment method of nickel-containing eluvial ores. The treatment method comprises the following steps: (1) dividing the nickel-containing eluvial ores into magnesian ores and iron ores; (2) carrying out leaching treatment on the iron ores by utilizing sulfuric acid to obtain a leaching solution containing ferric sulfate, wherein the content of free acid in the leaching solution containing the ferric sulfate is 40-45g / l; (3) carrying out first neutralization treatment on the leaching solution containing ferric sulfate by utilizing the magnesian ores to enable the content of the free acid in the leaching solution to be lowered to 5g / l, and obtaining a solution after neutralization and leaching residues containing silicon dioxide; (4) carrying out second neutralization treatment on the solution after neutralization obtained in the third step by utilizing magnesium hydrate, and maintaining the pH value to be 1.0-1.5 to obtain precipitated iron concentrate and a solution after iron removal; and (5) carrying out third neutralization treatment on the solution after iron removal obtained in the fourth step by utilizing the magnesium hydrate to enable the pH value of the solution after iron removal to remain between 7.0-7.5, and obtaining nickel-cobalt hydroxide precipitates and a magnesium sulfate solution.

Owner:CHINA ENFI ENGINEERING CORPORATION

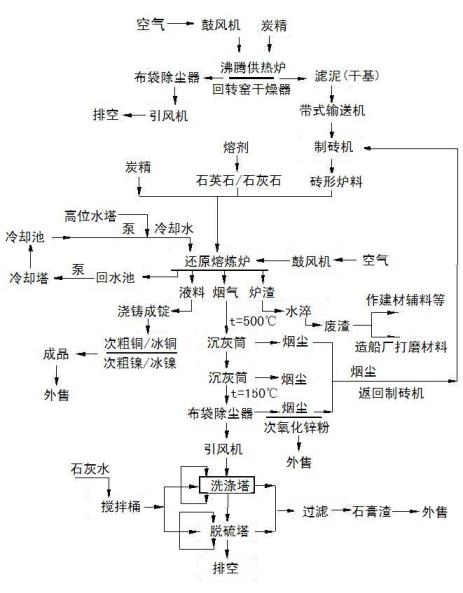

Method for treating copper-nickel containing solid waste

InactiveCN101928832AImprove pollutionReduce pollutionProcess efficiency improvementPhysical chemistryExhaust fumes

The invention relates to a method for treating copper-nickel containing filter mud generated through the waste water treatment of printed-circuit board production enterprises, belonging to the field of non-ferrous metal production realized by treating non-ore raw materials. The method comprises the following steps of: pretreating the filter mud into charging materials, and then adding quartz / limestone and carbon; carrying out reduction smelting treatment at 1150-1250 DEG C; and then respectively treating obtained liquid materials, waste gases and waste residues. The invention greatly improves the problem of environmental pollution caused by cupolette production and has wide raw material adaptation range; the granularity of the filter mud ranges from 0.1mm to 100mm, and the water content thereof is 75-80 percent; and in addition, a detection result shows that the invention has good separation effect of non-ferrous metals and impurities and high recovery rate of the non-ferrous metals.

Owner:杭州富阳申能固废环保再生有限公司

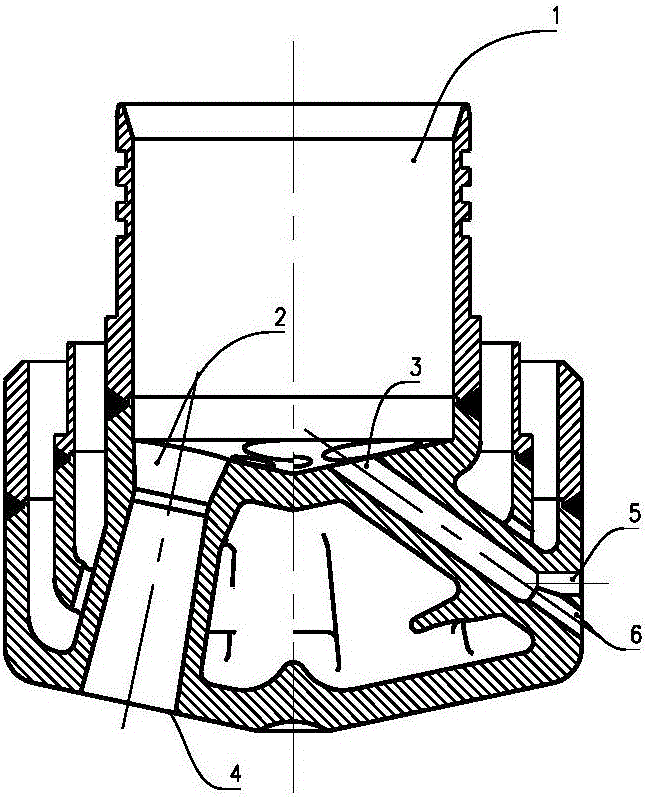

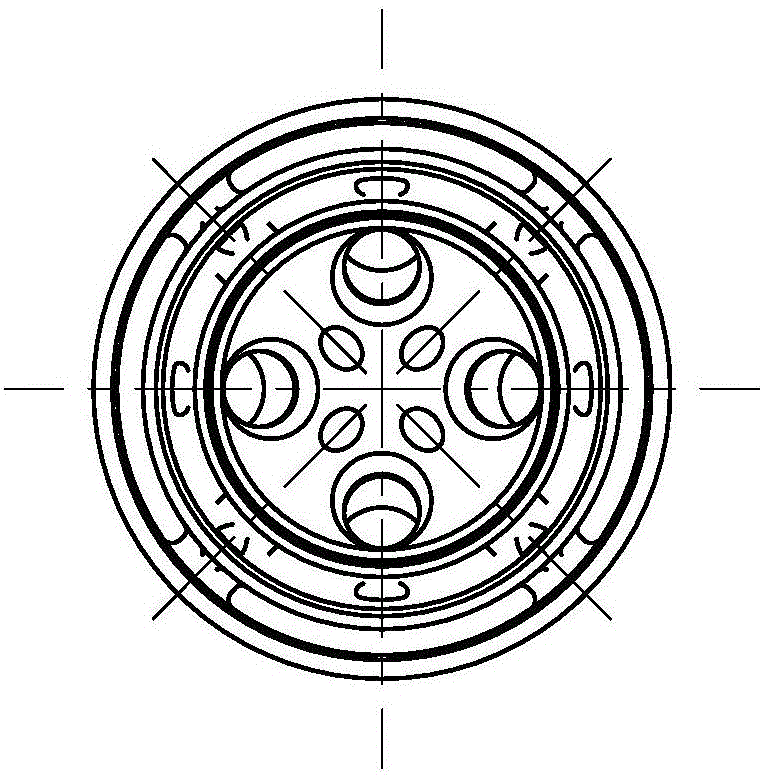

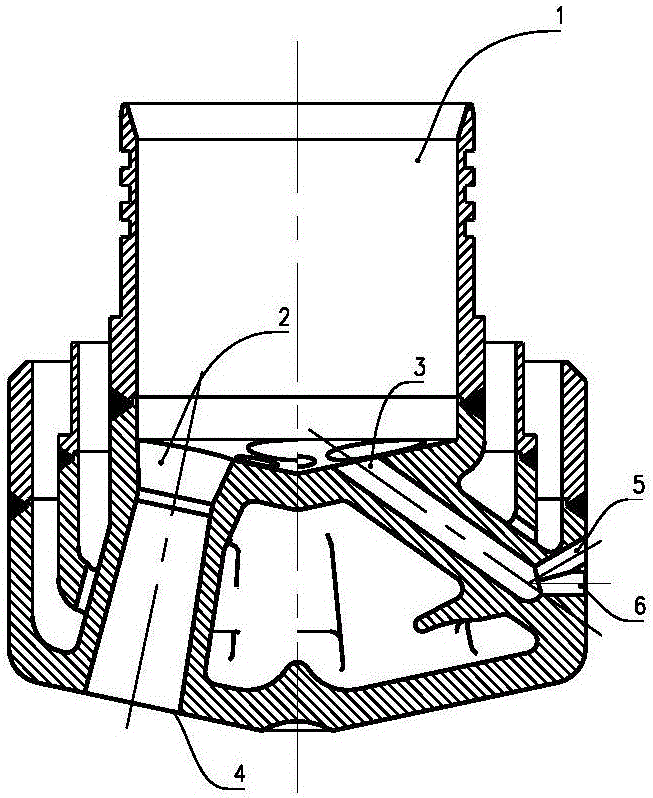

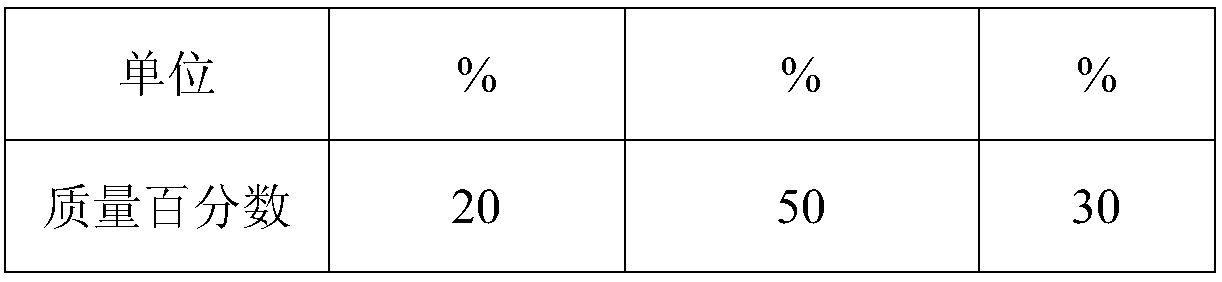

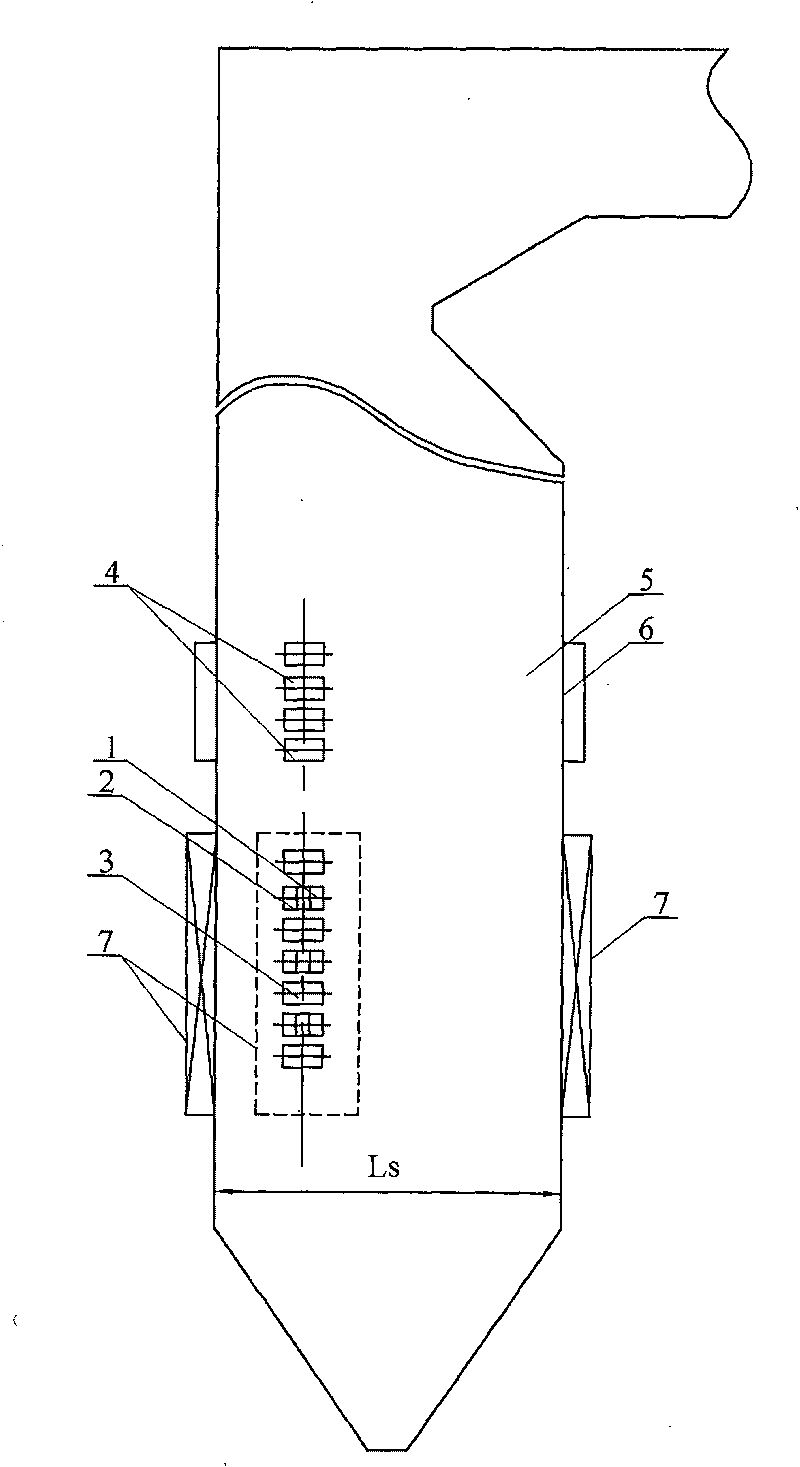

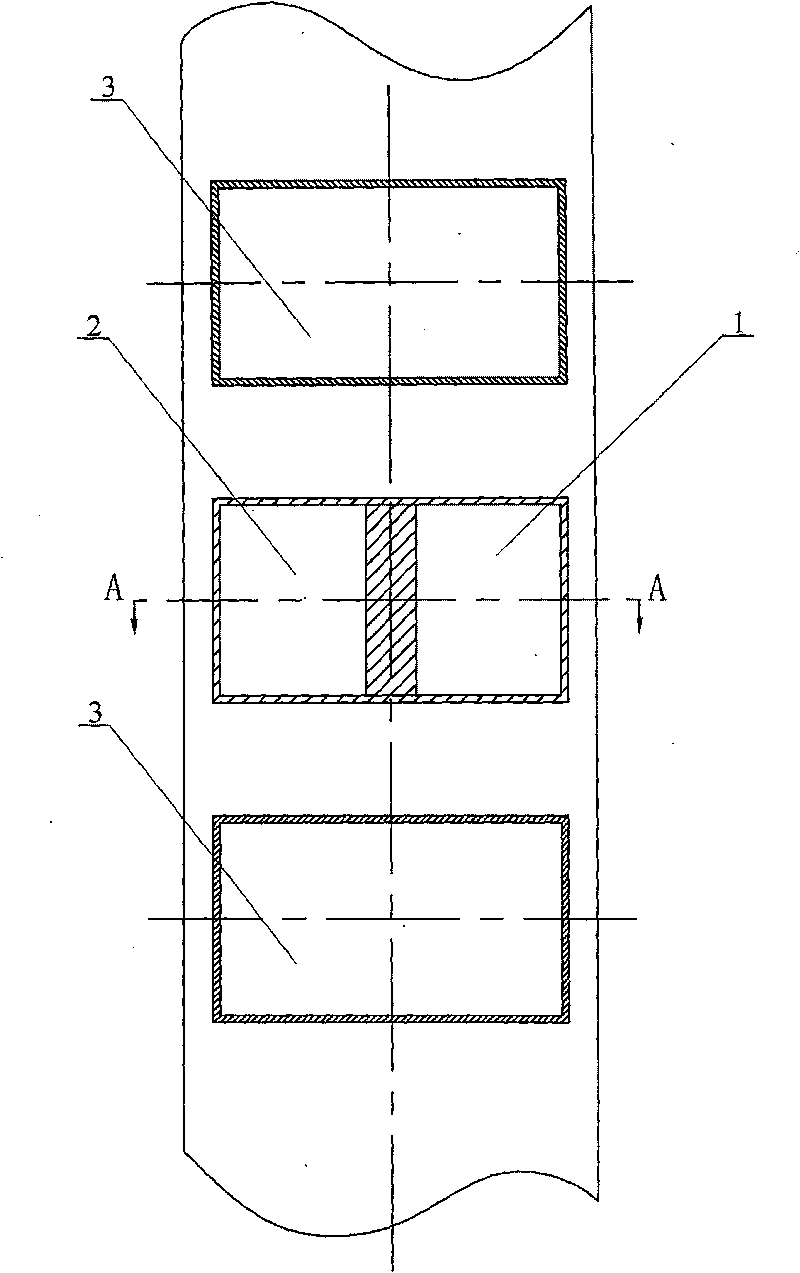

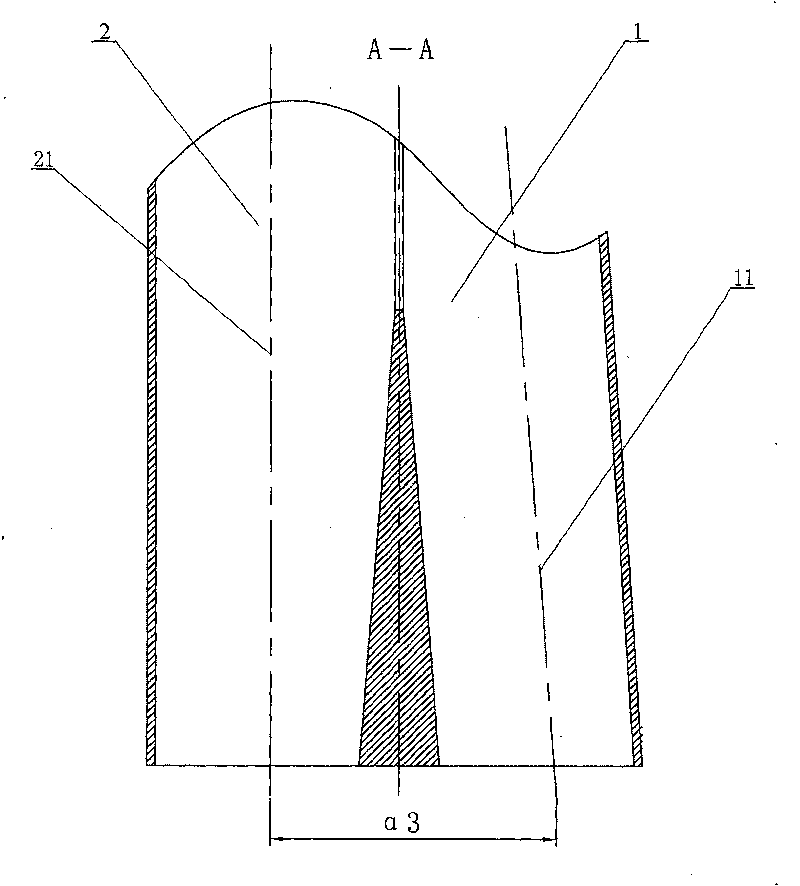

Double-flow oxygen gun and use method thereof

ActiveCN106282481AAdapt to recyclingAdapt to requirementsManufacturing convertersSputteringSteelmaking

The invention relates to a double-flow oxygen gun and a use method thereof, and belongs to the technical field of converter steelmaking. The double-flow oxygen gun has the advantages that a novel structure is used, and the converter steelmaking heat efficiency is improved, so that the converter cold material ratio, the slag melting effect and the terminal temperature hit rate are improved. Oxygen gun main holes and sub holes are formed in the spray head. The number of main holes and the number of sub holes at an oxygen inlet in the oxygen inlet direction of the spray head are identical; in the oxygen outlet direction of the spray head, the number of the main holes is unchanged, and the number of the sub holes at the outlet can be 1 to 3 times of the number of the sub holes at the inlet. The number of the main holes at the outlet of the spray head is 3 to 6, and the number of the sub holes is 6 to 15. The flow rate of the main holes accounts for more than 85 percent of the total flow rate; the flow rate of the sub holes accounts for less than 15 percent of the total oxygen supply. The outlet direction of the sub holes is not limited by the inlet direction of the sub holes, can be in various directions, and can be downward, horizontal and upward, so that the secondary combustion rate of a converter is sufficiently improved. During the oxygen gun operation, the blowing gun position is 100 to 200 mm higher than a conventional gun position; the slag sputtering gun position is 50 to 100mm higher than the conventional oxygen gun position.

Owner:CENT IRON & STEEL RES INST

Method for controlling furnace bottom by adding ferro-silicon

InactiveCN101619374AGuaranteed to proceed normallyGuaranteed smelting effectManufacturing convertersFerrosiliconEngineering

The invention relates to a method for controlling a furnace bottom by adding ferro-silicon, which adopts a mode of adding the ferro-silicon while blowing oxygen into a furnace to control the height of the furnace bottom of a combined blowing converter. Compared with the prior art, the method has the advantage of ensuring the existence of a bottom gun of the combined blowing converter to achieve stable converting effect. Taking a 250-ton top-bottom combined blowing converter as an example, the furnace bottom height BL value is stably controlled to be about 200 centimeters, thus the smelting effect of the top-bottom combined blowing converter is ensured, the smelting time of the converter is reduced by 1.5 minutes, the slugging in the converter is good, the dephosphorizing effect is stable, and the final phosphorus content is less than 150 ppm and accounts for 98 percent.

Owner:ANGANG STEEL CO LTD

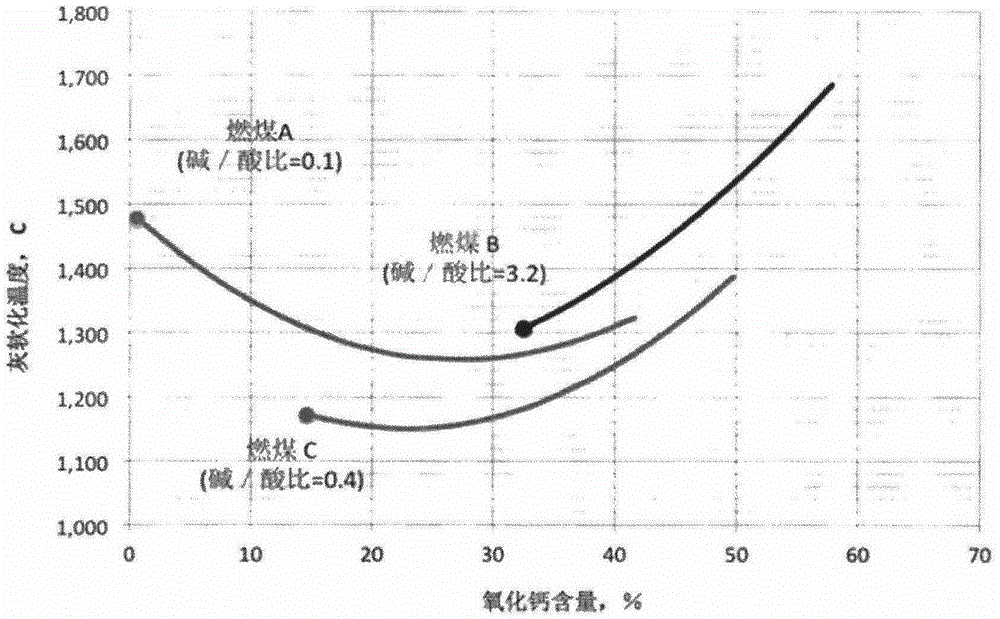

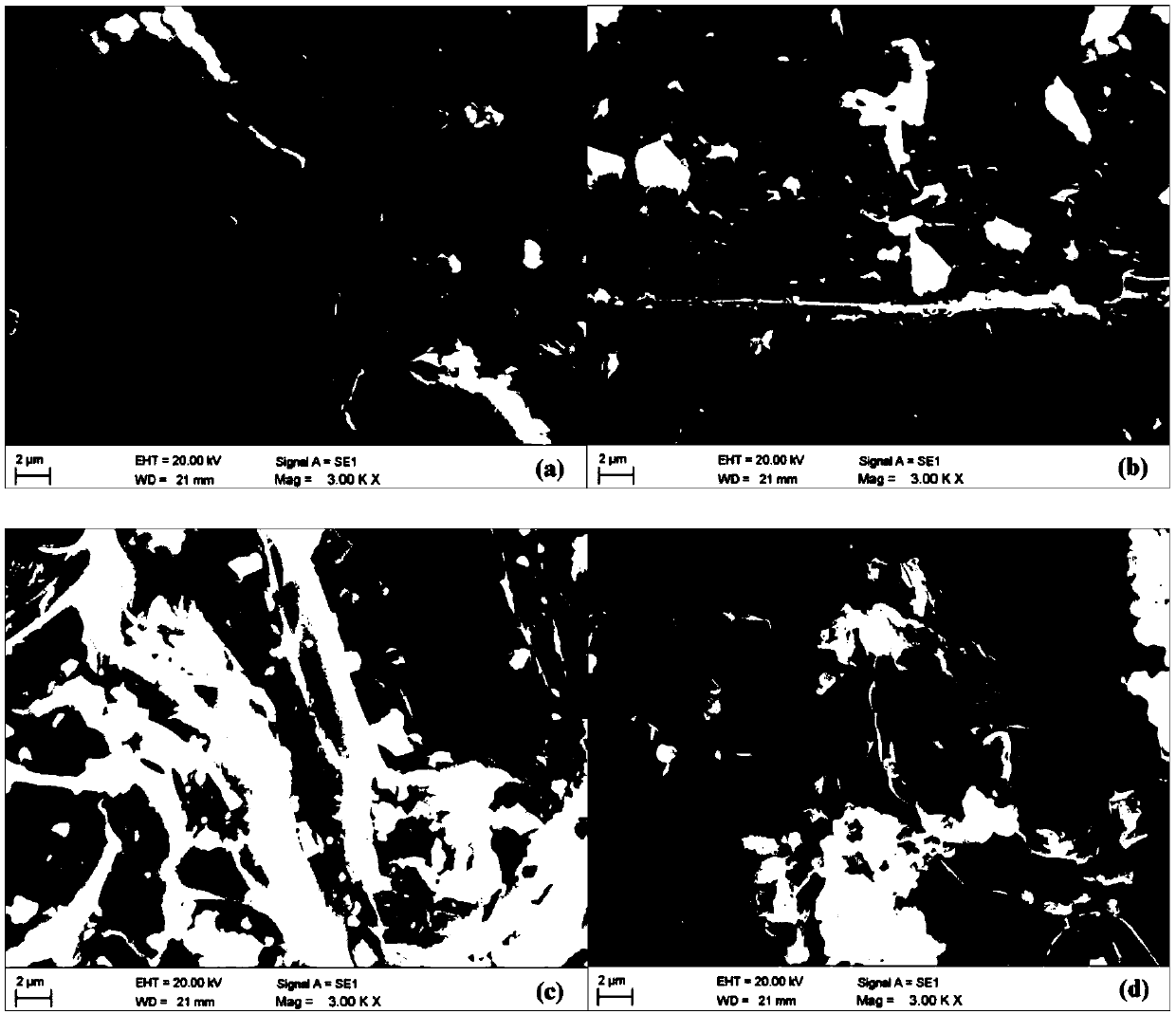

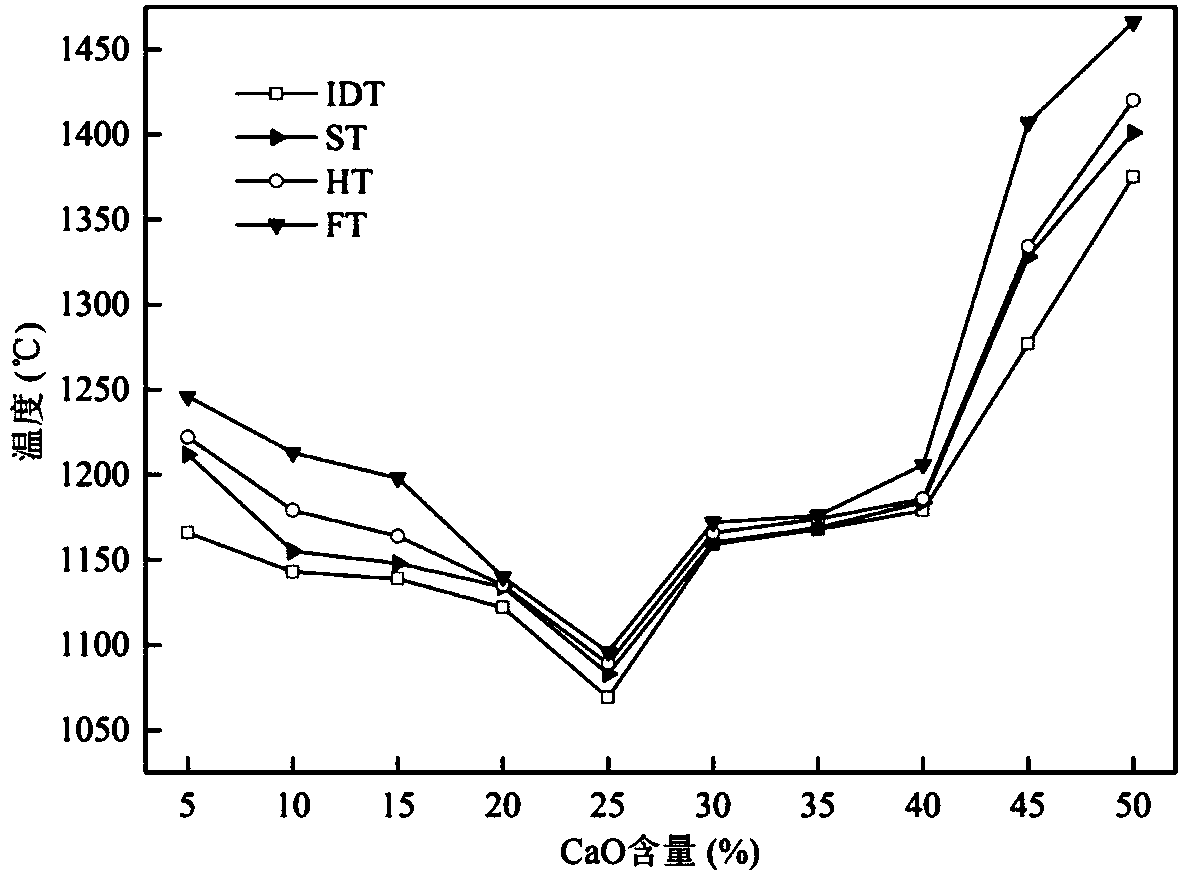

Calcium and magnesium additive for improving coal slagging performance and application

PendingCN108676601AHigh melting pointImprove slagging characteristicsSolid fuelsFuel additivesSlagToxic industrial waste

The invention discloses a calcium and magnesium additive for improving the coal slagging performance and application, and belongs to the technical field of coal chemical industry. The calcium and magnesium additive is a mixture of carbide slag and magnesium-containing waste slag; when the addition amount of the calcium and magnesium additive is within a suitable range, the ash melting point can beincreased by 100-150 DEG C, and calcium oxide in the carbide slag is produced into calcium-containing aluminosilicate having a melting point higher than that of sodium aluminosilicate through a competitive reaction so as to increase the ash melting point and solve the slagging problem; meanwhile, calcium carbide in the carbide slag reacts with water in air to produce acetylene gas, so that a combustion-supporting effect is achieved and flameout of a hearth is avoided; magnesium oxide in the magnesium-containing waste slag reduces the viscosity and avoids large slag formation in a boiler through prevention of aggregation of a polymer; the used carbide slag and the used magnesium-containing waste slag are industrial wastes, and the purchase cost thereof is much lower than that of kaolin, diatomite and bauxite, so that low-cost improvement on the slagging performance can be achieved, and thus the operating cost of a power plant is greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Freon-free slagging agent for rotating furnace

The invention discloses a freon-free slagging agent for a rotating furnace, mainly comprising the following materials in parts by weight: 5-30 parts of manganese (Mn), 0-20 parts of silicon dioxide (SiO2) and 10-50 parts of total iron (TFe). The freon-free slagging agent is prepared into 5-50mm particles and the adding amount thereof is determined according to the silicon content in molten iron and is controlled to be within 5-7kg / t steel. The freon-free slagging agent has the advantages of prolonging the service life of a rotating furnace body, reducing the wastage rate of fettling material, accelerating the joint concentration of steelmaking of the rotating furnace, and reducing the time of daily maintenance and overhauling. Under the condition that the materials and the status of equipment are not changed, after the rotating furnace is added with the freon-free slagging agent, the technical indexes are all improved with different degrees, also the blowing is stable, the slagging is good, the phenomenon that the slag is re-dried is avoided, the operating conditions of steelmaking of the rotating furnace are improved, certain main consumption indexes of the rotating furnace take on downward trend, and the effects of dephosphorization and desulfurization are superior to that of other slagging agents.

Owner:郑州市鑫磊冶金材料有限公司

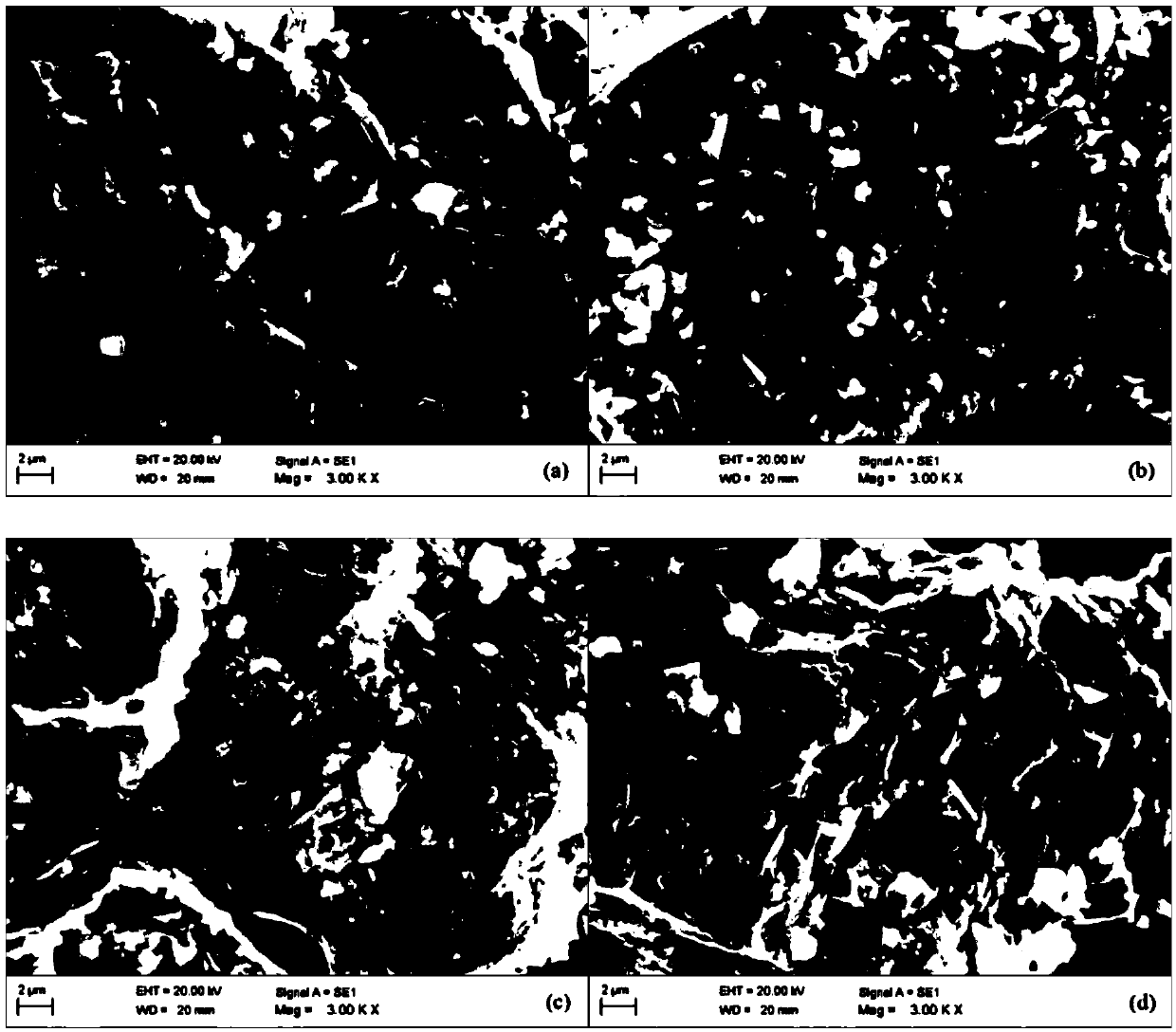

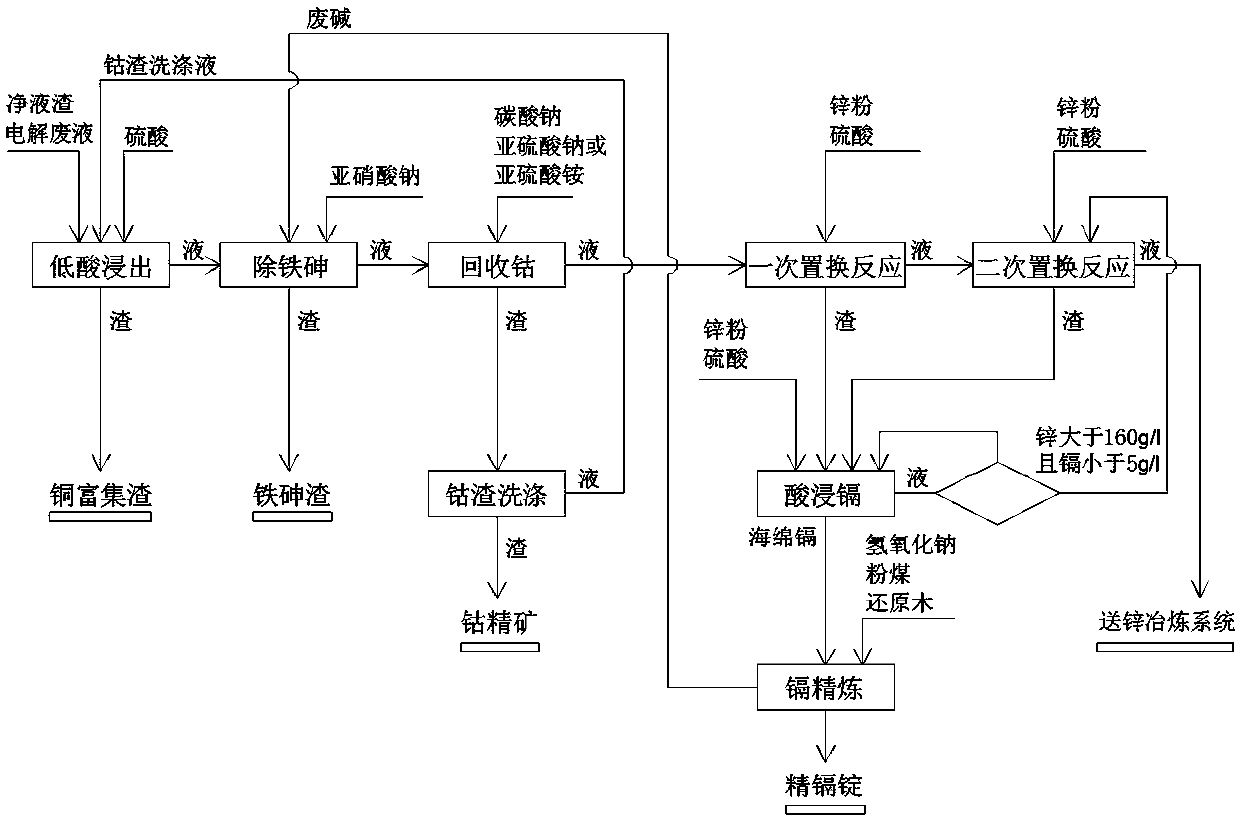

Comprehensive recovery method for zinc hydrometallurgy net liquid slag

InactiveCN110195160ANot easy to operateIncreased complexityProcess efficiency improvementRecovery methodChemical reaction

The invention discloses a comprehensive recovery method for zinc hydrometallurgy net liquid slag. The method comprises the steps of low-acid leaching, neutralization and removal of iron and arsenic, recovery of cobalt and recovery of cadmium in sequence; zinc-enriched leaching liquid is returned to a zinc smelting system after removal of copper, iron, arsenic, cobalt and cadmium; the step of recovery of cobalt is to heat iron and arsenic removal leaching liquid to 90-95 DEG C; sodium carbonate is fed to adjust the pH value within 4.5-5.0; ammonium persulfate or sodium persulfate is fed for chemical reaction, and is fed according to a ratio that the molar weight of S2O32+ is 4-6 times of the molar weight sum of Fe2+, Mn2+ and Co2+; the reaction time is 1-2 hours; and cobalt slag and cobaltremoval leaching liquid are obtained through solid-liquid separation.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

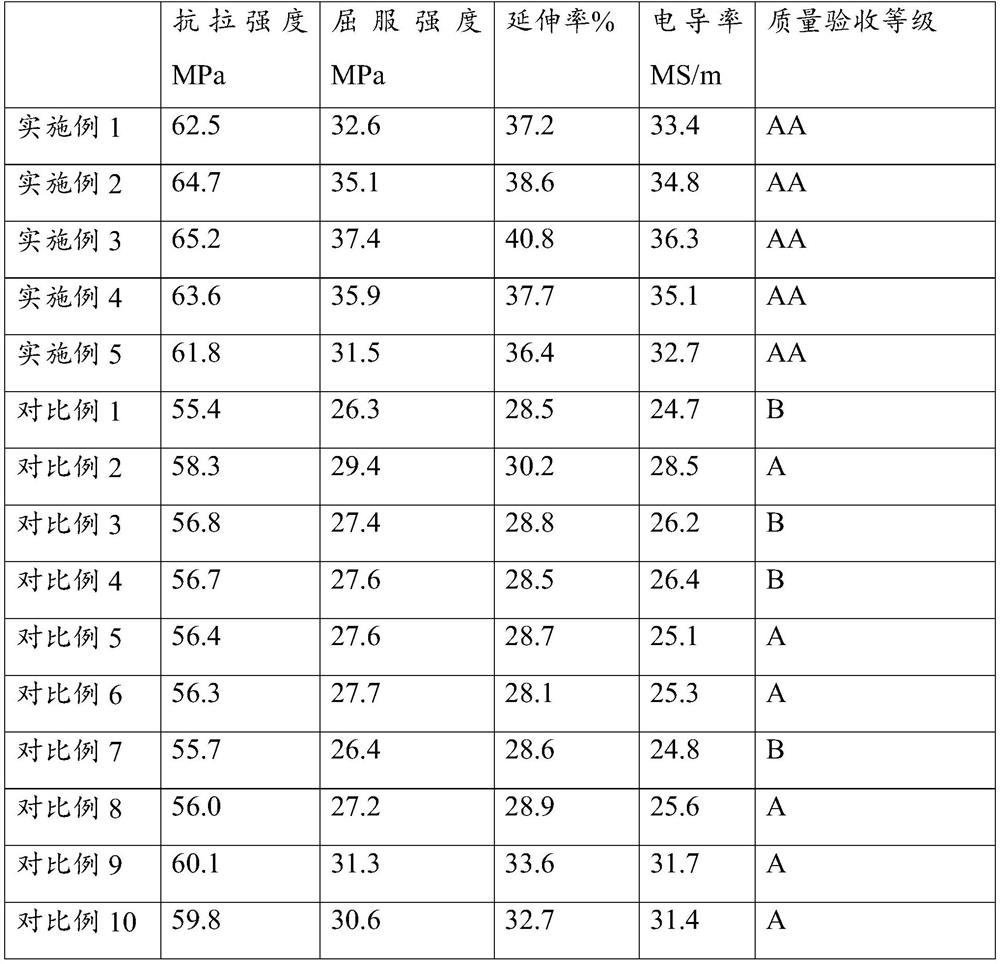

Preparation method of low-segregation-degree motor rotor microalloy aluminum of new energy automobile and microalloy aluminum prepared through preparation method

The invention discloses a preparation method of low-segregation-degree motor rotor microalloy aluminum of a new energy automobile, which comprises the following steps: (1) preheating a mixture of titanium, boron, silicon, iron, copper, magnesium, zinc and aluminum, charging into a furnace for smelting, paving a layer of covering agent on the surface, and heating to 670-800 DEG C; (2) adding a refining agent for refining, performing standing and slag removal to obtain refined melt A; (3) heating the refined melt A to 800-900 DEG C, firstly adding lanthanum, preserving heat for 15-30 minutes, then adding ytterbium, stirring, paving a covering agent, preserving heat for 10-60 minutes, and then cooling; (4) when the temperature is reduced to 670-800 DEG C, adding a refining agent for refining, standing, covering and slagging off to obtain refined melt B; and (5) spraying coating on the inner side of a casting mold, pouring the refined melt B into the casting mold, performing centrifugal casting for 20-40 s, and taking the microalloy aluminum out. According to the method, by adding lanthanum and ytterbium, pinholes are eliminated, and the mechanical property of the microalloy aluminum is improved; and through the regulation and control of each preparation step, the cooling time is shortened, migration and aggregation of TiAl3 and TiB2 are reduced, and segregation is reduced.

Owner:SHANDONG BOYUAN PRECISION MASCH CO LTD

Method for smelting ultra-low carbon steel with carbon lower than or equal to 20 PPm

ActiveCN104988271AGuaranteed mechanical propertiesLow costManufacturing convertersHigh carbonMechanical property

The invention discloses a method for smelting ultra-low carbon steel with carbon lower than or equal to 20 PPm. The method comprises the steps that molten iron desulphurization is conducted through pure magnesium and slaked lime, smelting in another furnace is conducted, high carbon ferromanganese is added according to high oxygen content; argon blowing is conducted; vacuum treatment is carried out inside a RH furnace; vacuum decarburization is conducted, a low-carbon refining agent is added to carry out desulfuration and slugging, and when the vacuum treatment is conducted for 15 min, aluminum balls are added; after recycling is conducted for 3 min, silicon iron, ferromanganese, a low-carbon desulfurizing agent are added immediately, and after the recycling is conducted for 5 min, the vacuum treatment is finished; the aluminum balls are sprinkled on the surface of steel slag, and after the total content of iron oxide and MnO in the slag is lower than 5.5 wt%, a later procedure is conducted. On the premise that the mechanical property of the ultra-low carbon steel is guaranteed, the carbon can be lower than or equal to 20 PPm, parts of low-carbon ferromanganese is replaced with parts of the high carbon ferromanganese, the carbon content is lower than 0.15 wt%, parts of slugging materials and parts of a deoxidizing agent are replaced with the low-carbon refining agent and the low-carbon desulfurizing agent, the cost can be lowered by at least 30 yuan per ton of steel, the smelting process is stable, and slagging is good in the refining process.

Owner:武汉钢铁有限公司

Clean pulverized coal combustion industrial boiler device

InactiveCN103388820AEnhanced Mixed BurnoutOvercome the defects of unsatisfactory combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention discloses a high-efficiency clean pulverized coal combustion industrial boiler device in the field of combustion devices with combustors. The high-efficiency clean pulverized coal combustion industrial boiler device comprises a hearth, a cyclone pulverized coal burner, a high-temperature vortex burnout device, a transition chamber, a convection flue and a tail flue, wherein the high-temperature vortex burnout device is arranged at an upper outlet of the hearth; the cyclone pulverized coal burner is arranged on the front and rear walls or the left and right walls on the lower part of the hearth in a hedge mode; the transition chamber is arranged on the rear part of the high-temperature vortex burnout device; the inlet of the convection flue is connected with the rear part of the transition chamber; the outlet of the convection flue is connected with the tail flue. According to the device, the defect that the organizing combustion effect in a short and small space of an industrial boiler is not ideal is overcome.

Owner:SHANGHAI JIAO TONG UNIV

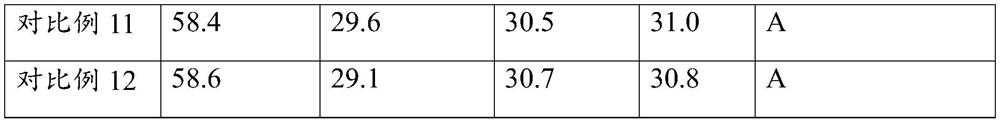

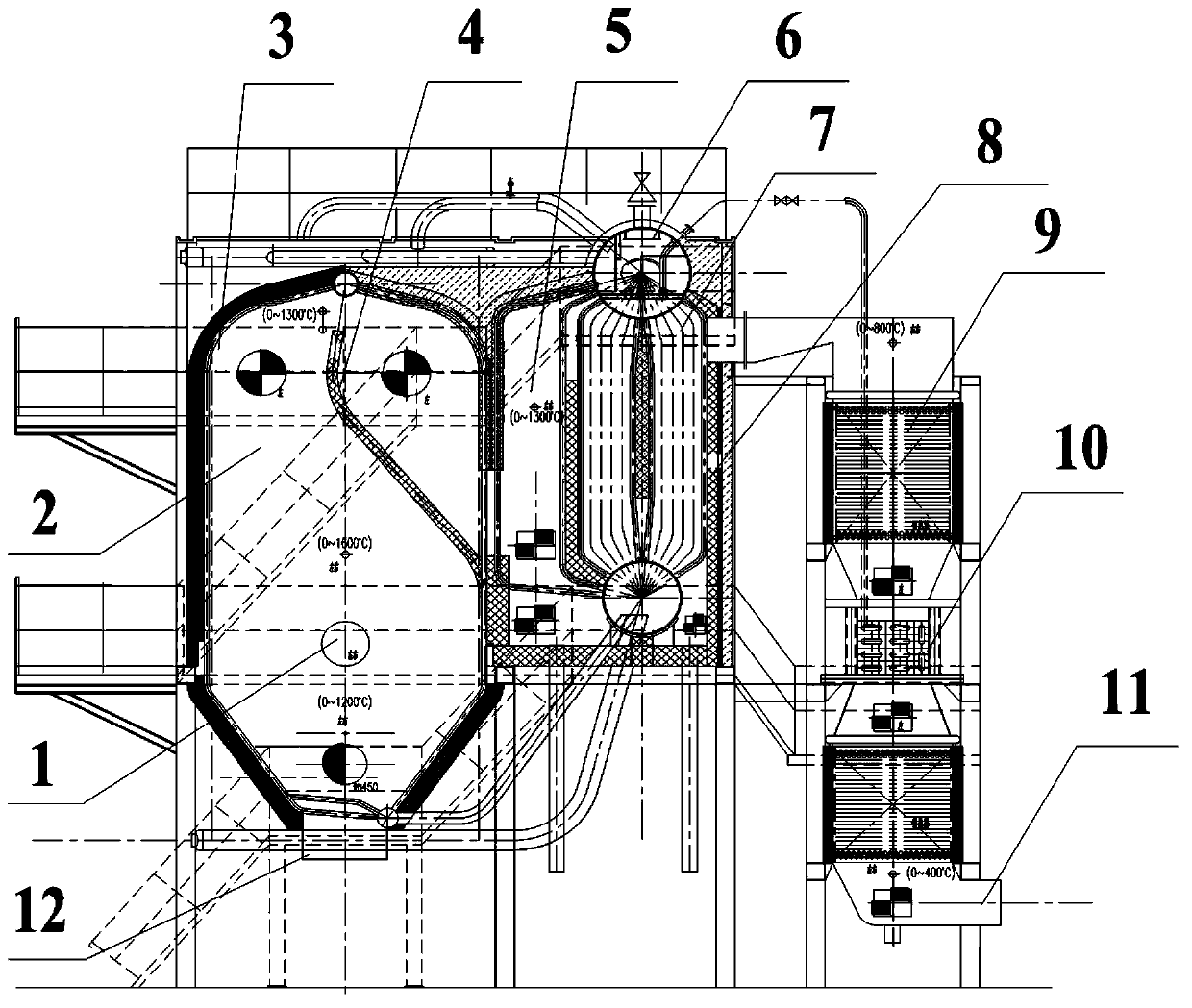

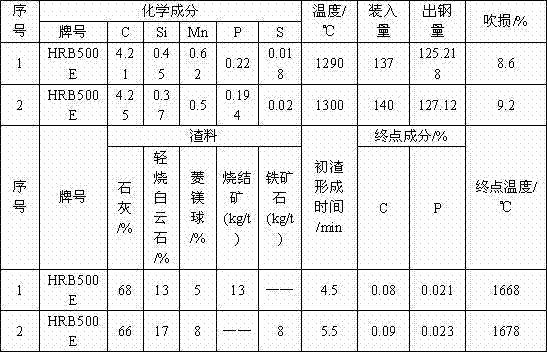

Method for converter steelmaking by using small-particle grade high-basicity sintered ore

ActiveCN103614506AIncrease contentImproving the conditions of blowing slagManufacturing convertersSteelmakingMolten steel

The invention discloses a method for converter steelmaking by using a small-particle grade high-basicity sintered ore. The method comprises the steps of adding waste steel and molten iron into a converter; blowing gas into the converter, and after the success of blowing ignition, adding lime, light burned dolomite, magnesite balls and a high-basicity sintered ore of which the particle size is 3-5mm and the basicity is 2-3 into the converter sequentially by using an overhead bunker; stopping blowing when end-point components and temperature of molten steel meet requirements; turning down the converter to ensure that the molten steel flows into a ladle, and adding a deoxidizing agent; casting the molten steel. The high-basicity sintered ore has a trend of increasing oxygen, can be used as a latent solvent, can cool a molten pool after being heated and reduced and is tiny and lightweight, so that the sintered ore can float in slag easily, can increase the content of ferric oxide in the slag and improve blowing slag melting conditions, and is favorable for slag melting; the method can improve the recovery rate of metals and reduce the consumption of oxygen, the consumption of steel and iron materials of a steel plant and the production cost. The basicity and the MgO content of a sinter returned ore are higher than those of an iron ore, so that a furnace liner can be better protected, and the furnace age of the converter can be effectively prolonged.

Owner:WUKUN STEEL

Slagging method for electrosmelting

InactiveCN101824508AIncrease the content of MgOReduce erosionElectric furnaceLime productionSlagIron oxide

The invention relates to a slagging method of the field of metallurgy, in particular to a slagging method for electrosmelting. Slagging materials comprise three kinds of slagging assistant materials: bulk lime, bulk calcined dolomite and bagged lime, and a deoxidization furnace protective agent, wherein the bagged lime is distributed under waste steel and is added to an electrical furnace along with the waste steel; and the bulk lime and the bulk calcined dolomite are added to the electrical furnace by a charging system above the waste steel. The invention solves a series of problems of sparsity of electrosmelting slag, excessively high content of ferric oxide in the slag, high consumption of steel materials, serious furnace lining corrosion, substantial reduction of furnace age, sharp slag boiling in the early phase of blowing smelting, increase of slag quantity caused by a large quantity of flowing slag, high lime consumption and the like after the quantity of iron water is largely increased.

Owner:NANJING IRON & STEEL CO LTD

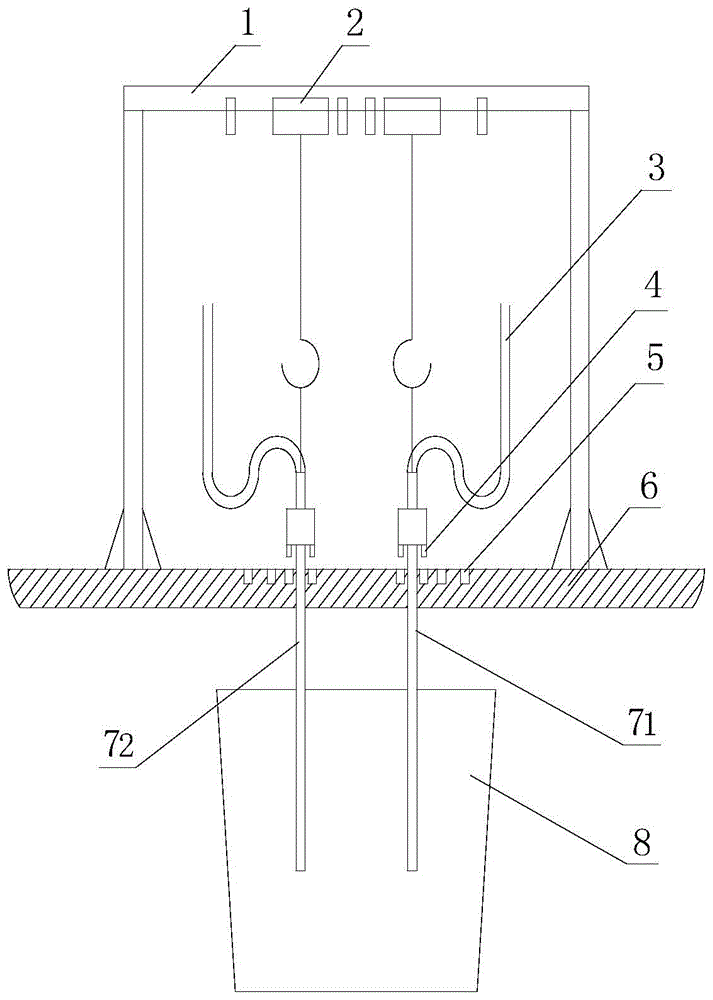

Surging molten iron slag-off method

ActiveCN105296709ASolve the deflection problemSimple mechanical structureCasting cleaning apparatusProcess efficiency improvementSlagInsertion depth

The invention provides a surging molten iron slag-off method. Two air injection guns are perpendicularly inserted into molten iron from the top of a molten iron tank. The interval between the two guns is 1 / 2 of the radius of a tank opening, the insertion positions are located at the points 1 / 2 of the radius of the tank opening, and the insertion depth ranges from 0.5 m to 2.5 m; the air supply intensity is controlled to be larger than or equal to 2 NL / (min t) and the pressure is larger than 0.7 MPa; the air supply intensity of the air injection gun A is controlled to be 2 NL / (min t), the air supply intensity of the air injection gun B is gradually increased till the molten iron boiling exposed face makes contact with the wall of the molten iron tank, the air supply intensity of the air injection gun A is adjusted to be the same as that of the air injection gun B till the area of the molten iron boiling exposed face is larger than 1 / 2 of the tank opening of the molten iron tank, and therefore slag-off operation is started; after slag-off operation is finished, the air injection guns are pulled out of the molten iron and inject air continuously for over 30 s; and hoist cranes are used for lifting the air injection guns, so that locating pins are away from locating holes from 190 mm to 210 mm, the hoist cranes are transversely moved till the interval between the two guns reaches the length of the radius of the tank opening and then the hoist cranes fall, and the locating pins fall into new locating holes. By the adoption of the surging molten iron slag-off method, slag-off time can be shortened and iron loss and the converter resulfurization amount generated in the desulfuration slag-off process can be effectively reduced.

Owner:ANGANG STEEL CO LTD

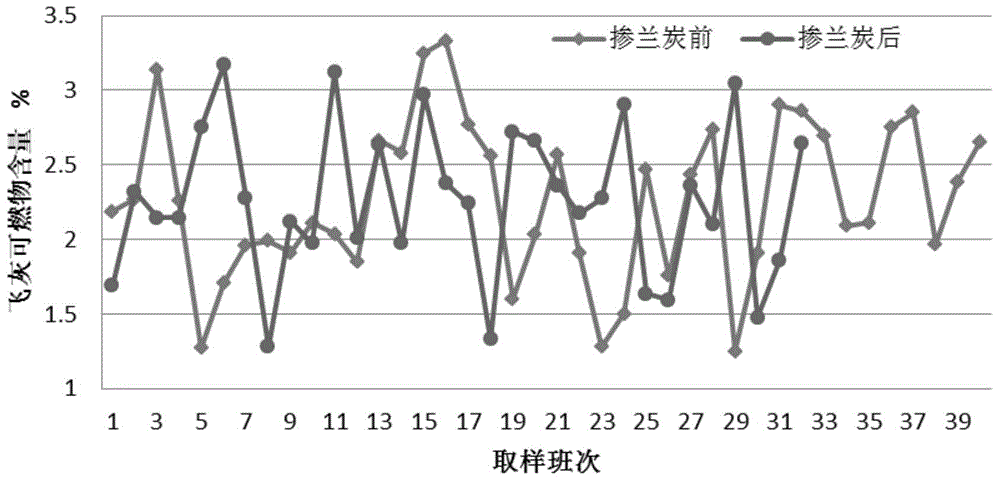

Blending method for power station pulverized coal boiler safe burning ramsbottom coke

ActiveCN104791827AEasy to determineGood slagLump/pulverulent fuel preparationPower stationProcess engineering

The invention discloses a blending method for power station pulverized coal boiler safe burning ramsbottom coke. The blending method for the power station pulverized coal boiler safe burning ramsbottom coke comprises the following steps that 1, ash softening temperature ST of the ramsbottom coke and a coal sample is measured; 2, erosion wear index Ke of the ramsbottom coke and the coal sample is measured; 3, with the total weight of coal used for burning as a benchmark, the ramsbottom coke and the coal sample are blended by the weight percentage to obtain the premixed coal after being blended; 4, grading is performed on the wear property of the premixed coal according to the erosion wear index Ke; 5, on the basis of the step 3, according to the erosion wear index Ke value obtained by measuring in the step 2, the erosion wear index Ke of the premixed coal after the ramsbottom coke and the coal sample are blended is converted, the final ramsbottom coke blending proportion is determined by combining with the grade of the wear property of the premixed coal, and finally, the mixed coal with determined blending proportion is fed into a boiler for burning. According to the blending method for the power station pulverized coal boiler safe burning ramsbottom coke, the power station pulverized coal boiler safe burning ramsbottom coke is achieved through the blending of the coal sample and the ramsbottom coke of different slagging properties and erosion wear properties.

Owner:XIAN THERMAL POWER RES INST CO LTD

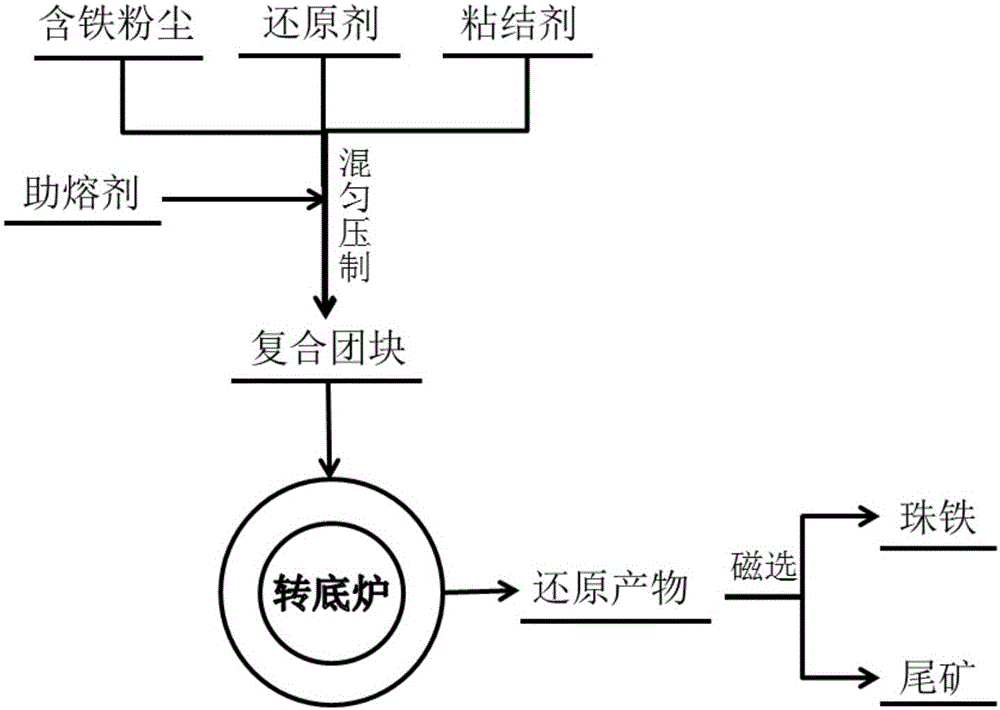

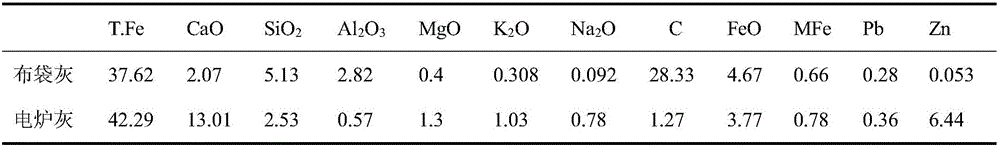

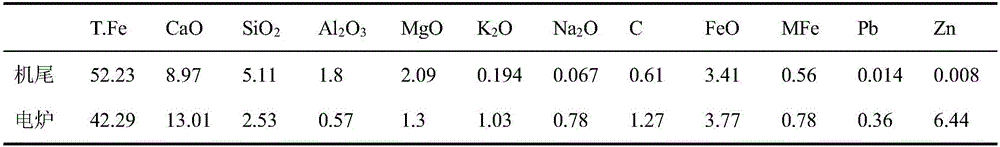

Method for producing iron beads at low temperature through dust of iron and steel plant

The invention relates to a method for producing iron beads at the low temperature through dust of an iron and steel plant. The method has high adaptability to raw materials, can utilize dust generated during different processes of the iron and steel plant, and carries out matching according to basic physical properties of the raw materials. One or more kinds of dust is evenly mixed with a reduction agent, an adhesive agent and a fluxing agent, then the mixture is pressed into cold solidified pellets, the pellets are subjected to reduction, smelting and slag-iron separation in a rotary hearth furnace, and accordingly iron beads with a low metallization ratio and low-iron slag are obtained. The method mainly includes the two steps that the self-reduced dust pellets are prepared through raw materials such as dust and the fluxing agent, and the dust pellets are smelted by the rotary hearth furnace at the low temperature to produce iron beads. The problem that melt separation is difficult as self-reduced dust pellets are high in melt separation temperature, harmful ingredient content and slag amount is solved.

Owner:UNIV OF SCI & TECH BEIJING

High-performance slag collecting agent

InactiveCN105925747AImprove structure and propertiesGood slag collecting performanceProcess efficiency improvementThermal insulationSlag

The invention discloses a high-performance slag collecting agent which is prepared from the following components: clay, modified perlite, straw ash, forsterite powder, pottery clay powder, zeolite powder, sepiolite powder, mullite powder, hollow glass microsphere powder, pyrophillite powder and palygorskite powder. The slag collecting agent provided by the invention resists high temperature, has favorable heat-resistance and thermal-insulation effects, keeps a nodulizing process stable, has high slag removal efficiency and does not affect the components of molten iron; iron slag is fragile after being cooled, so that the iron slag is convenient to recover and the loss of the molten iron is can be reduced; and the slag collecting agent can change the form of desulfurized slag to reduce the slag content of the molten iron entering a converter and the phenomenon of molten iron resulfurization, the loss of iron is reduced by an average of 48%, and on average, the desulfurized molten iron contains about 0.061% of sulfur.

Owner:HEFEI CITY TENVER PRECISION CASTING

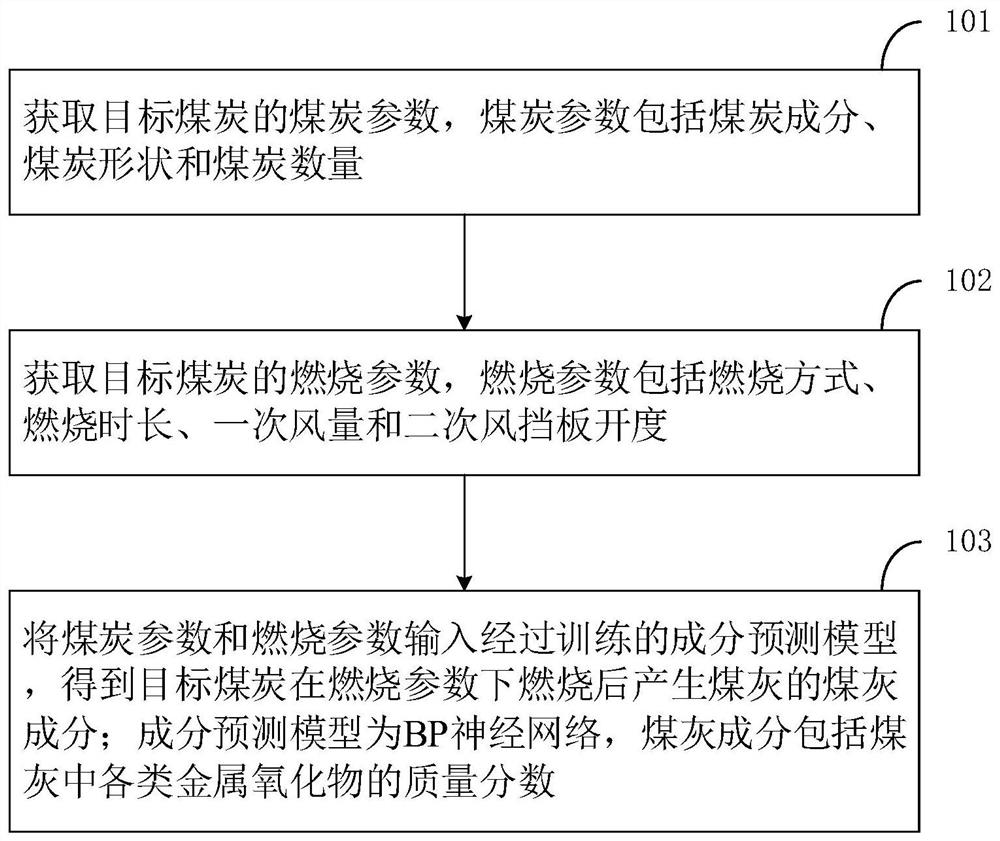

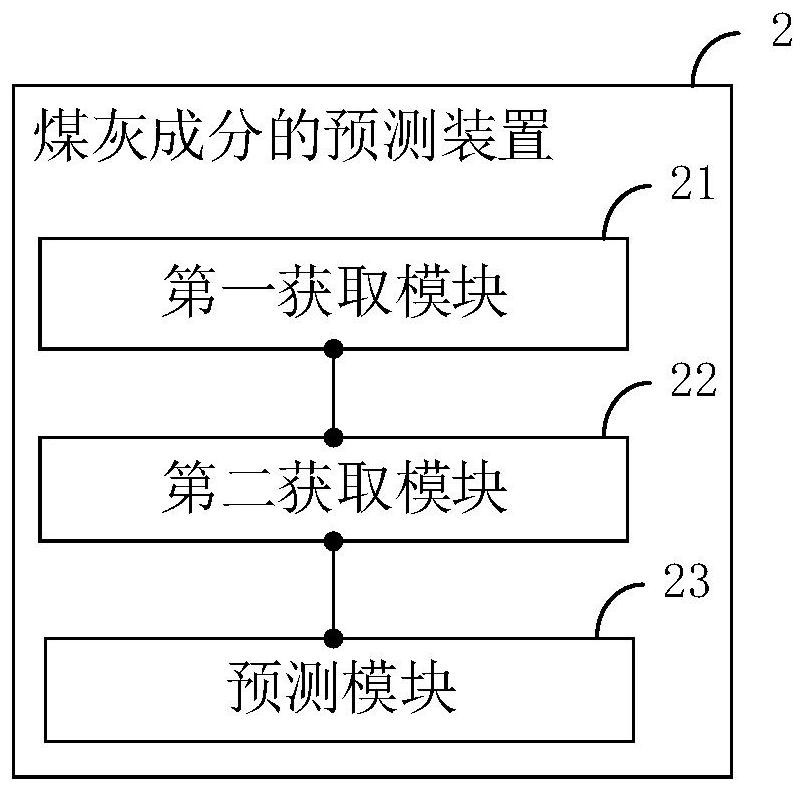

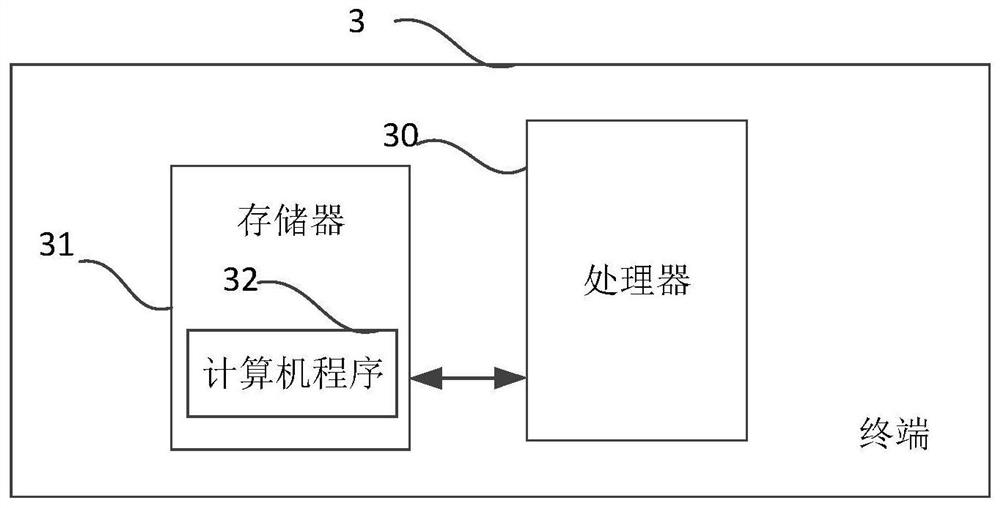

Coal ash component prediction method and device and terminal

PendingCN114021457AGood slagImprove coking phenomenonForecastingCharacter and pattern recognitionNerve networkAir volume

The invention provides a coal ash component prediction method and device and a terminal. The method comprises the following steps: acquiring coal parameters of target coal, wherein the coal parameters comprise coal components, coal shapes and coal quantity; obtaining combustion parameters of the target coal, wherein the combustion parameters comprise the combustion mode, the combustion duration, the primary air volume and the opening degree of a secondary air baffle; inputting the coal parameters and the combustion parameters into a trained component prediction model to obtain coal ash components of coal ash generated after the target coal is combusted under the combustion parameters, wherein the component prediction model is a BP neural network, and the coal ash components comprise mass fractions of various metal oxides in coal ash. According to the method, the coal ash component after coal combustion is predicted through the BP neural network, and the coal ash component can be determined before coal combustion, so that the coal ash component can be changed by adjusting the combustion parameters of coal, and the slagging and coking phenomena of the water cooling wall of the tail flue of the power station boiler are improved.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

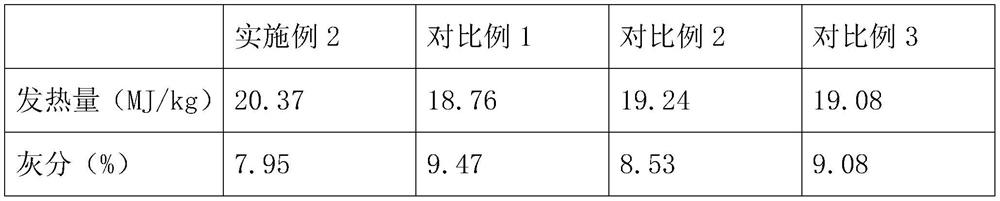

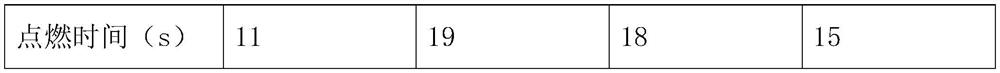

Compound biomass granular fuel

The invention discloses a compound biomass granular fuel. The compound biomass granular fuel comprises the following components: sawdust, crop straws, anthracite powder, corncobs, rice hull powder, attapulgite clay, montmorillonite and red mud. The biomass granular fuel provided by the invention is reasonable in component compatibility, the current slag-bonding phenomenon of the biomass granular fuel is greatly improved, the emission of polluted gas is greatly reduced, the combustion ratio of the biomass granular fuel is improved, and the combustion value and combustion time of the biomass granular fuel are greatly improved.

Owner:安徽盛昌生物能源科技开发有限公司

Biomass granular fuel with high combustion performance and preparation method thereof

The invention discloses a preparation method of a biomass granular fuel with a high combustion performance. The preparation method comprises the following steps: loading iron oxide on peat by an in-situ method to form a peat-iron oxide composite material, mixing the peat-iron oxide composite material with rosin emulsion, drying, pulverizing, mixing the obtained peat-iron oxide composite material with a biomass main material and an anti-slagging agent according to a proper ratio, and granulating to obtain the biomass granular fuel with high combustion performance. The biomass granular fuel hasthe advantages of being high in combustion rate, high in heat value, complete in combustion and not prone to slagging, and the combustion performance is remarkably improved.

Owner:怀宁县泰华新能源科技有限公司

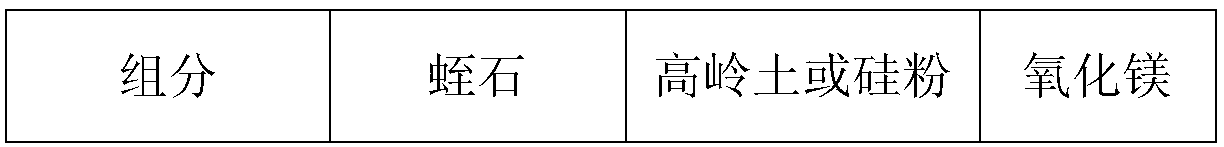

Composite additive for improving slagging and ash falling characteristics of Zhundong coal and application method thereof

The invention discloses a composite additive for improving the slagging and ash falling characteristics of Zhundong coal and an application method thereof. The composite additive is composed of an expansion type additive--vermiculite, a silica-alumina type additive--kaolin or silicon powder, and a desulfurizing agent--magnesium oxide. The composite additive comprises the following components by mass: 15%-60% of vermiculite and 30%-60% of kaolin or silicon powder, with the balance being magnesium oxide. In the composite additive of the invention, vermiculite is used as an expansion type additive, has good thermal stability and strong gas adsorbing ability, and exerts certain auxiliary sodium fixation and sulfur fixation effect; through the addition of vermiculite, ash becomes loose and porous and is thus easy to remove, so the vermiculite is an additive with excellent anti-slagging properties; silicon powder and kaolin can increase an ash melting point and fix sodium; and magnesium oxide can play the role of desulfurization.

Owner:XI AN JIAOTONG UNIV

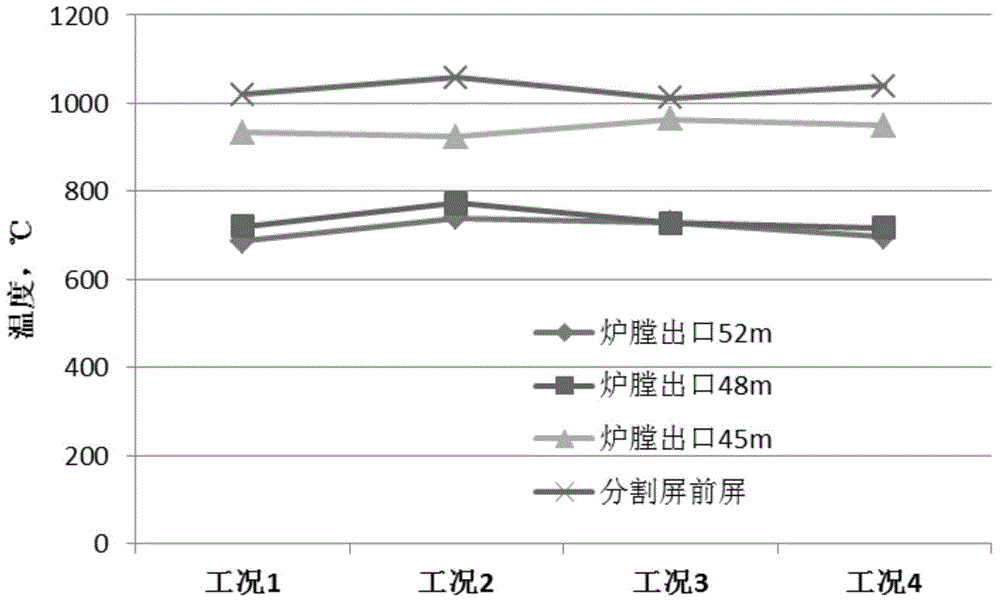

Wall type arranged horizontal rich-lean direct current combustion device

ActiveCN101315184BReduce skewReduce smoke temperature deviationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

A wall-mount horizontal bias direct-flow combustion device relates to a horizontal bias direct-flow combustion device. The invention solves the problems of the prior direct-flow combustor, such as four-corner tangential arrangement, different air supply conditions of coal flows on two sides, high risk of slag deposition due to declination and corrosion at high temperature. First dense / dilute air jet ports and a second air jet port (3) are formed on the water-cooled wall (6) of a furnace cavity (5) and combined to form a group of combustors (7). The central line (31) of the second air jet portand the central line (21) of the first dilute air jet port (2) are positioned in the fire-facing side direction, and have the included angles of alpha 1 and alpha 2 with relative to the water-cooled wall (6), on which the jet ports are positioned. The included angle between the central line (11) of the first dense air jet port and the central line (21) of the first dilute air jet port (2) is alpha3. After-burn air jet ports (4) are arranged on the water-cooled wall (6) or at each corner of the furnace cavity (5). The After-burn air jet ports (4) are positioned above the combustors (7). The wall-mount horizontal bias direct-flow combustion device realizes reasonable combination of coal particles and air, prevents the deflection of coal flow, and ensures stable combustion, low load and lowNOx discharge of boilers.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com