Patents

Literature

188results about How to "Easy to blow off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

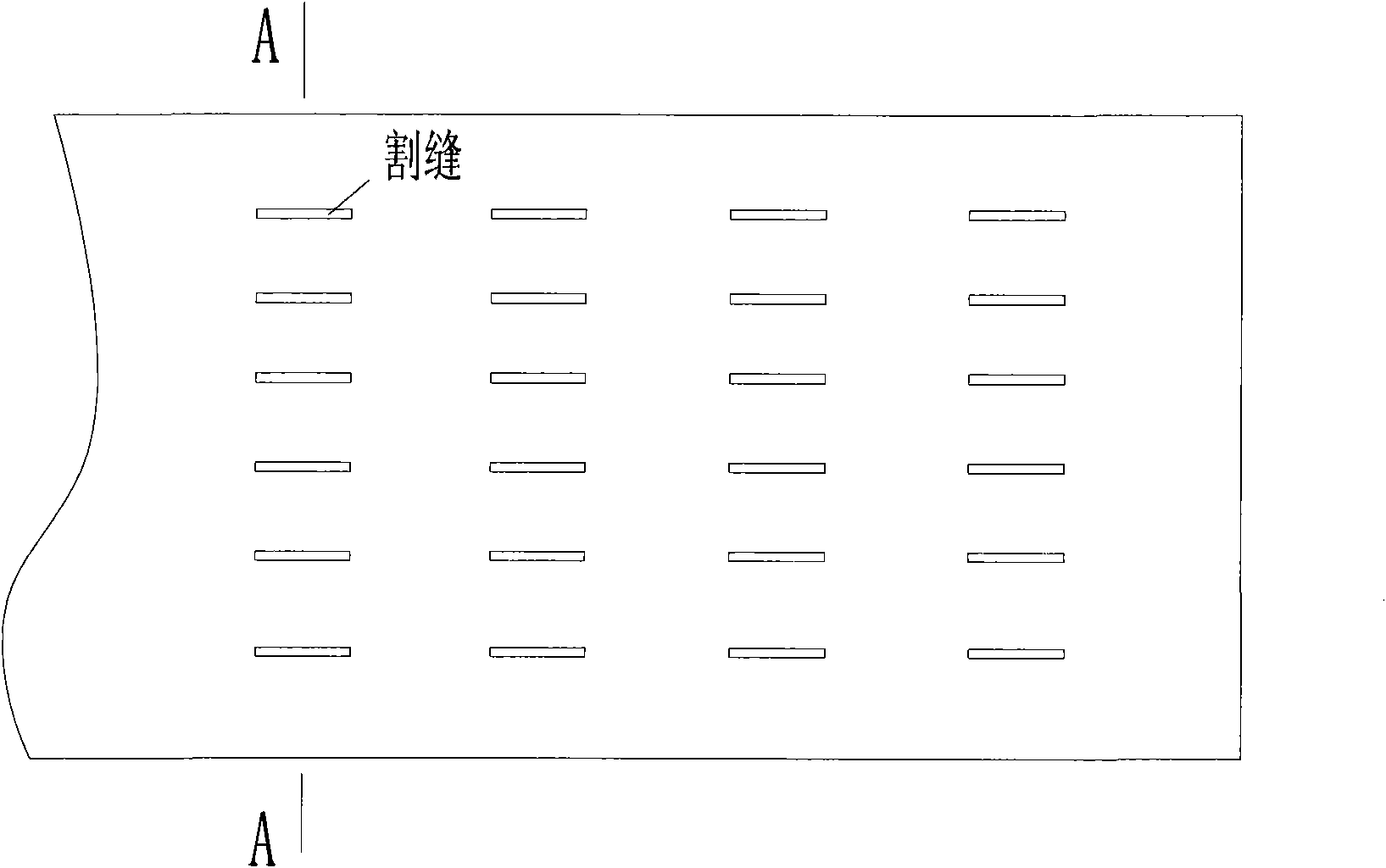

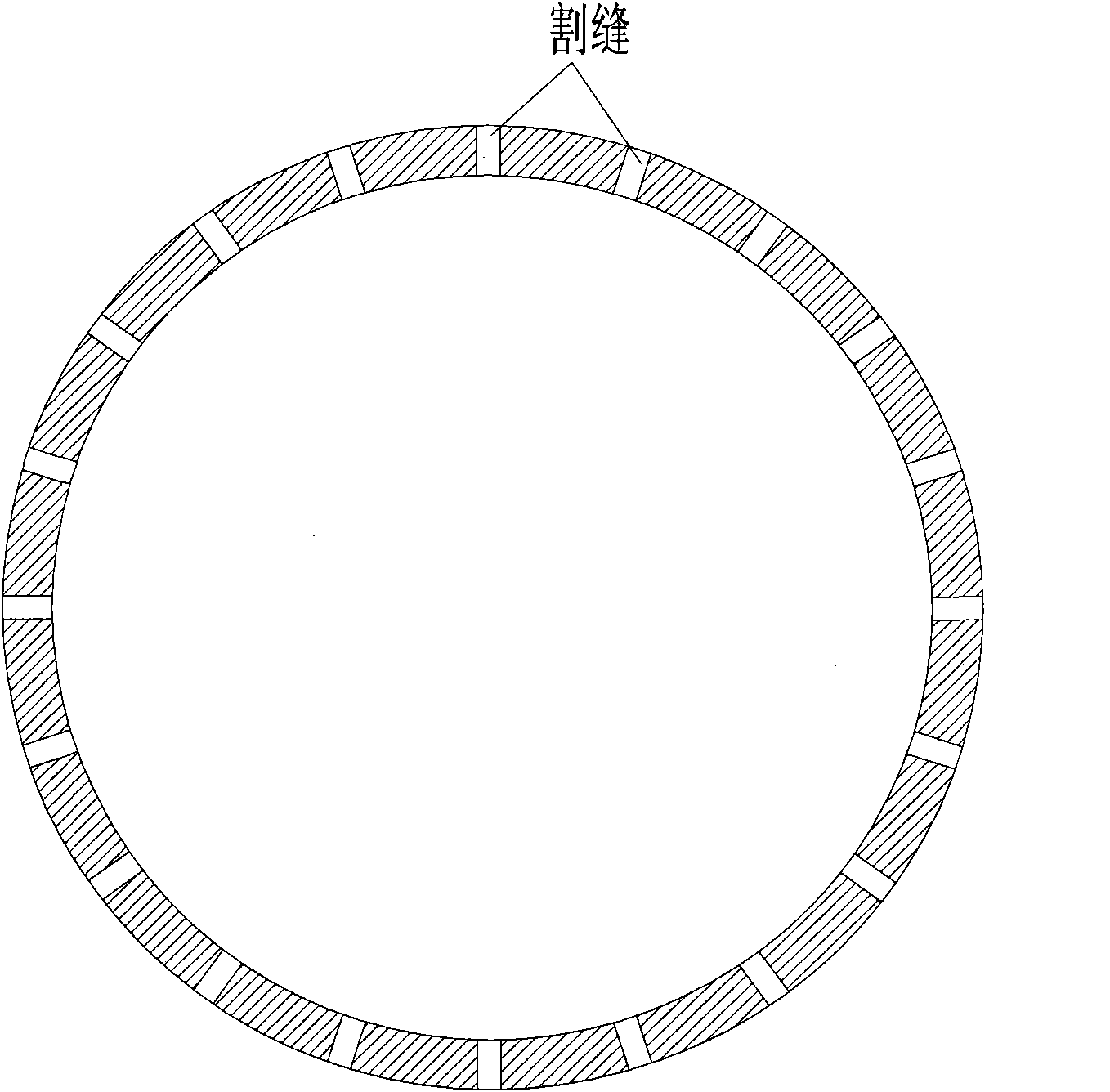

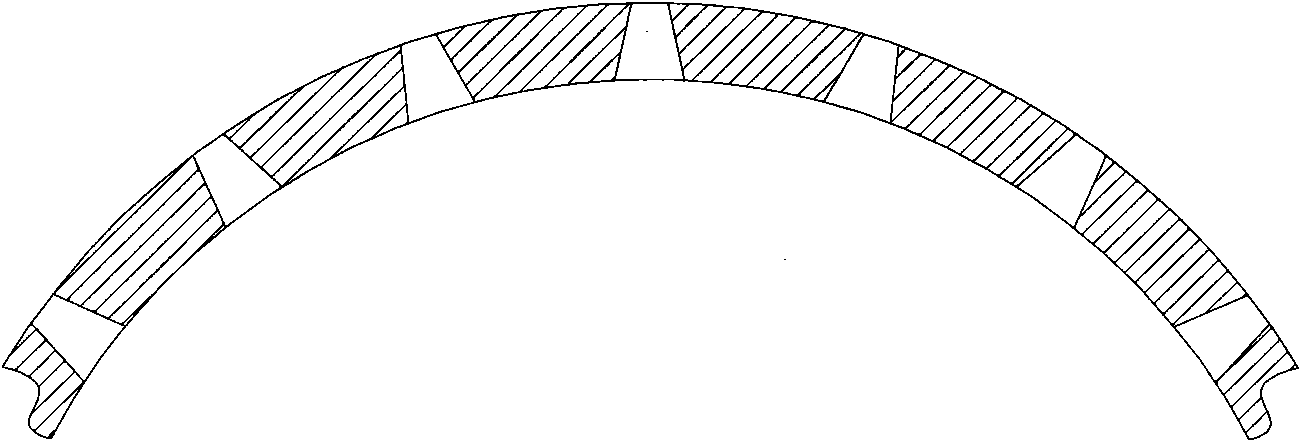

Laser processing method for steel sieve tube slit

InactiveCN101890582AGuaranteed trafficGuaranteed flow rateLaser beam welding apparatusLaser processingChemical reaction

The invention discloses a laser processing method for a steel sieve tube slit. One end point of one long edge of the slit is used an initial point. The method comprises the following steps of: perforating a hole at the initial point of a cut by using pulse laser, and then finishing the cutting of the whole slit from the initial point by using continuous laser. During cutting, oxygen is used as an auxiliary gas, the metal at a cutting point is further heated by using reaction heat released by the reaction of the oxygen and the molten iron at the cutting point, meanwhile the molten iron is changed into ferroferric oxide with good liquidity by using chemical reaction, and the ferroferric oxide is blown away the cutting point by using airflow so as to ensure continuous cutting. The processing method solves the problems of irregular slit shape, slag adhesion at the cut and oblique blowing trace in the conventional laser cut sieve tube slit.

Owner:北京宏诚拓业科技发展有限公司 +1

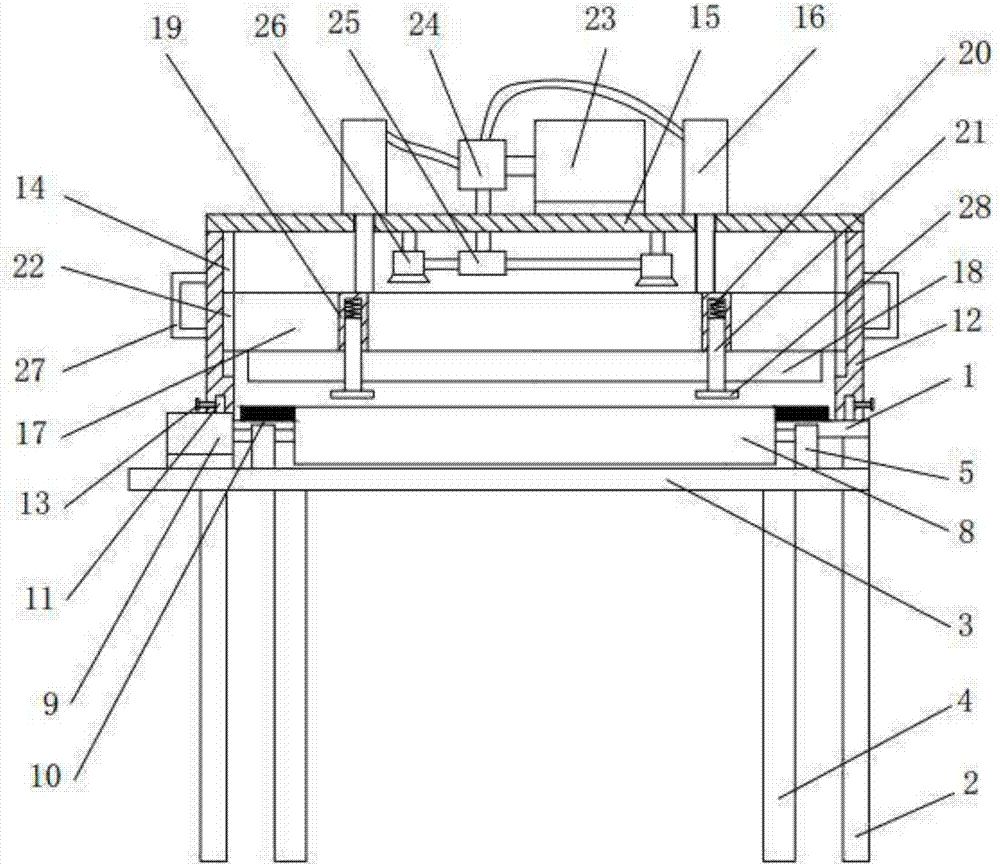

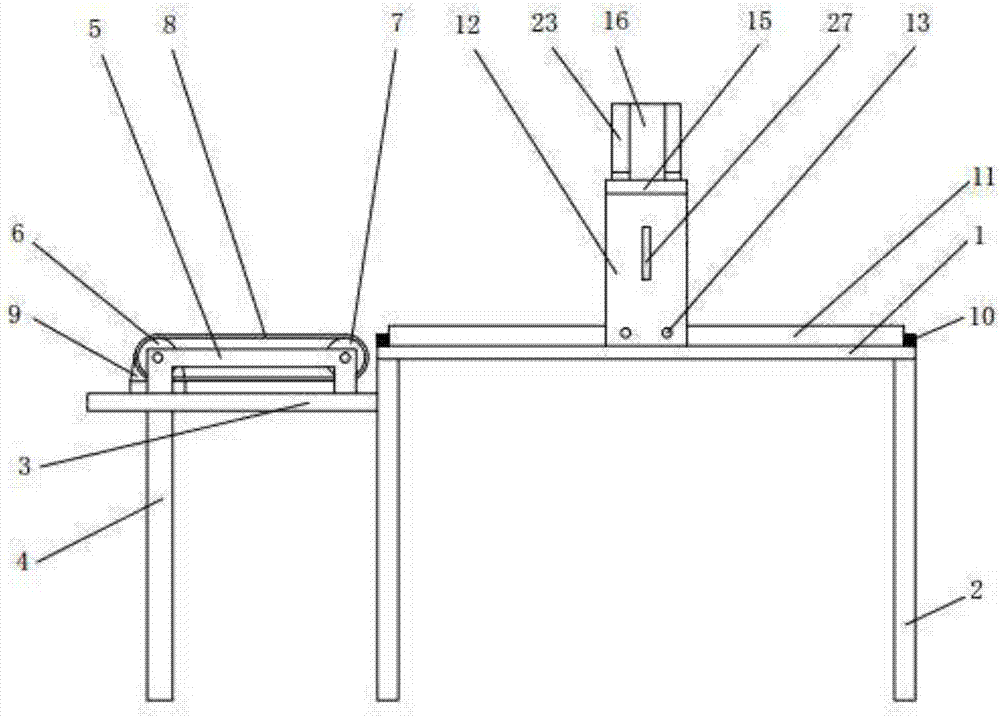

Cutter device for board printing production line

InactiveCN107379043AAvoid adverse effectsGuarantee product qualityMetal working apparatusEngineeringElectromagnetic valve

The invention discloses a cutter device for a board printing production line. Through guide strips, side plates can move frontwards and backwards and cannot be inclined at the same time. Through fastening screws, the side plates can be conveniently fixed and prevented from sliding when working. Through cooperative arrangement of air cylinders, a cutter installation plate, a cutter, tightly pressing rod sleeves, springs and tightly pressing rods, a board can be tightly pressed when cut, and the cutter stably cuts off the board. Through cooperative arrangement of guide grooves and guide sliding blocks, the cutter installation plate can stably and vertically move. Through cooperative arrangement of an air pump, electromagnetic valves and spray heads, chippings can be conveniently blown off. By the adoption of the cutter device for the board printing production line, the horizontal position of the cutter can be arranged at will, the boards can be conveniently cut to have different lengths according to needs, the chippings which may be generated during cutting can be blown off, an adverse influence on the cutting process is avoided, and the product quality is guaranteed.

Owner:江苏韵燕印刷版材有限公司

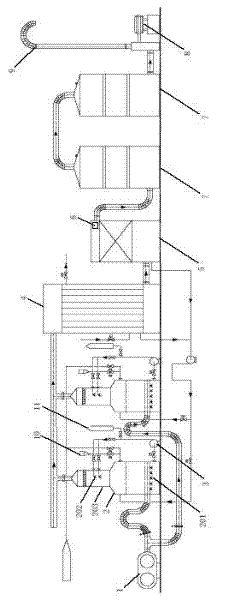

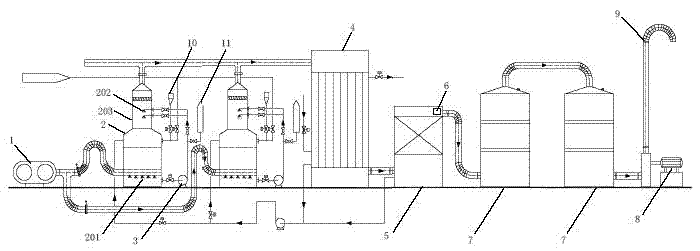

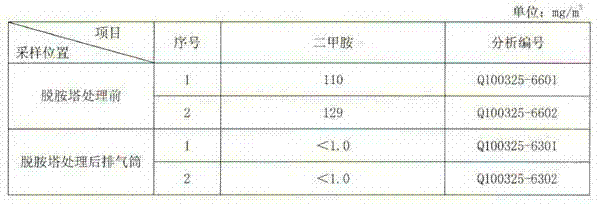

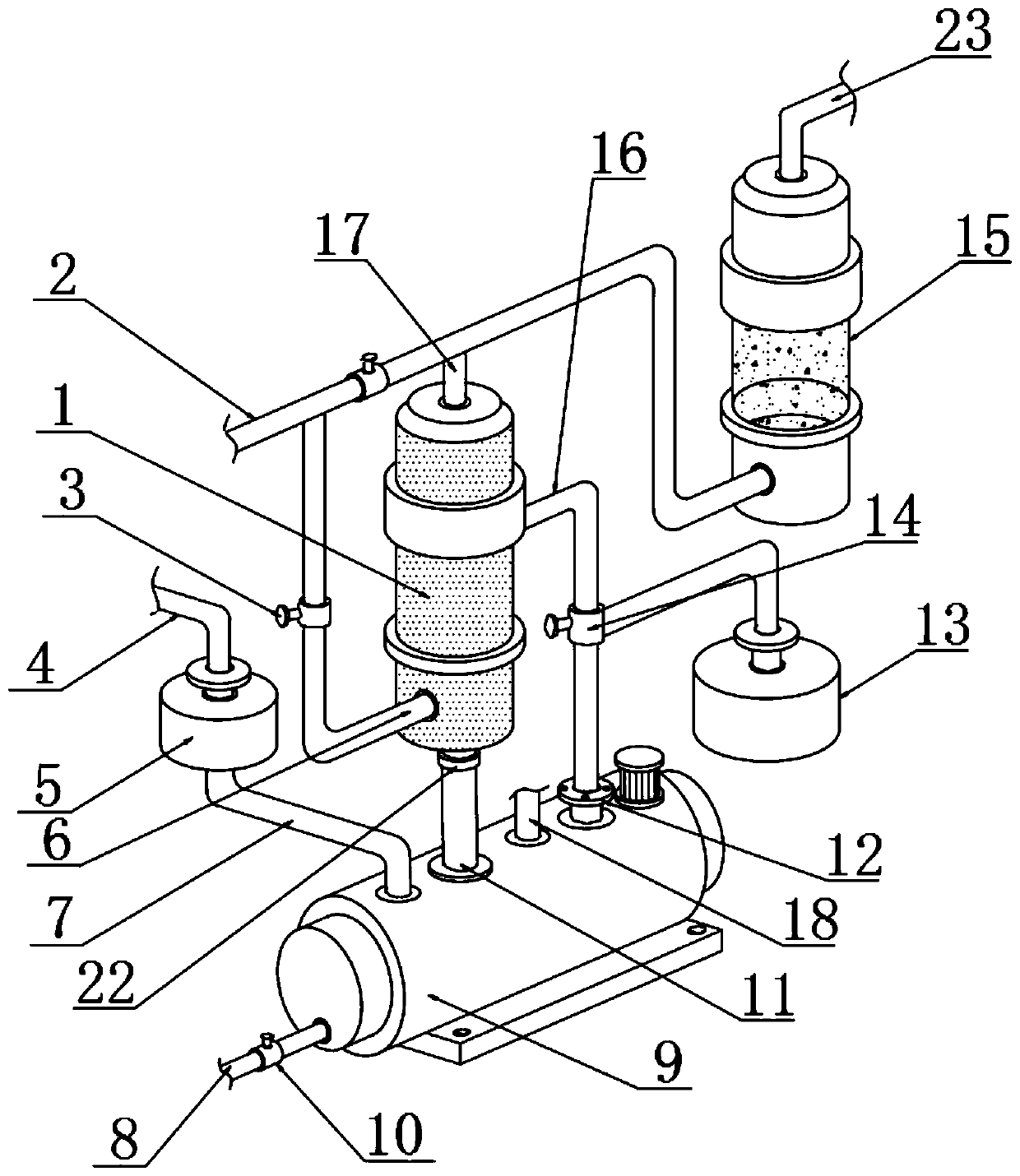

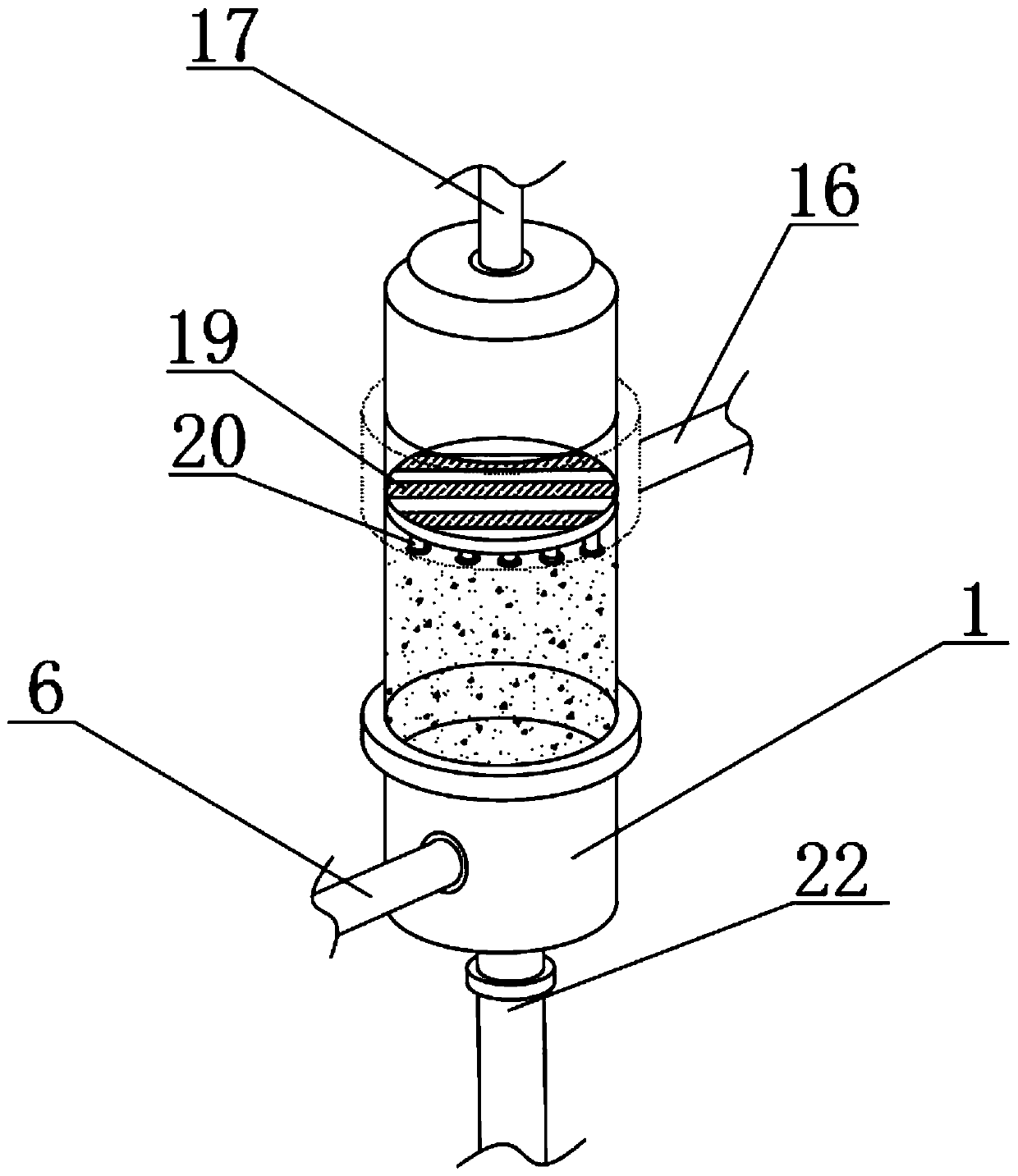

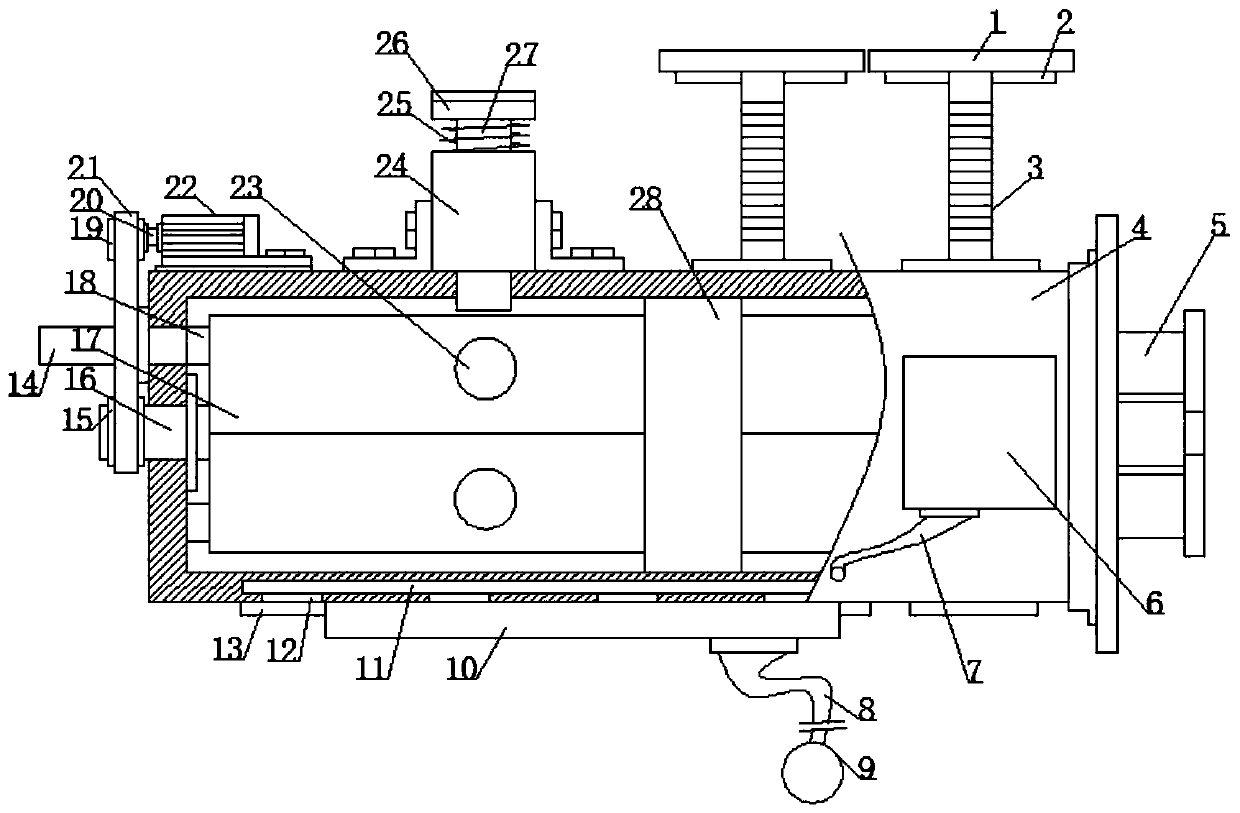

Device for processing dimethylamine exhaust gas and wastewater

InactiveCN102161534AReduce concentrationStrong concentrationWater contaminantsDispersed particle separationEngineeringSpray tower

The invention discloses a device for processing dimethylamine exhaust gas and wastewater. A fan is respectively connected with a plurality of shower nozzles on the bottoms of a plurality of blowing oxidation cans; the bottom of each blowing oxidation can is externally connected with a water pump; the water pump is connected with an atomizing shower nozzle arranged in a spray tower on the upper part; the lower part of the blowing oxidation can is a dimethylamine solution cavity; the dimethylamine solution is discharged from the outlet on the top of the blowing oxidation can after being blown off by air; after the dimethylamine solution is cooled by a condenser and separated by a moisture separator, mixed gas enters a low-temperature plasma purifier to carry out purification and deodorization; and the purified air is discharged from a chimney via an induced draft fan. The device has the advantages that removal effect is above 90%, and the content of the discharged dimethylamine exhaust gas is low, thereby saving energy, reducing emission, and causing low energy consumption.

Owner:SHANGHAI KAIZHAN ENVIRONMENTAL PROTECTION TECH

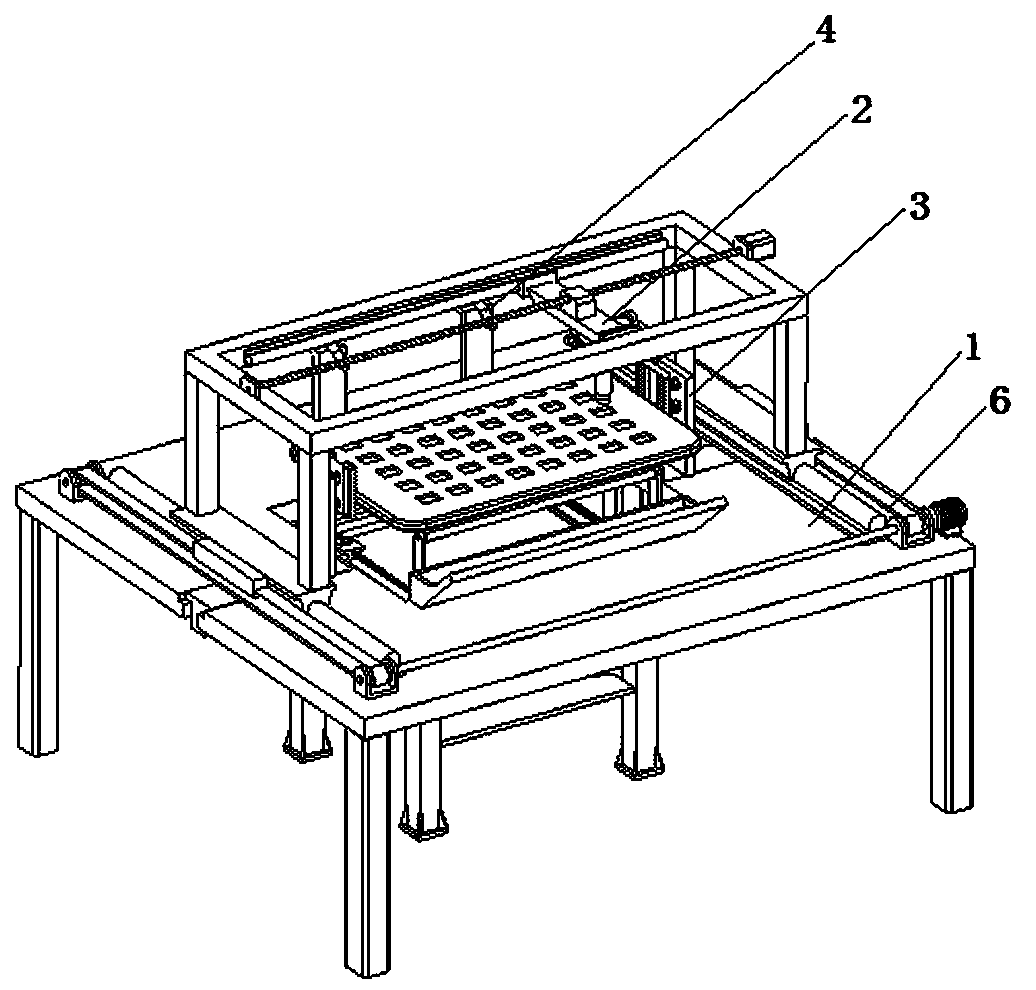

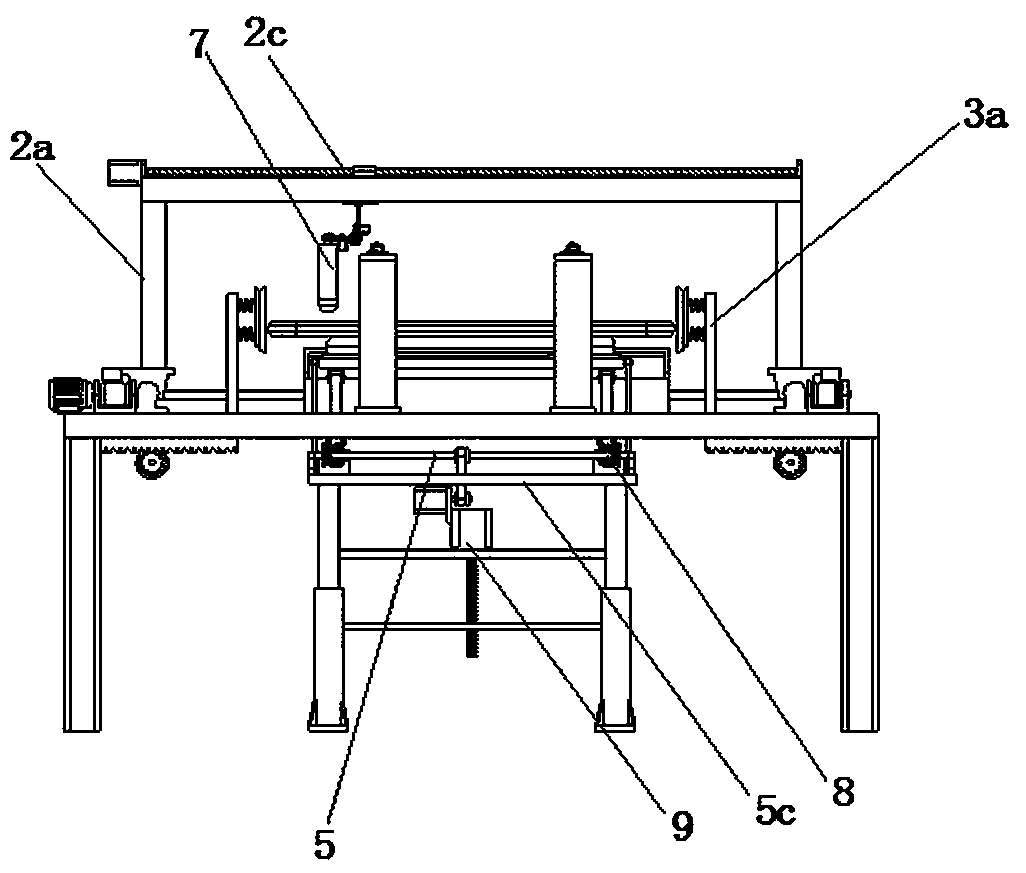

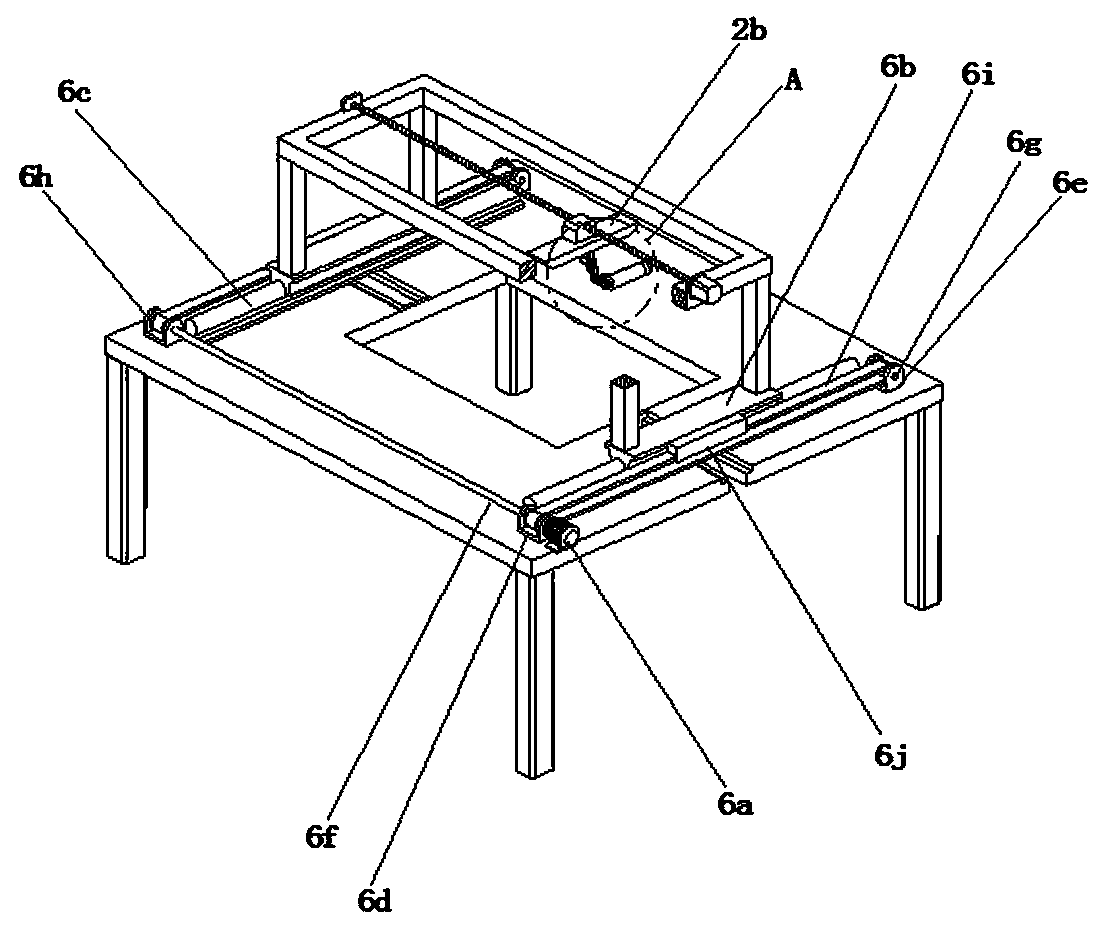

Computer metal keyboard housing polishing device

ActiveCN110744398AImprove grinding efficiencyHigh degree of automationGrinding carriagesGrinding drivesPolishingDust control

The invention discloses a computer metal keyboard housing polishing device, and belongs to the technical field of computer hardware production equipment. The computer metal keyboard housing polishingdevice comprises a workbench, a polishing mechanism, a limiting mechanism, a dust removal mechanism and a keyboard housing position adjusting mechanism, wherein a feeding assembly is arranged on the top of the workbench; the polishing mechanism comprises a rack, a polishing assembly, a bearing plate and a lead screw sliding table; the polishing assembly comprises a mounting strip, a polishing head, a polishing roller, a supporting plate and a rotating component; and a mounting shaft is inserted in the mounting strip. According to the computer metal keyboard housing polishing device, the polishing roller can conduct polishing work on the two sides and the top face of a keyboard housing through the polishing mechanism, under the action of the lead screw sliding table and the feeding assembly, all-dimensional polishing work of the polishing roller on the top face of the keyboard housing can be achieved, the polishing head can conduct polishing work on a key groove in the keyboard housing,the automation degree is high, and the polishing efficiency of the keyboard housing is improved.

Owner:SUZHOU SHUOFENG PRECISION MACHINERY CO LTD

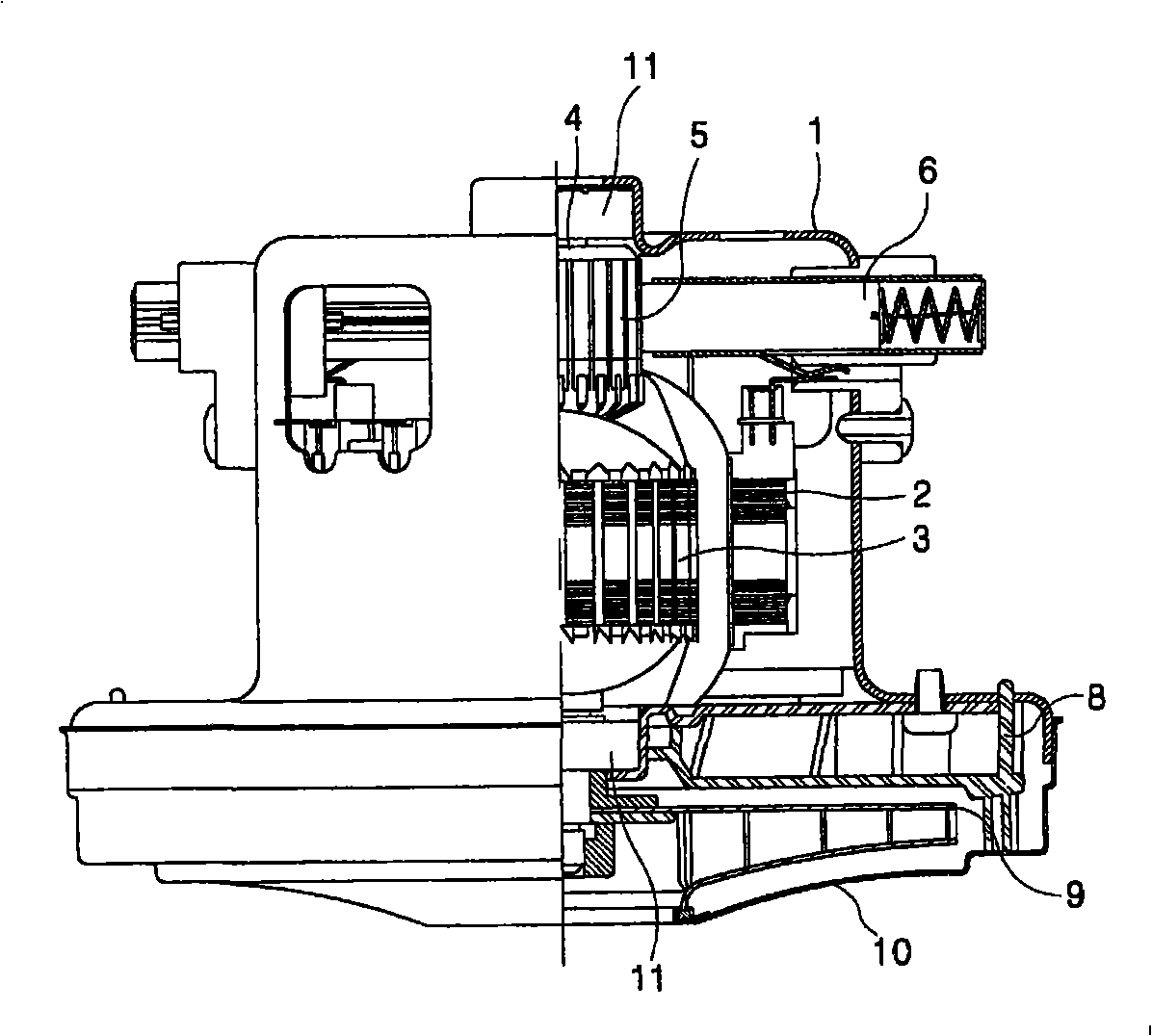

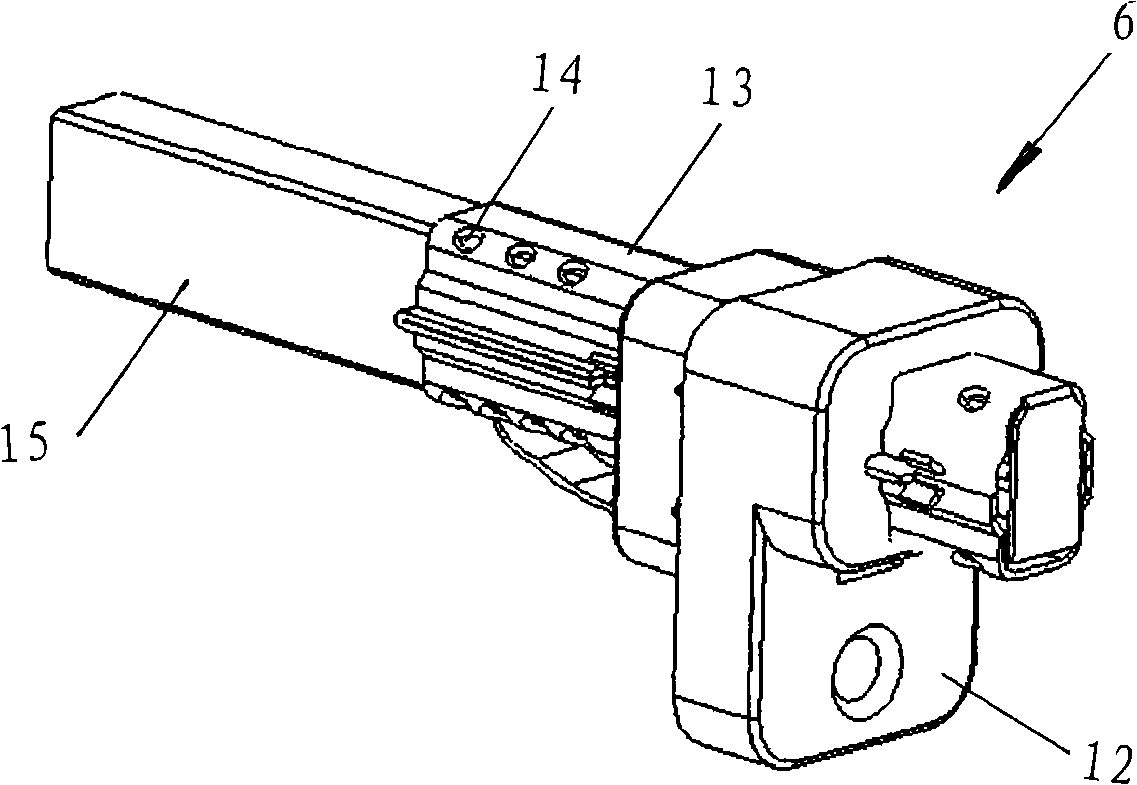

Novel carbon brush structure

InactiveCN101330186AEasy to blow offImprove cooling effectRotary current collectorMetal sheetEngineering

The invention discloses a novel carbon brush structure, which comprises a support connected to one end of a copper sleeve, a plurality of heat dissipating holes formed on the copper sleeve, a carbon rod connected to the other end of the copper sleeve, a metal sheet arranged at the lower part of the copper sleeve and coming into contact with a connecting terminal, rectangular slots formed respectively at the top and at the bottom of the carbon rod along the length direction of the carbon rod, and a plurality of uniformly distributed grooves formed on the peripheral surface of the carbon rod. The carbon brush structure has the advantages that the heat dissipation is simple, and the powder generated by the friction between a commutator and the carbon rod can be easily blown off along the grooves so as to prevent the powder from adhering on an armature.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

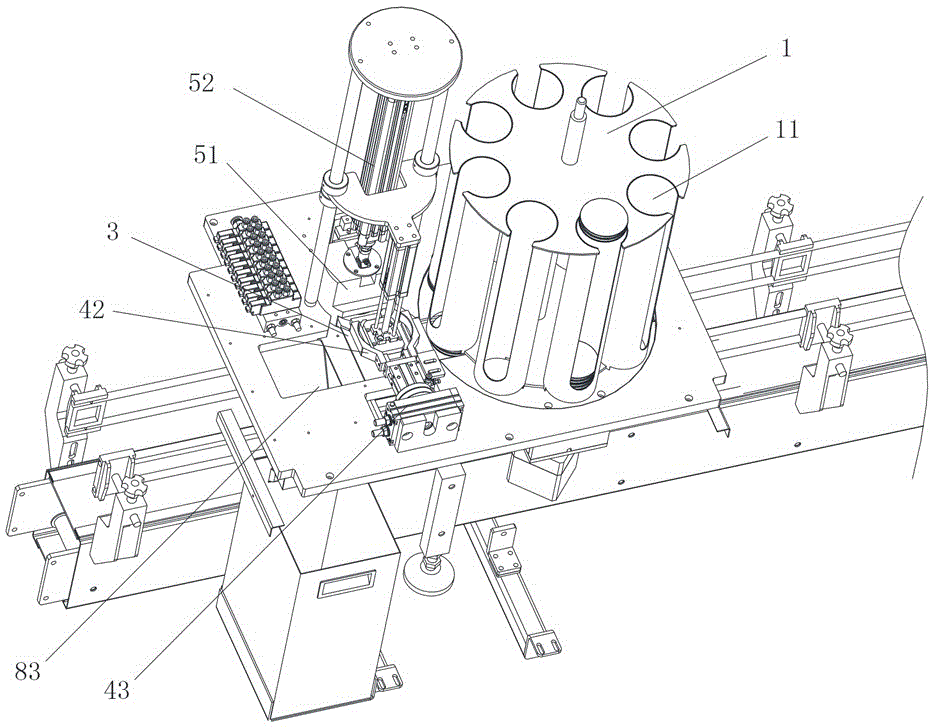

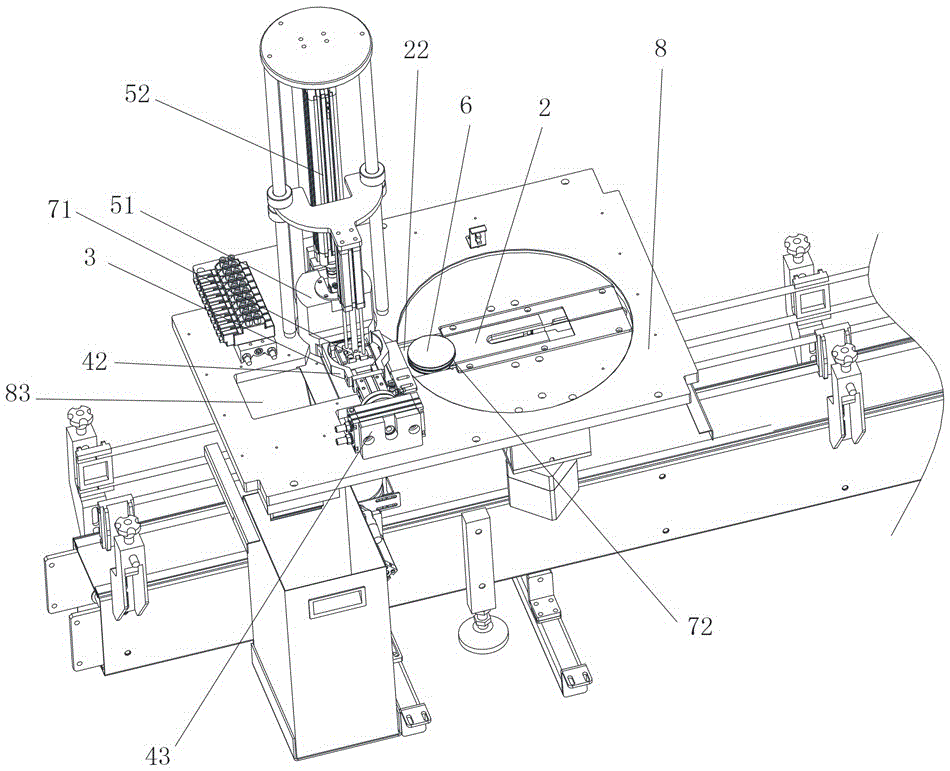

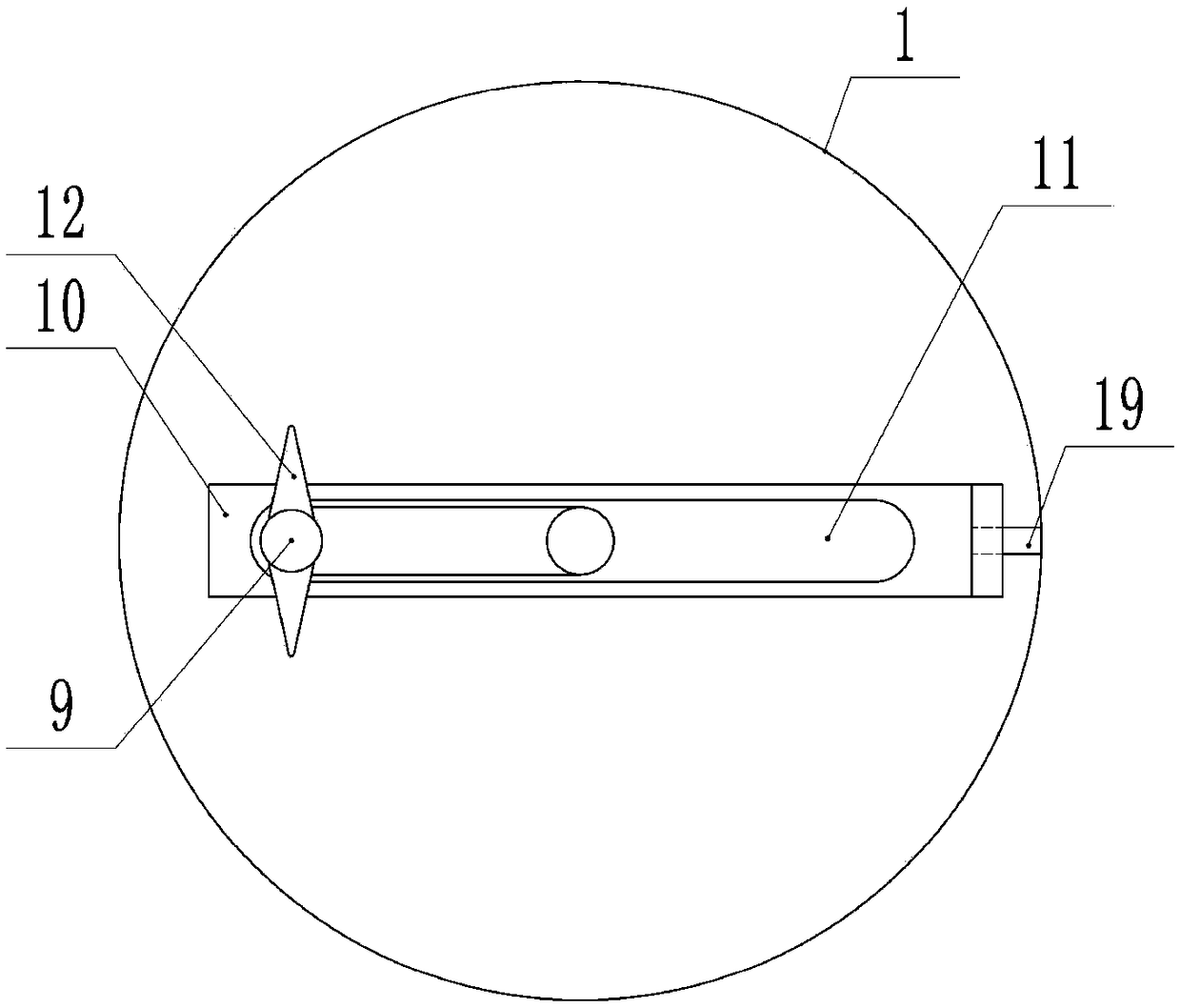

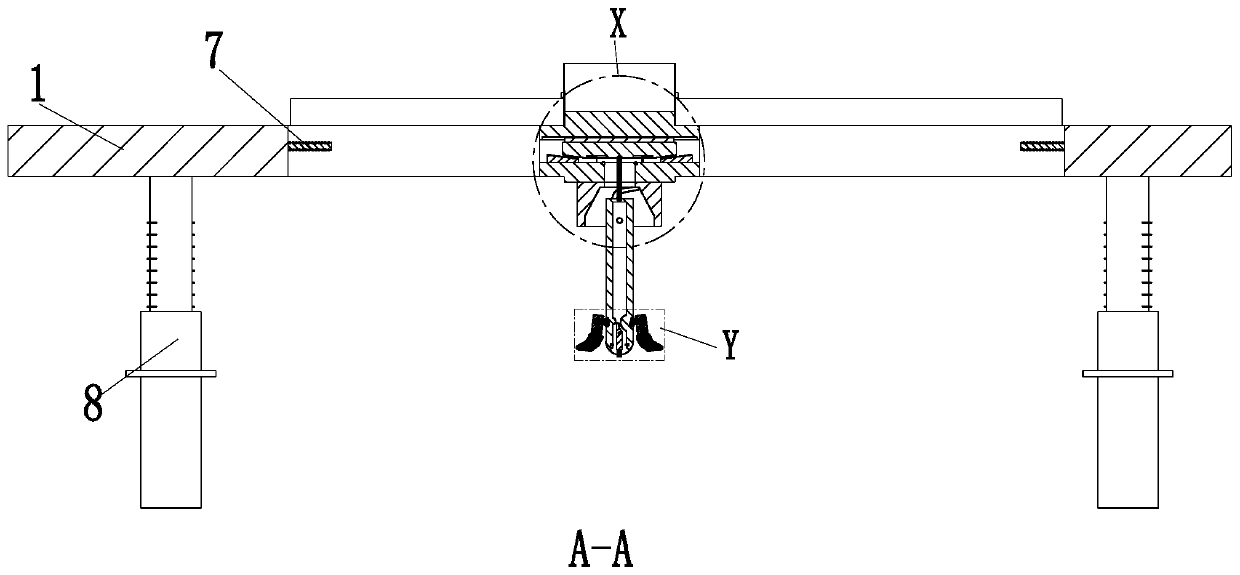

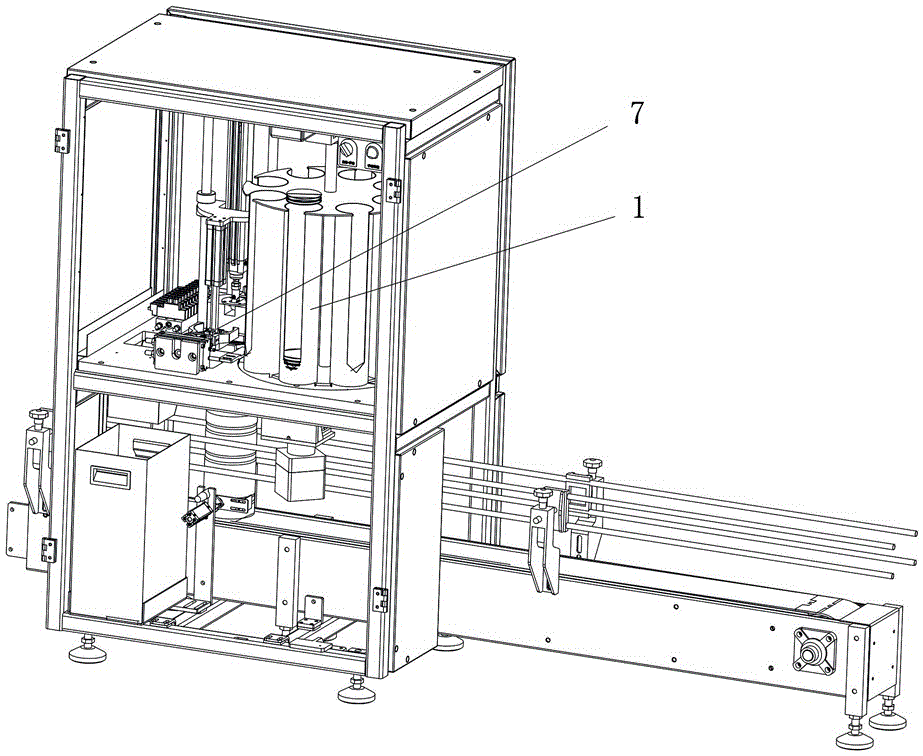

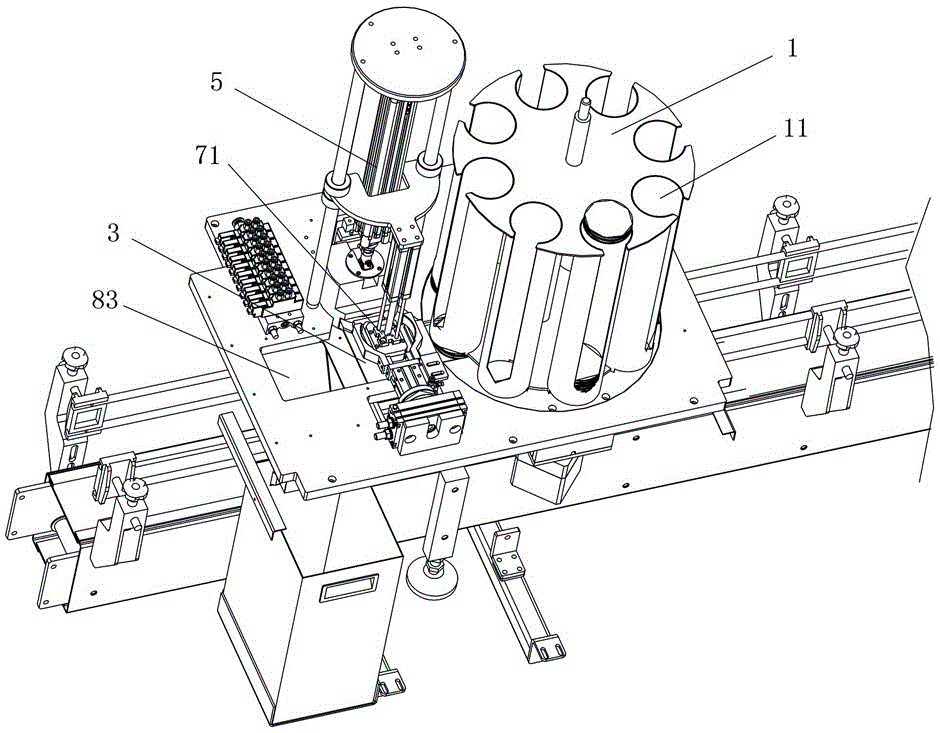

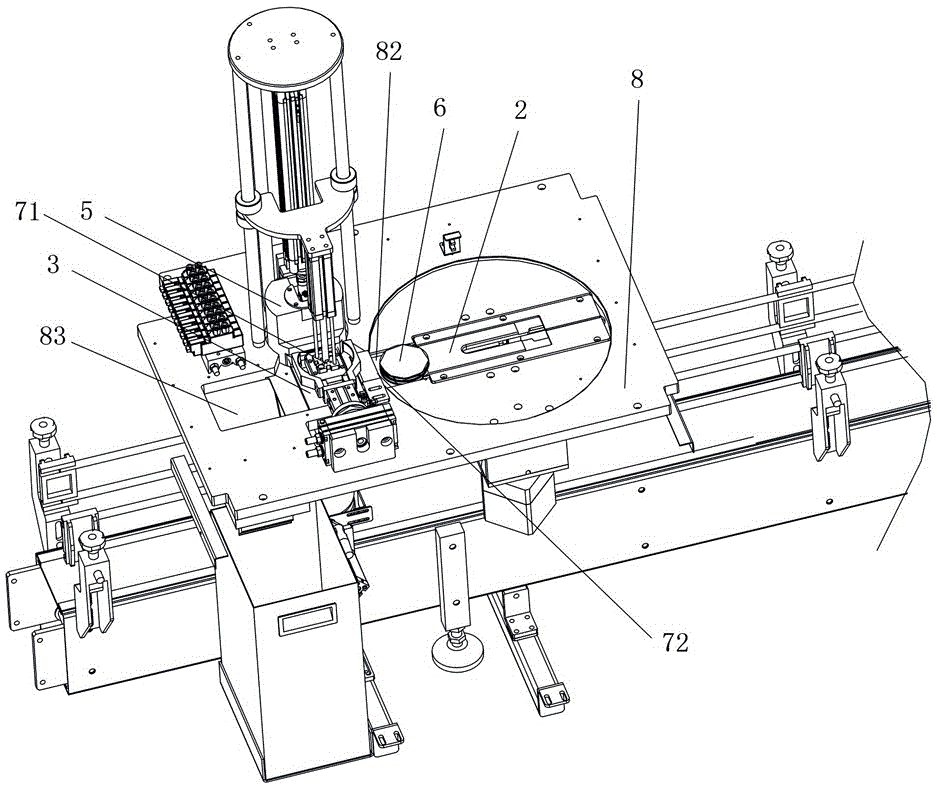

Intelligent sample bottle lid pressing machine for sampling

ActiveCN106564841ASimple and compact structureHigh degree of intelligenceFlanged caps applicationEngineeringBottle

The invention discloses an intelligent sample bottle lid pressing machine for sampling. The machine comprises a storage mechanism, a pushing block module, a translation jacking mechanism, a turnover correcting mechanism, a lid pressing mechanism and a detecting mechanism; the storage mechanism is used for storing multiple bottle lids; the pushing block module is arranged below the storage mechanism for horizontally pushing the bottle lids output by the storage mechanism onto the translation jacking mechanism one by one; the translation jacking mechanism has a translation travel for translation conveying of the normal bottle lids with downward openings output by the storage mechanism below the lid pressing mechanism for lid pressing; the turnover correcting mechanism and the detecting mechanism are both arranged above the translation jacking mechanism; the turnover correcting mechanism is used for overturning and correcting the abnormal bottle lids with upward openings on the translation jacking mechanism; and the detecting mechanism is used for detecting the bottle lids on the translation jacking mechanism and blowing away the unqualified bottle lids. The machine has the advantages of simple and compact structure, high intelligent degree, high reliability, high lid pressing safety and high working efficiency.

Owner:HUNAN SUNDY SCI & TECH DEV

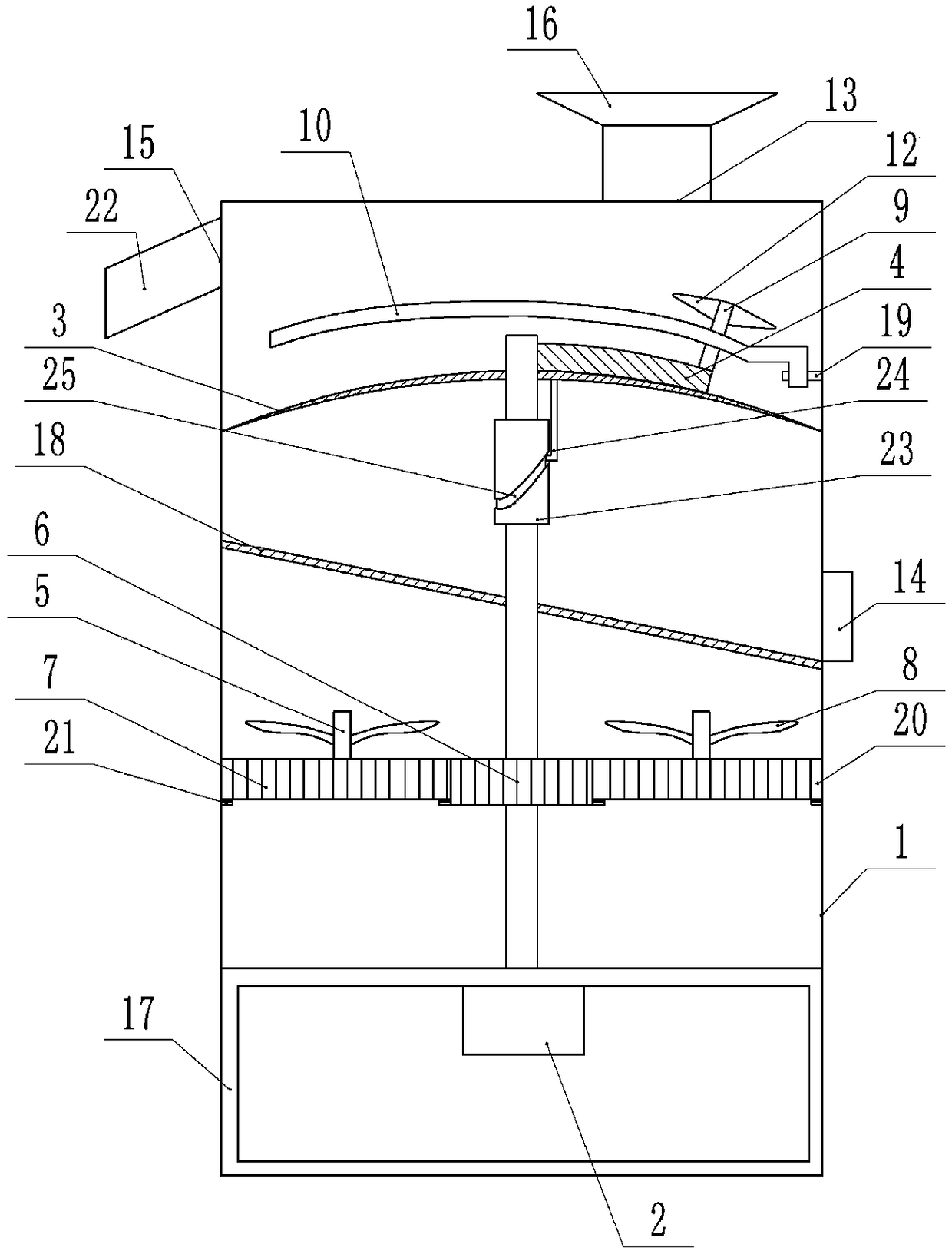

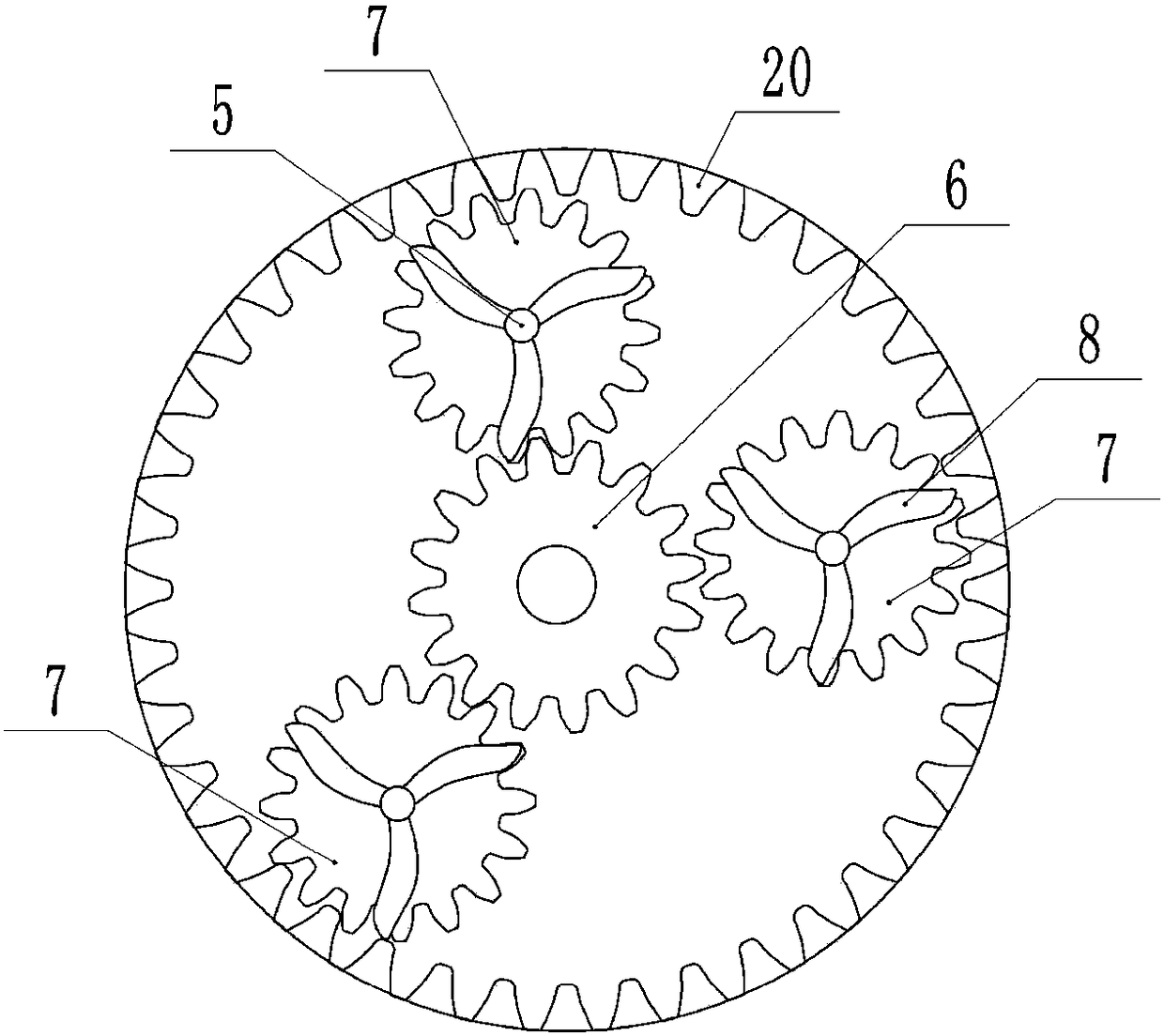

Cassia seed screening device

ActiveCN108499674AIncrease separation rateGood peeling effectGrain treatmentsEngineeringFood processing

The invention belongs to the technical field of food processing equipment and in particular discloses a cassia seed screening device which comprises a case, wherein a motor provided with an upward output shaft is arranged at the lower part of the case; a screening plate, a guide plate, a discharge hole and a screening waste hole are arranged on the case; a transverse rod is arranged in a position,above the screening plate, of the output shaft; a feeding hole is formed in the upper part of the case; the case is a cylindrical case; the case is provided with convex teeth in a circumferential direction below the guide plate; the output shaft is provided with a first gear which is fixedly connected with the output shaft and is arranged in a position below the guide plate; a plurality of secondgears are arranged between the first gear and the case; the second meshes are meshed with both the first gear and the convex teeth; first vertical shafts which are fixedly connected with the second gears are arranged on the second gears; fans which are fixedly connected with the first vertical shafts are arranged on the first vertical shafts. The device is mainly used for screening cassia seeds,and the problem that product waste can be caused since fruit peel is not well crushed can be solved.

Owner:凤冈县万福食品有限责任公司

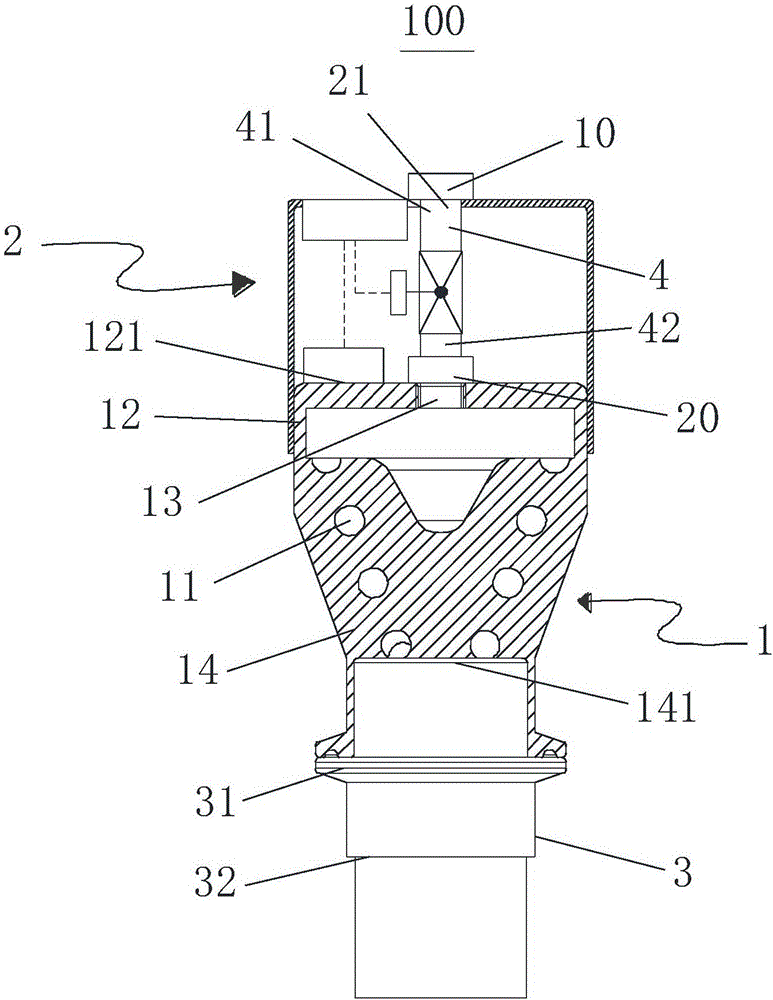

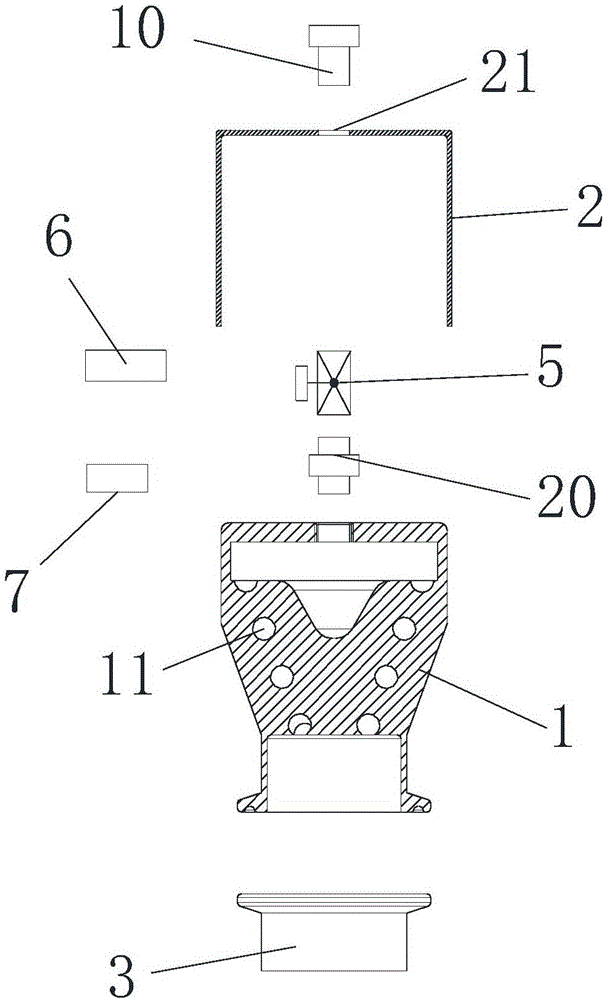

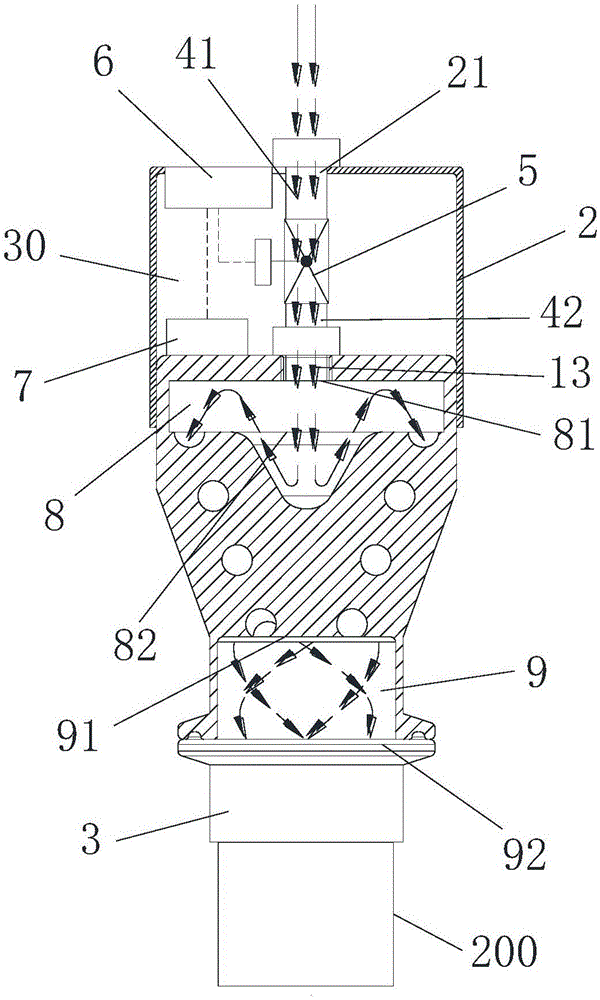

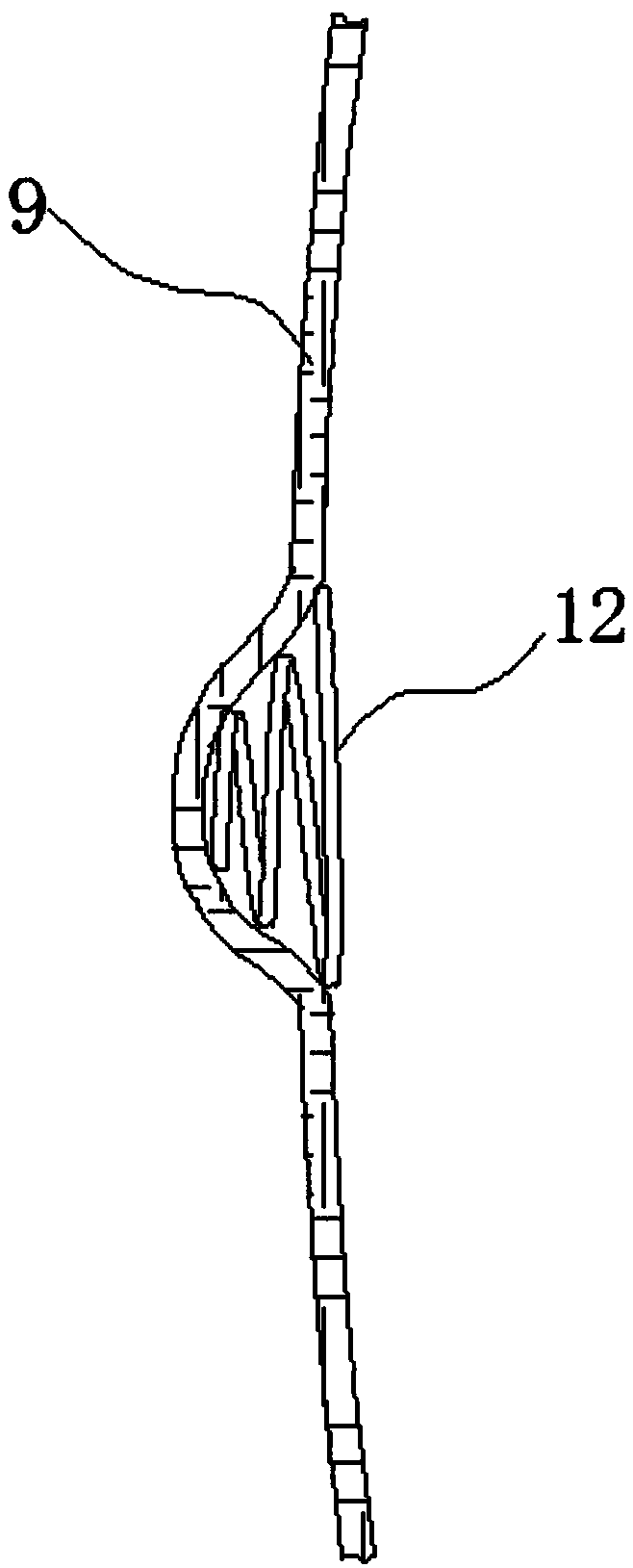

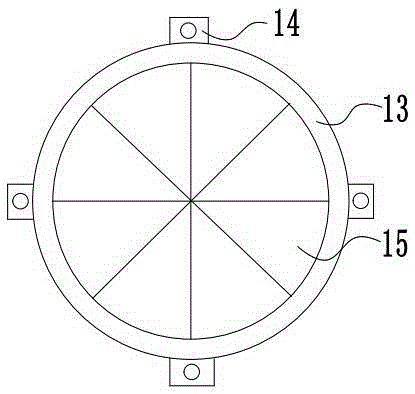

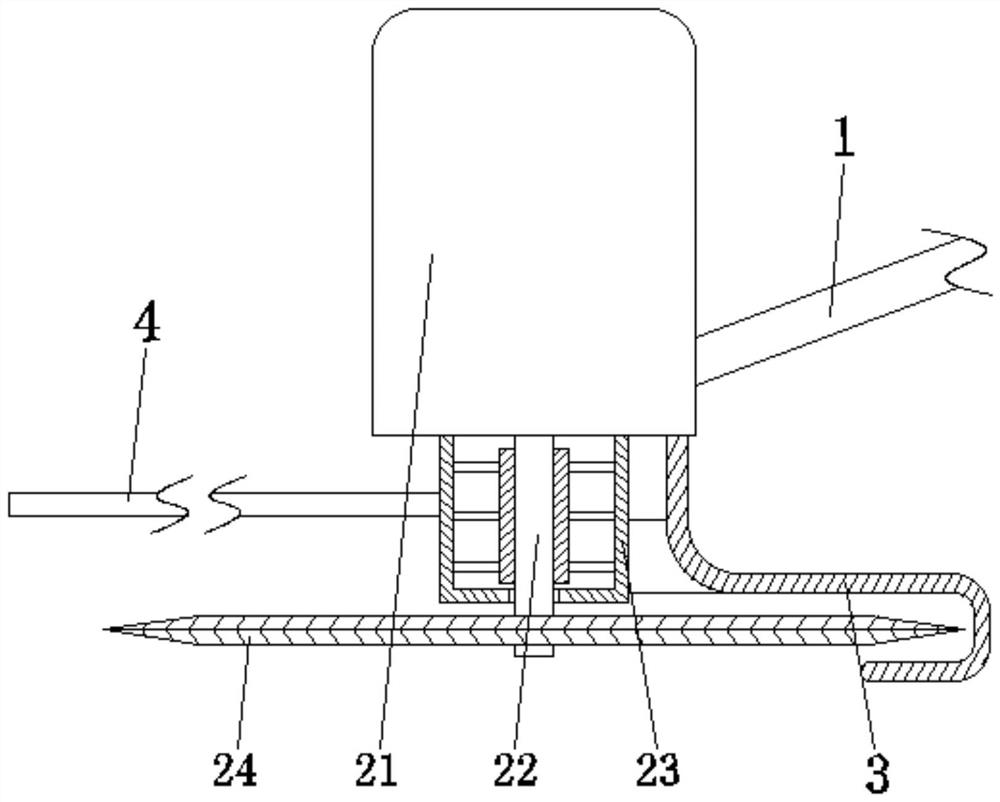

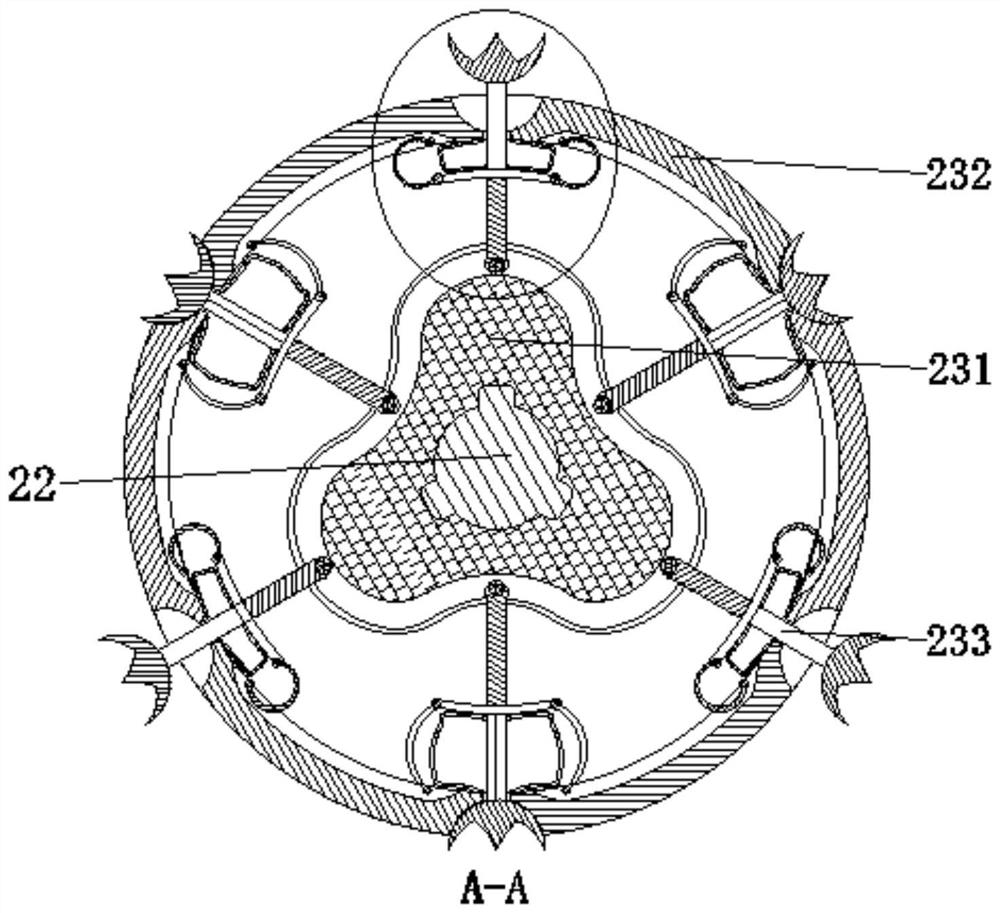

Eddy blowing device for pipelines

ActiveCN106140742AEasy to blow offIncrease the sweeping powerHollow article cleaningExhaust gasElectrical and Electronics engineering

The invention relates to the technical field of tail gas removing equipment, and discloses an eddy blowing device for pipelines. The eddy blowing device comprises a blowing device body; a spiral channel is arranged inside the blowing device body; an inlet communicating with a gas inlet of the spiral channel is formed in the upper end face of the blowing device body; and an outlet which communicates with a gas outlet of the spiral channel to provide lateral force and vortex force for blowing the pipelines is formed in the lower end face of the blowing device body. The eddy blowing device has the advantages of being good in blowing effect and capable of achieving automatic blowing.

Owner:WEICHAI POWER CO LTD

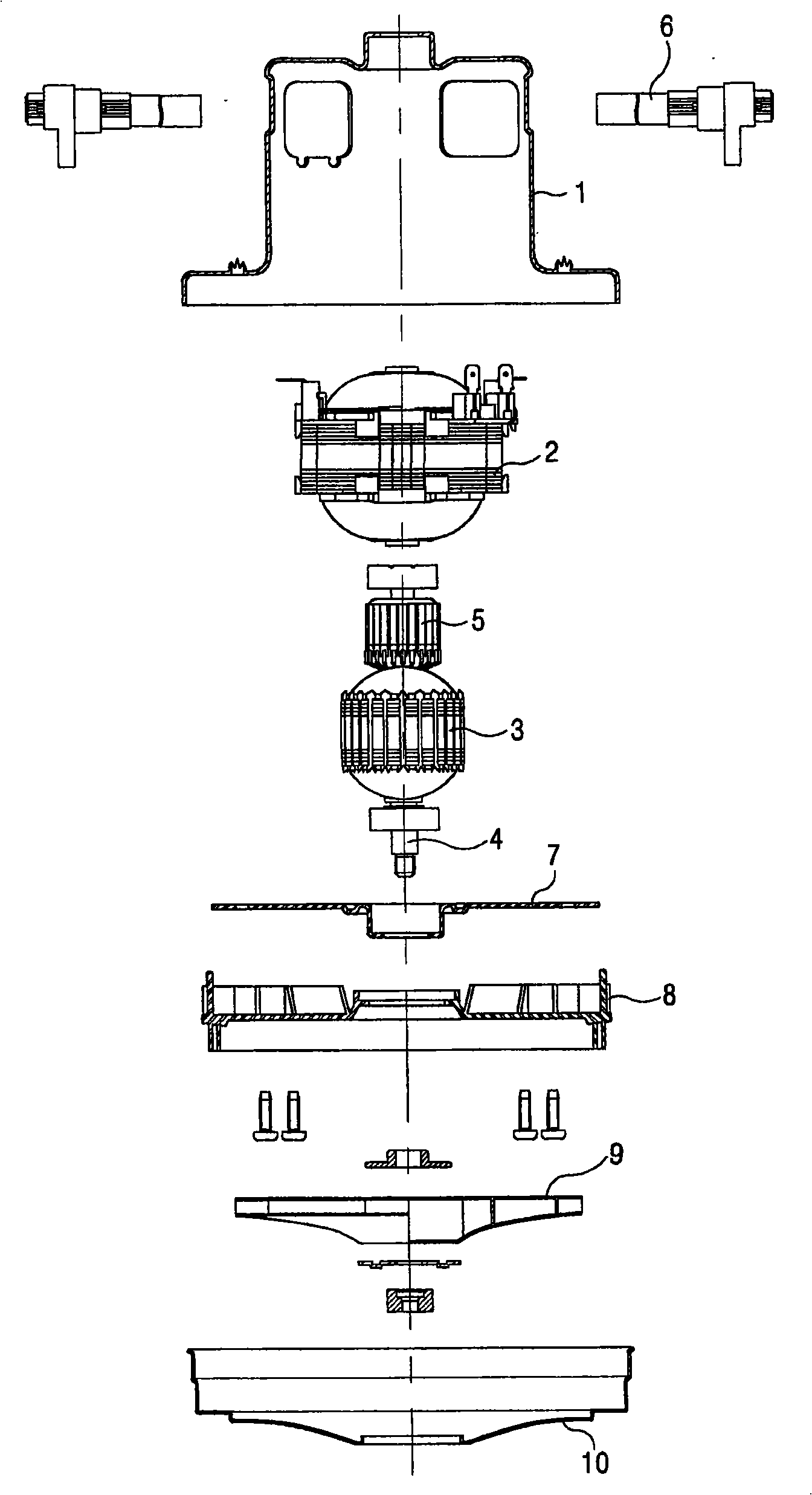

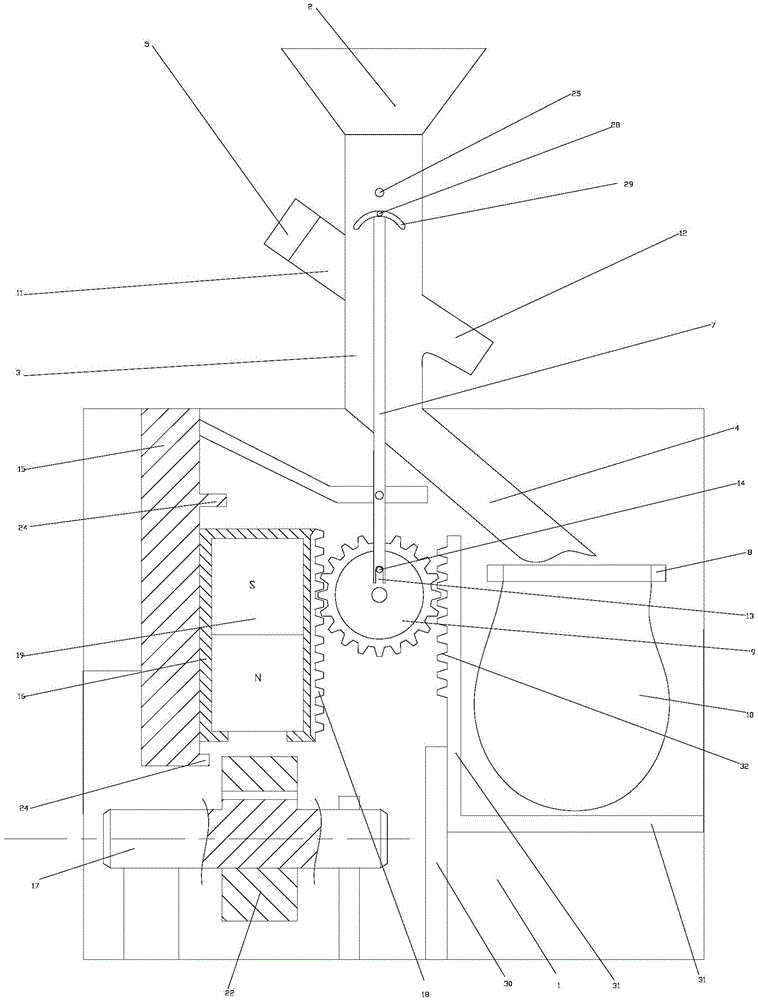

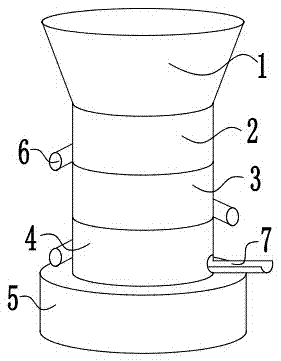

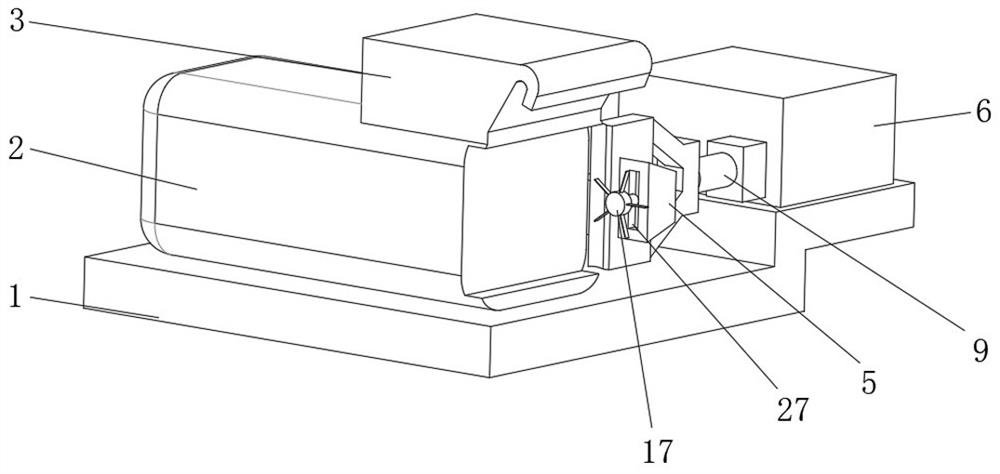

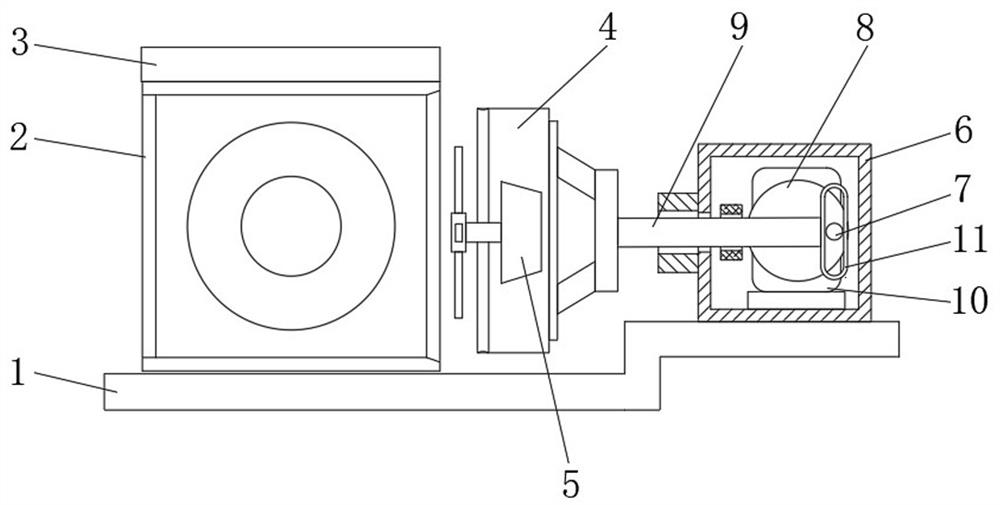

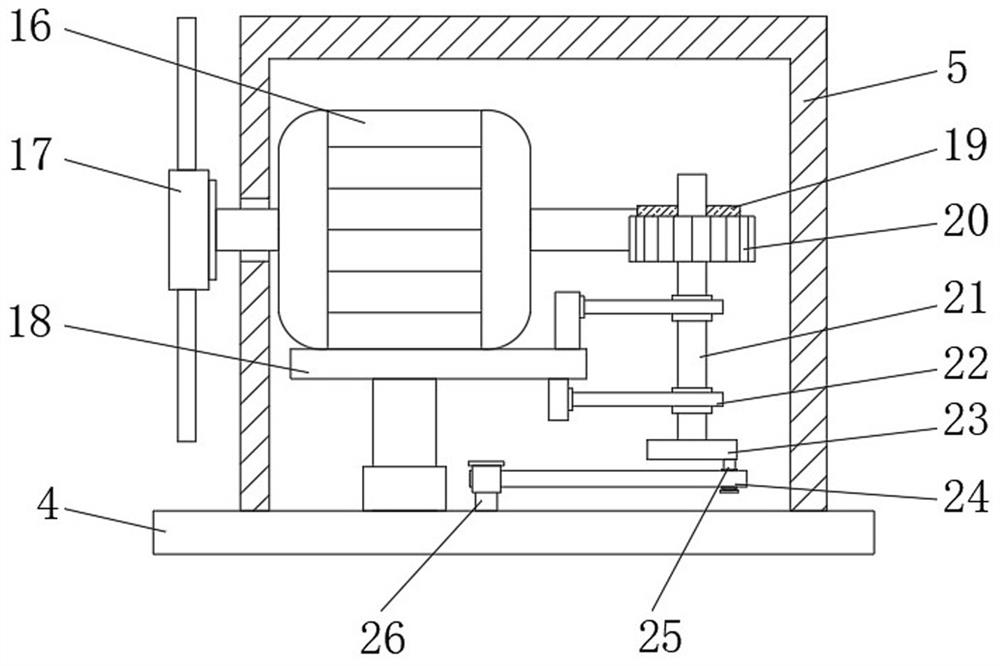

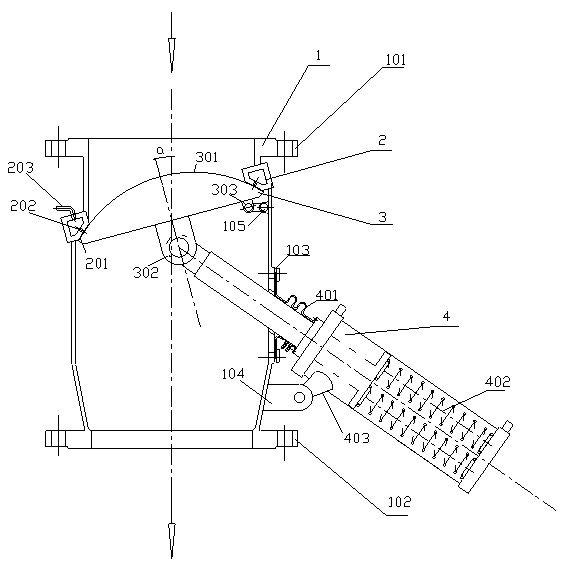

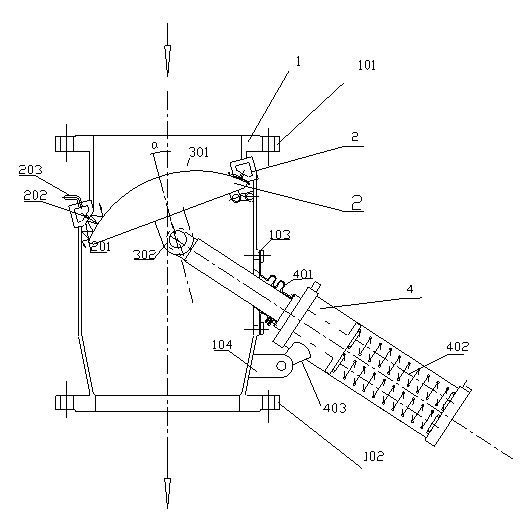

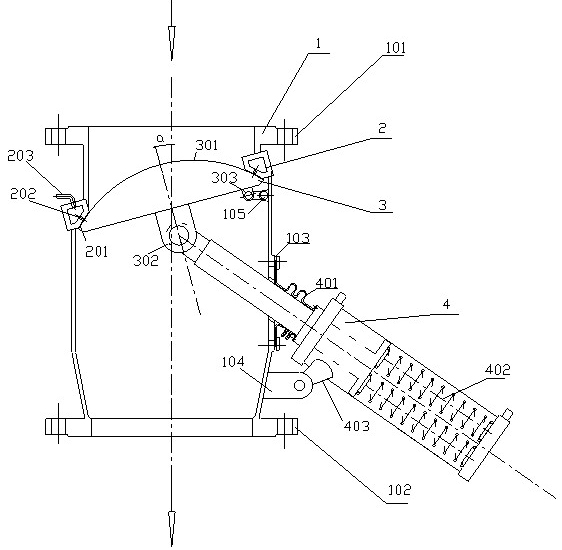

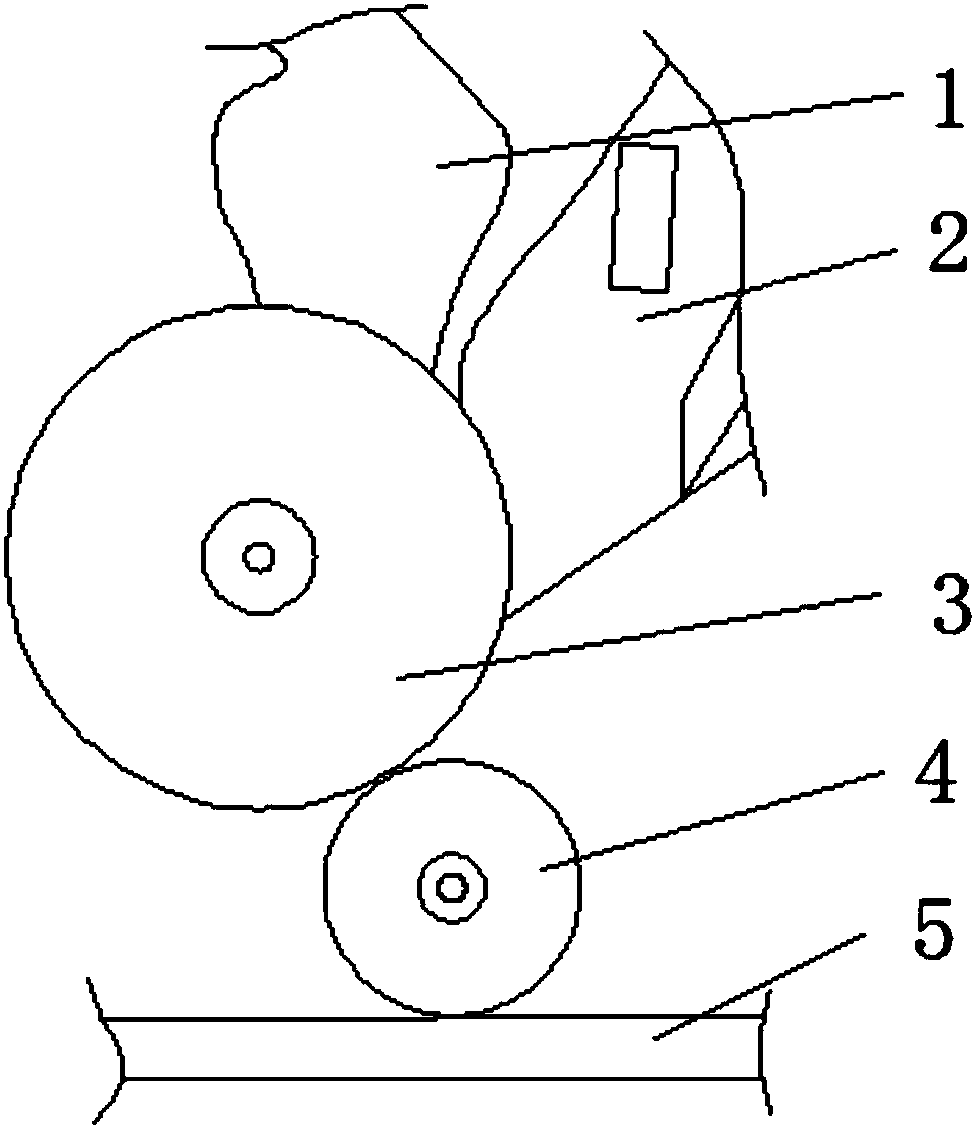

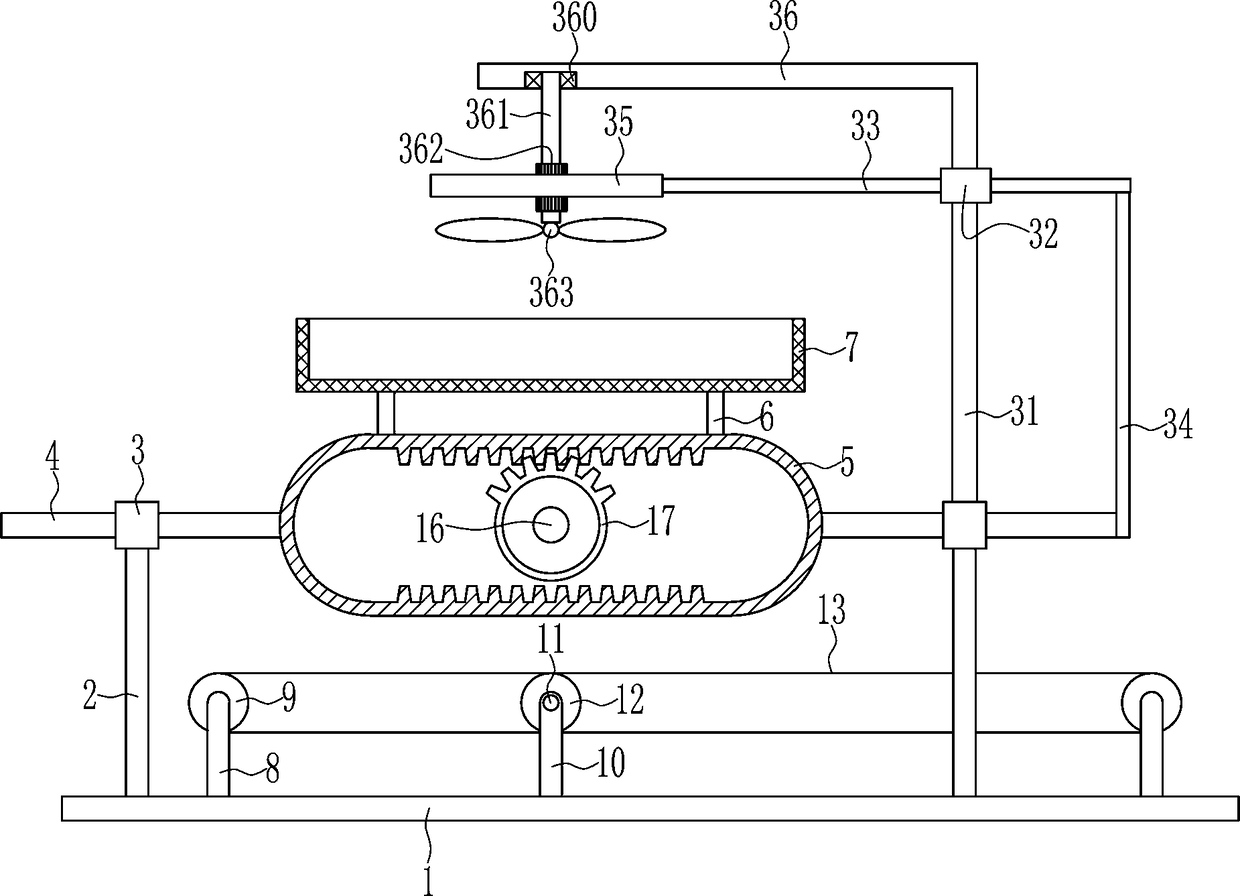

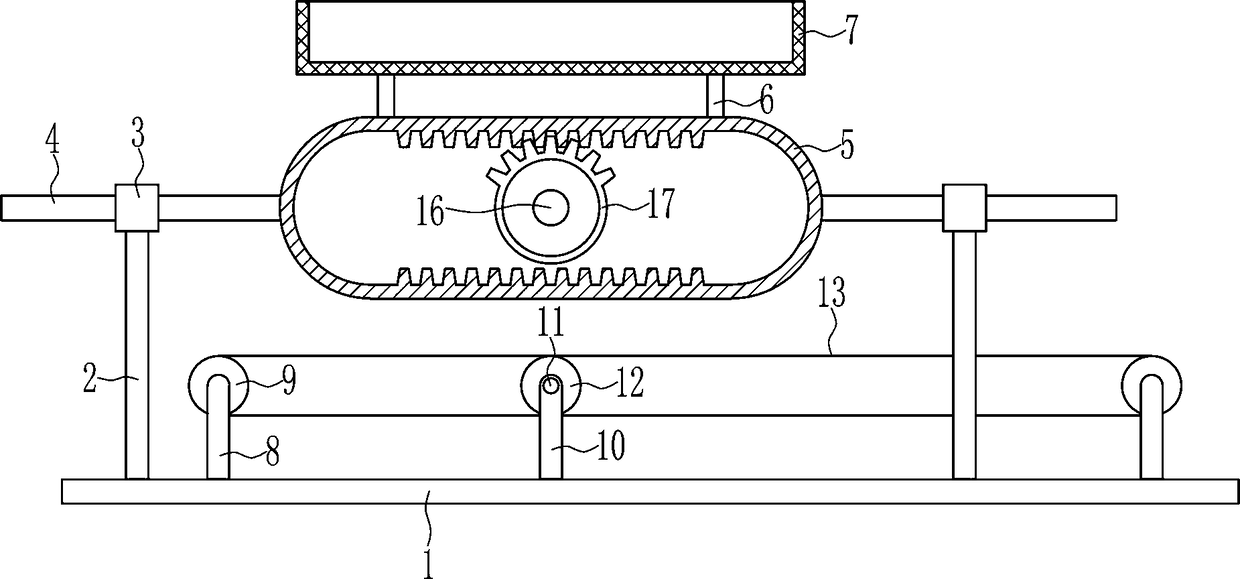

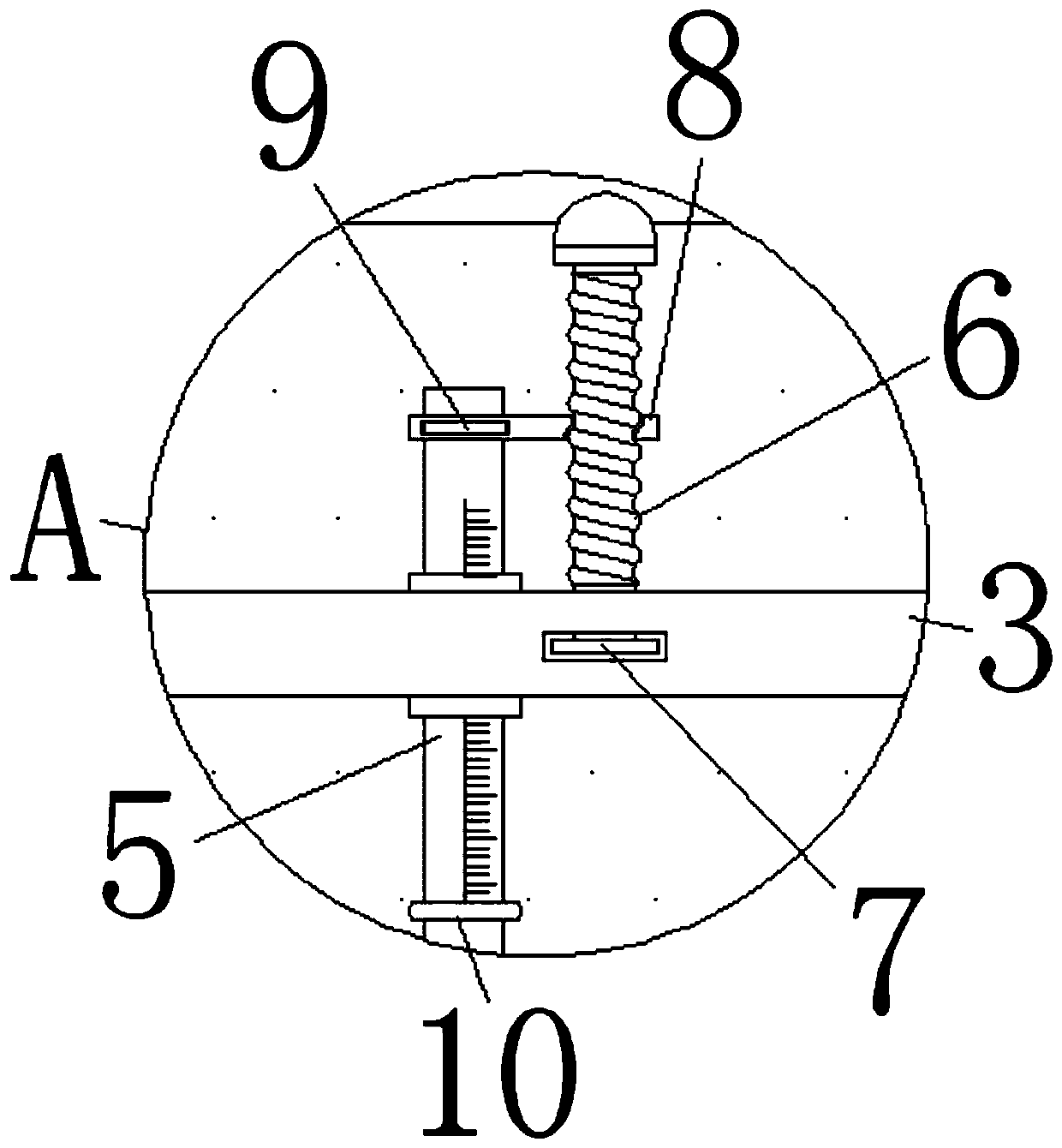

Grain screening device

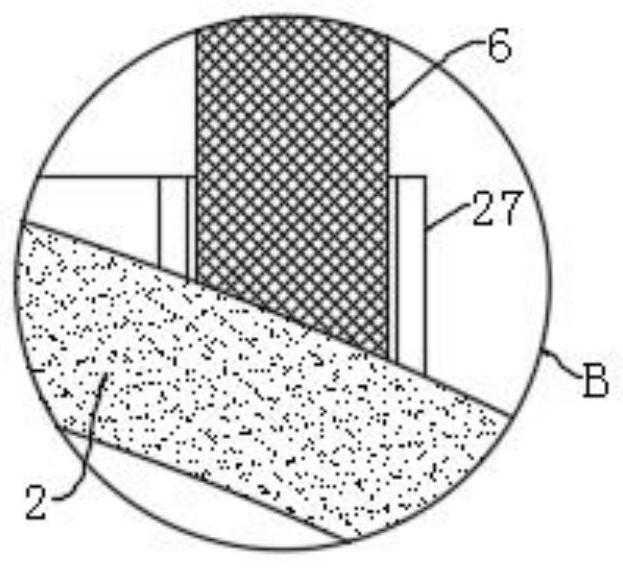

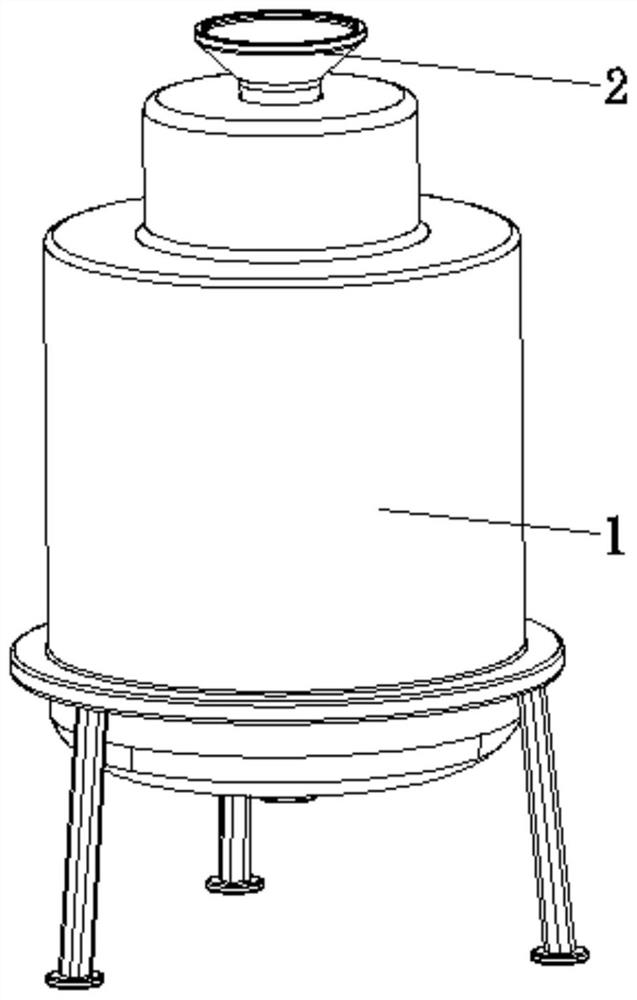

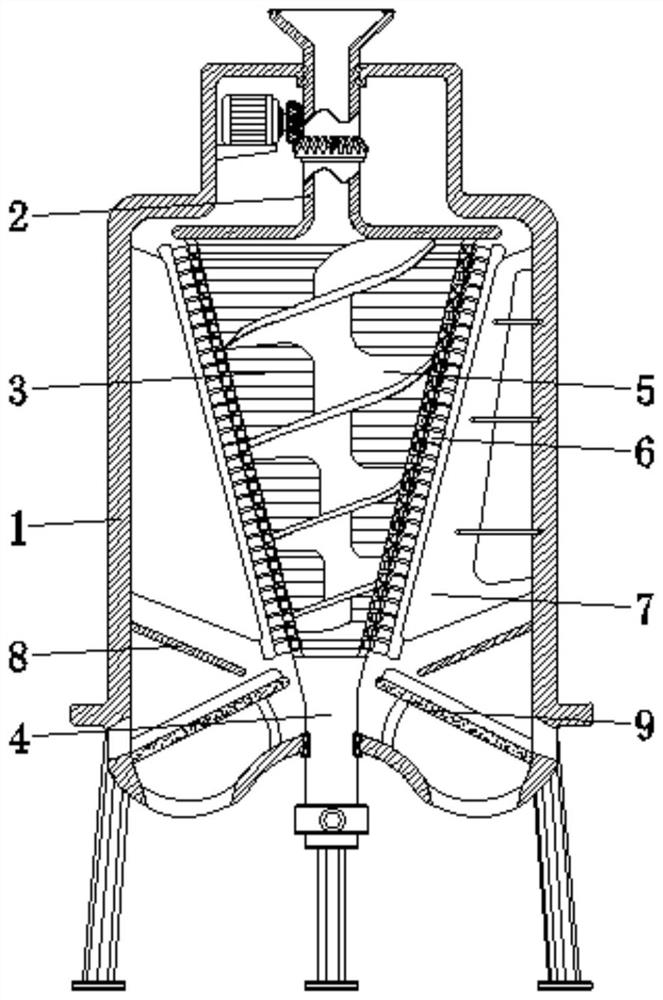

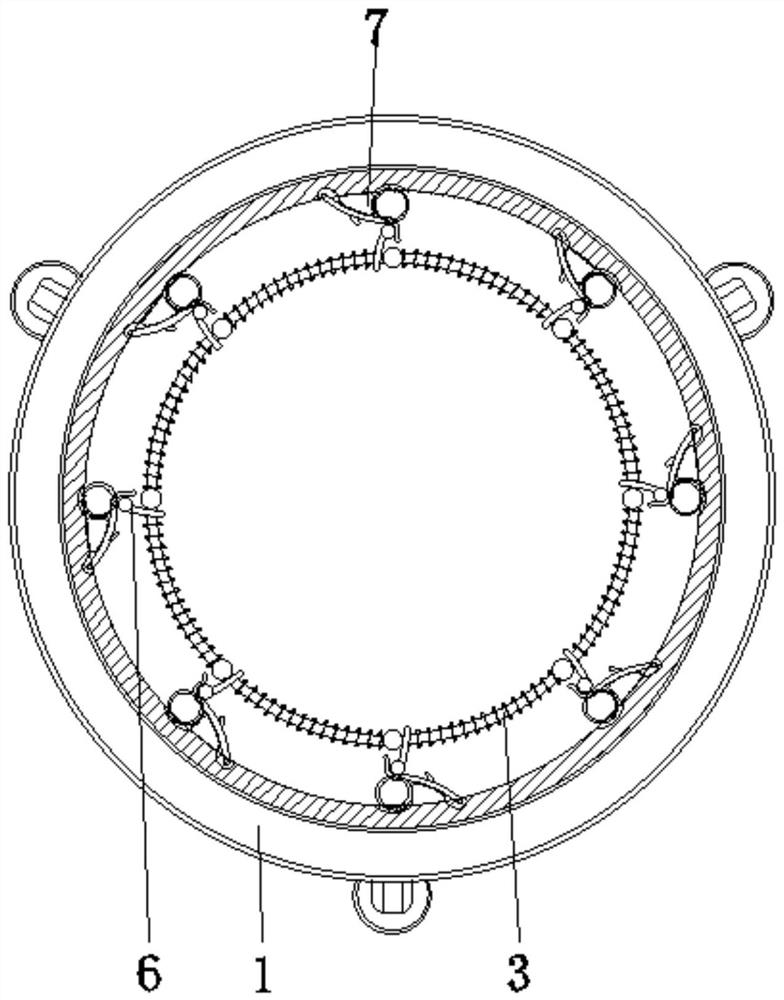

The invention discloses a grain screening device. The grain screening device comprises a base (1), a hopper (2), a vertical channel (3), an inclined channel (4), a fan (5), a swing plate (6), a swing rod (7), a bracket (8) and a transmission gear (9); and the bracket (8) is fixedly connected to the base (1), and is coated with an accommodating bag (10) for accommodating impurity-removed grains. The grain screening device, provided by the invention, is low in labor intensity of peasants and high in screening efficiency.

Owner:贵港市通达米业有限公司

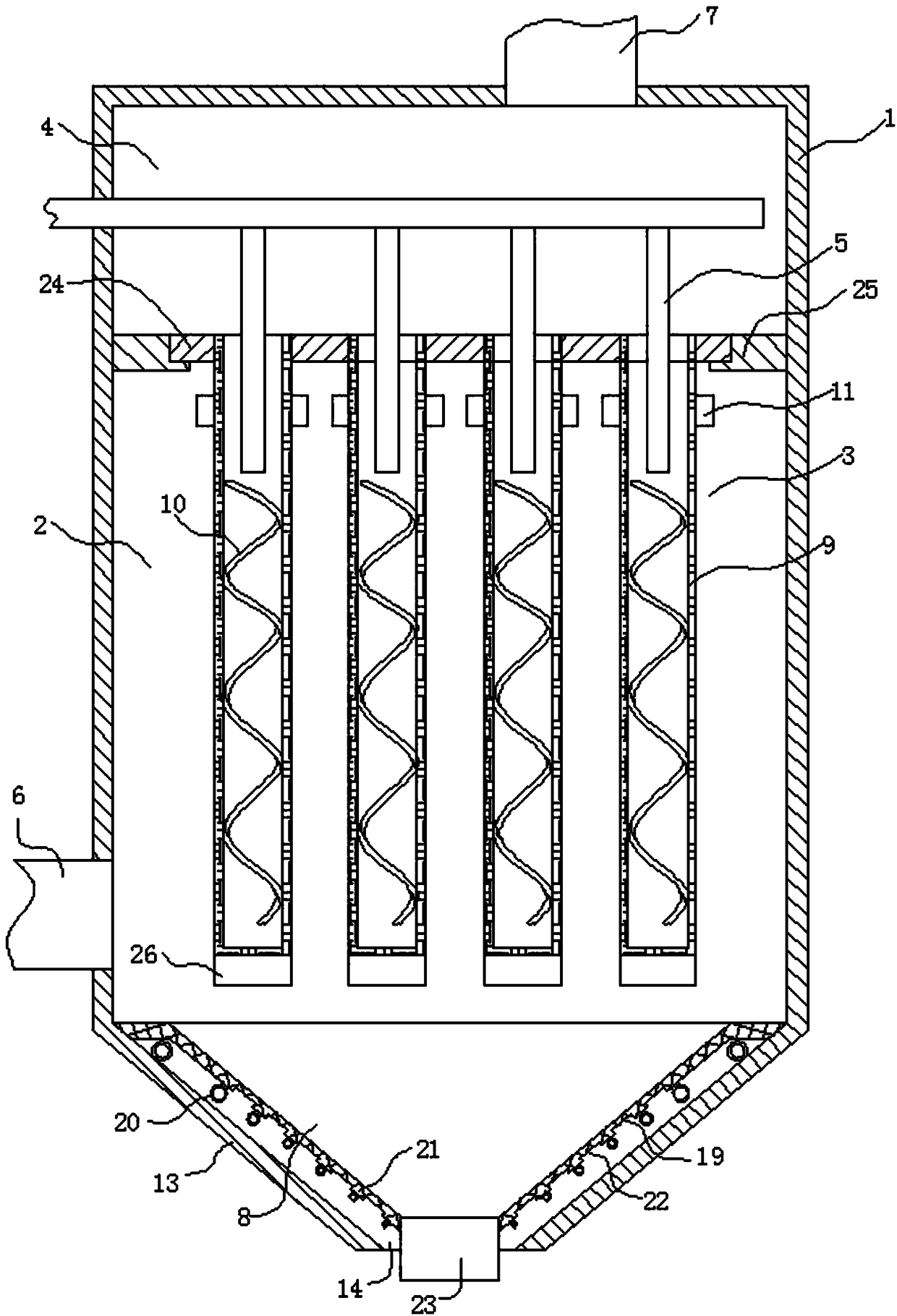

Novel high-efficiency dust remover

ActiveCN108465304AImprove cleaning efficiencyEasy to blow offDispersed particle filtrationEngineeringCharge pump

The invention discloses a novel high-efficiency dust remover comprising a box body, wherein a partition plate is arranged in the box body, the inner cavity of the box body is separated into an upper exhaust chamber and an underneath dust removing chamber by the partition plate, the upper end of a dust removing filter bag is installed in a dust removing filter bag mounting hole, the exhaust chamberis connected with the upper end opening of the dust removing filter bag, the exhaust chamber is internally provided with a back-blowing pipe for blowing air from the upper end opening of the dust removing filter bag into the dust removing filter bag, the bottom of the box body is further provided with a dust discharging chamber connected to the dust removing chamber, the bottom of the box body isfurther provided with a dust discharging device, the dust removing filter bag comprises an elastic bag body, and the inner surface of the elastic bag body is provided with an elastic air charging tube connected with the elastic bag body; an air charging pump is used for charging air to the elastic air charging tube, the elastic air charging tube expands to be larger to drive the elastic bag bodyto enlarge, and pores of the elastic bag body become large, so that when the back-blowing tube blows the air into the dust removing filter bag, accumulated dust outside the elastic bag body can be more easily blown off, and the cleaning efficiency of the elastic bag body can be effectively improved.

Owner:福建龙兰环保科技有限公司

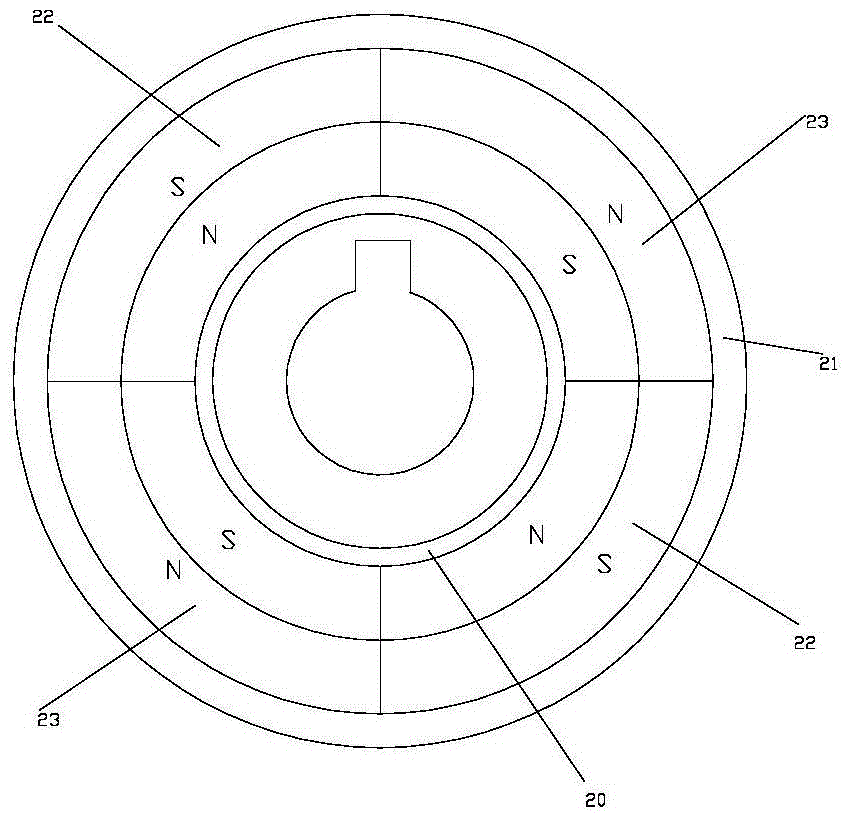

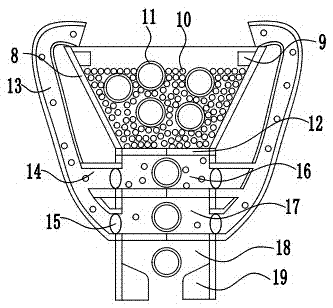

Working method for sorting device for bearing rings

ActiveCN105436089AEasy to sort and collectConvenient automatic sortingSortingMicrocontrollerEngineering

The invention discloses a working method for a sorting device for bearing rings. A motor is rotated to pour bearings into a hopper. By means of centrifugal force generated through rotation of the motor and the gravity of the bearings, the hopper directly feeds the bearings to an outer diameter detecting layer, a channel detecting layer and a surface detecting layer which are located at the lower portion one by one. When each layer is qualified through detection, a microcontroller controls electromagnets on overturning plates to be opposite to magnets on discharge pipes in magnetism, and the qualified bearing rings can smoothly enter the next procedure along a spiral channel. When the passing products are not qualified, the microcontroller enables the electromagnets on the overturning plates to be the same as the magnets on the discharge pipes in magnetism, the overturning plates block the channel, the discharge pipes are exposed, and the disqualified bearing rings are directly discharged along the discharge pipes. The sorting device for the bearing rings is small in occupied area, and can automatically sort different kinds of disqualified products.

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

Coal conveying side camera dust removal device for high-humidity area power plant

PendingCN112055140AAutomate cleaningSave human effortTelevision system detailsColor television detailsThermodynamicsDust control

The invention discloses a coal conveying side camera dust removal device for a high-humidity area power plant, and relates to the technical field of cameras, the coal conveying side camera dust removal device comprises a bottom plate, a camera is fixedly connected to the top of one side of the bottom plate, a first shell is fixedly connected to the top of the camera, and a fan and an electric heating wire are fixedly connected to the interior of the first shell; an air cavity is formed in the first shell, and a third shell is fixedly connected to the top of the side, away from the camera, of the bottom plate. According to the dustproof camera for pulverized coal conveying, through cooperation of the scraping plate, the fixing rod, the rotating disc, the ejector rod and the first motor, thescraping plate can automatically clean dust on the surface of the camera, manpower is saved, use is convenient, a good dustproof effect is achieved, and through cooperation of a fan, an electric heating wire, an air cavity and an air baffle, wet pulverized coal on the surface of the camera is dried through warm air, a scraper blade can conveniently clean the pulverized coal, dust cleaning is convenient and efficient, and application and popularization are facilitated.

Owner:SHANXI SANHESHENG IND TECH

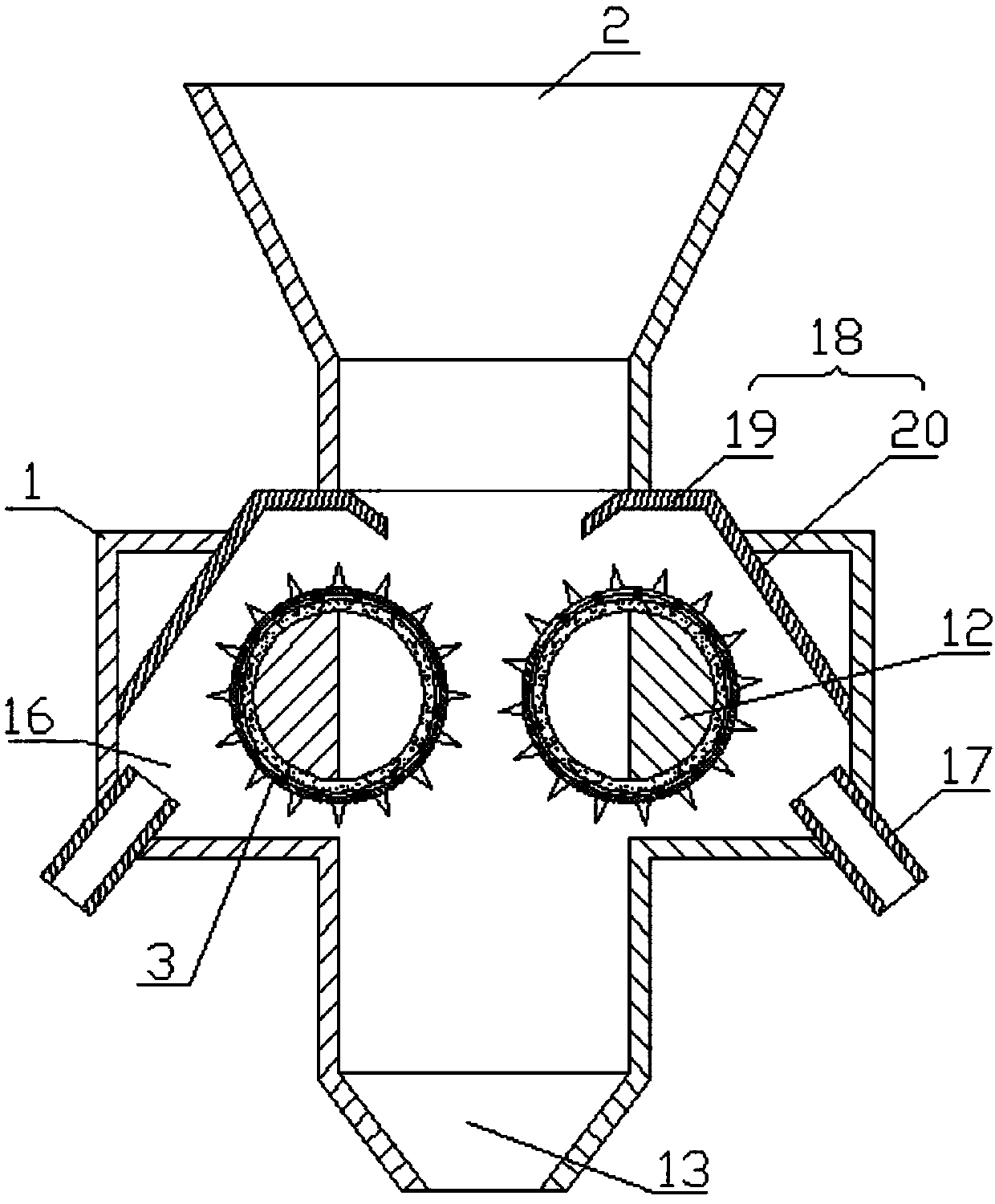

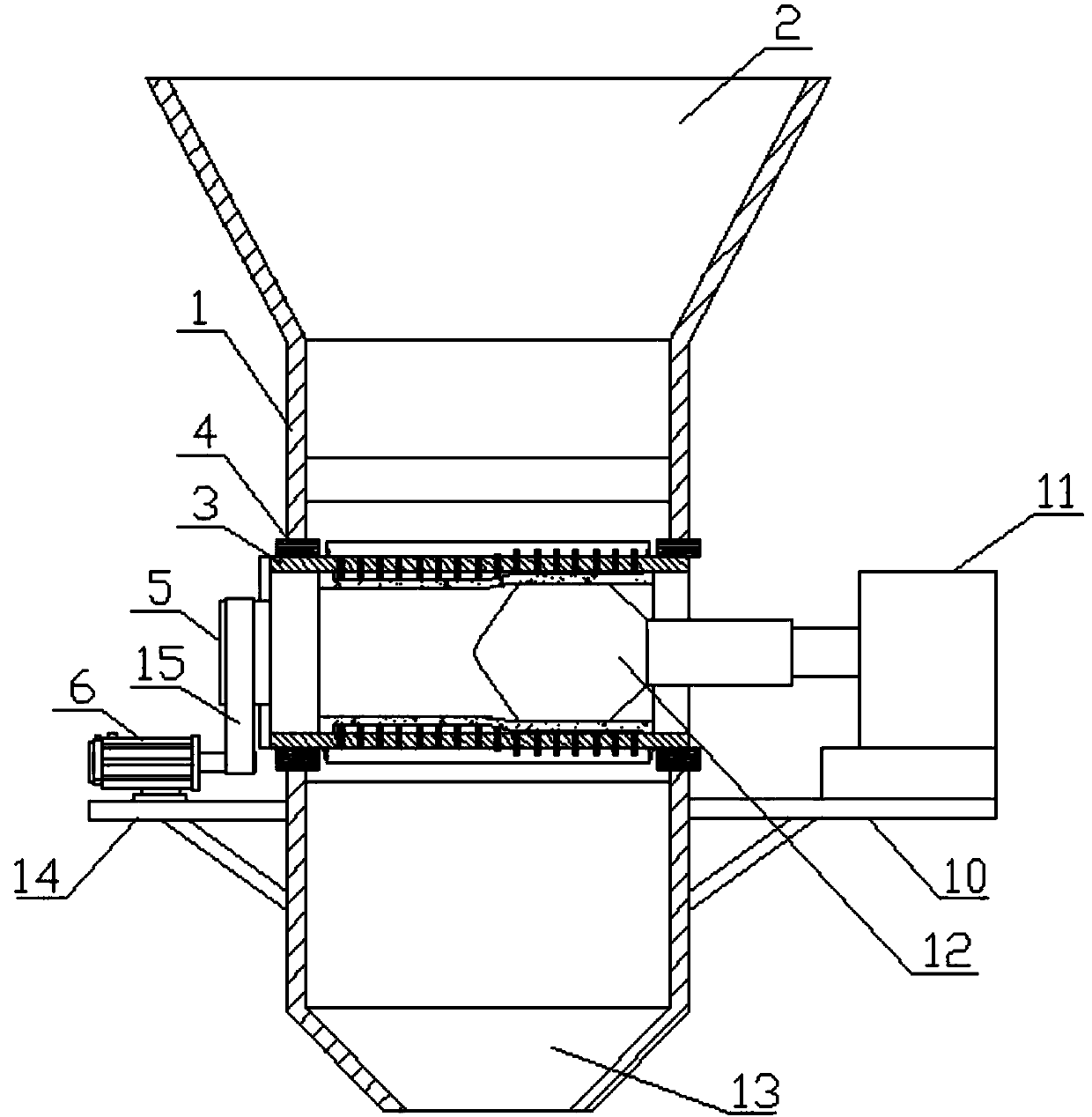

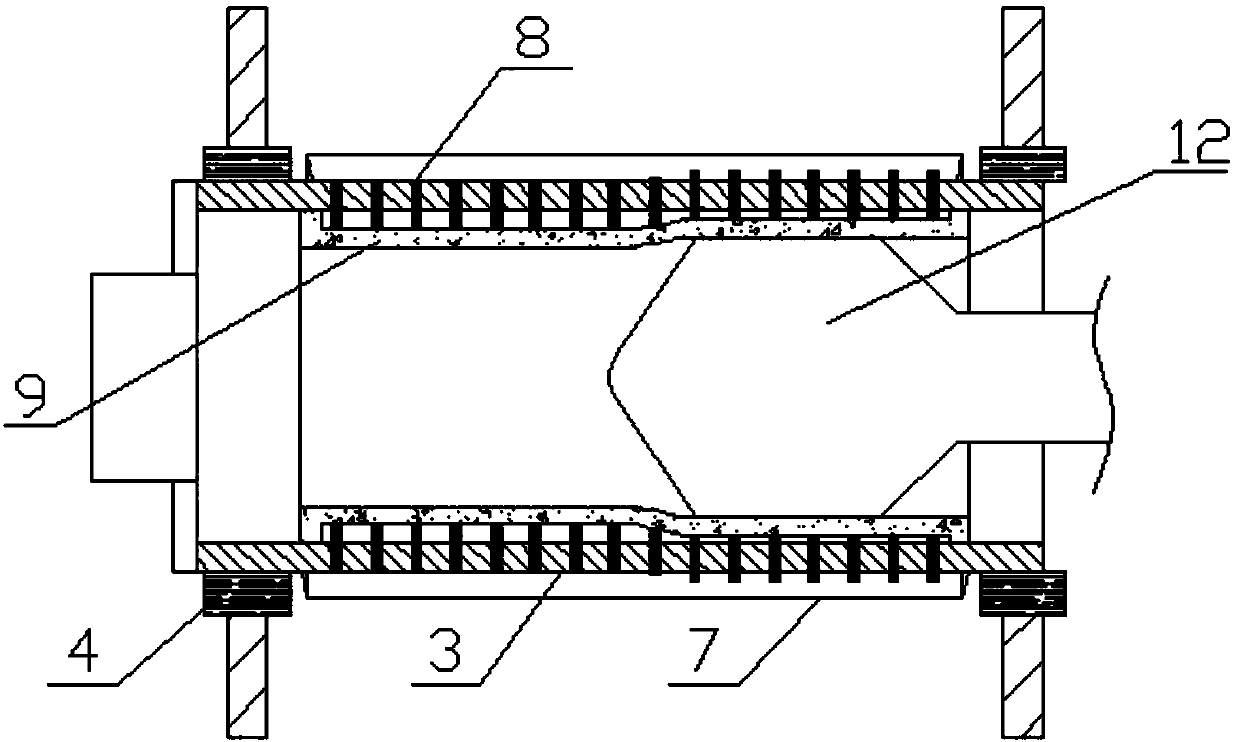

Self-cleaned double-roller type crushing machine

The invention discloses a self-cleaned double-roller type crushing machine which comprises a shell, wherein a feeding hopper is arranged at the upper end of the shell; a crushing chamber is arranged below the feeding hopper inside the shell; crushing rollers are arranged at intervals inside the crushing chamber; two side ends of the crushing rollers are opened; crushing teeth are arranged in an annular array manner on the outer surfaces of the crushing rollers; thimbles are arranged at intervals among adjacent crushing teeth; the thimbles moveably insert and extend into the crushing rollers; the tail ends of the thimbles are fixedly arranged on rubber sleeves; the rubber sleeves are fixedly arranged inside the crushing rollers; hole expanding devices are arranged inside the rubber sleeves;air inlet tubes are arranged below the crushing rollers on the shell; an air guide plate is arranged above the air inlet tubes inside the shell; a discharge hopper is arranged below the crushing chamber. The invention aims to provide the self-cleaned double-roller type crushing machine, residue twigs adhered to the crushing rollers can be separated from the crushing rollers, and thus the crushingquality is improved.

Owner:会同会泓新材料科技有限公司

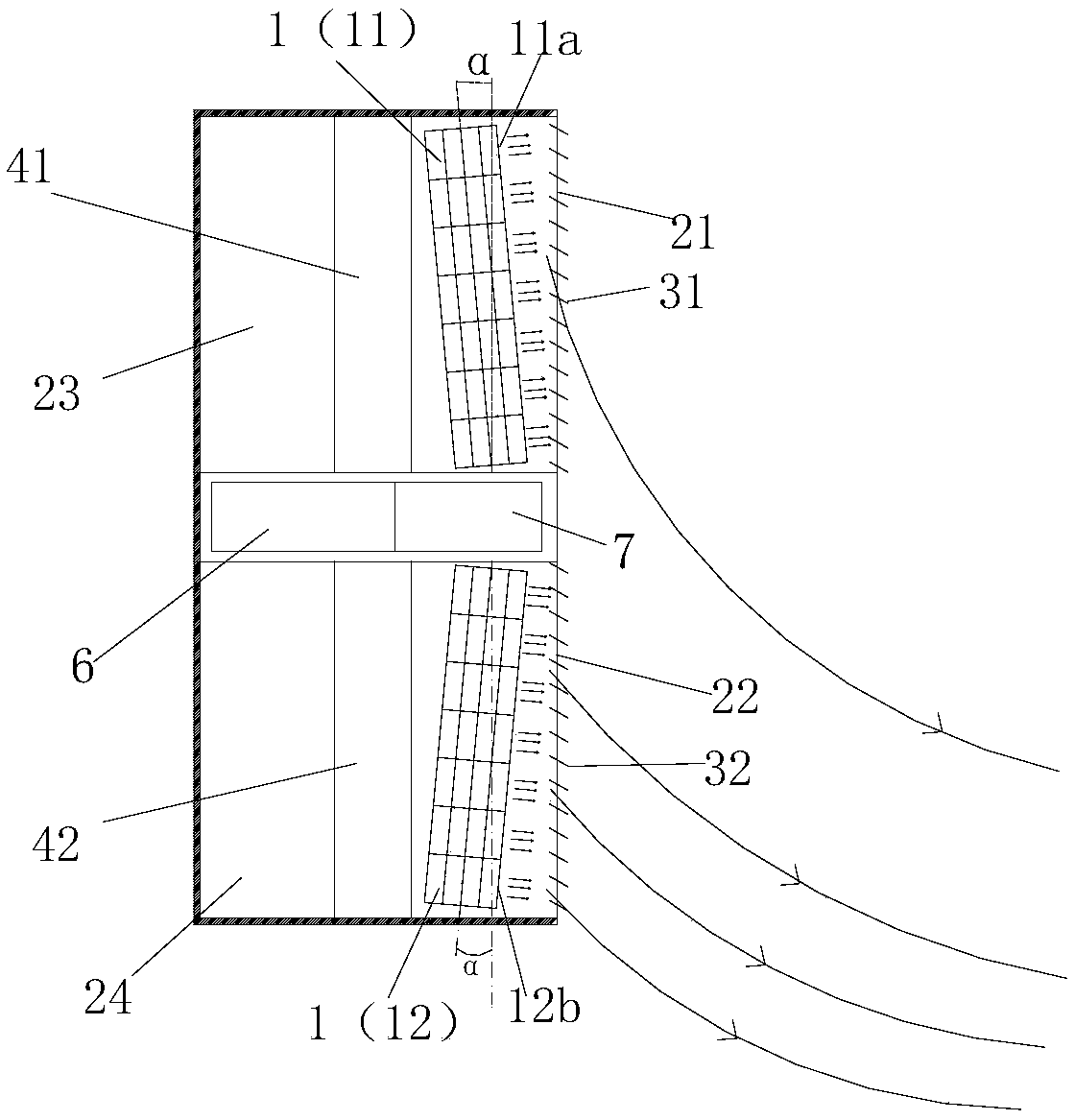

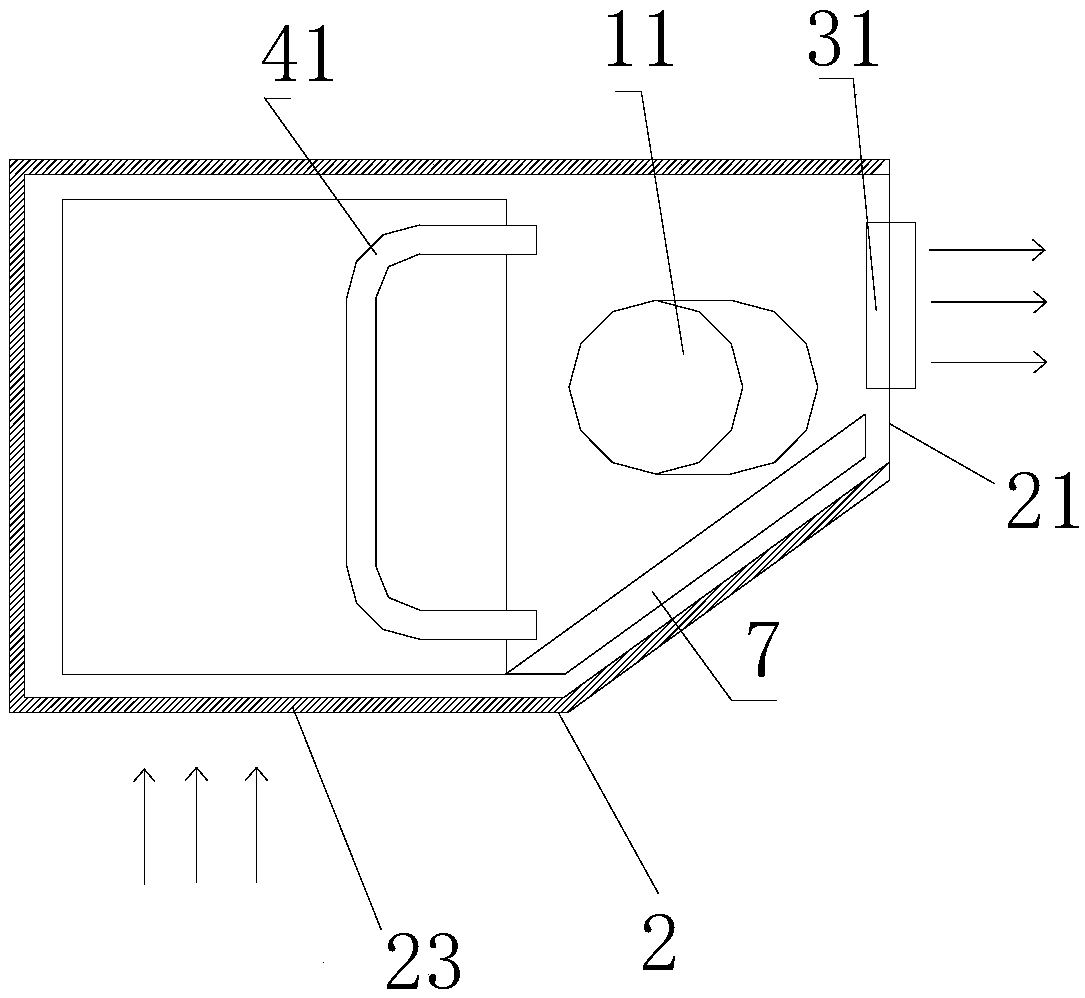

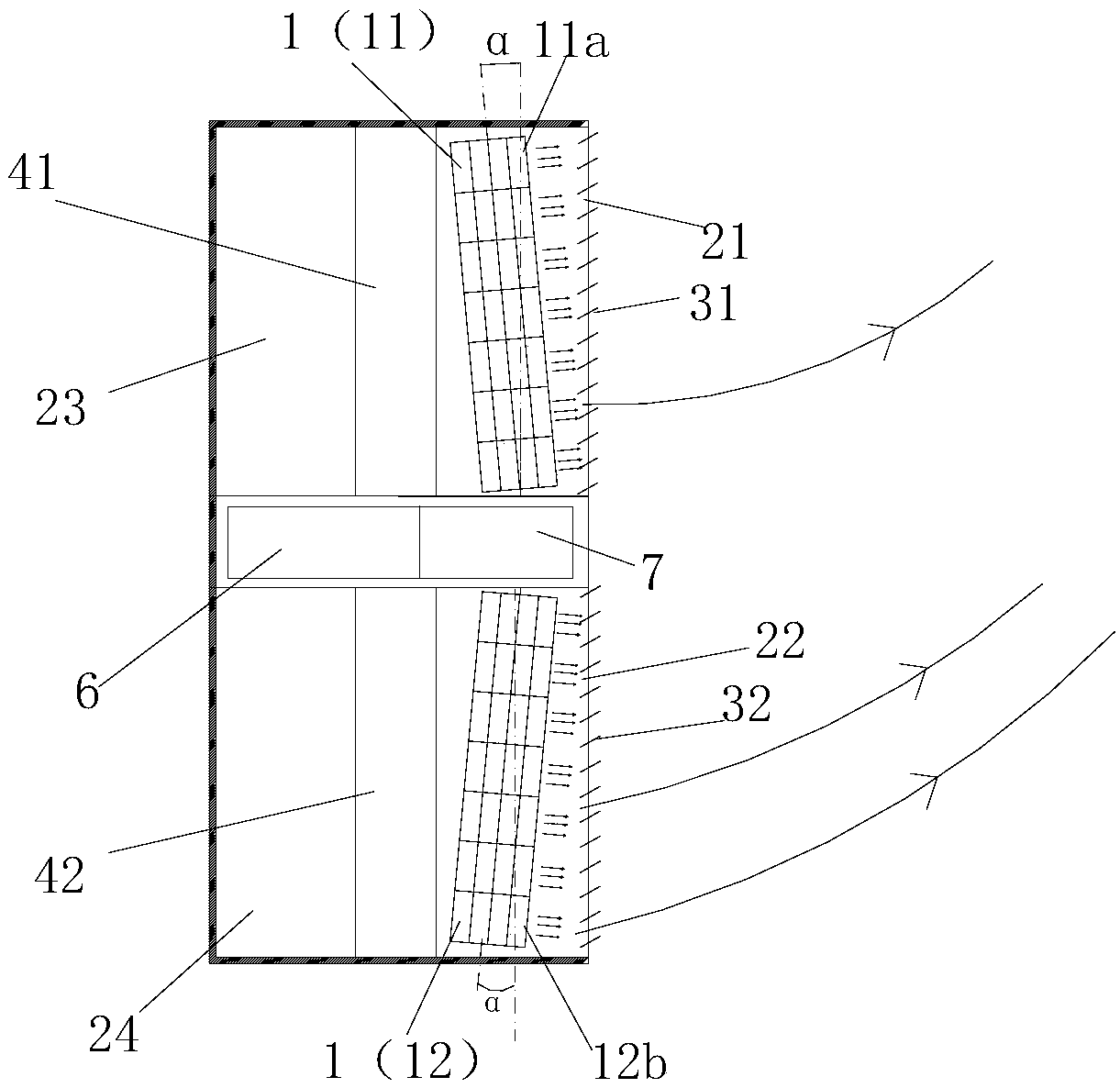

Air conditioner indoor machine, control method thereof and air conditioner

PendingCN108626800AEasy to blow offIncrease floor air volumeSpace heating and ventilation safety systemsLighting and heating apparatusThermal comfortRoom temperature

The invention provides an air conditioner indoor machine, a control method thereof and an air conditioner. The air conditioner indoor machine comprise a cross flow fan blade (1), the axis direction ofthe cross flow fan blade (1) is inclined relative to the vertical direction, and an included angle a is formed; and the included angle is larger than 0 degree and is smaller than 90 degrees, so thata wind outflow face (11) of the cross flow fan blade (1) makes wind flow out obliquely and downwardly. Due to the air conditioner indoor machine, the control method thereof and the air conditioner, airflow during heating of the air conditioner can be downwards conveyed, hot air can be blown to the ground more easily, the amount of hot air falling to the ground is increased, and therefore the airflow flowing direction requirement during heating can be well met, a user can personally experience the warming effect from the feet to the head, the room temperature effectively meets the set requirement, and the user can have a very good heating comfort effect.

Owner:GREE ELECTRIC APPLIANCES INC

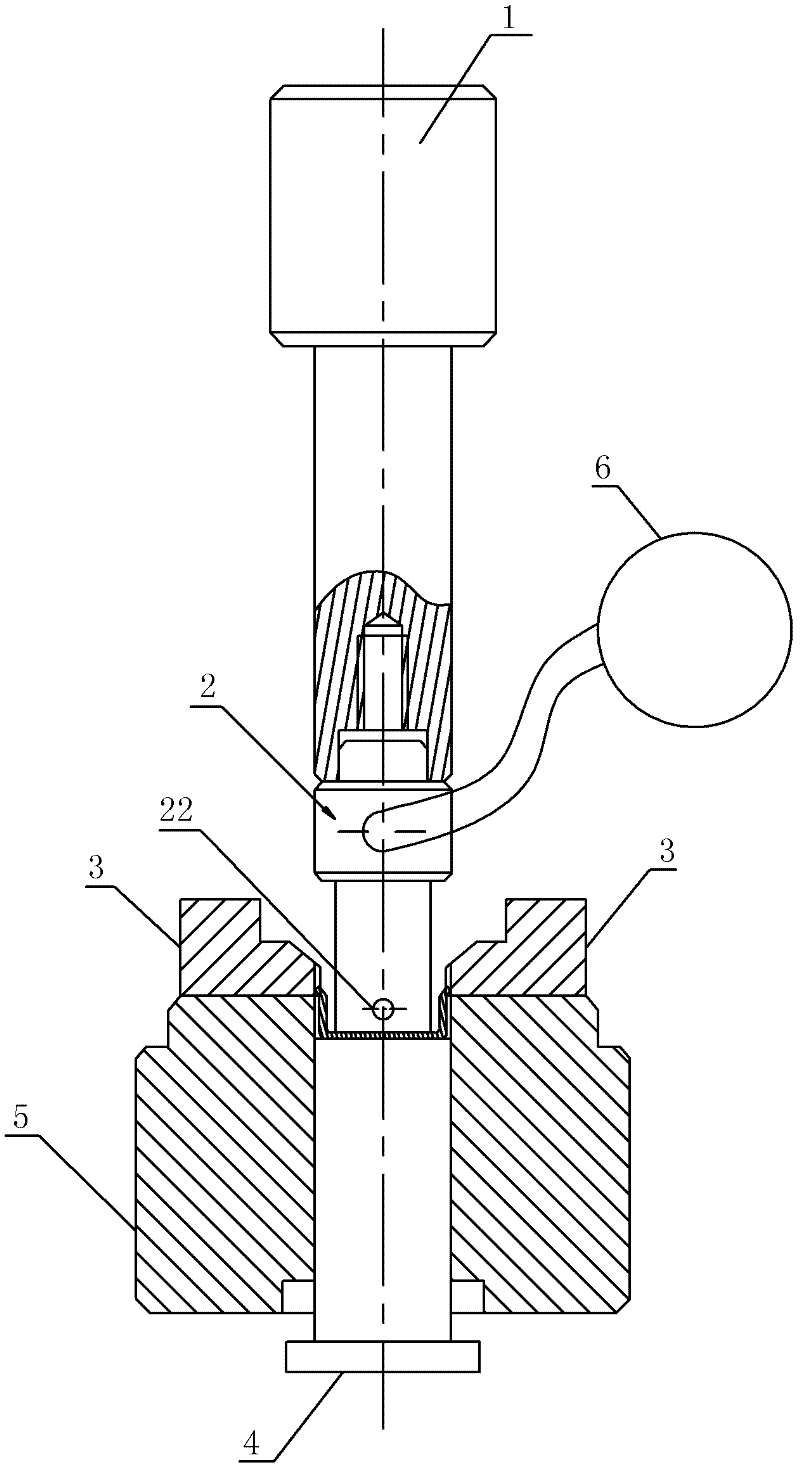

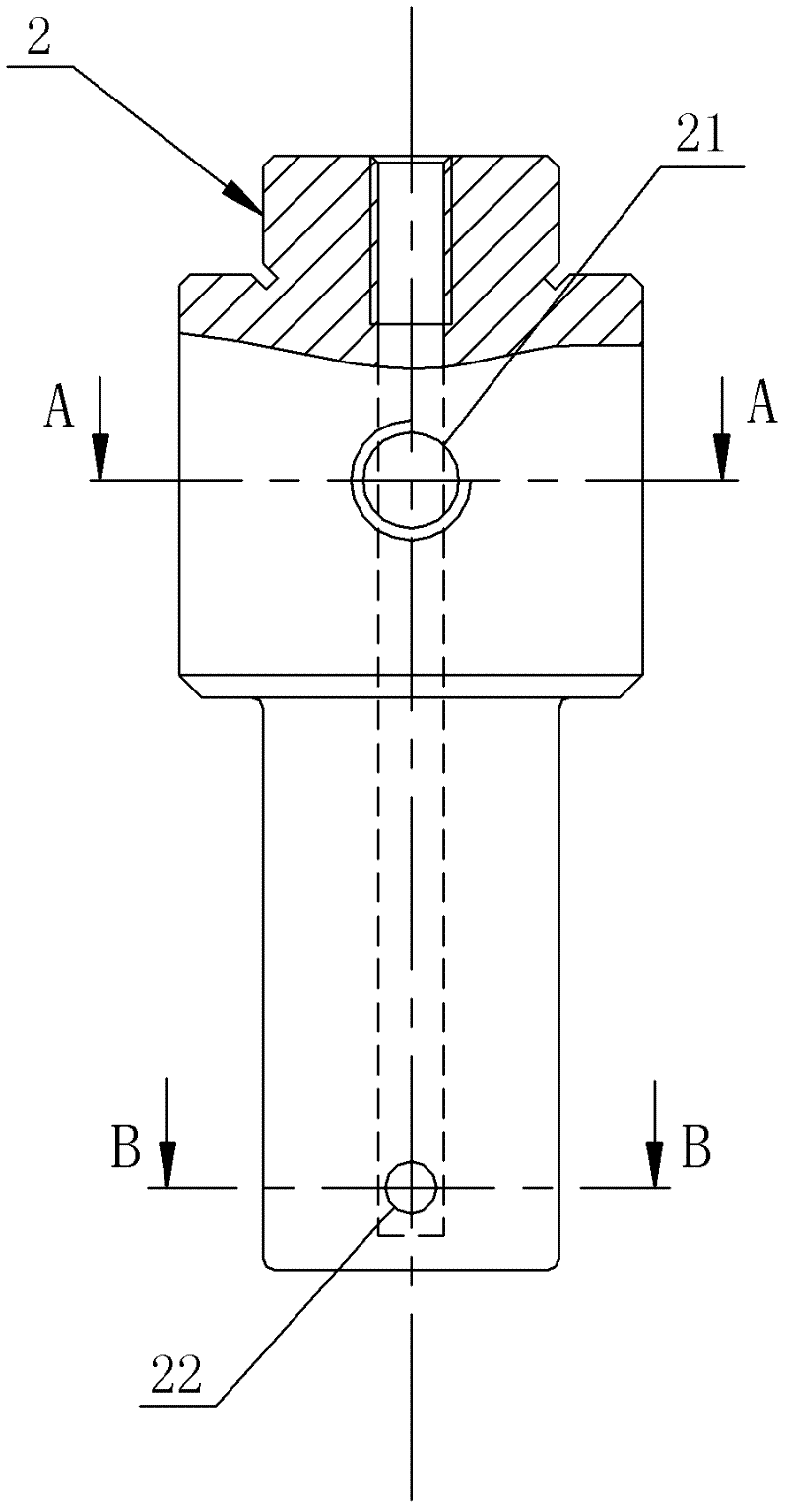

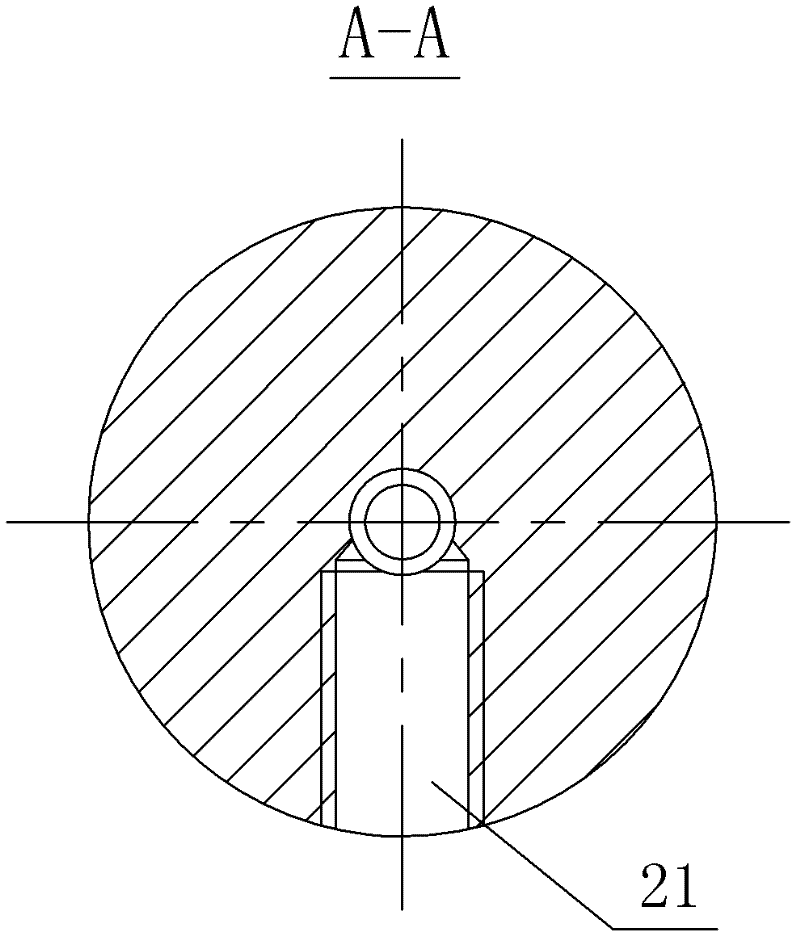

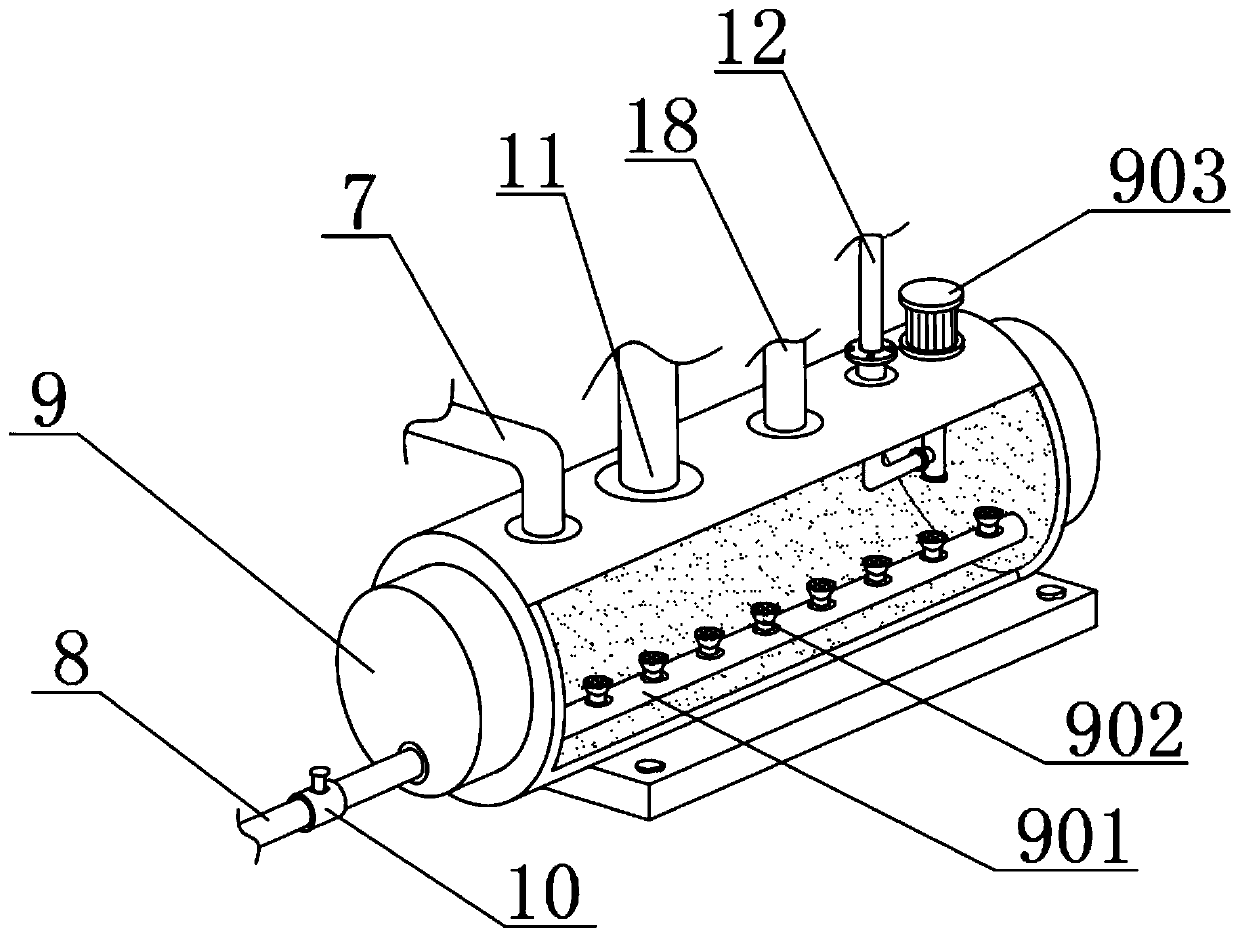

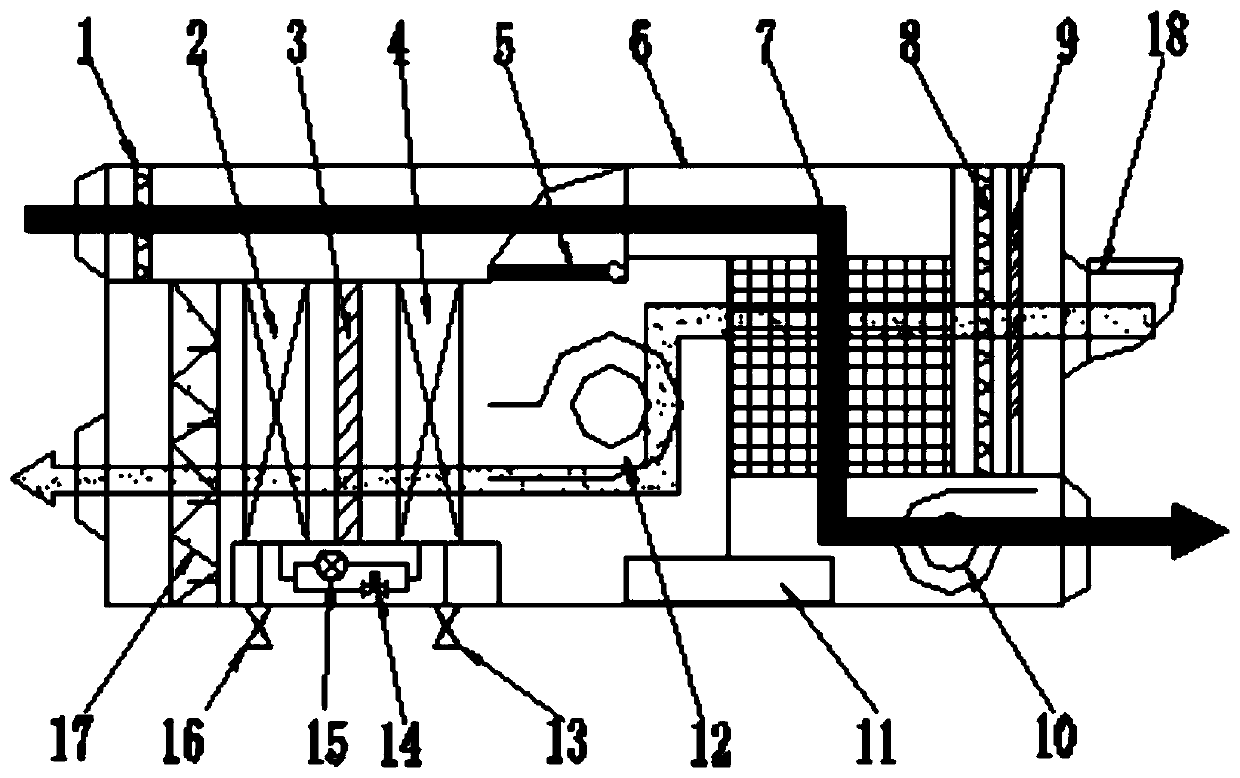

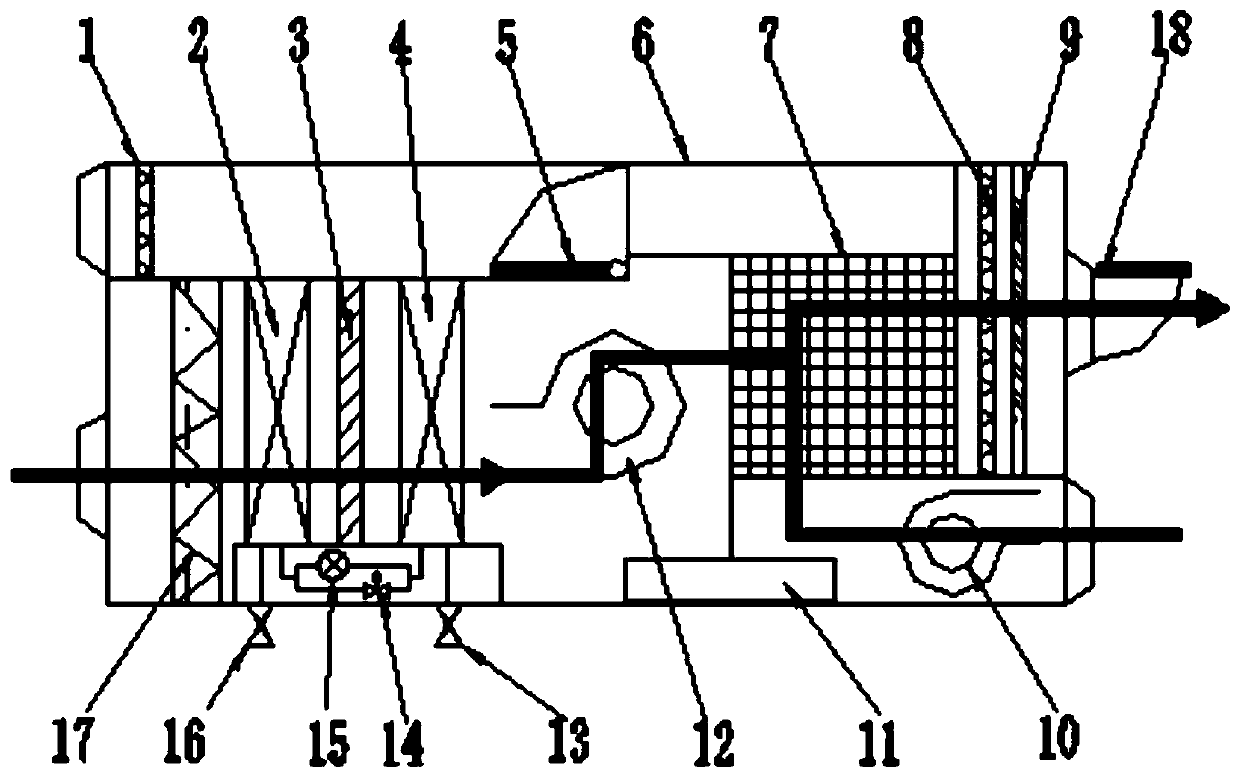

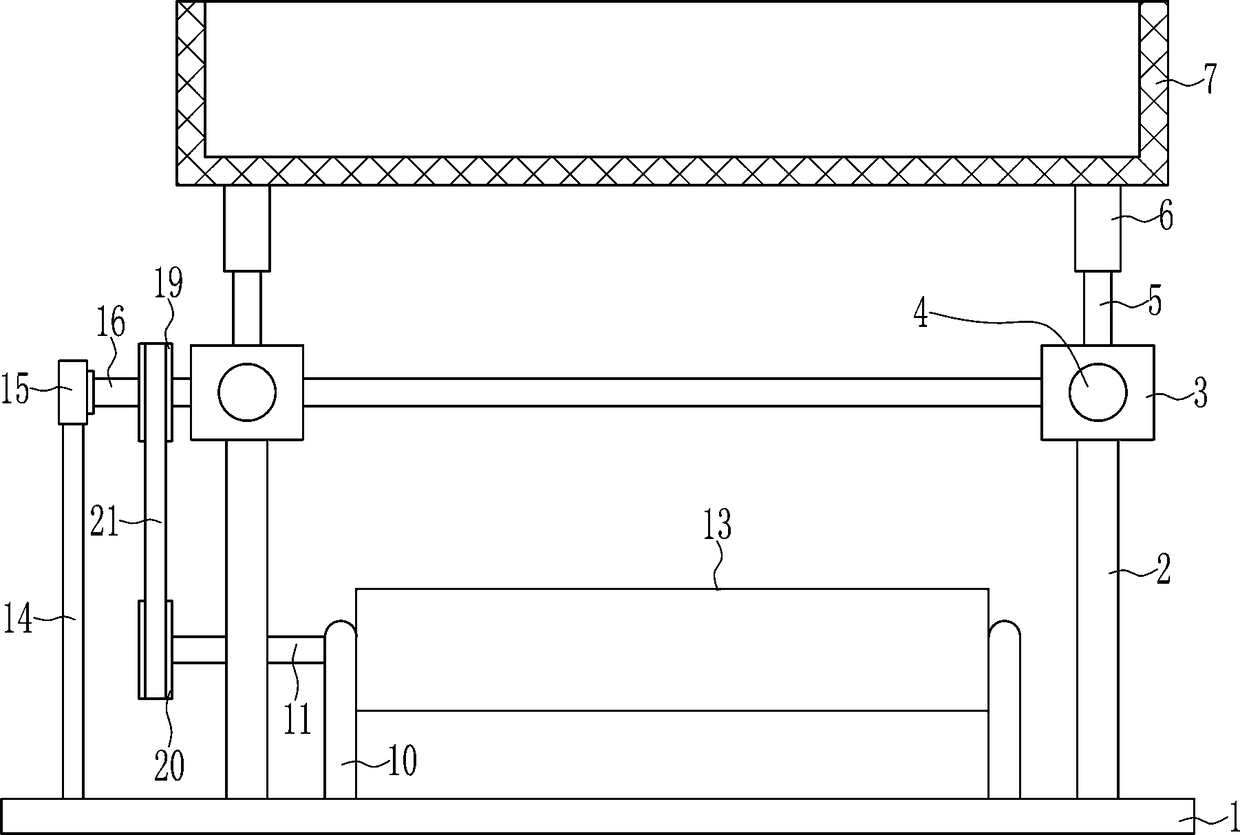

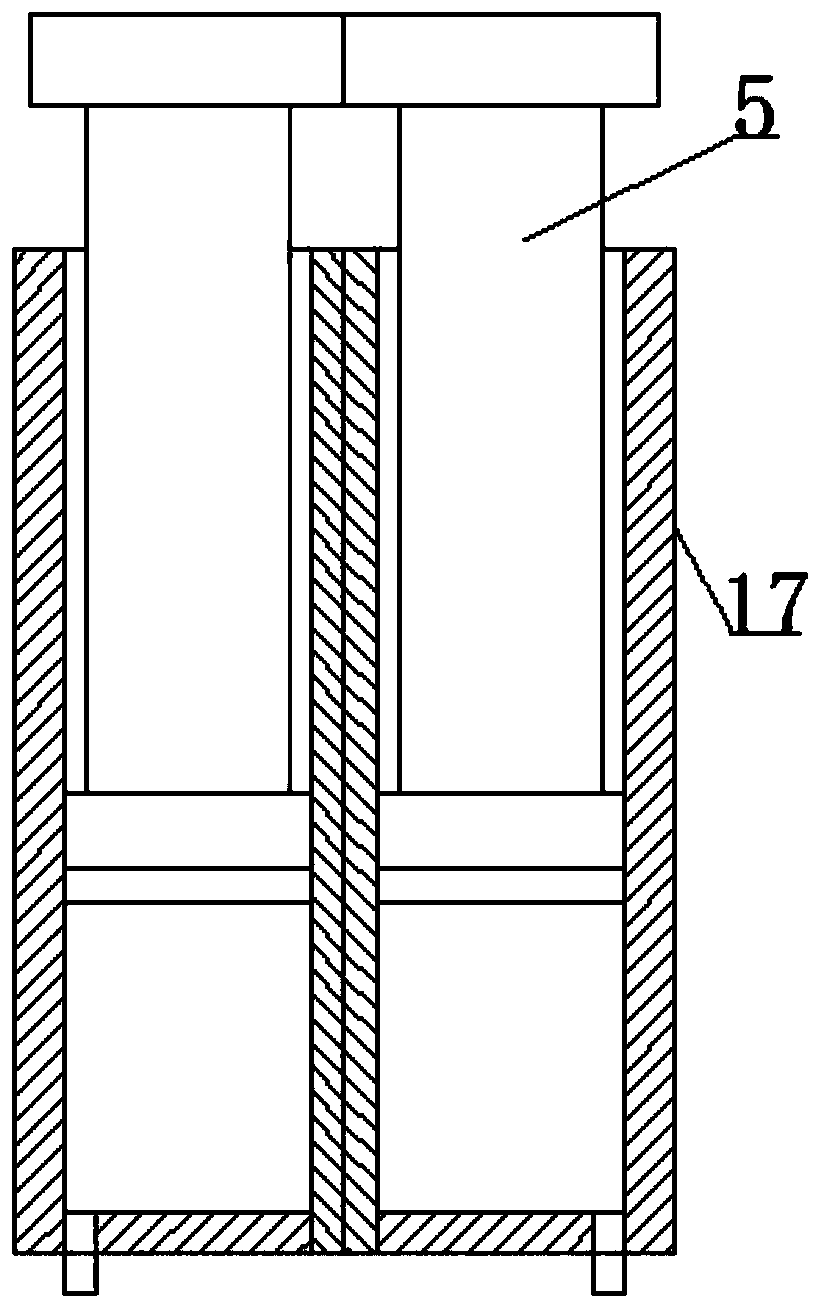

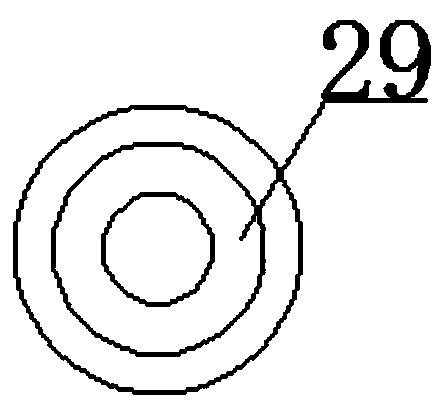

Blowing device of multi-station pressure machine

ActiveCN102514229AEasy to blow offStable deliveryForging/hammering/pressing machinesPressesEngineeringCushion

The invention relates to the technical field of blowing devices, in particular to a blowing device for a multi-station pressure machine, which comprises a die shank, a cylindrical blowing convex die, two clamping blocks, a material withdrawing core, a cushion block with inner holes and an air supply device used for providing an air source. The lower end of the die shank is fixedly connected with the top of the blowing convex die, an air inlet hole is arranged in the middle of the blowing convex die, a plurality of air outlet holes which are circumferentially uniformly distributed are disposed on the outer wall of the lower portion of the blowing convex die, the air supply device is communicated with the air inlet hole by a pipeline, the two clamping blocks are oppositely disposed on two sides of the bottom end of the blowing convex die, the top of the cushion block contacts with bottom surfaces of the two clamping blocks, and the material withdrawing core is inserted in an inner hole of the cushion block. An airflow method is adopted, the air supply device is used for the blowing device of the multi-station pressure machine, accordingly, strong airflow is conveniently used for blowing impurities away from the surface of a workpiece, simultaneously, the workpiece can be clamped due to the design of the clamping blocks while a correction effect can be realized, and the workpiece can be stably conveyed to a next station.

Owner:JIANG SU NAN FANG BEARING CO LTD

Powder sealing valve

InactiveCN102042417AGuaranteed cleanlinessSolve the sticky problemCleaning using gasesLift valveEngineeringNitrogen gas

The invention discloses a powder sealing valve comprising a valve body, a sweeping mechanism, a valve core and an executing mechanism; the valve core is arranged in the valve body to open and close the valve under the effect of the executing mechanism; the sweeping mechanism is an annular gas chamber; the annular gas chamber is also arranged in the valve body; the valve core is in sealed contact with the gas chamber; the sealing surfaces of the valve core and the gas chamber are both spherical surfaces; the annular gas chamber is provided with a gas inlet and a gas outlet; and the gas outlet is arranged on the sealing surfaces of the gas chamber and the valve core. In the invention, the annular gas chamber is arranged in the valve body, the gas inlet is arranged outside the gas chamber, the gas outlet is arranged on the sealing surfaces of the interior of the gas chamber and the valve core, and dry gas (compressed gases of air and nitrogen can be selected according to conditions for use) is injected between the sealing surfaces to keep the sealing surfaces clean by means of the sweeping of gas flow, thereby solving the problem of material sticking, realizing reliable sealing and achieving zero leakage.

Owner:LIMIN CHEM CO LTD

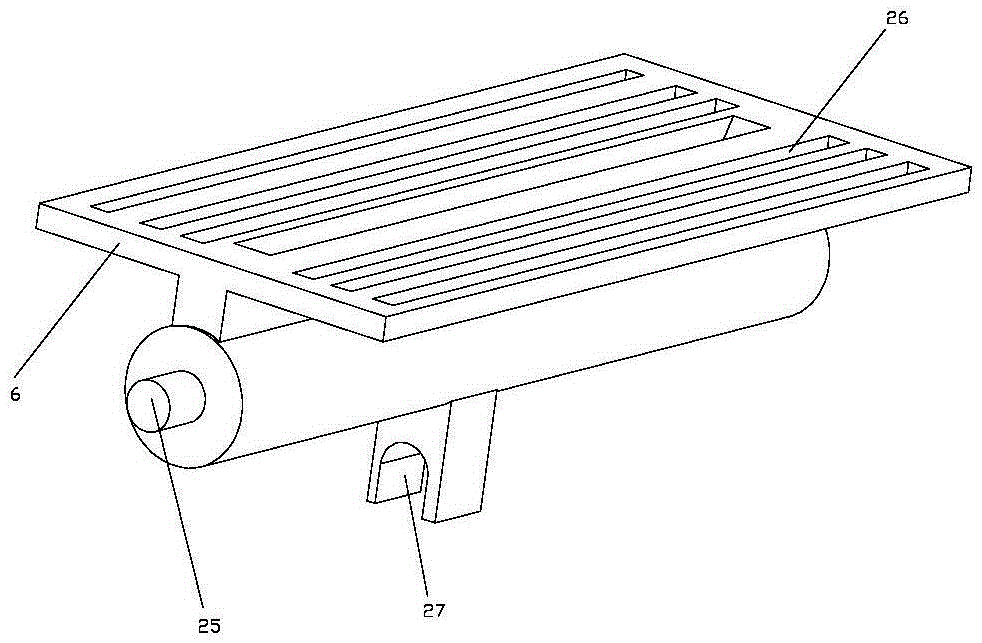

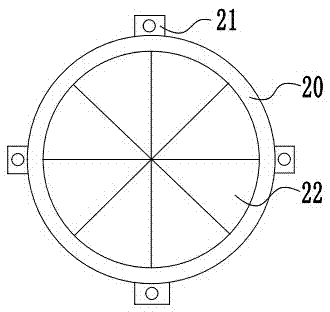

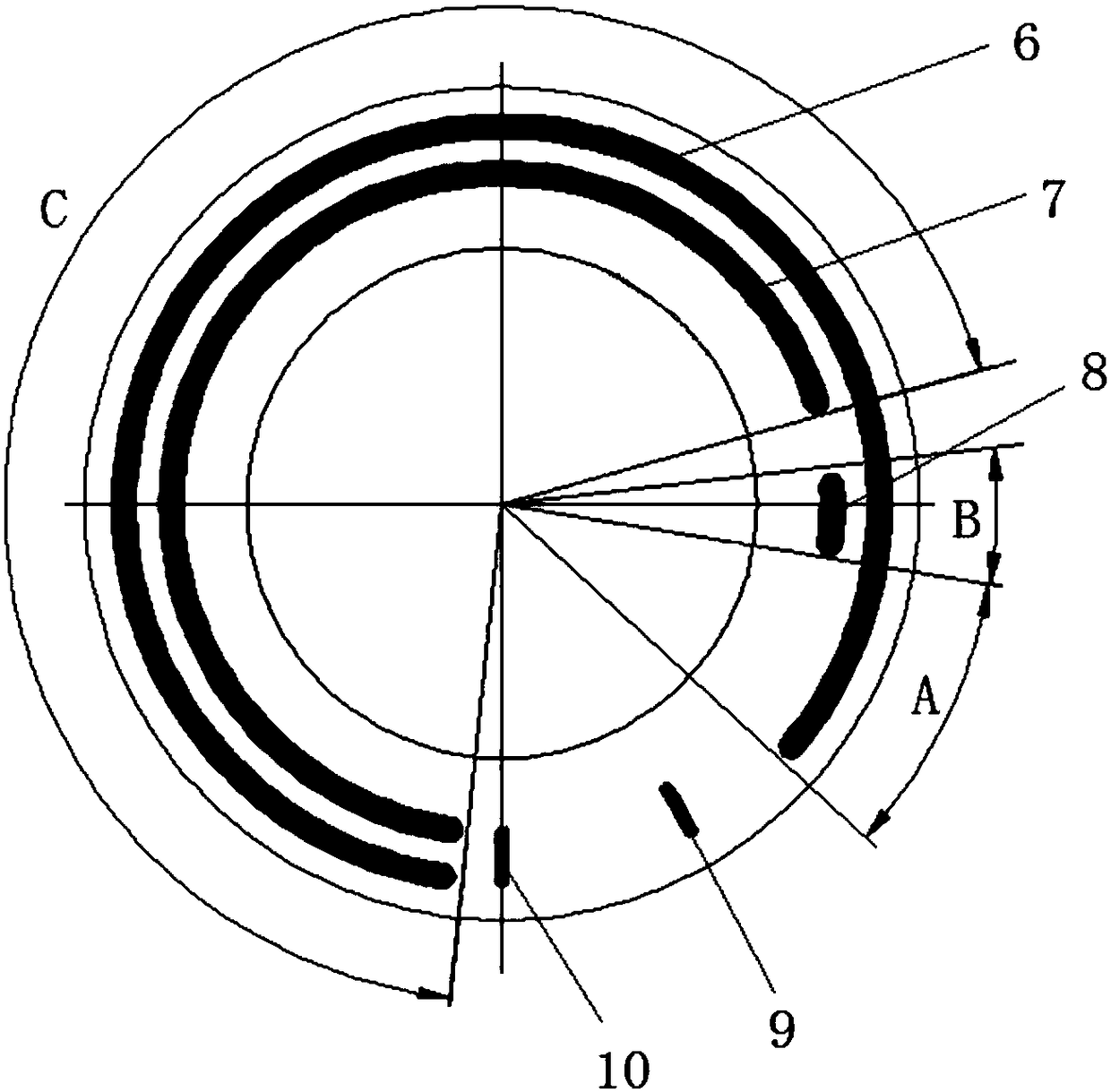

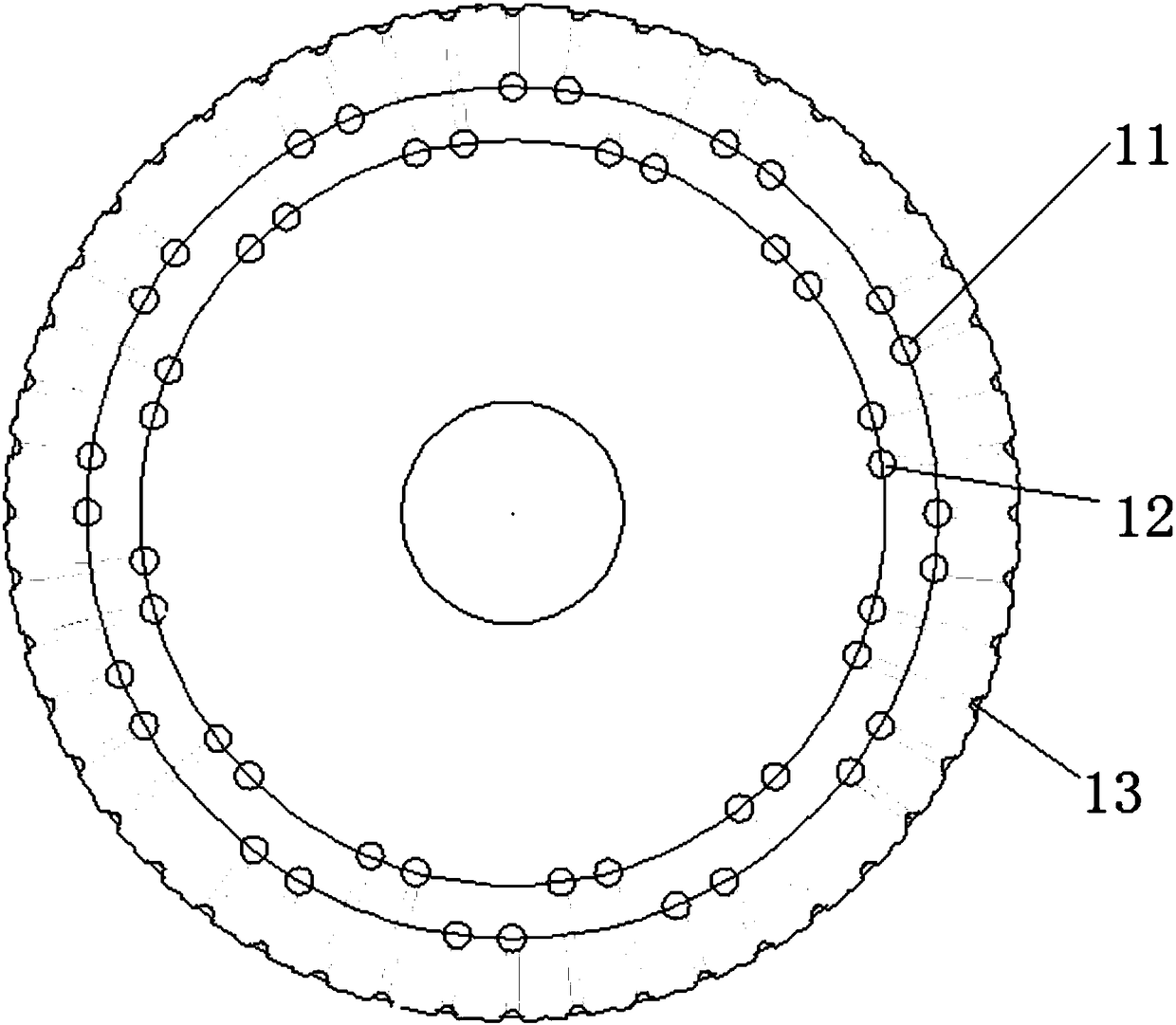

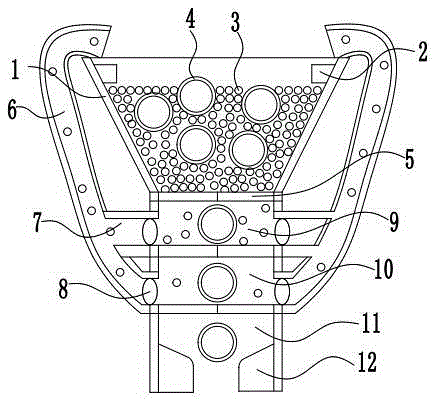

Air distribution plate for preparing double-filter-capsule filter rod and preparation device

The invention discloses an air distribution plate for preparing double-filter-capsule filter rod and a preparation device. The air distribution plate comprises a plate body, an inside suction slot, anoutside suction slot and an alternating air blowing structure, wherein the inside suction slot and the outside suction slot are both arranged on the plate body, an arc-shaped groove body is coaxial with the plate body, a radius of the inside suction slot is less than that of the outside suction slot, and one end of the inside suction slot is radially flush with one end of the outside suction slot; the central angle of the outside suction slot is 90-340 degrees, the central angle of the inside suction slot is at least 30 degrees, and at least 30 degrees smaller than that of the outside suctionslot; the alternating air blowing structure is arranged at one end of the inside suction slot radially flush with the outside suction slot; the inside suction slot and the outside suction slot are connected with a vacuum pump, the vacuum pump provides negative pressure for adsorbing negative pressure of a filter capsule; the alternating air blowing structure is connected with the air source, andprovides positive pressure for transferring the filter capsule to next process.

Owner:山东将军烟草新材料科技有限公司

System and method for producing refined sulfuric acid through pyrite acid manufacturing system

The invention discloses a system and method for producing refined sulfuric acid through a pyrite acid manufacturing system, and relates to the technical field of chemical engineering. The system for producing the refined sulfuric acid comprises a refined acid tower; a first smoke discharging port is connected to the upper end of the refined acid tower in a penetrating mode; a smoke feeding port isinstalled in one side of the lower end of the refined acid tower; a smoke feeding pipe is connected to one end of the smoke feeding port in a penetrating mode; and a gas valve A for controlling the feeding quantity of sulfur trioxide smoke is installed between the smoke feeding port and the smoke feeding pipe. According to the design, refined acid overflowing parts are lined with tetrafluorohydrazine, so that iron dissolved in acid is reduced; deionized water is adopted to adjust the concentration of the refined acid; dried air is utilized for air stripping of dissociative sulfur dioxide dissolved in the refined acid; the concentration of the dissociative sulfur dioxide in the acid is lowered; and the problem that in traditional pyrite acid manufacturing production, the content of industrial sulfuric acid impurities is relatively high, and particularly iron ions and the dissociative dioxide exceed a standard, so that the refined acid quality requirements cannot be achieved, and the economic value is reduced is solved.

Owner:ZHAOYUAN ZHAOJIN JINHE TECH

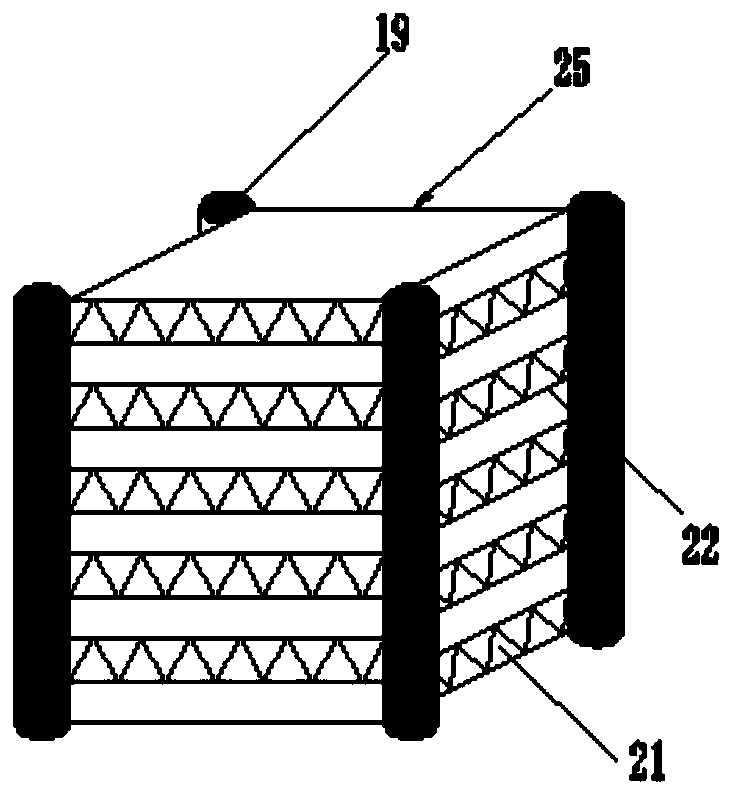

Fresh air system with heat exchange core and air conditioner

InactiveCN110986213AImprove heat transfer efficiencyFlow preventionEnergy recovery in ventilation and heatingMechanical apparatusFresh airEngineering

The invention provides a fresh air system with a heat exchange core, and the system comprises a shell; a fresh air duct and an air return duct which are distributed in a staggered mode are arranged inthe shell, and the heat exchange core is arranged at the intersection of the fresh air duct and the air return duct; a filtering device is arranged at an inlet of the fresh air duct, a fresh air fanis arranged in the middle of the fresh air duct, and the heat exchange core is located between the filtering device and the fresh air fan; an electric controller is arranged at one side in the shell.A heat exchanger assembly and a humidifying and filtering assembly are arranged at the other side of the fresh air duct; an air return fan is arranged at the side, close to the heat exchange core, ofthe air return duct, and a filtering component is arranged at the other side. The invention also discloses an air conditioner, and the air conditioner comprises the fresh air system; the fresh air system is provided with the heat exchange core. By improving the cleaning effect of the core body, the cleanliness of circulating gas is improved, the adverse effect of dust on use is reduced, and the service life of equipment is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

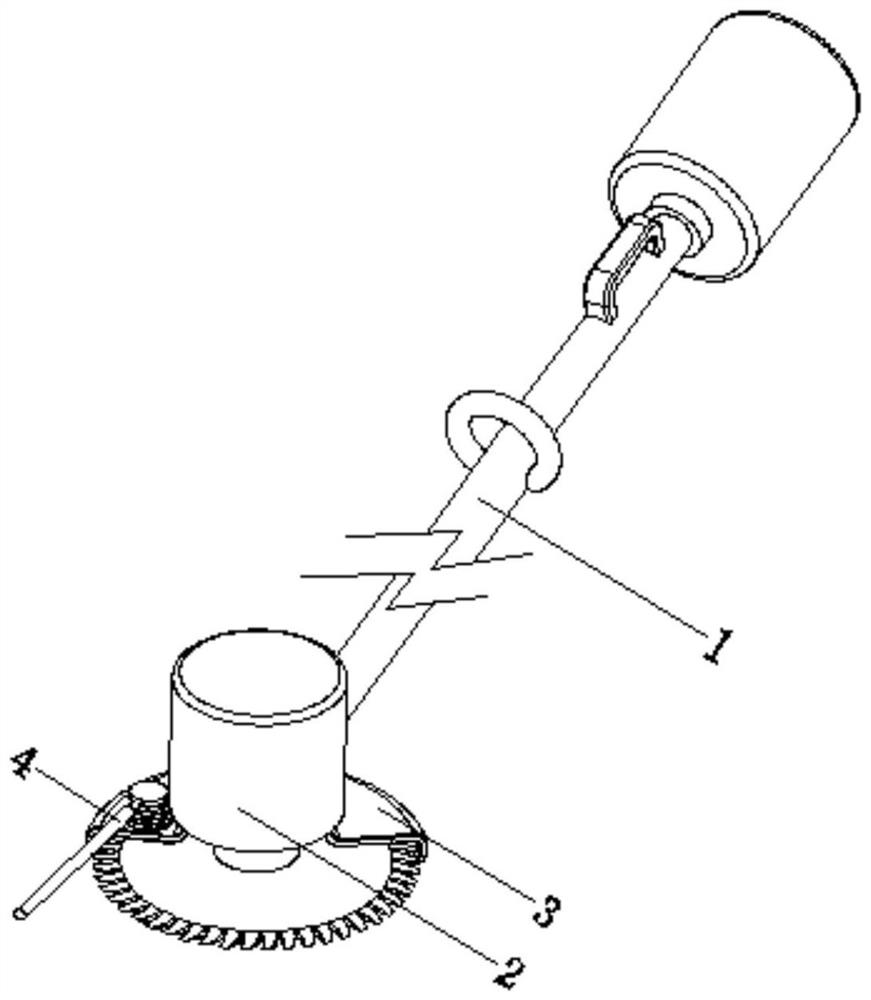

Hopper

ActiveCN105329565AAvoid collisionAvoid scratchesLarge containersConoidElectrical and Electronics engineering

The invention relates to a hopper, and particularly discloses a hopper used for conveying bearings. The hopper comprises a big-end-up conical charging barrel and a connecting pipe connected with the bottom end of the charging barrel; three screening plates are sequentially arranged in the connecting pipe from top to bottom and divide the connecting pipe into a first cavity, a second cavity and a third cavity from top to bottom; the top end of the first cavity and the bottom end of the charging barrel are isolated through one screening plate, and the bottom end of the third cavity is in an opening state; branch pipes are arranged on the lateral walls of the first cavity and the second cavity, and a draught fan is arranged in each branch pipe; the branch pipes are communicated with recycling pipes; outlets of the recycling pipes are located at the inlet of the charging barrel; a plurality of lubricating balls used for isolating the bearings are arranged in the charging barrel; the screening plates are hinged to the connecting pipe and can be reset automatically; an annular boss is arranged on the lateral wall of the third cavity, and a gap allowing only one bearing to pass through is formed in the middle of the boss. The hopper can independently convey the bearings and avoid the bearings from being scratched in the conveying process.

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

Preliminary ore beneficiation equipment after rare earth mining in mine lot

InactiveCN109433584AReduce dust contentReduce the chance of contracting pneumoconiosisSievingCombination devicesDrive wheelWorking environment

The invention relates to ore beneficiation equipment, in particular to preliminary ore beneficiation equipment after rare earth mining in a mine lot. The invention aims to provide the preliminary orebeneficiation equipment after rare earth mining in the mine lot, which is convenient to effectively reduce the dust content in air and fast in rare earth screening speed. The invention provides the technical scheme that the preliminary ore beneficiation equipment after rare earth mining in the mine lot comprises a first installation plate, first support rods, first guiding sleeves, a first guidingrod, a rack frame, a second support rod, a filter frame, a third support rod, a first driven wheel, a first bearing seat and the like, wherein the first support rods are symmetrically arranged in front and rear of the left side and the right side of the top part of the first installation plate; and the first guiding sleeves are arranged on the top parts of the first support rods. According to thepreliminary ore beneficiation equipment after rare earth mining in the mine lot provided by the invention, dust is deposited on the bottom part in a water frame through the function of water, so thatthe dust content in the air is effectively reduced, the pneumoconiosis infection probability of workers is indirectly reduced, and a favorable working environment is provided for the workers; and through positive and negative alternate rotating of blades, the dust drifted in air is conveniently blown away, so that the favorable working environment is provided for the workers.

Owner:刘帮

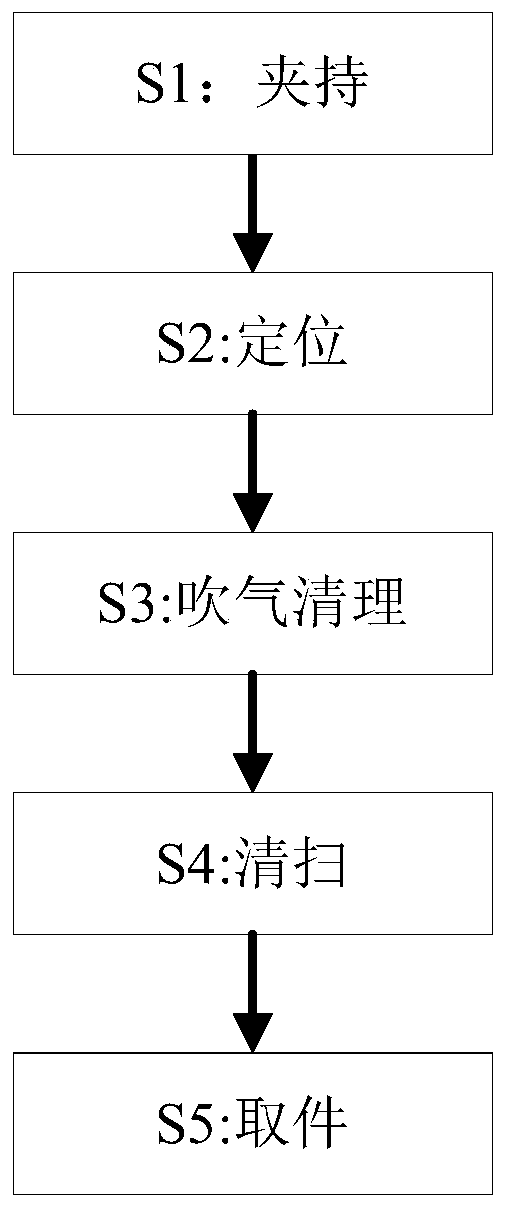

Compressor cylinder cover manufacturing and machining process

The invention provides a compressor cylinder cover manufacturing and machining process. A work plate, two electric sliding blocks, an air conveying type movable plate, two clearing devices, two connecting rods, two sweeping devices, four extruding plates and four positioning blocks cooperate to complete work. According to the compressor cylinder cover manufacturing and machining process, the problems that when a cylinder cover is cleared, due to the fact that the upper end face of the compressor cylinder cover is uneven, many clearances exist, and the dead corners of the clearances are hard toclear through brushes; and when the brushes are used for sweeping, the positions of part of chips are just moved along with the positions of the brushes, the chips are not swept out and are still left in the clearances, the manual sweeping efficiency is low, the removal rate of the chips is not high, and the sweeping mode can hardly adapt to clearing in large-scale production are solved.

Owner:WENZHOU RUIMING IND

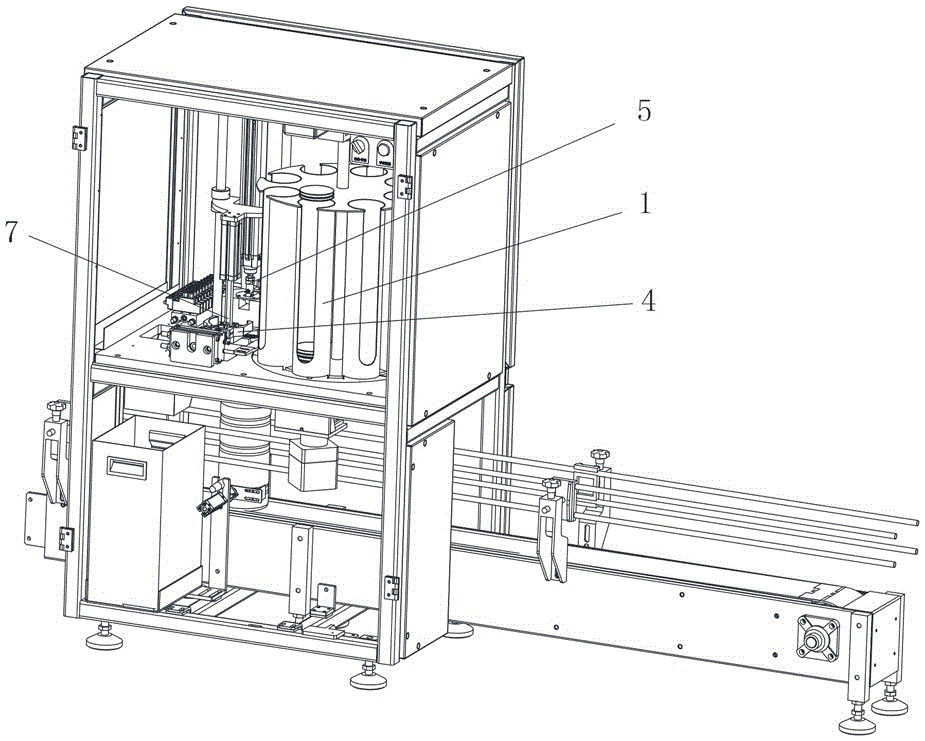

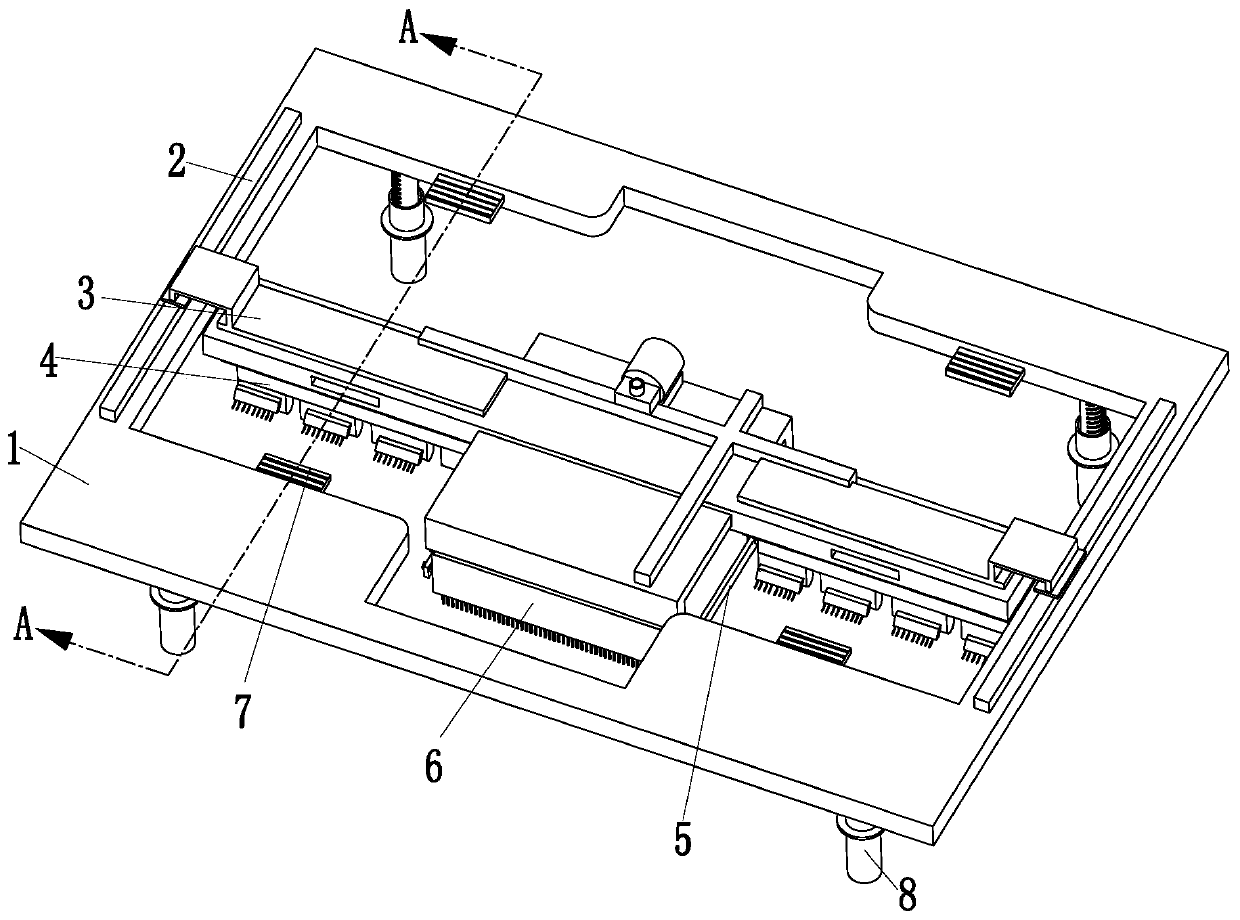

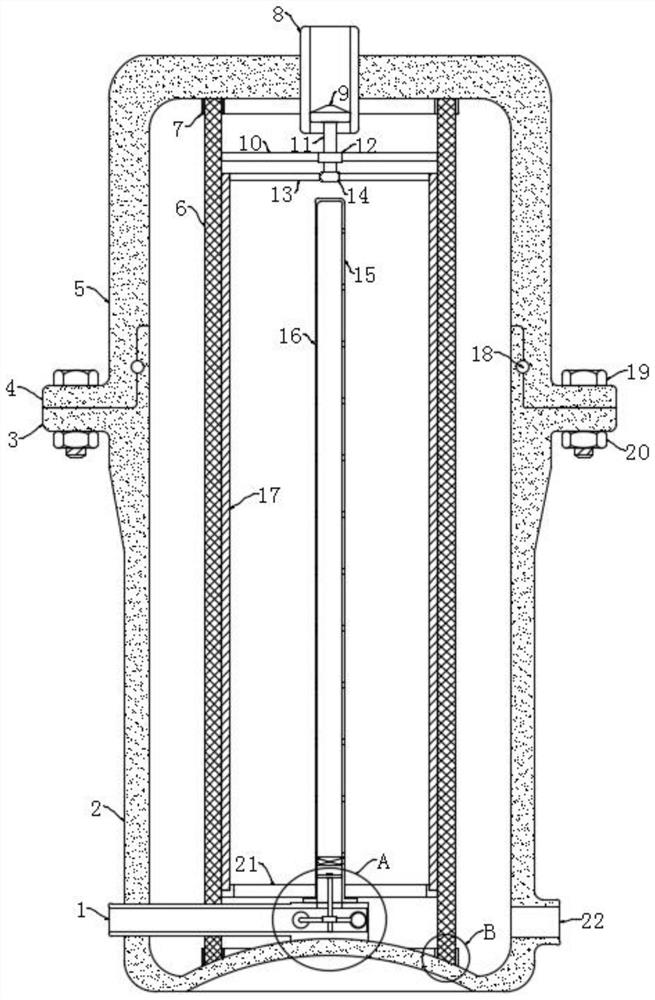

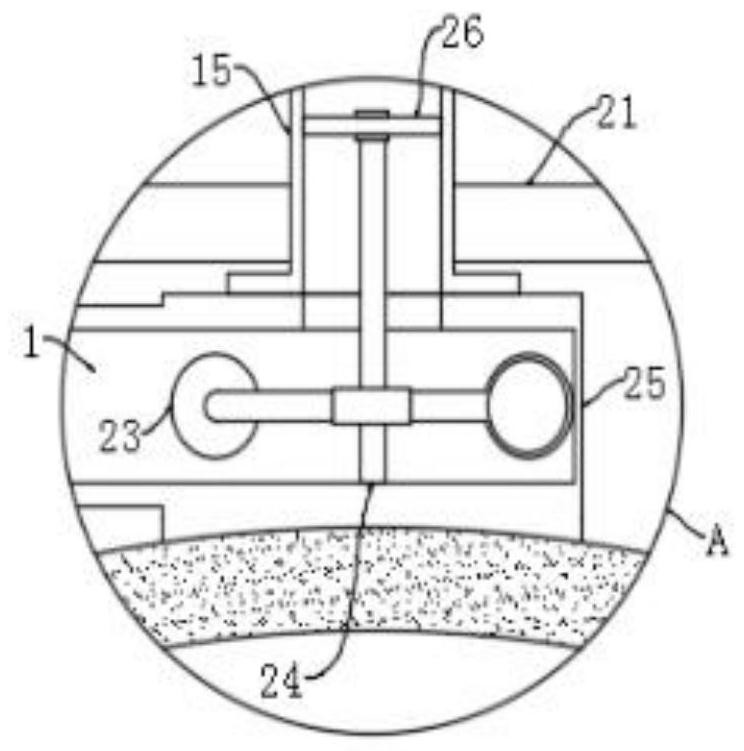

Sample bottle capping machine for sample collection and preparation

ActiveCN106430042AGuaranteed reliabilityImprove securityFlanged caps applicationEngineeringRisk stroke

The invention discloses a sample bottle capping machine for sample collection and preparation. The sample bottle capping machine comprises a storage mechanism, a translation jacking mechanism, a capping mechanism and a detection mechanism, wherein the storage mechanism is used for storing a plurality of bottle caps; the translation jacking mechanism comprises a translation stroke which is used for translating the bottle caps output by the storage mechanism to the downward side of the capping mechanism, so as to carry out capping operation; the detection mechanism comprises a detection component and an air blowing component matched with the detection component; and the detection component is arranged above the translation jacking mechanism and is used for detecting the bottle caps output by the storage mechanism and blowing away the unqualified bottle caps through the air blowing component. The sample bottle capping machine has the advantages of being simple and compact in structure, high in intelligent level, high in safety and high in working efficiency, and effectively and timely getting rid of the unqualified caps.

Owner:HUNAN SUNDY SCI & TECH DEV

Device for sandwich injection

ActiveCN109893718ARelieve painInterior space controlRotating receptacle mixersAutomatic syringesRubber membraneCoil spring

The invention aims to solve the problem that existing injectors cannot inject three different medicines separately and discloses a device for sandwich injection. The device comprises a mounting plate,a flat mirror, a universal rod, an outer casing, a push rod, a small storage battery, a lead, a guide tube, a telescopic airbag, an air guide plate, a mounting rod, a connecting rod, a heating rod, an injection head, a first gear, a first rotating shaft, an inner barrel, a liquid passing hole, a second gear, a second rotating shaft, a chain, a motor, a rubber membrane, a guide barrel, a coil spring, a press plate, a sliding rod, a lantern ring and a rubber gasket. The structures of three chambers of the inner barrel are ingeniously combined, so that separate storage of three different medicines can be realized, meanwhile, injection of three different medicines is facilitated, use of three injectors is avoided, all that is required for injection of different liquid medicines through switching of the inner barrel is to perform injection sequentially by the injection heads of the injectors, and the device is more convenient to operate, meets social demands and is worth promoting in the medical field.

Owner:刘俊英

Ultrasonic anti-pollution detachable ultrafiltration membrane system

ActiveCN111871211AQuick splitEasy to disassemble and cleanSpecific water treatment objectivesUltrafiltrationFiberUltrafiltration

The invention discloses an ultrasonic anti-pollution detachable ultrafiltration membrane system, which comprises an upper shell and a lower shell arranged below the upper shell, wherein the upper shell and the lower shell are fixedly connected through a mounting mechanism, a filter cavity is formed between the upper shell and the lower shell, and a mounting ring is fixedly connected to the inner top of the upper shell; a positioning ring is fixedly connected to the inner bottom of the lower shell, an ultrafiltration membrane core used for filtering and purifying water is arranged between the positioning ring and the mounting ring, a water inlet is formed in the middle of the upper shell in a penetrating mode, and a cleaning mechanism used for cleaning the ultrafiltration membrane core is arranged in the water inlet. The ultrafiltration membrane system is reasonable in structural design, wherein the scraper blade can be driven in a hydraulic mode, so that impurities are convenient to clean; the cleaning pipe is driven to rotate and spray out in a wind power mode, the impurities on the fiber membrane core of the ultrafiltration membrane are conveniently and fully blown off; the ultrafiltration membrane system is convenient to assemble and disassemble through the arrangement of the installation mechanism.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

Sand filtering device for building

PendingCN112791928AAvoid shockExtended service lifeSievingScreeningSand filterStructural engineering

The invention discloses a sand filtering device for a building. The sand filtering device for the building comprises a machine body, a feeding hopper is rotationally connected to the top of the machine body, a conical screen is fixed to the bottom of the feeding hopper, an impurity storage cavity is fixed to the bottom of the conical screen, the surface of the impurity storage cavity is rotationally connected with the bottom of the machine body, a spiral blade is located in the conical screen and fixed to the bottom of the feeding hopper, a cleaning device is arranged on the surface of the conical screen, a pressing device is arranged on the inner wall of the machine body, a flow guide plate is fixed to the inner wall of the machine body and close to the bottom of the machine body, and a filter sieve is fixed to the bottom of the inner wall of the machine body. The invention relates to the technical field of building equipment. According to the sand filtering device for the building, the purpose of removing impurities in time is achieved, the impurities can be removed in time, impact generated after the impurities are thrown out is avoided, the service life of equipment is prolonged, meanwhile, wet sand balls are scattered in time, filtering is facilitated, and the working efficiency and the using performance are improved.

Owner:王长桂

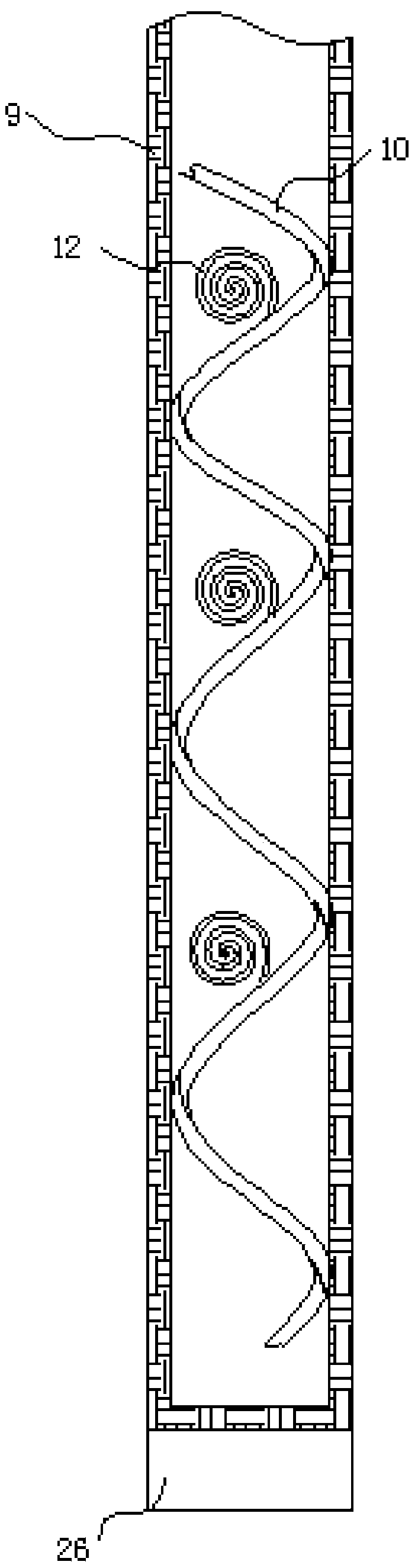

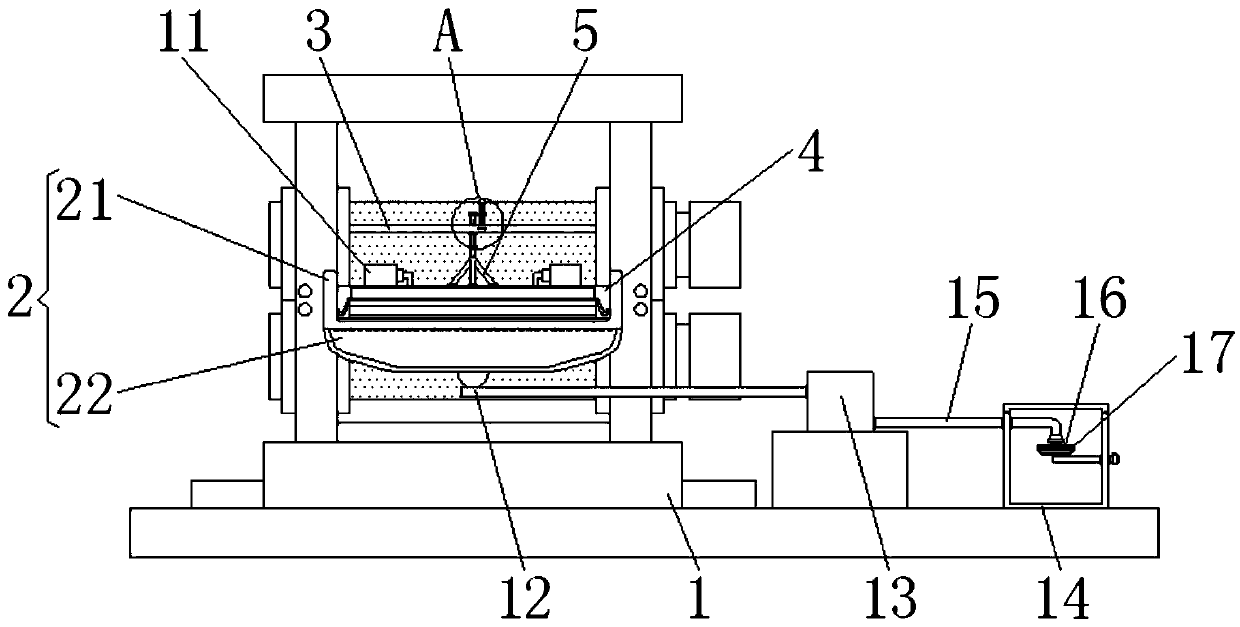

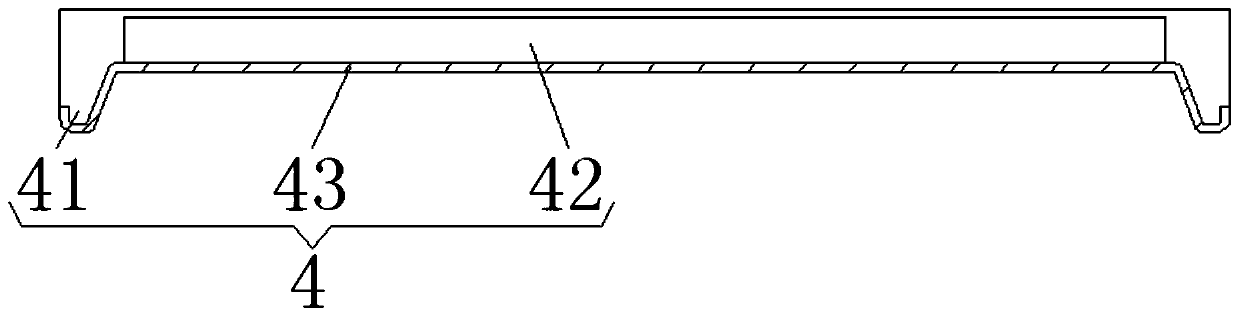

Emulsion control and recovery device for cold-rolling mill

ActiveCN110479779AEasy to blow offHigh Efficiency RecyclingCleaning using gasesWork cleaning devicesEmulsionEngineering

The invention relates to the technical field of intelligent manufacturing, and discloses an emulsion control and recovery device for a cold-rolling mill. The emulsion control and recovery device comprises a machine body, wherein a horizontal plate is fixedly mounted at the top of the front surface of the machine body; a connecting rod is movably connected to the inner part of the horizontal platein a sleeving manner; a limiting block is fixedly connected to the bottom of the connecting rod; a limiting plate is movably connected to the right side of the horizontal plate in a sleeving manner; athreaded rod is fixedly connected to the top of the limiting plate; and the top end of the threaded rod penetrates through the horizontal plate and extends to a position above the horizontal plate. According to the emulsion control and recovery device for the cold-rolling mill disclosed by the invention, through the cooperation of a blowing device and blowing fans, emulsion on the upper surface of iron sheets are convenient to blow away; emulsion which is blown away in the bottom and the upper part of the iron sheets is adsorbed through an overflow resisting baffle and an accommodating ware in an overflow resisting and absorbing device; and besides, the collected emulsion is purified through a fixing disk and a filtering device, so that the situation that emulsion remains on the outer surfaces of the iron sheets, and emulsifying spots are formed is avoided, the emulsion is recovered simultaneously, and the effect of recovering and utilizing of emulsion is improved.

Owner:山东乾钢金属科技有限公司

Garden mowing equipment

PendingCN112567963AAvoid rolling toAvoid winding stuckMowersAgricultural scienceAgricultural engineering

The invention discloses garden mowing equipment which comprises a rack, a mowing structure, a blocking cover and a weed poking device, the mowing structure is fixed to one end of the rack, the weed poking device is arranged on one side of the bottom edge of the surface of the blocking cover, a rotating shaft is arranged in the center of the bottom of a driving mechanism, and the rotating shaft isrotationally connected with the driving mechanism. A protection device is arranged on the surface of the rotating shaft and located at the bottom of the driving mechanism, and a cutting disc is fixedto the position, close to the bottom of the protection device, of the surface of the rotating shaft. The invention relates to the technical field of garden equipment. The garden mowing equipment achieves the effect of high adaptability, can adapt to both fragile straw weeds and flexible straw weeds, effectively avoids winding of rotating shafts by stems and leaves of the weeds, guarantees mowing efficiency, can reduce throwing of the weeds, facilitates subsequent sweeping, reduces harm to the face of a human body, is safe and reliable, and improves the service performance.

Owner:新昌县大菠萝农业发展有限公司

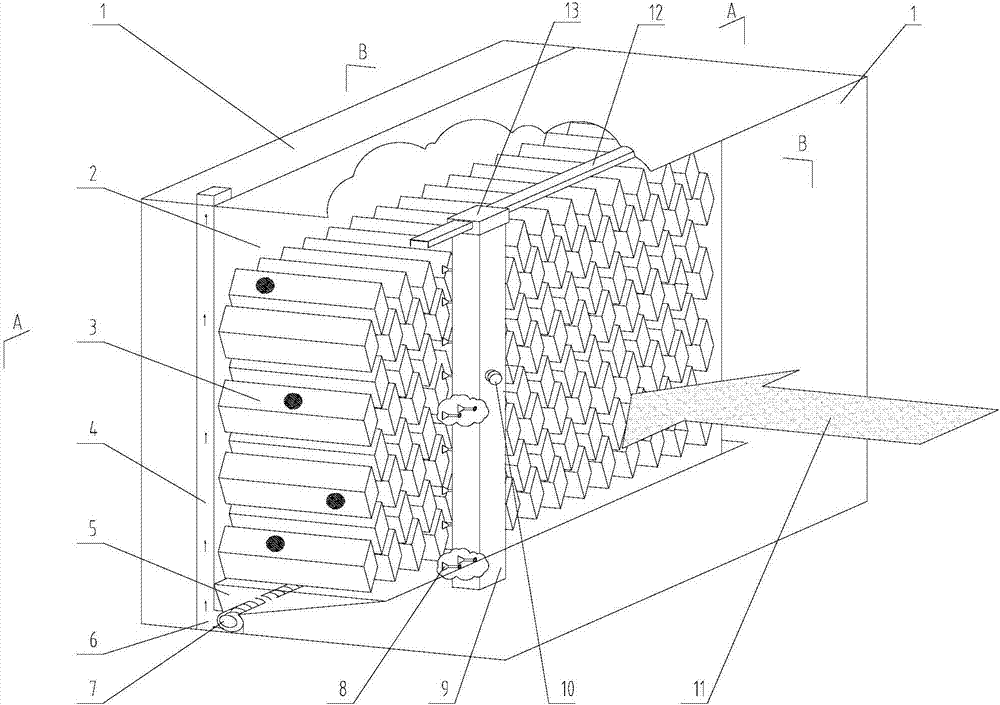

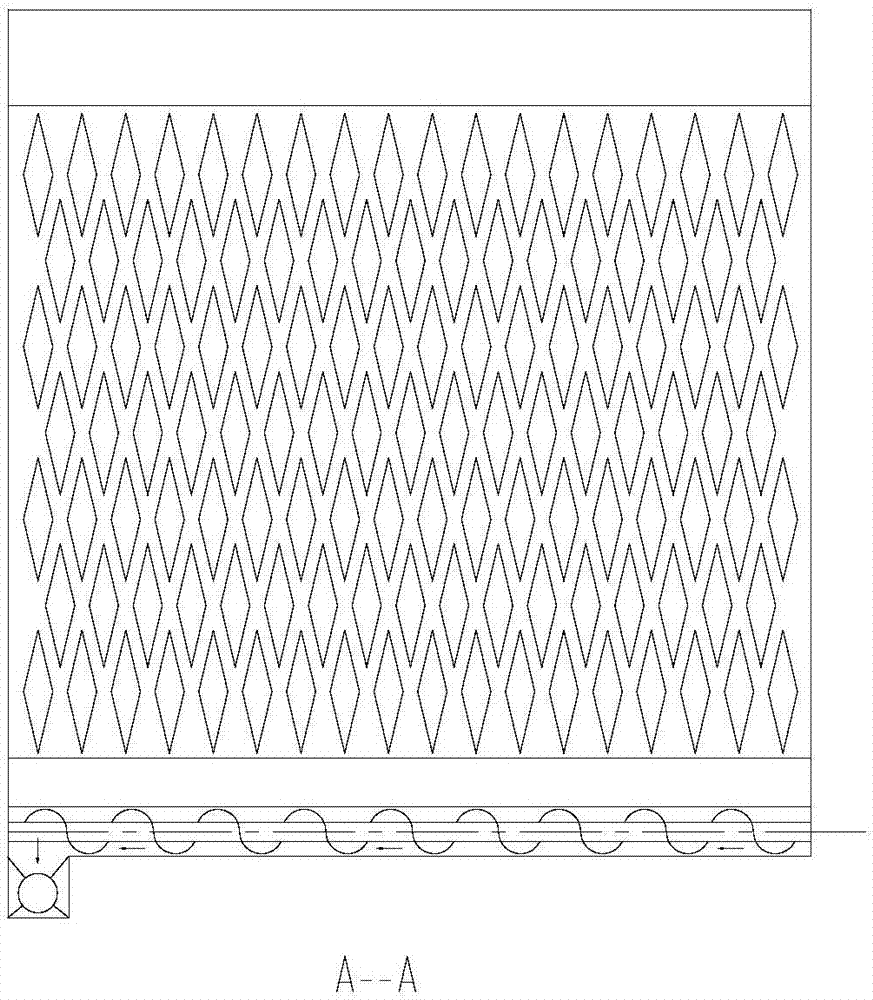

Dedusting unit

InactiveCN107019977ASave spaceLarge filter areaDispersed particle filtrationTransportation and packagingPropellerEngineering

The invention relates to the technical field of dedusting equipment, in particular to a dedusting unit. The dedusting unit comprises a sealing box body, rhombus small dust cage filtering units, a walking blowing box body and a dust collecting hopper, wherein the rhombus small dust cage filtering units are arranged on one side of the sealing box body in an array form; one side, which is close to the rhombus small dust cage filtering units, of the walking blowing box body is provided with a plurality of nozzles; the other side of the walking blowing box body is provided with an S-shaped hose; the dust collecting hopper is arranged under the rhombus small dust cage filtering units; the bottom of the dust collecting hopper is provided with a screw rod dust propeller; a dust pipeline is arranged at a tail end of the screw rod dust propeller. The rhombus small dust cage filtering units and the walking blowing box body are adopted, so that the dedusting unit has the advantages of simple structure, small occupied space, reliable running, less failures, easiness in machining and low cost, and is only a half of the size of a product produced by the Rova company of the LTG company; under the condition of the same size, the dust collecting system has the advantages that the filtering area and filtering capability are improved by one time.

Owner:孙家驹

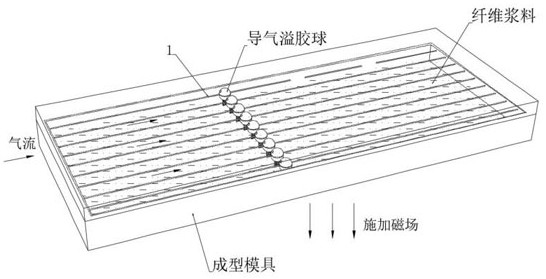

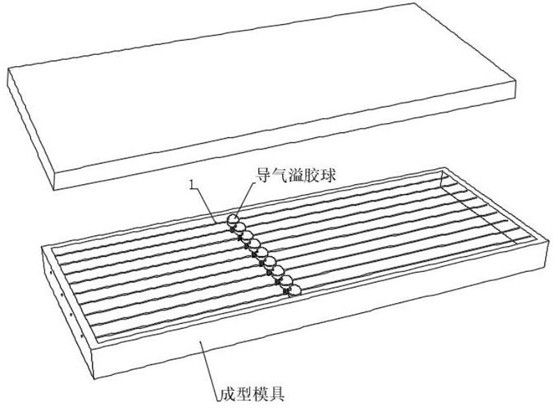

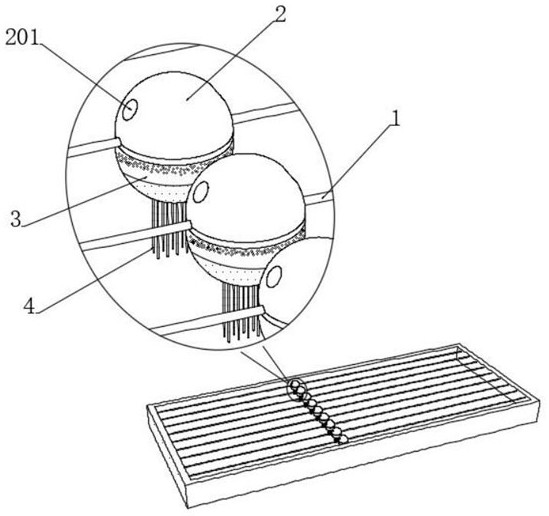

Semi-dry airflow forming preparation process of fiberboard

ActiveCN113279289APlay a preliminary role in breaking up and combingImprove combing effectFibreboardWater-repelling agents additionRubber materialFiber

The invention discloses a semi-dry type airflow forming preparation process of a fiberboard, and belongs to the field of fiberboard preparation processes. A plurality of guide rods are erected on a mold, the guide rods are movably sleeved with air guide glue overflow balls, airflow is intermittently supplied to the two ends of the mold, the introduced air flow is beneficial for playing a preliminary scattering role on the agglomerated fibers on one hand and pushing the air guide glue overflowing ball to horizontally move on the guide rod on the other hand, and the magnetic agglomerate breaking component at the bottom of the air guide glue overflowing ball mechanically scatters the agglomerated fibers in the moving process, so that the fiber carding effect is further improved; and a magnetic field is intermittently applied below the mold, so that the magnetic cluster breaking component moves up and down in a reciprocating manner, the scattering depth is effectively adjusted, rubber materials are uniformly attached to fiber yarns along with overflowing of the rubber materials and airflow under the pressure applying condition, the adhesive forming effect is improved, and bubbles formed at the air guide glue overflowing ball overflowing positions easily blow away small clusters.

Owner:南通跃香拉链有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com