Method for treating copper-nickel containing solid waste

A solid waste and pretreatment technology, which is applied in the field of processing non-ore raw materials to produce non-ferrous metals or their compounds, can solve the problems of complex sources of copper-containing and nickel-containing filter mud, large differences in composition, and low metal grades, so as to adapt to raw materials The effect of wide range, high recovery rate and reasonable slag type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

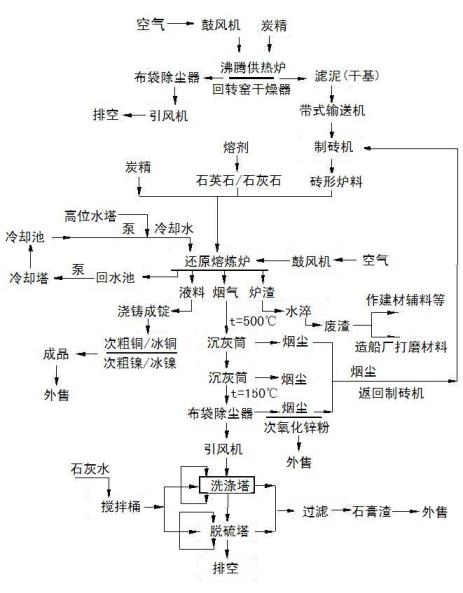

[0033] Production process see figure 1 . This embodiment provides a perennial process operation mode in large-scale production. The process parameters involved in all embodiments can be adjusted reasonably within the range shown by those skilled in the art, so as to realize the recovery of solid waste containing copper and nickel. Deal effectively.

[0034] Put the filter mud into the fluidized heating furnace and rotary kiln dryer, and dry it continuously for 24 hours at a temperature of 800-900°C. During the drying process, it is detected that the water content of the filter mud drops below 25%, and the dried filter mud can be dried The brick-shaped furnace charge is sent to the brick making machine by a belt conveyor to be pressed into a brick-shaped furnace charge, which is a standard brick size of 240mm×115mm×53mm, and is used as the furnace charge for the reduction smelting furnace. The heat source required for the drying of the rotary kiln comes from the combustion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com