Laser processing method for steel sieve tube slit

A technology of slitting and sieve tube, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as difficult to achieve results, and achieve the effect of overcoming irregular slit shape, improving cutting efficiency, and ensuring cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the embodiments.

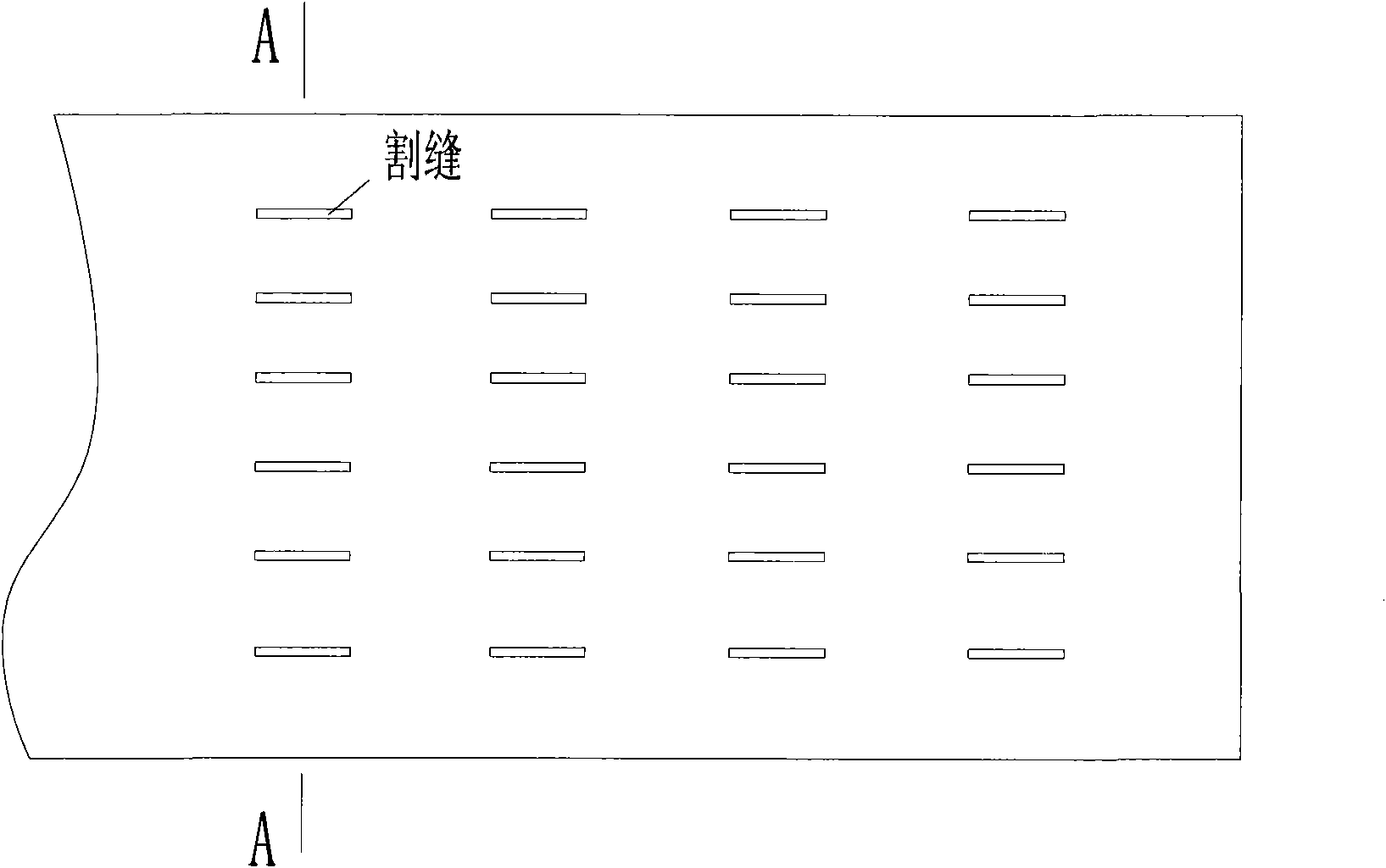

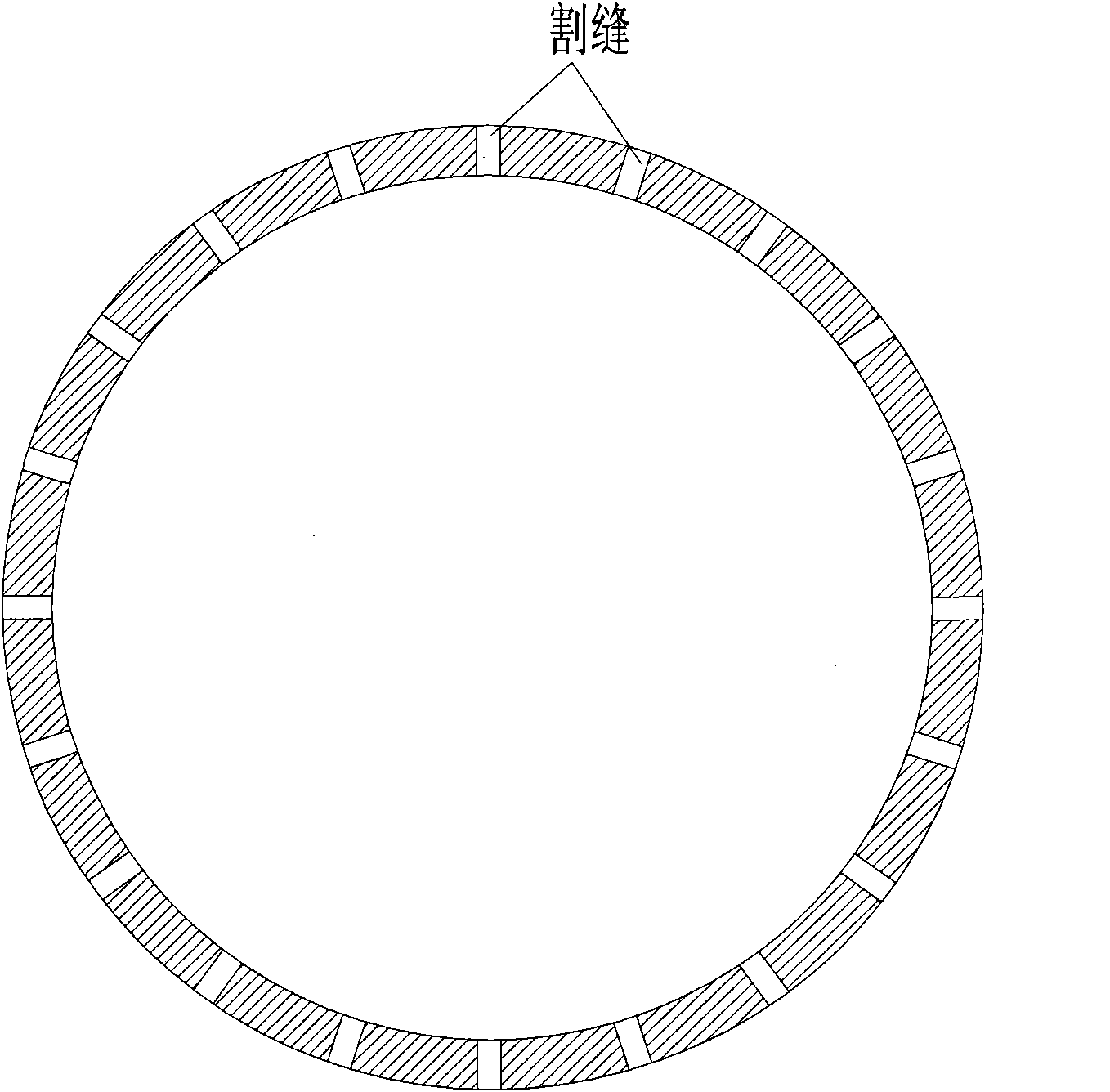

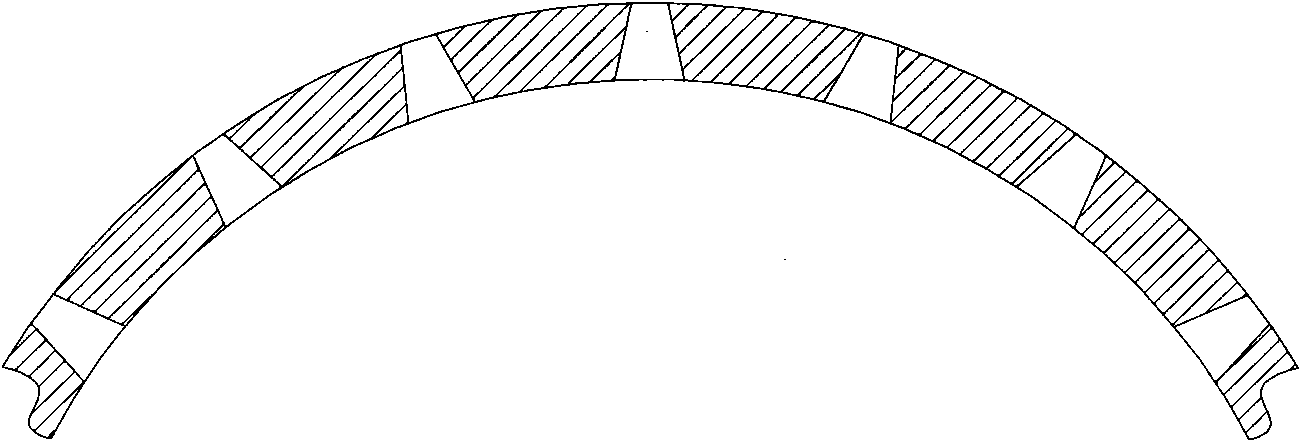

[0027] The cross-sectional shape of the steel screen slot includes Figure 2a the rectangle shown, Figure 2b the trapezoid shown, and Figure 2c combination shown.

[0028] When the cross-sectional shape of the slit of the screen pipe is rectangular, the cutting process of the slit can be completed only by moving the laser head.

[0029] Such as Figure 3a As shown, first move the laser head above the screen, make the optical axis of the laser head perpendicular to the axis of the screen, and move the laser head to the left (or right) for a distance of B / 2-D / 2 according to the slot width B , where B is the width of the slit, D is the diameter of the laser focus spot, and then the laser is turned on for cutting. Of course, as long as the optical axis of the laser head is perpendicular to the axis of the screen pipe, the initial position of the laser head can also be on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com