Composite additive for improving slagging and ash falling characteristics of Zhundong coal and application method thereof

A compound additive and additive technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of Zhundong coal slagging and other problems, and achieve the effect of avoiding economic loss, avoiding efficiency reduction and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

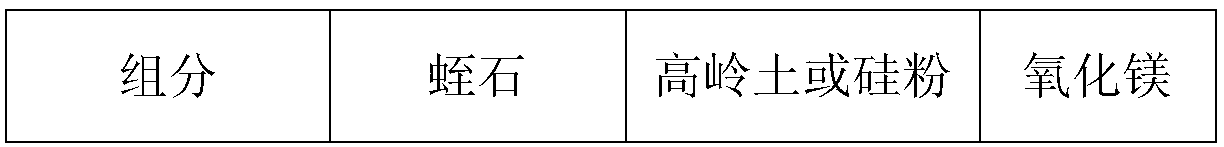

[0038] The mass percentages of each component of the composite additive in Zhundong coal are shown in Table 1:

[0039] The mass percent of each component of composite additive in Zhundong coal in table 1, embodiment 1

[0040] components

[0041] The ash melting points of the coals that are prone to slagging after blending according to the data in Table 1 are respectively reduced by 60-90°C. After testing on the high-sodium and high-calcium Zhundong coal and the high-sodium, high-calcium and high-iron Zhundong coal in the sinking furnace, it is found that without adding The slag sample surface of the deposition probe at 1100°C was completely melted when the intumescent additive was used. After adding 4% intumescent additive, there was no completely melted or partially melted char on the surface of the deposition probe, and all of them were non-melted ash samples.

Embodiment 2

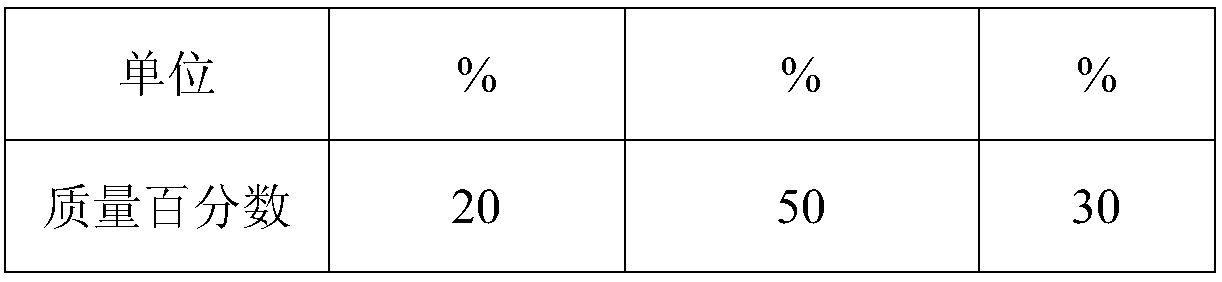

[0043] The mass percentages of each component of the composite additive in Zhundong coal are shown in Table 2:

[0044] The mass percent of each component of composite additive in Zhundong coal in table 2, embodiment 2

[0045] components

[0046] The ash melting points of coals that are prone to slagging after blending in Table 2 are respectively reduced by 20-50°C. After testing on high-sodium and high-calcium Zhundong coal and high-sodium, high-calcium and high-iron Zhundong coal in the sinking furnace, it was found that the addition of 2 After the deposition of the intumescent additive, there is still a very small amount of partially melted coke on the surface of the probe, so it is necessary to add 6% kaolin or 9% silica fume to increase the ash melting point, which can partially replace the intumescent additive and help power plants reduce costs. In the actual production process, the amount of intumescent additives used can also be appropriately reduced accordi...

Embodiment 3

[0048] The mass percentage composition of each composition is as shown in table 3 in the composite additive of the present invention:

[0049] The mass percent of each component in the composite additive in table 3, embodiment 3

[0050] components

[0051] In Example 3, the particle diameters of vermiculite and kaolin are both 200 μm. Silicon powder is a powder with a silicon content of 80%; the particle size of silicon powder is 100 μm. The desulfurizing agent magnesium oxide is a powder with a magnesium oxide content of 80%; the particle size of the desulfurizing agent magnesium oxide is 100 μm. The expansion coefficient of the expansion additive vermiculite is 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com