Method for producing iron beads at low temperature through dust of iron and steel plant

A technology for iron and steel plants and dust, applied in the field of dust treatment technology in iron and steel plants, can solve the problems of high melting temperature of pearl iron, low processing efficiency, high temperature, etc., and achieve the effects of improving production efficiency, reducing pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

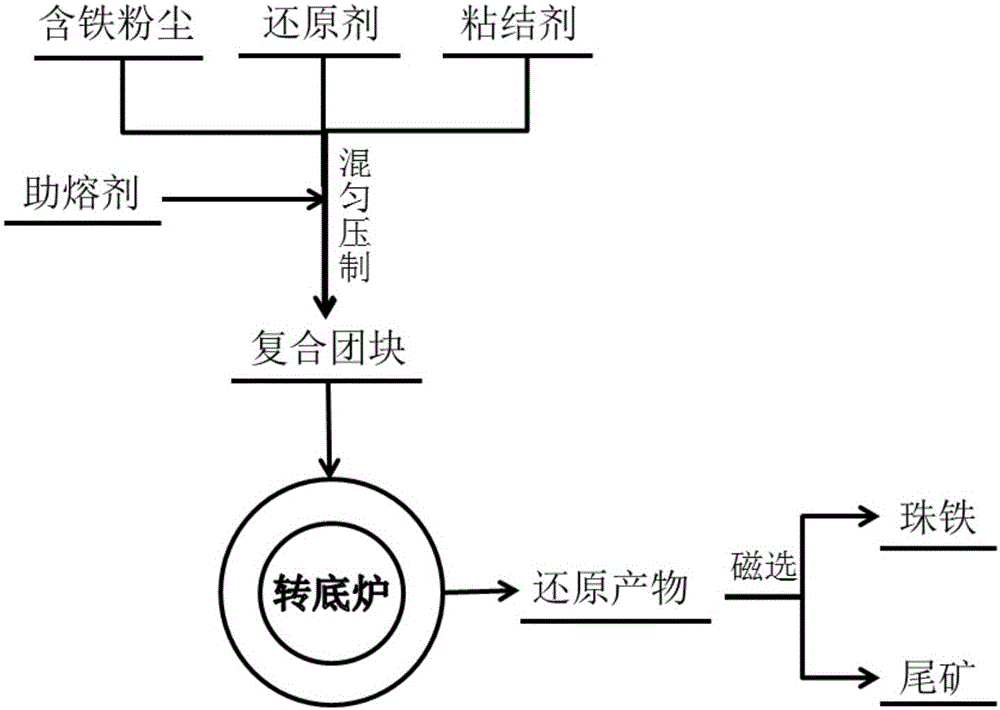

Method used

Image

Examples

Embodiment 1

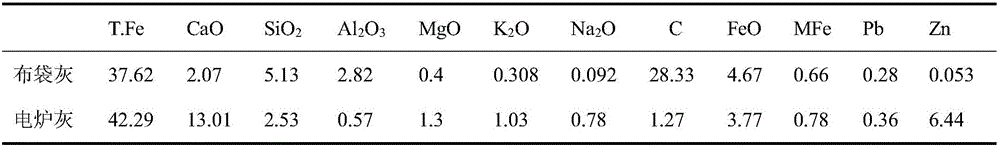

[0023] The bag ash and electric furnace ash are mixed in a mass ratio of 3:7. The composition is shown in Table 1. Coke powder is added to the dust according to C / O=1.0, and the amount of binder cement is 10% of the mass of the mixed dust. The dosage of flux ferrite is 2% of the mass of the mixed dust, and the mixture is mixed in a high-speed mixer. During the mixing process, water is added to the mixture in the form of spraying. The total amount of water added is controlled within the dust, About 10% of the total mass of coke, cement and flux after mixing. Subsequently, the fully mixed mixture was kept under pressure for 1 minute under a pressure of 80 MPa in a ball press to make the mixture into blocks. The agglomerates were cured for 72 hours at a humidity of 95% and 25° C. and then dried for 4 hours to obtain self-reducing dust agglomerates. The self-reducing agglomerate can be roasted in the rotary hearth furnace for a certain period of time to achieve good melting of sl...

Embodiment 2

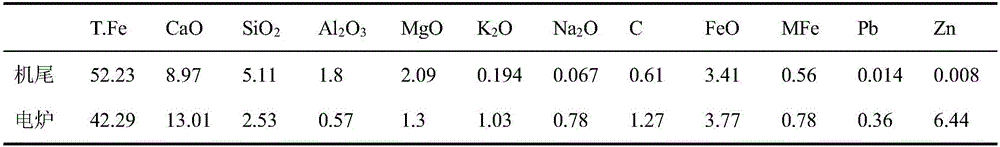

[0025] As in Example 1, the dust is changed to machine tail ash and electric furnace ash, and the mass ratio is still mixed at a ratio of 3:7. The composition is shown in Table 2. The flux is spodumene, and the addition amount is 2% of the mass of the mixed dust. %. The produced self-reducing agglomerate can be roasted in a rotary hearth furnace for a short period of time to achieve good melting of slag iron and the reduction degree of iron oxide is higher than 90%. The produced iron pearl can be directly used in steelmaking or smelting iron craft.

[0026] Table 1 Example 1 Dust Main Components

[0027]

[0028] Table 2 Example 2 dust main components

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com