Hopper

A hopper and barrel technology, used in containers, packaging, transportation and packaging to reduce damage, improve qualification rates, and avoid collisions and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

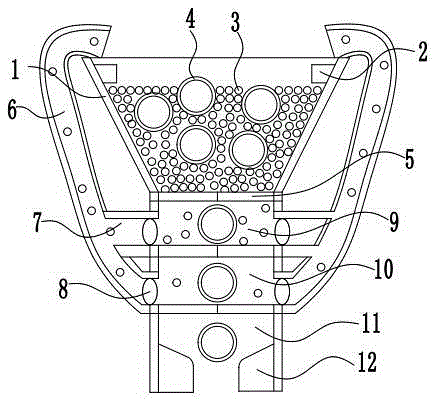

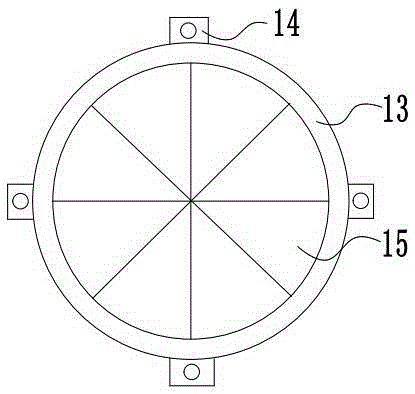

[0018] The reference signs in the accompanying drawings of the specification include: barrel 1, blower 2, lubricating ball 3, bearing 4, screening plate 5, recovery pipe 6, branch pipe 7, suction fan 8, first cavity 9, second cavity 10, second cavity Three cavity 11, boss 12, fixed ring 13, connecting plate 14, sector plate 15.

[0019] Such as figure 1 As shown, a hopper includes a conical barrel 1 with a large top and a small bottom. A connecting pipe is connected to the bottom of the barrel 1 . The connecting pipe is provided with three screening plates 5 sequentially from top to bottom and the connecting pipe is divided into a first chamber 9, a second chamber 10 and a third chamber 11 from top to bottom; The bottom ends are blocked by a screening plate 5, and the bottom end of the third chamber 11 is open. There are a plurality of lubricating balls 3 used to isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com