Patents

Literature

140results about How to "Increase separation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide industrial-scale separation and purification system and method in mixture gas by hydrate method

ActiveCN101456556AIncrease concentrationIncrease separation rateProductsCarbon compoundsCollection systemFractionation

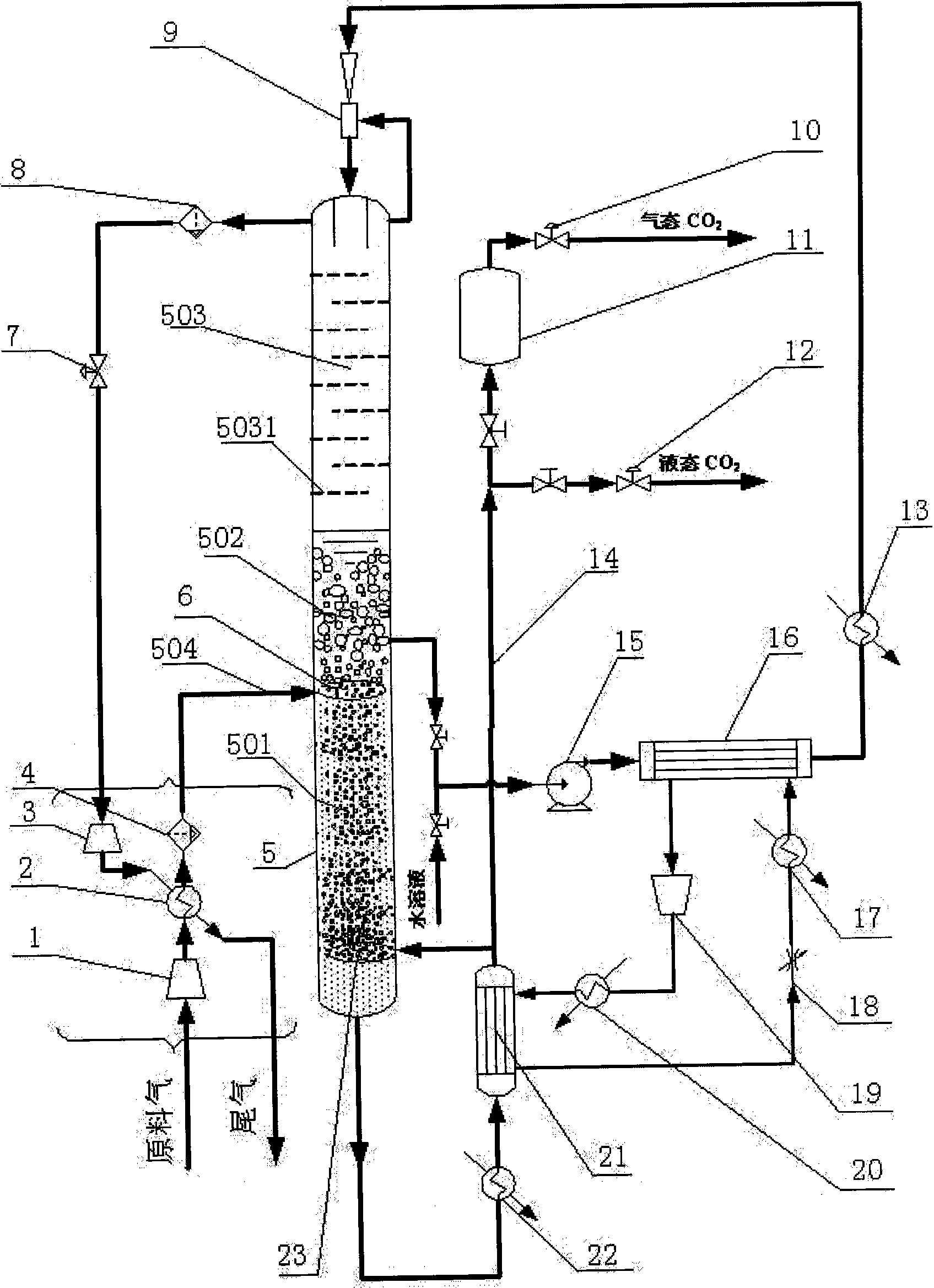

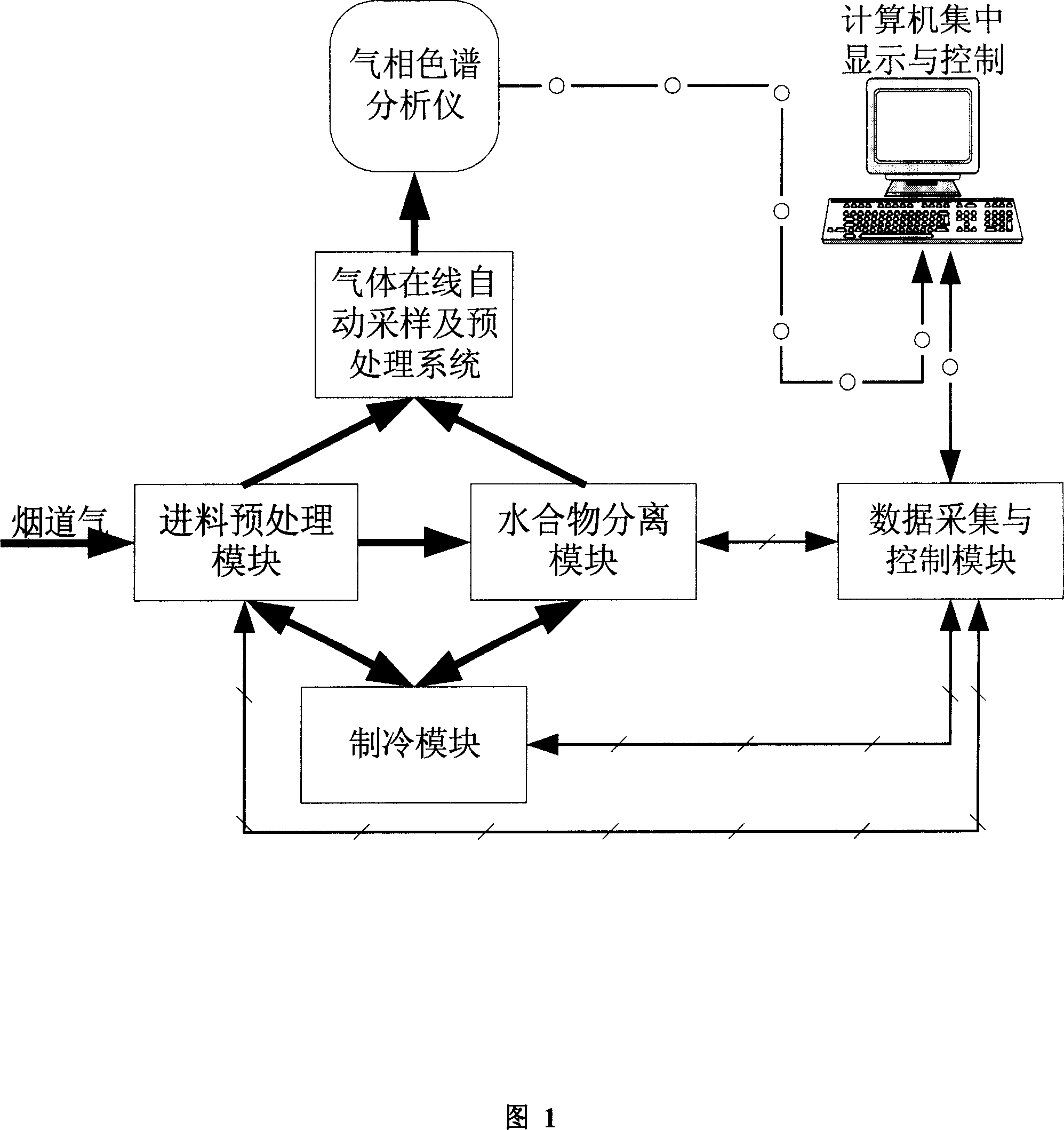

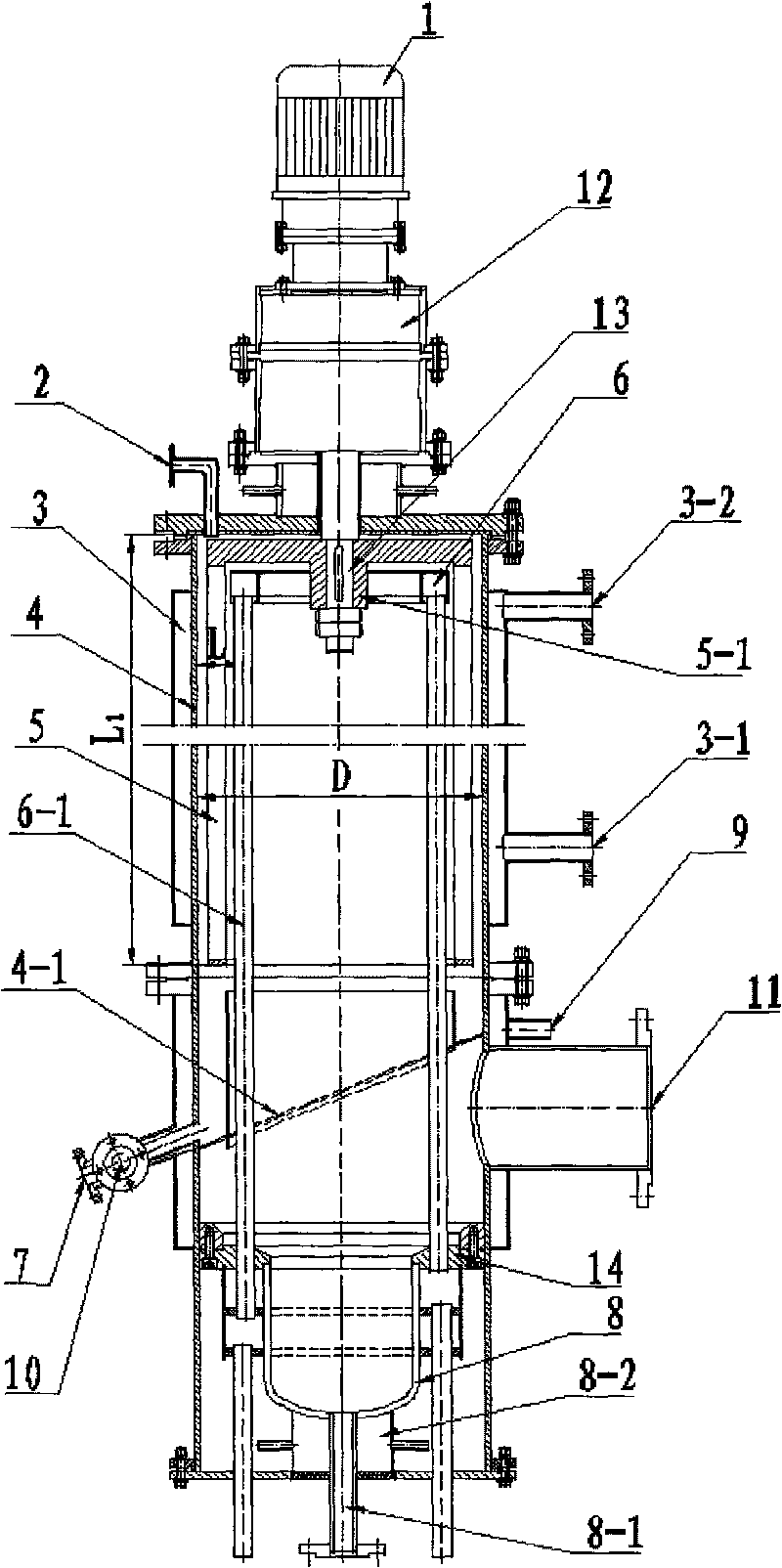

The invention discloses a system and a method for industrially separating and purifying CO2 in mixed gas by a hydrate method. The system consists of a feed gas pretreatment system, a hydrate separation tower, a micro-bubble jet-loop reaction system, a column bottom hydrate decomposition system, a CO2 product collection system, a hydrate formation and decomposition heat comprehensive utilization system and a tail gas energy recovery system. The method integrates hydrate bubbling reaction technology, spraying reaction technology and micro-bubble jet reaction technology, adopts CO2 reflux displacement fractionation technology to improve the concentration of the CO2 in a hydrate phase, has simple separation technology and device and high separation rate and efficiency, comprehensively utilizes the formation heat and decomposition heat of the hydrate during refrigeration cycle, simultaneously recovers compression work of tail gas and cold energy for feed gas pretreatment, and has low energy consumption and cost during separation. The system and the method can be applied to industrial and continuous separation and purification of the CO2 in the mixed gas such as flue gas (CO2 / N2), IGCC synthetic gas (CO2 / H2), biomass synthetic gas (CO2 / H2), natural gas (CO2 / CH4), coalbed gas and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

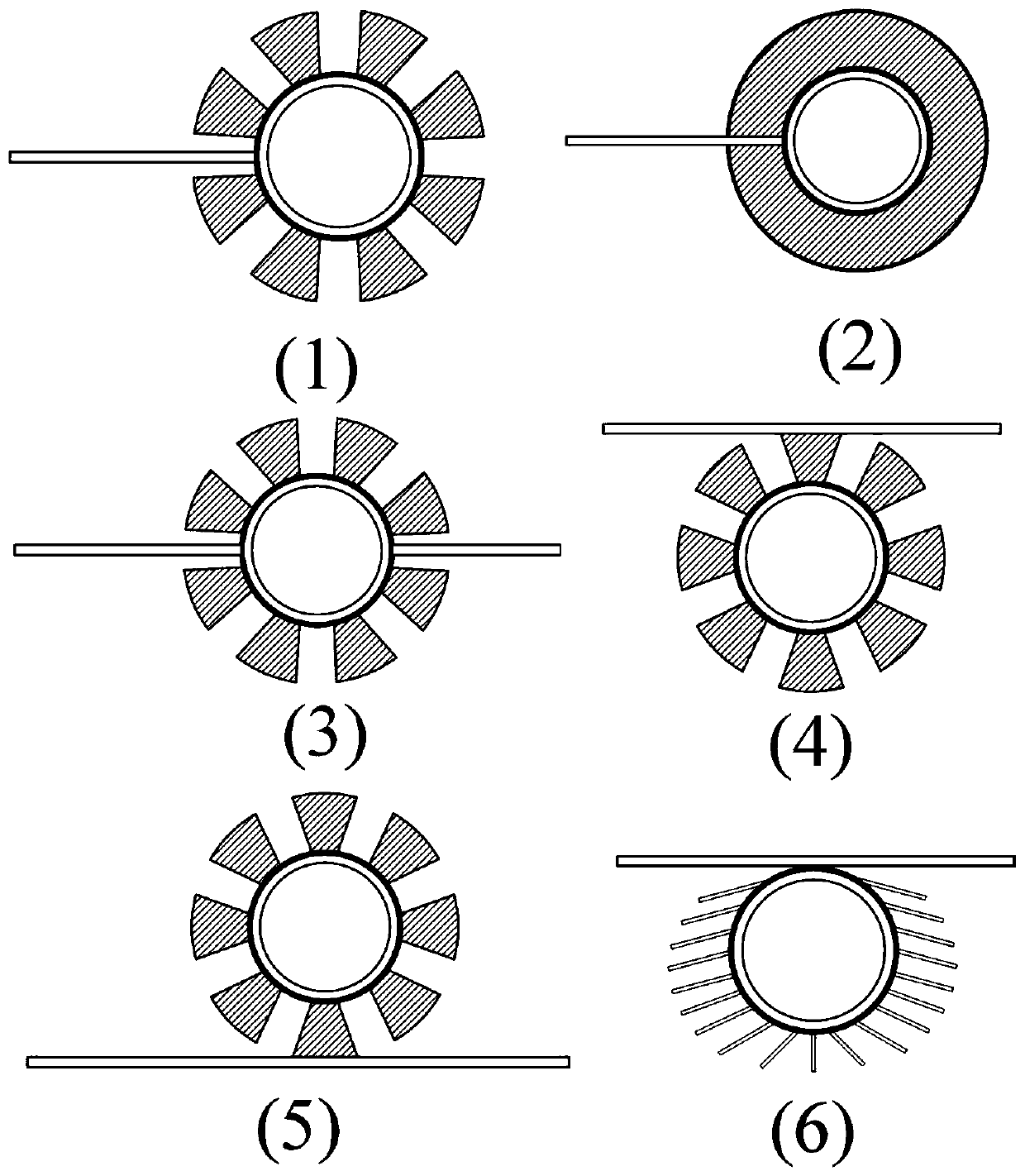

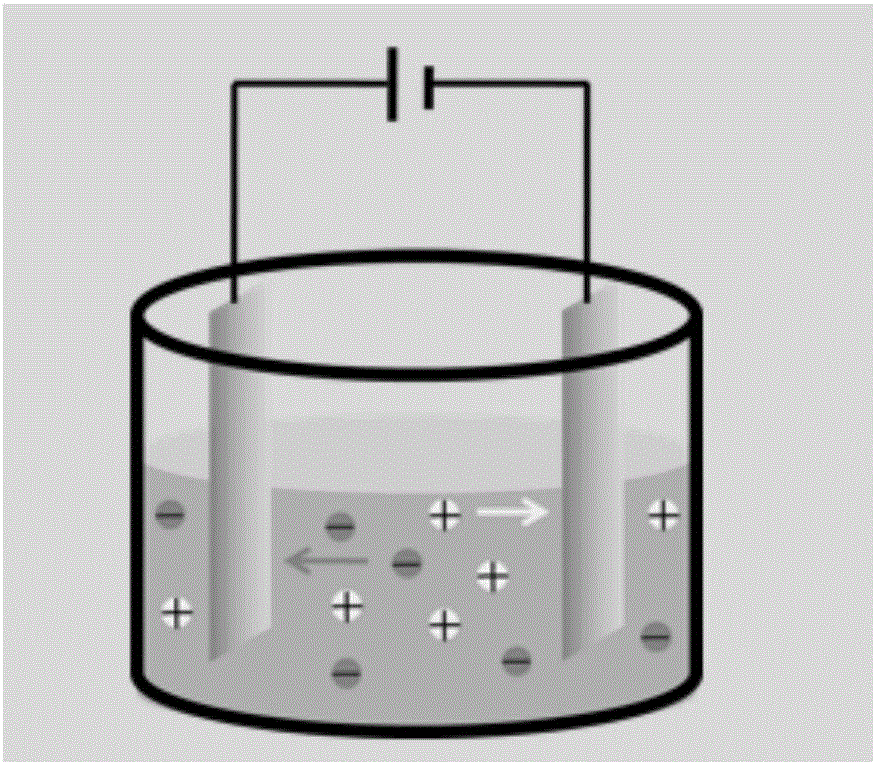

Hydrate process and apparatus for separating gas mixture continuously

ActiveCN1973959AIncrease concentrationHigh recovery rateProductsCarbon compoundsChemical industryMicro bubble

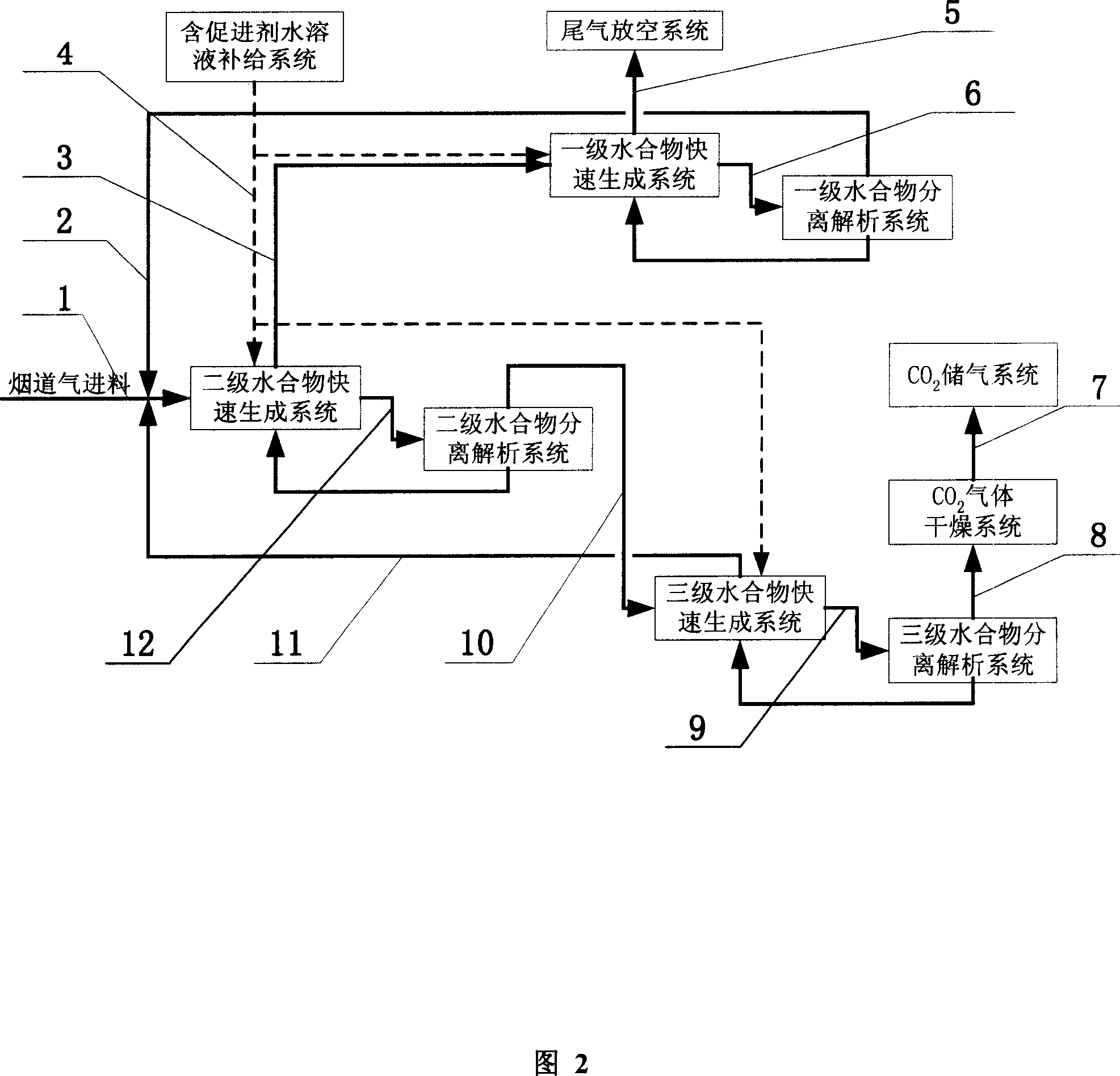

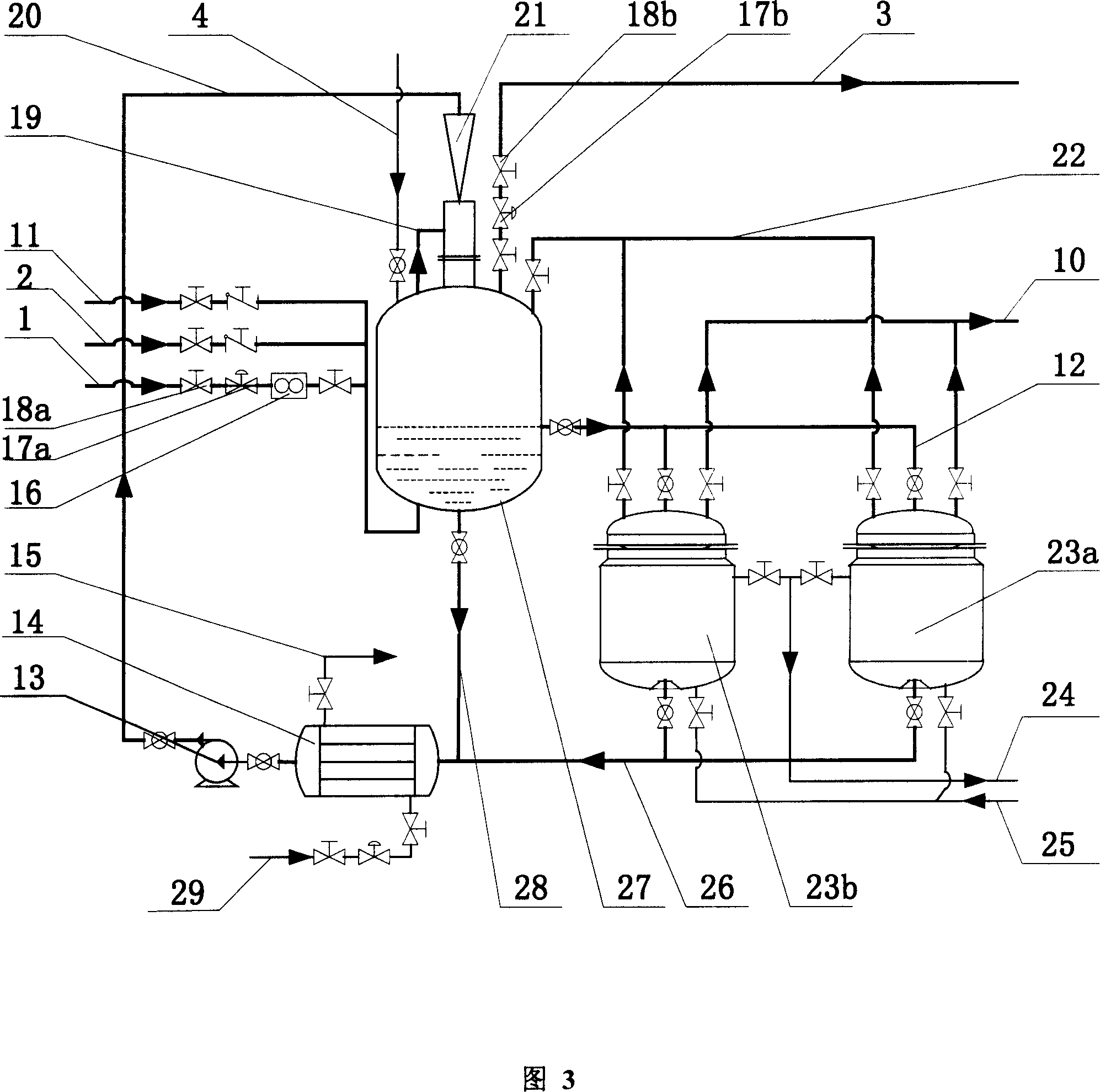

The present invention proposes hydrate process and apparatus for separating gas mixture continuously. The countercurrent continuous separation process in three serially connected stages is adopted to raise the CO2 recovering rate from fume, the CO2 concentration in the product and the separation rate and efficiency. Each of the separating systems consists of a hydrate synthesizer, a hydrate decomposer, a circulating pump, a heat exchanger, and a micro bubble mixing and jetting reactor. The present invention is suitable for continuous separation and enrichment of CO2 in the fume of coal burning power plant, and may be also used in the continuous separation and enrichment of gas mixture containing CO2 in chemical industry, metallurgy, petroleum and other fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

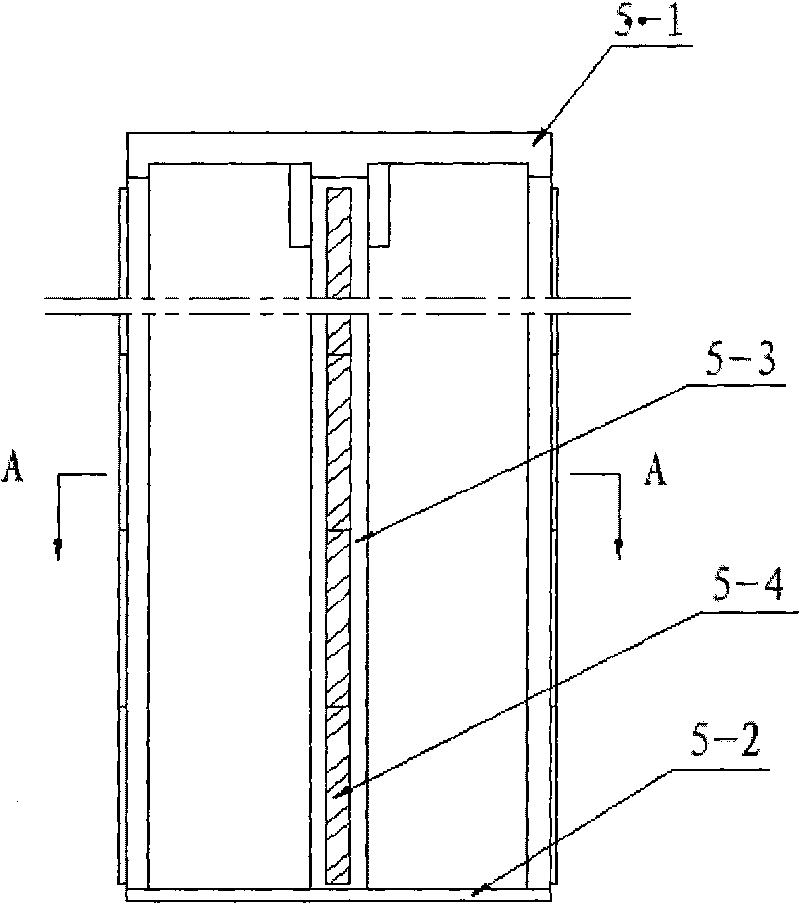

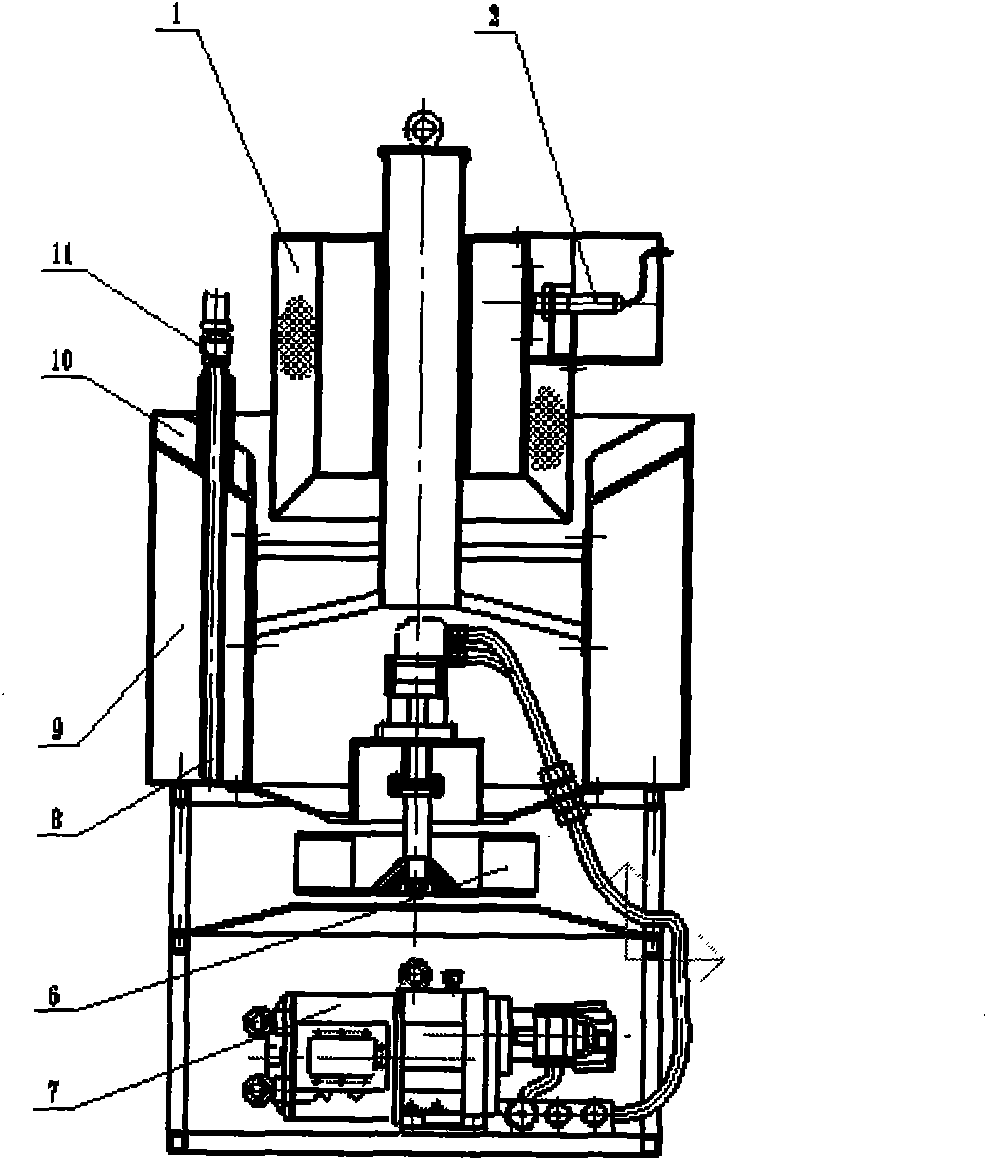

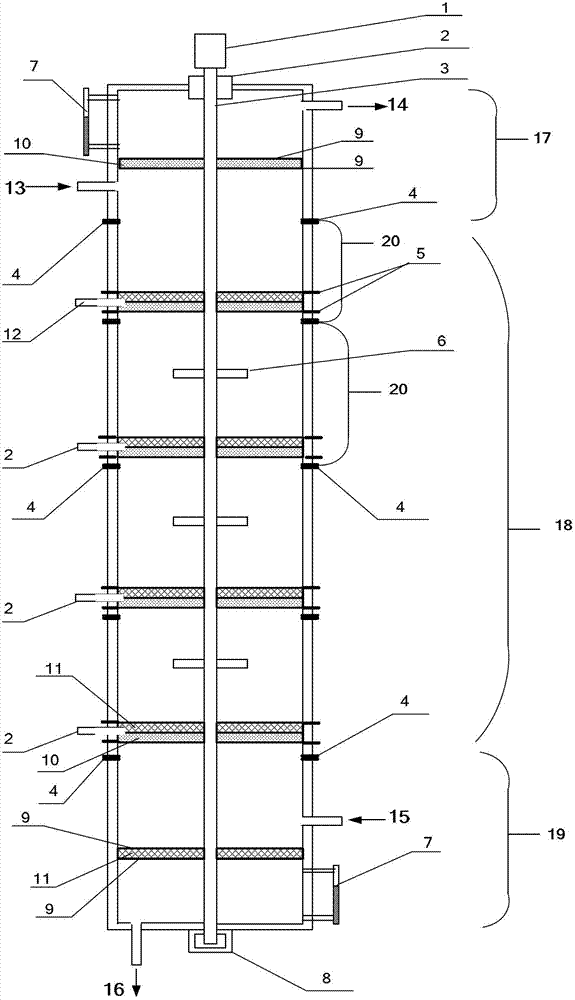

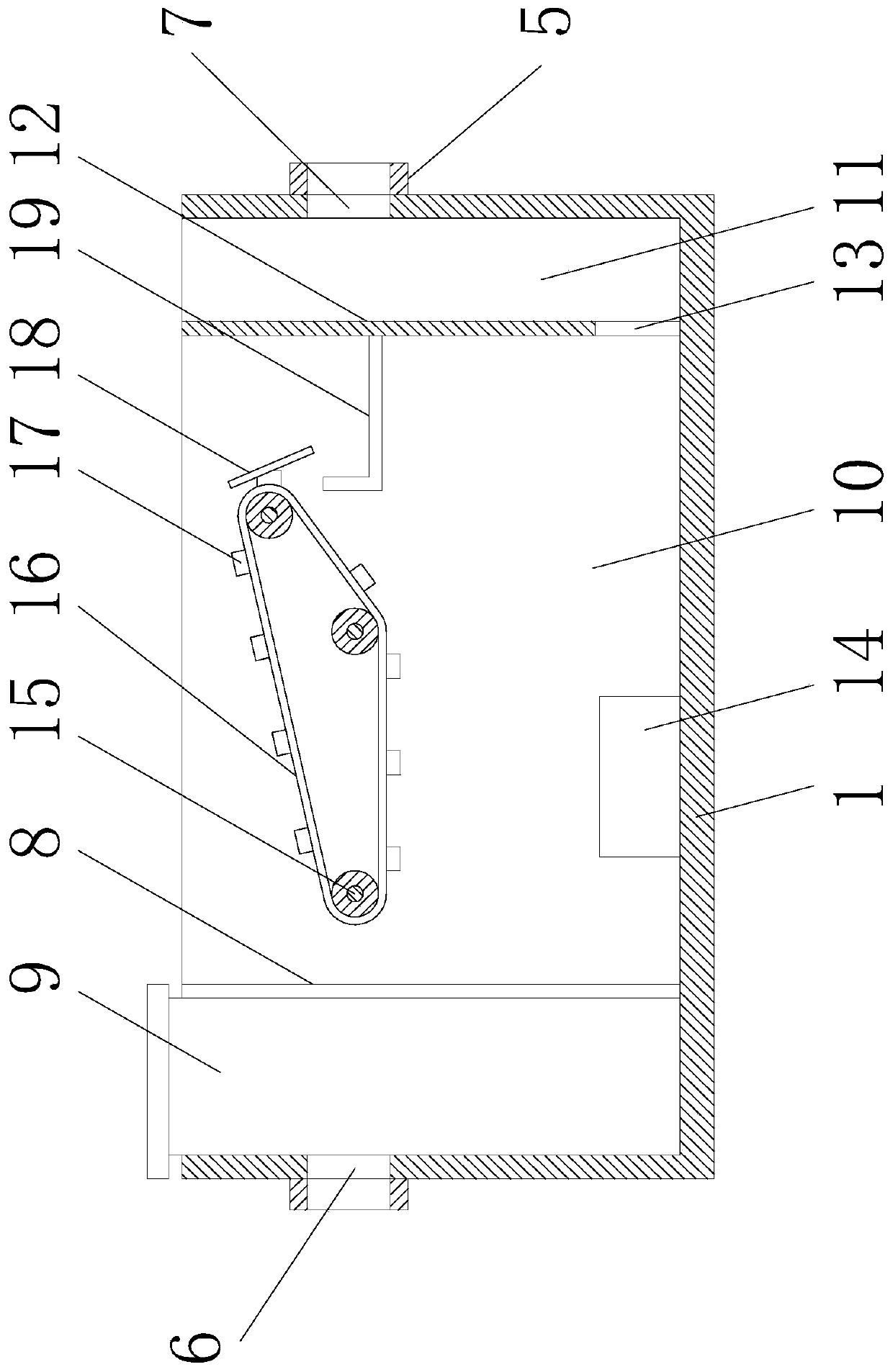

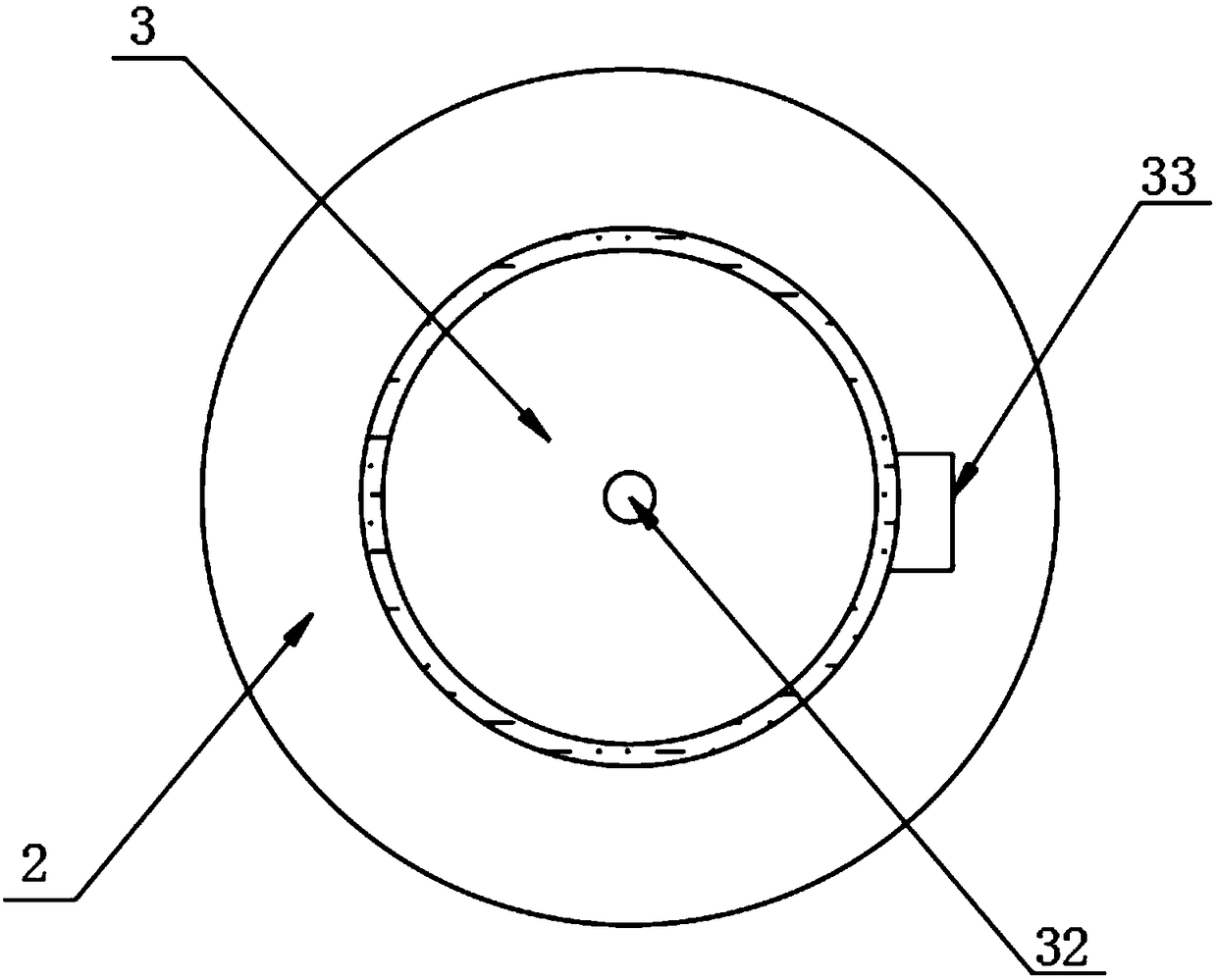

Molecular distillation apparatus

The invention relates to a molecular distillation apparatus, comprising a motor, a cylinder body, sleeves around the cylinder body, a feed inlet, a rotary shaft, a running wheel device, a condensation pipe assembly, and a light oil collecting flute, wherein the condensation pipe assembly is a cylindrical device formed by enclosing of a plurality of condensation pipes; and the motor is connected with the rotary shaft via a reducing gear, and the rotary shaft penetrates through the end cover of the cylinder body to be fixedly connected with the running wheel device. The molecular distillation apparatus is characterized in that the radial distance between the outer side pipe wall and the inner wall of the cylinder body of the condensation pipe is set to be 3.6-4.2cm. The invention has simple structure and convenient operation.

Owner:朱文冲

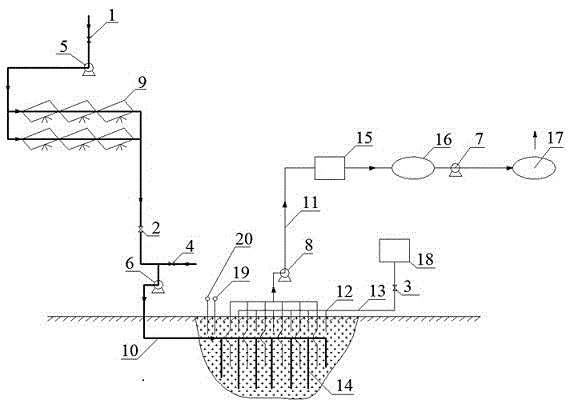

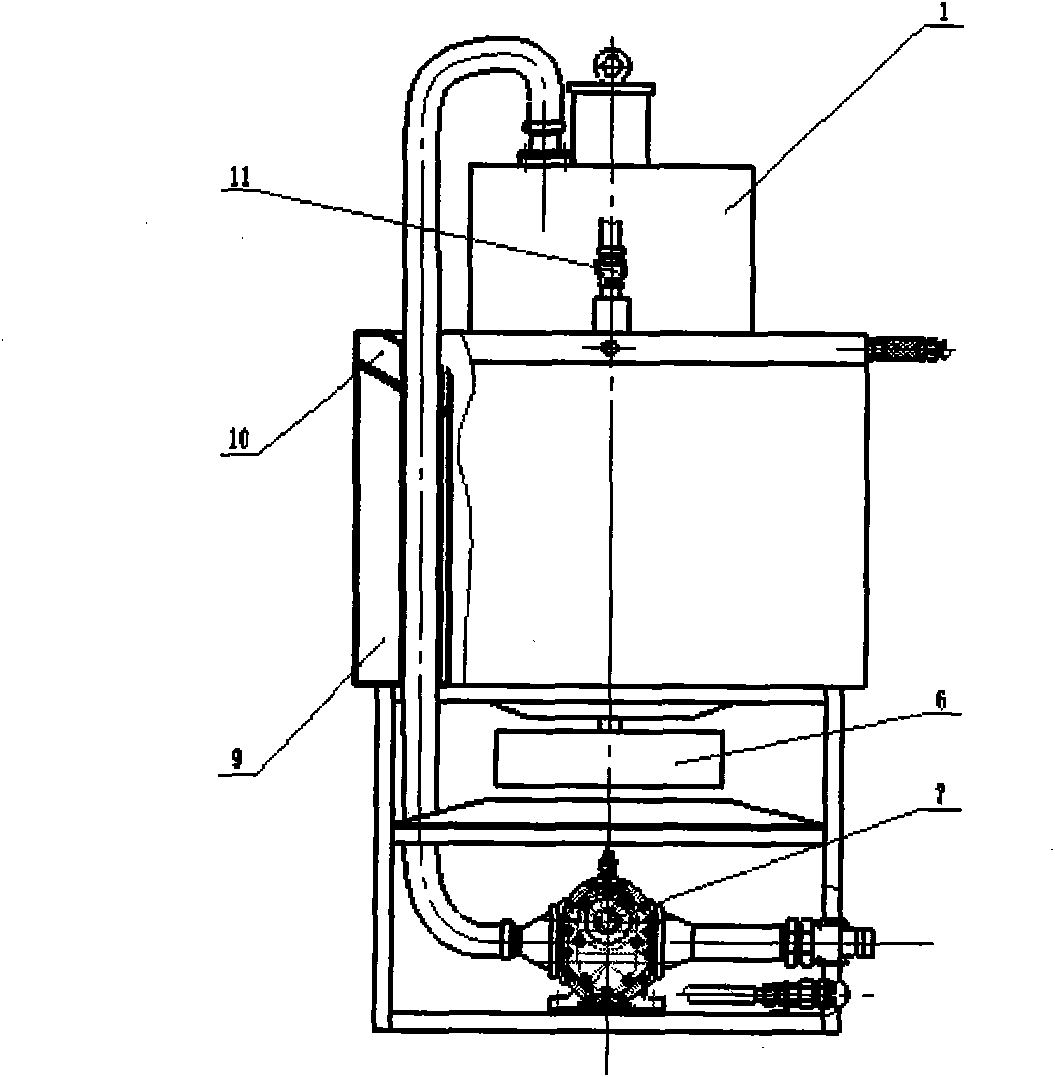

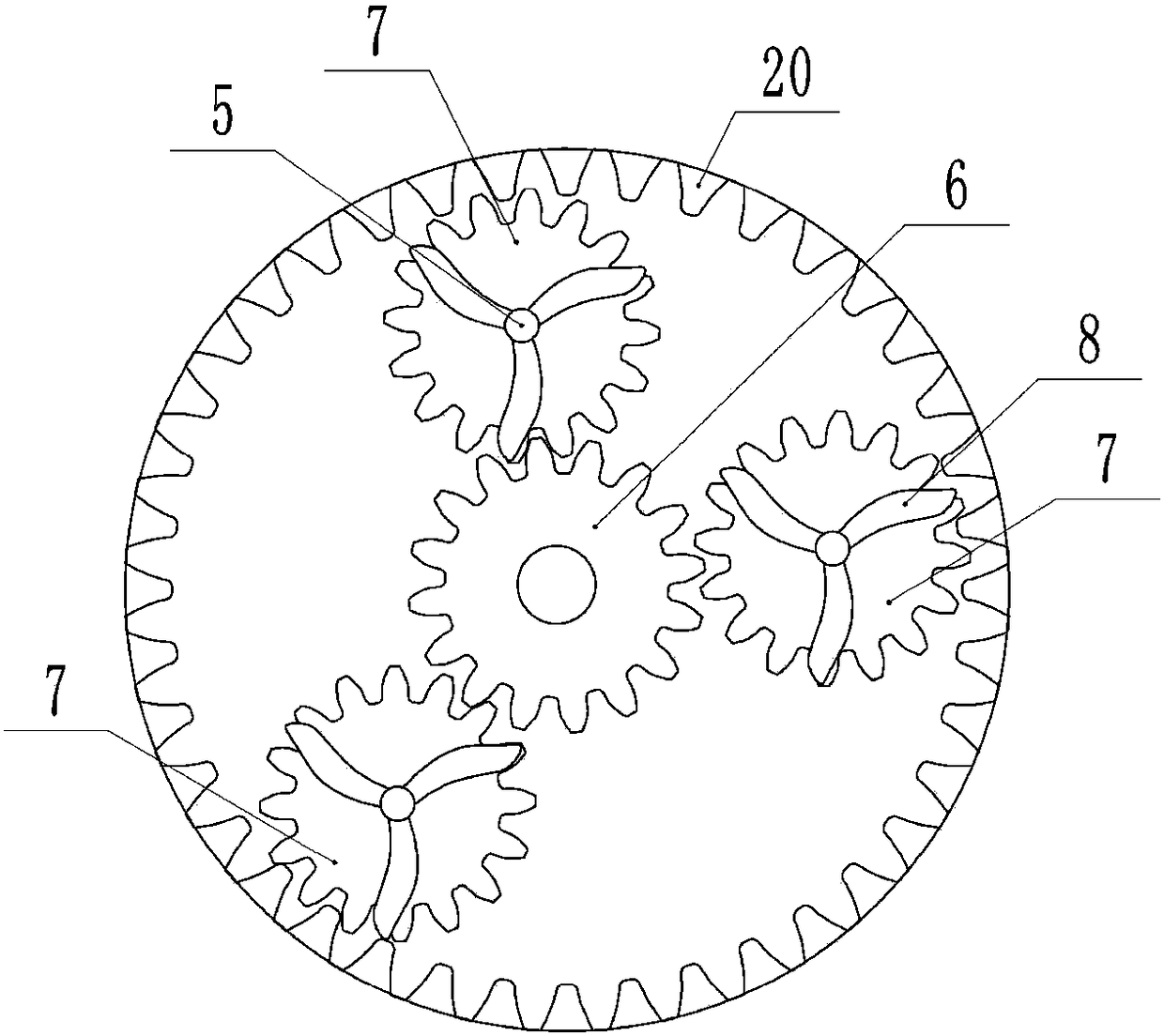

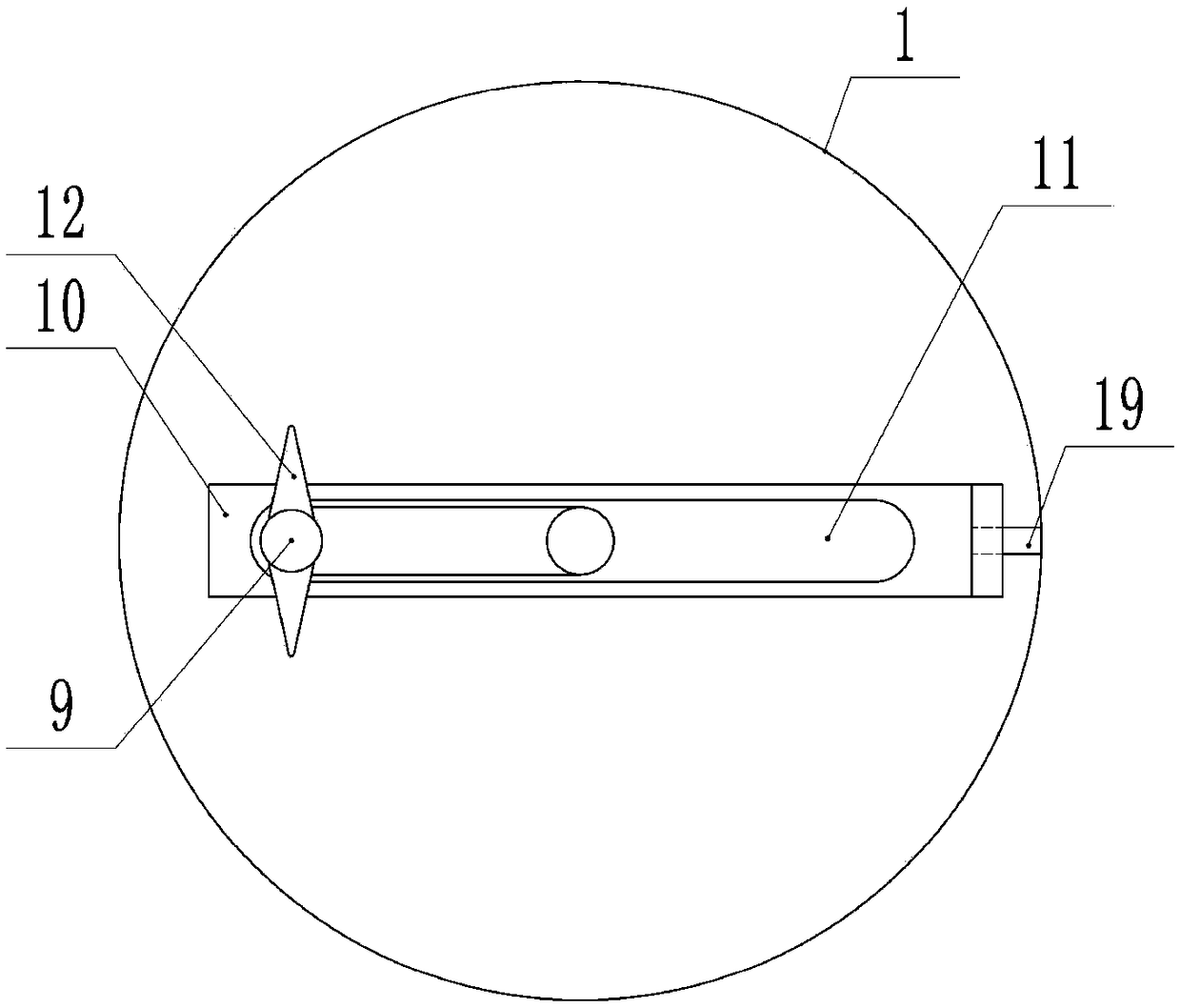

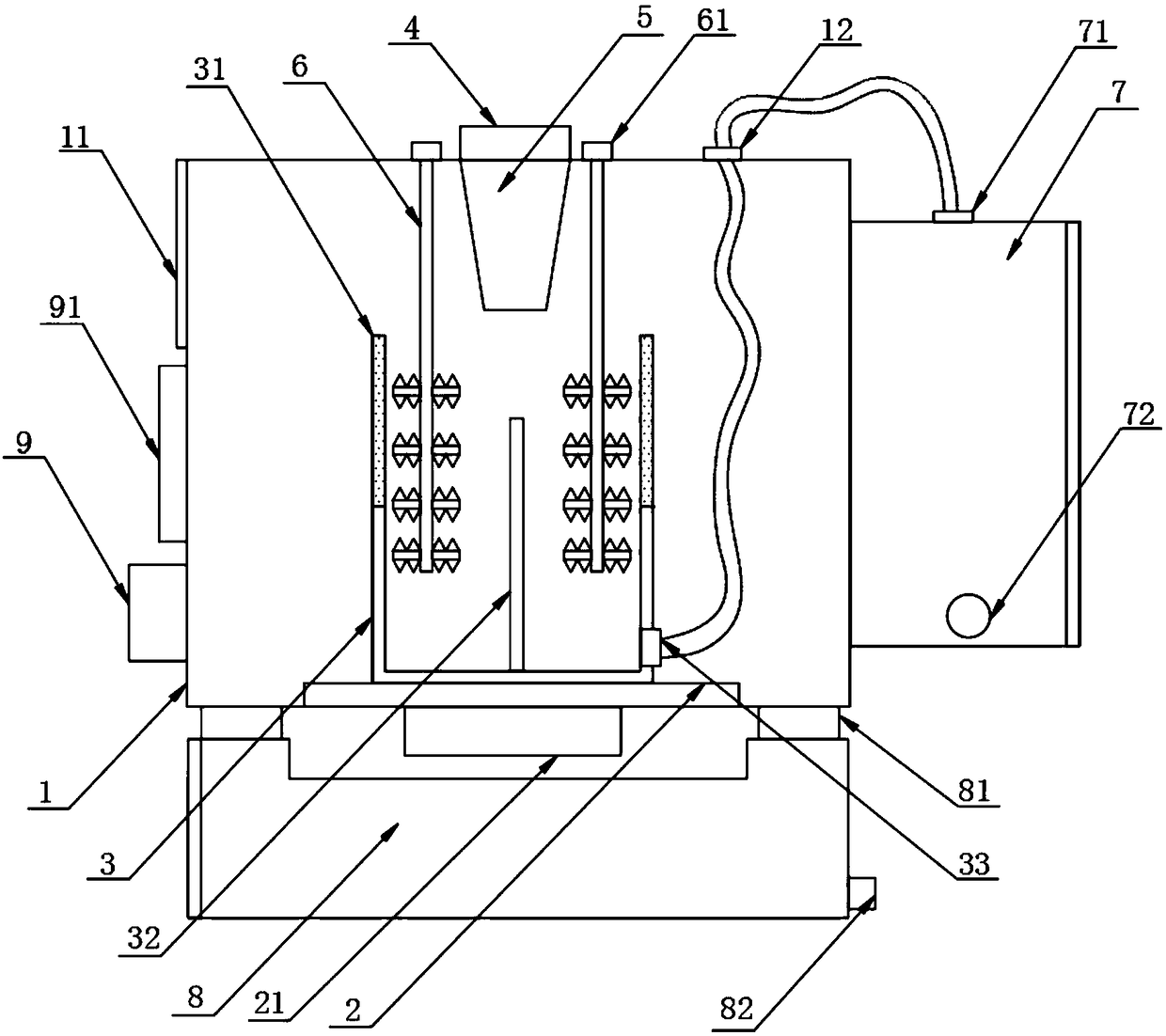

Solar hot air system enhanced in-situ bio-ventilation soil restoration system

InactiveCN105478468AAdjustable temperaturePromote degradationContaminated soil reclamationVacuum extractionCollection system

The invention relates to a solar hot air system enhanced in-situ bio-ventilation soil restoration system. The system comprises a solar air heat collection system, a ventilation system, a contaminant vacuum extraction system and a gas purification system. The ventilation system is a ventilation pipeline, and the solar air heat collection system is connected with the ventilation pipeline and used for heating air in the ventilation pipeline. The contaminant vacuum extraction system comprises a gas phase extraction pipe and a vacuum pump, the gas phase extraction pipe is directly buried in the heated contaminated soil area, and the upper portion of the gas phase extraction pipe is connected with the gas purification device. The solar hot air system enhanced in-situ bio-ventilation soil restoration system further comprises a nutrient solution injection system, and a nutrient solution is evenly pumped into organic matter contaminated soil through the nutrient solution injection system. According to the system, solar energy serves as a heat source, heated air is injected into a soil embedded radiating pipe, soil temperature is adjusted, soil microbial flora and the nutrition environment are optimized, degradation of microorganisms for organic matter in the contaminated soil is promoted, and then following vacuum extraction is facilitated. By means of the system, energy is saved, the emission of greenhouse gas is reduced, and secondary pollution generated by combustion of fossil fuel is avoided.

Owner:中钢集团天澄环保科技股份有限公司

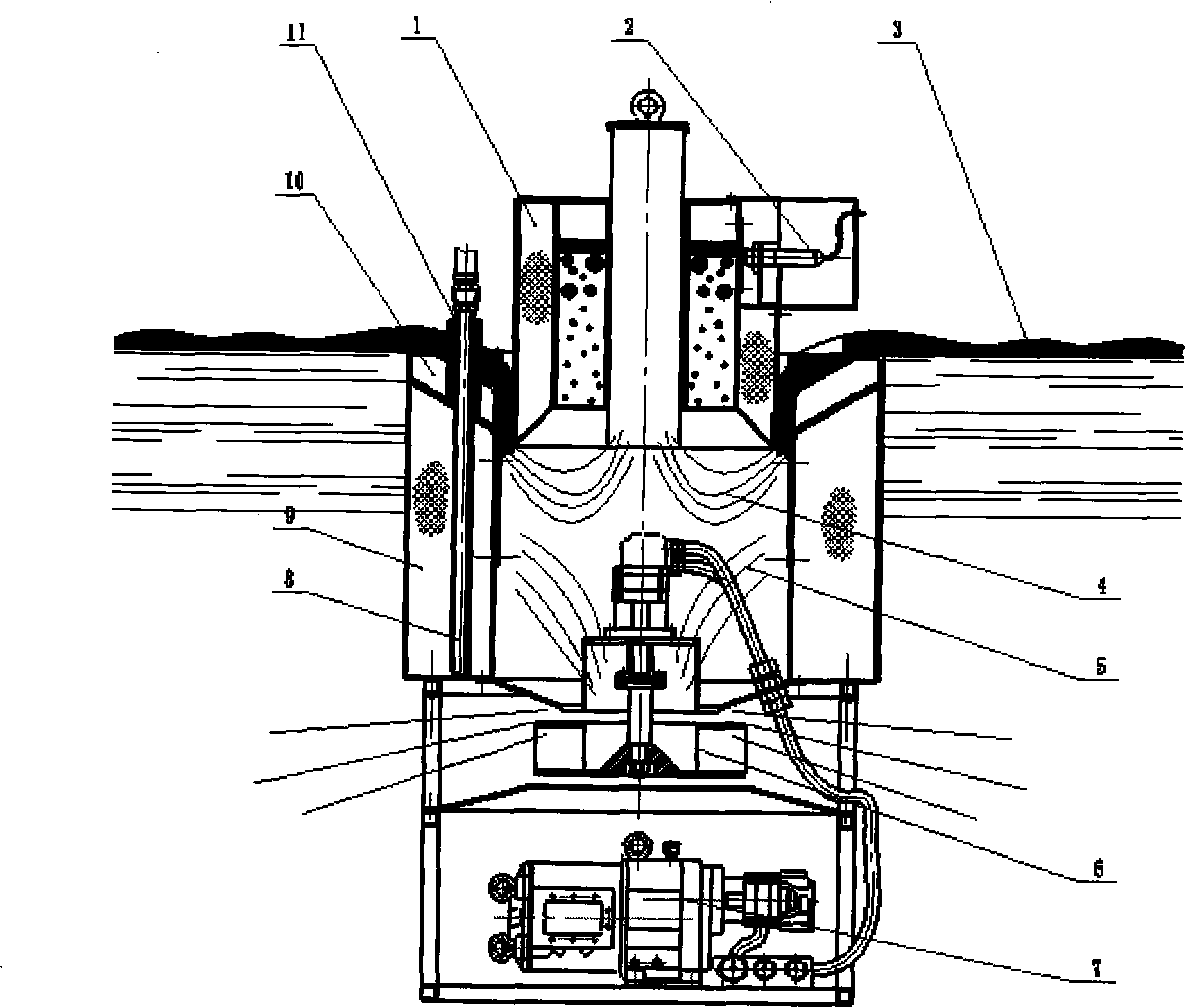

Buoy-type weir oil recovery device

ActiveCN102644262AImprove recycling efficiencyFast recovery rateWater cleaningGeneral water supply conservationBuoyEngineering

The invention provides a buoy-type weir oil recovery device which can be used for solving the problems that the traditional weir oil recovery device in the prior art has the disadvantages of poor stochastic volatility, poor oil recovery efficiency and the like. The buoy-type weir oil recovery device comprises an upper container and buoyancy compartment device, a lower container and buoyancy compartment device, a turbine device and a pump station system. The upper container and buoyancy compartment device is a container defined by a buoyancy material, wherein the container is mainly used for collecting overwater overflowing oil and providing buoyancy; and an oil-water interface monitoring probe is arranged on the upper container and buoyancy compartment device so as to intelligently control the pump station to operate. The lower container and buoyancy compartment device is also a container defined by the buoyancy material, wherein the container is mainly used for initially collecting an oil-water mixture and providing certain buoyancy; and the container is provided with a weir crest heating device for heating overflowing oil at the weir crest of the oil recovery device and a water injection pipe for adjusting the buoyancy of the entire oil recovery device. The turbine device is mainly used for guiding water in a lower container to overflow, so that the overflowing oil is better collected. The pump station system uses hydraulic power and sucks the oil sucked in an upper container to discharge. The buoy-type weir oil recovery device provided by the invention not only has functions of the traditional weir oil recovery device but also can be used for efficiently recovering the overwater overflowing oil, is slightly influenced by waves, and is a combined oil recovery device.

Owner:QINGDAO GUANGMING ENVIRONMENTAL TECH

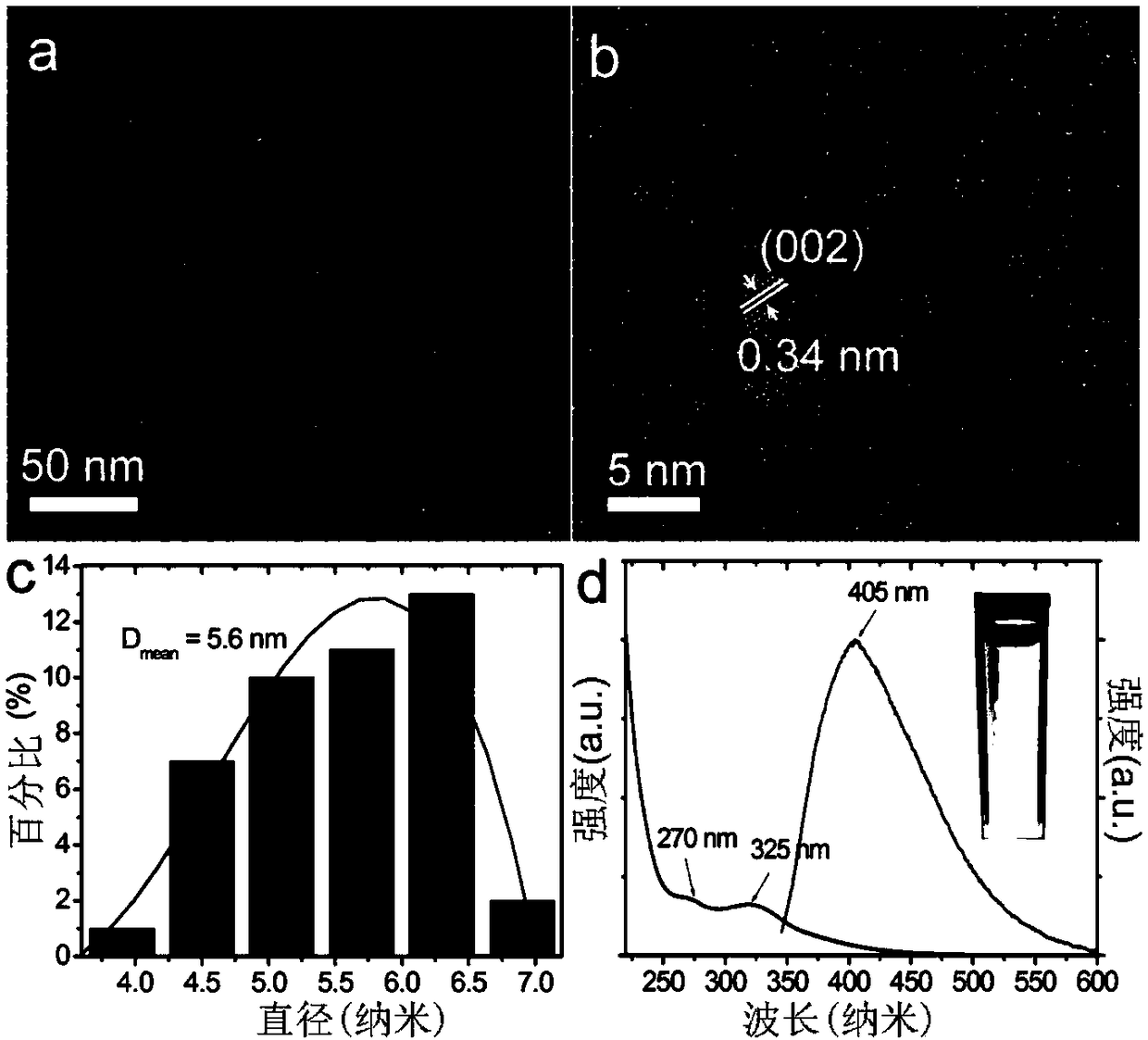

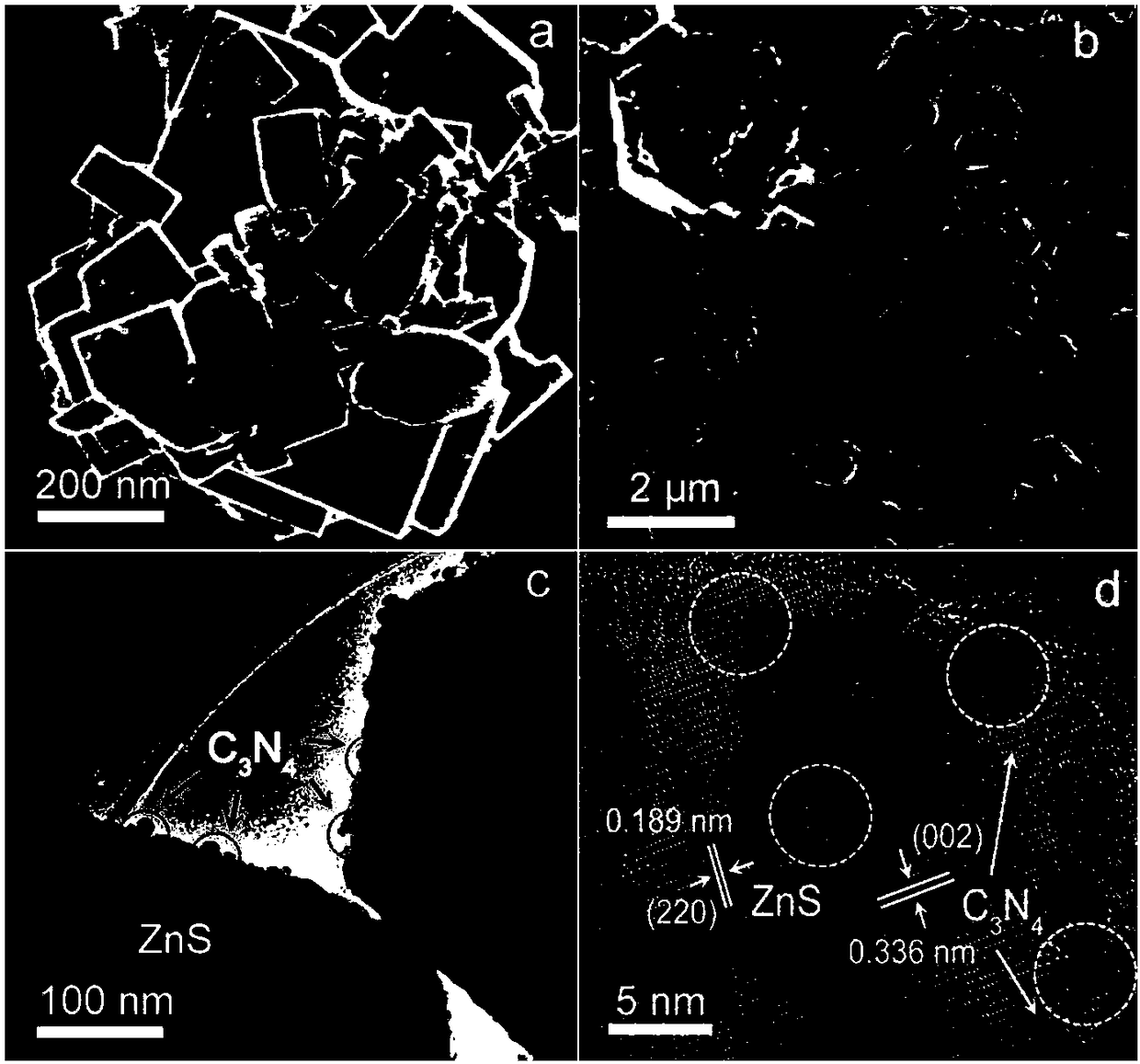

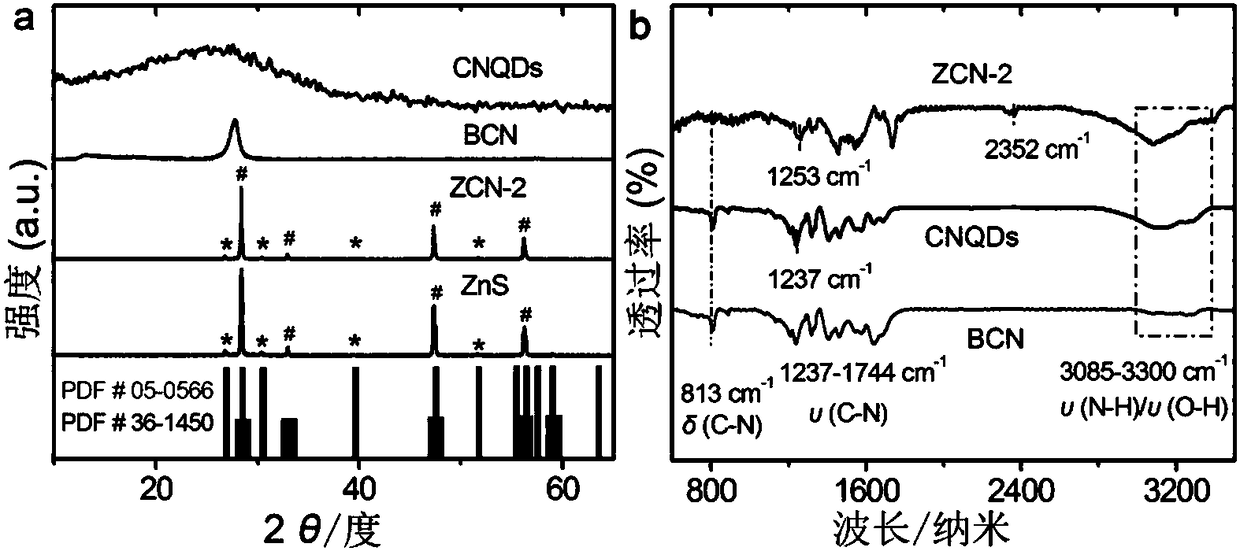

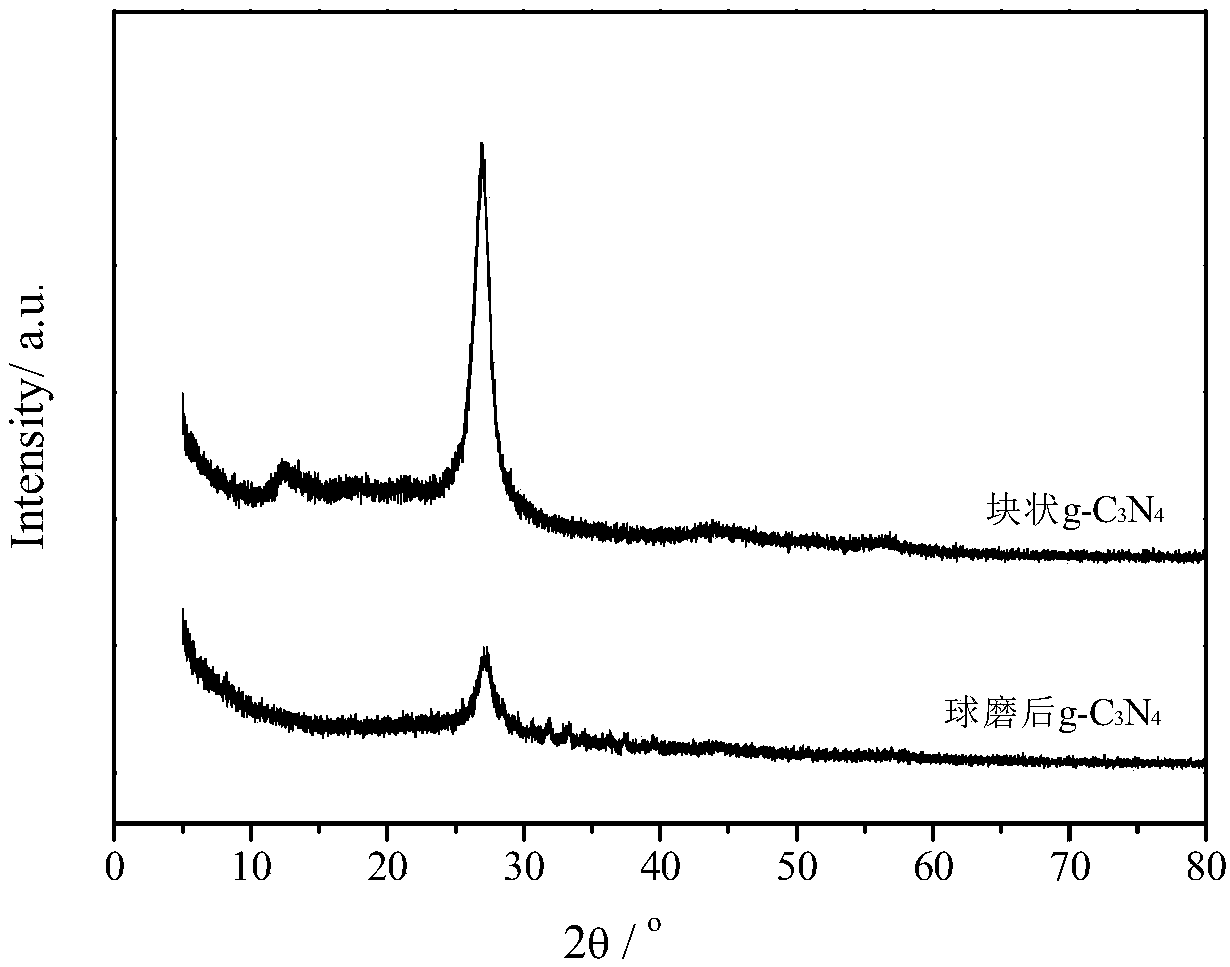

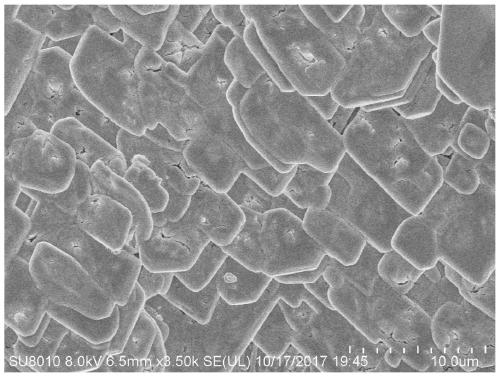

Graphene nitrogen carbide quantum dot modified ZnS micrometer composite material as well as preparation method and application thereof

ActiveCN108246331AGood water solubilityVisible light response ability is strongCatalyst activation/preparationHydrogen productionCatalytic effectHydrogen production

The invention provides a graphene nitrogen carbide quantum dot modified ZnS micrometer composite material as well as a preparation method and application thereof and belongs to the technical field ofsemiconductor composites. The method comprises the following steps: preparing ZnS(en)0.5 nanosheets; adding amino compounds into a porcelain boat, and raising the temperature and reacting in a tube furnace so as to obtain bulk phase g-C3N4 powder; finally, mixing and stirring the ZnS(en)0.5 nanosheets and the g-C3N4 powder, and carrying out a hydrothermal reaction in a reactor, thereby obtaining the graphene nitrogen carbide quantum dot modified ZnS micrometer composite material. The invention further provides application of the graphene nitrogen carbide quantum dot modified ZnS micrometer composite material serving as a photocatalyst. The photocatalyst can reach hydrogen production activity of 5600u mol h-1g-1 under visible light and has excellent photocatalytic stability, the hydrogen production activity is 140 times that of the ZnS under the same condition, and after four cycles, the catalytic effect is not obviously decreased.

Owner:NORTHEAST NORMAL UNIVERSITY

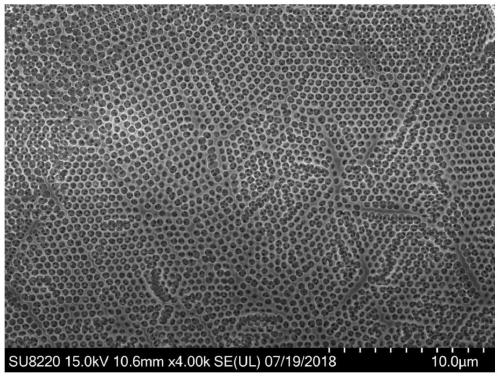

Carbon nitride and graphene composite material modified by organic dye and application of carbon nitride and graphene composite material

ActiveCN107649159AHigh surface areaHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic dyeWater vapor

The invention discloses a carbon nitride and graphene composite material modified by organic dye. A method for preparing the carbon nitride and graphene composite material includes ultrasonically uniformly mixing g-C3N4 alcoholic solution and graphene alcoholic solution with each other, keeping the temperature of 100-240 DEG C constant for 8-24 h, centrifugally removing ethyl alcohol and carryingout vacuum drying on obtained precipitates to obtain g-C3N4 / r-graphene compositions; ultrasonically uniformly mixing the g-C3N4 / r-graphene compositions, the organic dye and organic alcohol C with oneanother, carrying out centrifuging, washing precipitates by the aid of organic alcohol C and then drying the precipitates under dark conditions to obtain the carbon nitride and graphene composite material modified by the organic dye. The carbon nitride and graphene composite material has the advantages that the carbon nitride and graphene composite material is provided with mesoporous structures and has large specific surface areas, the hole-charge separation speeds, the light absorption rate and the light utilization rate can be increased, the photocatalytic performance of the carbon nitrideand graphene composite material is higher than 8 times the photocatalytic performance of graphite-phase carbon nitride if the carbon nitride and graphene composite material is used for carrying out reduction on carbon dioxide and water vapor in visible light to obtain methanol.

Owner:ZHEJIANG UNIV OF TECH

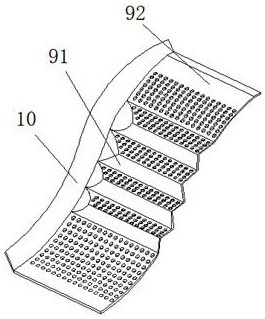

Filler extraction tower for gradient fractionating separation of large phase ratio system, and extraction method thereof

InactiveCN102728099AImprove cell-level efficiencyIncrease separation rateLiquid solutions solvent extractionPhase ratioTower

The present invention discloses a filler extraction tower for gradient fractionating separation of a large phase ratio system, and an extraction method thereof. The tower body of the extraction tower is formed by sequentially connecting an upper section cylinder, a middle section cylinder and a lower section cylinder, wherein the middle section cylinder is provided with a double-layer mesh filler layer, the upper filler layer of the double-layer mesh filler layer is a hydrophilic mesh filler layer, and the lower filler layer of the double-layer mesh filler layer is a hydrophobic mesh filler layer. According to the present invention, hydrophilicity and hydrophobicity of the filler layer are gradiently and alternately arranged inside the middle section cylinder from top to bottom along the vertical direction of the tower body, such that repeated gathering and phase forming of the dispersion phase of the easily-emulsified system can be achieved in the a middle section cylinder filler layer so as to accelerate separation rate of the two phases of the easily-emulsified system and improve stage efficiency of the tower body units; the method is particularly suitable for performing rapid clarification phase separation operation on the two phases of the light phase and the weight phase under the condition of the large phase ratio difference or the large flow ratio difference; and with the method, gradient extraction and fractionating separation of the complex system containing a plurality of different hydrophilic components and hydrophobic components can be achieved in the tower.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

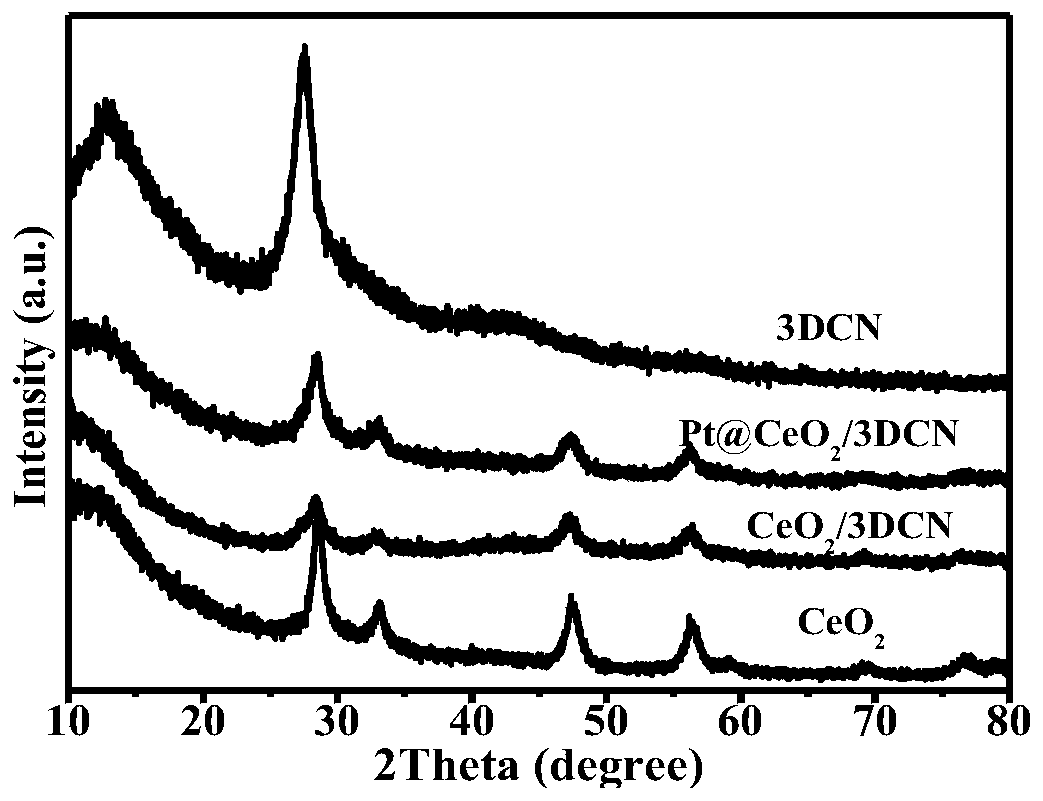

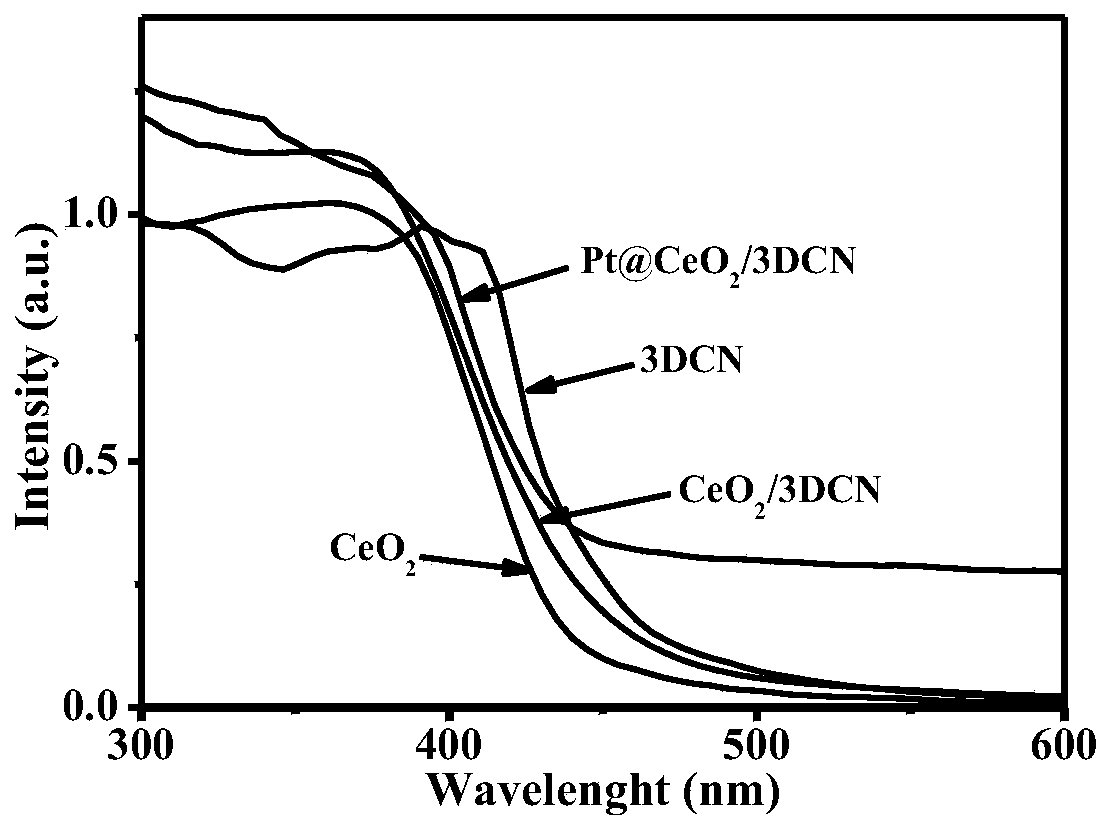

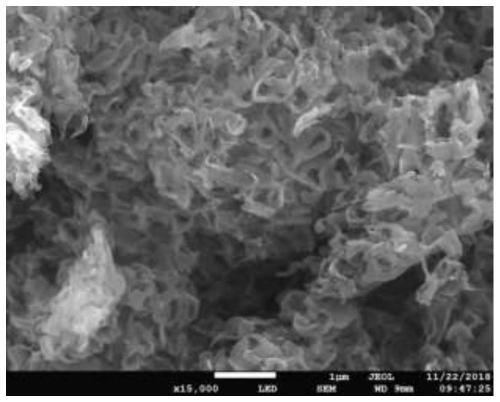

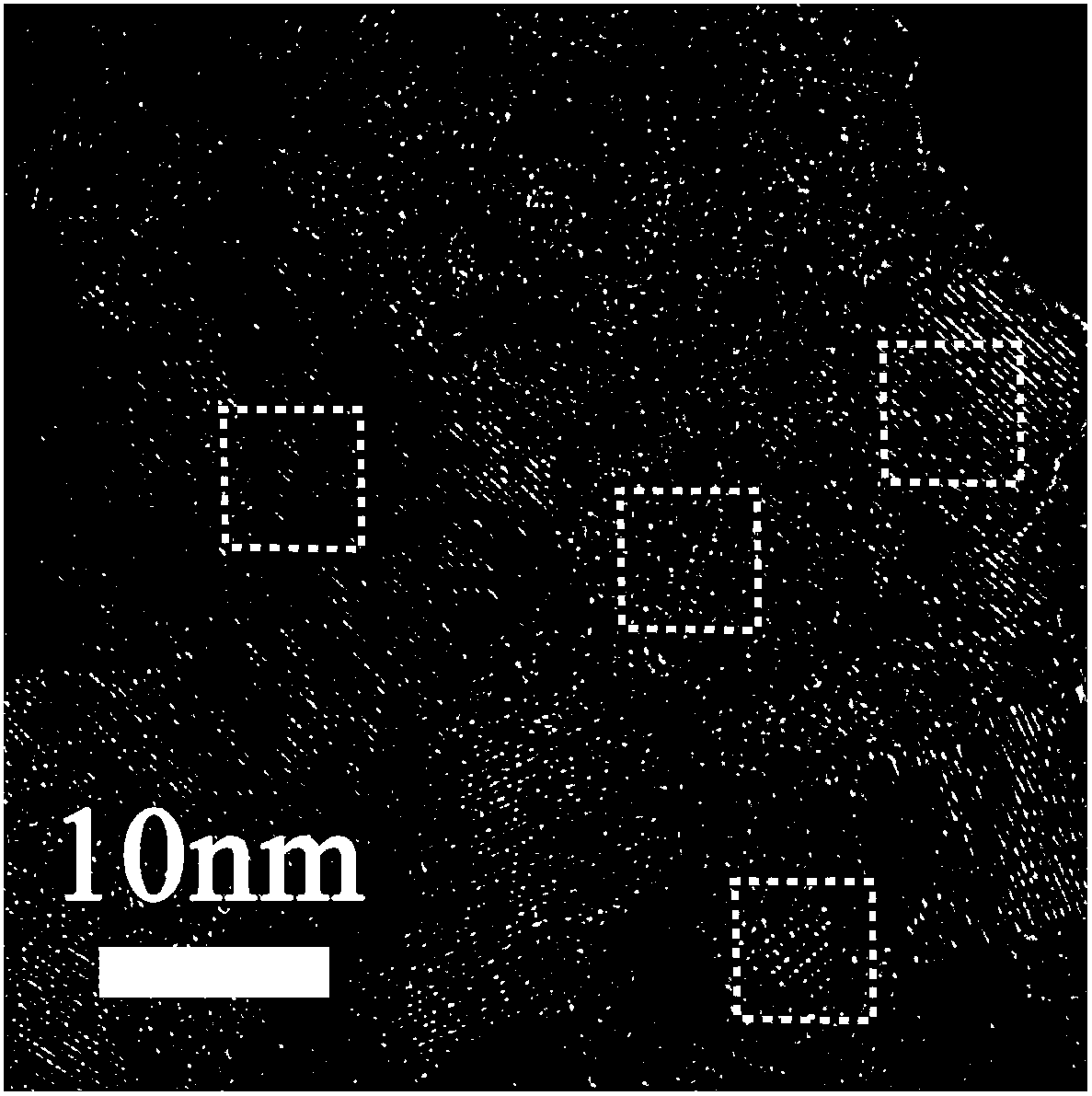

Preparation method for Pt@CeO2/3DCN composite photocatalyst applied to photocatalytic reduction of CO2

InactiveCN110252371ANo wasteWill not cause secondary pollutionHydrocarbon from carbon oxidesChemical industryPorous carbonUltraviolet lights

The invention provides a preparation method and application of a Pt@CeO2 / 3DCN composite photocatalyst, belonging to the technical field of preparation of energy conversion materials. The preparation method mainly includes the following three steps: firstly, preparing three-dimensional porous carbon nitride (3D CN); secondly, mixing cerium nitrate hexahydrate with 3D CN under stirring, and carrying out drying and calcining to obtain a CeO2 / 3DCN binary composite photocatalyst; and dispersing a certain amount of the CeO2 / 3DCN photocatalyst in an isopropanol solution, introducing nitrogen to remove gas in the solution, then adding a chloroplatinic acid solution drop by drop, carrying out stirring under the irradiation of an ultraviolet lamp, and after a reaction is completed, performing filtering, washing and vacuum drying so as to obtain the Pt@CeO2 / 3DCN ternary composite photocatalyst. The obtained Pt@CeO2 / 3DCN ternary composite photocatalyst is used for reducing CO2 under the irradiation of ultraviolet light. The preparation method of the invention is simple, and does not cause the waste of resources and the formation of secondary pollution; and the composite photocatalyst is an environment-friendly efficient energy conversion technology.

Owner:JIANGSU UNIV

Method for separating enriched uranium, thorium mixture and rare earth from preferred slag

The invention discloses a separating method of enriched uranium and thorium composition and rare earth, which comprises the following steps: leaching slag; extracting; separating extracting phase, residual phase and insoluble solid; obtaining the product.

Owner:YANGZHOU UNIV +2

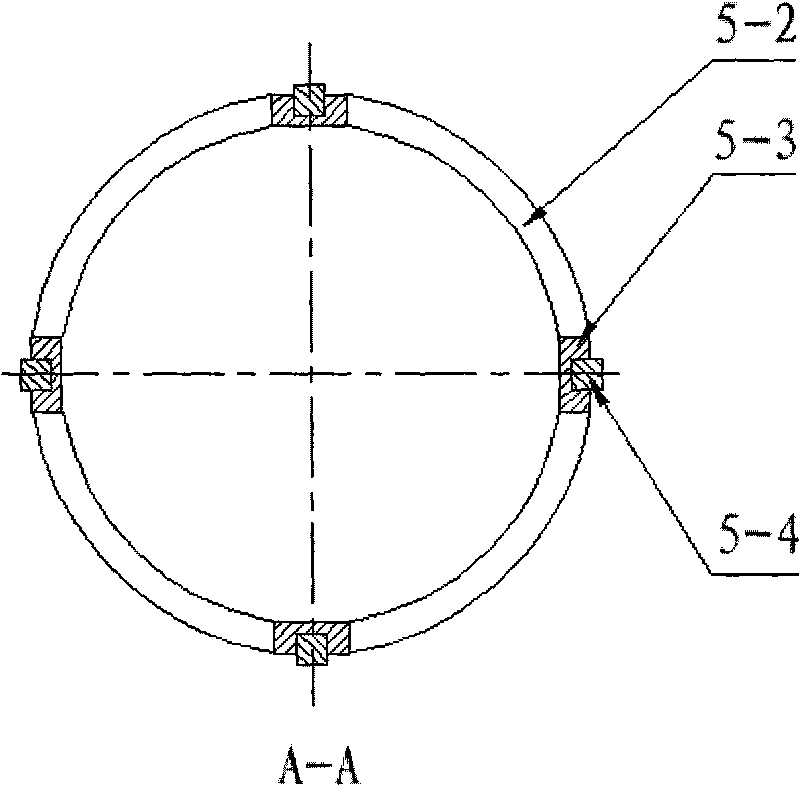

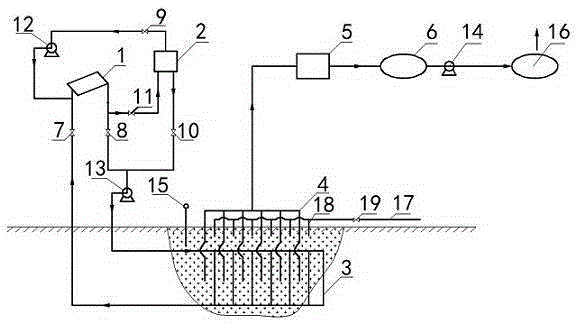

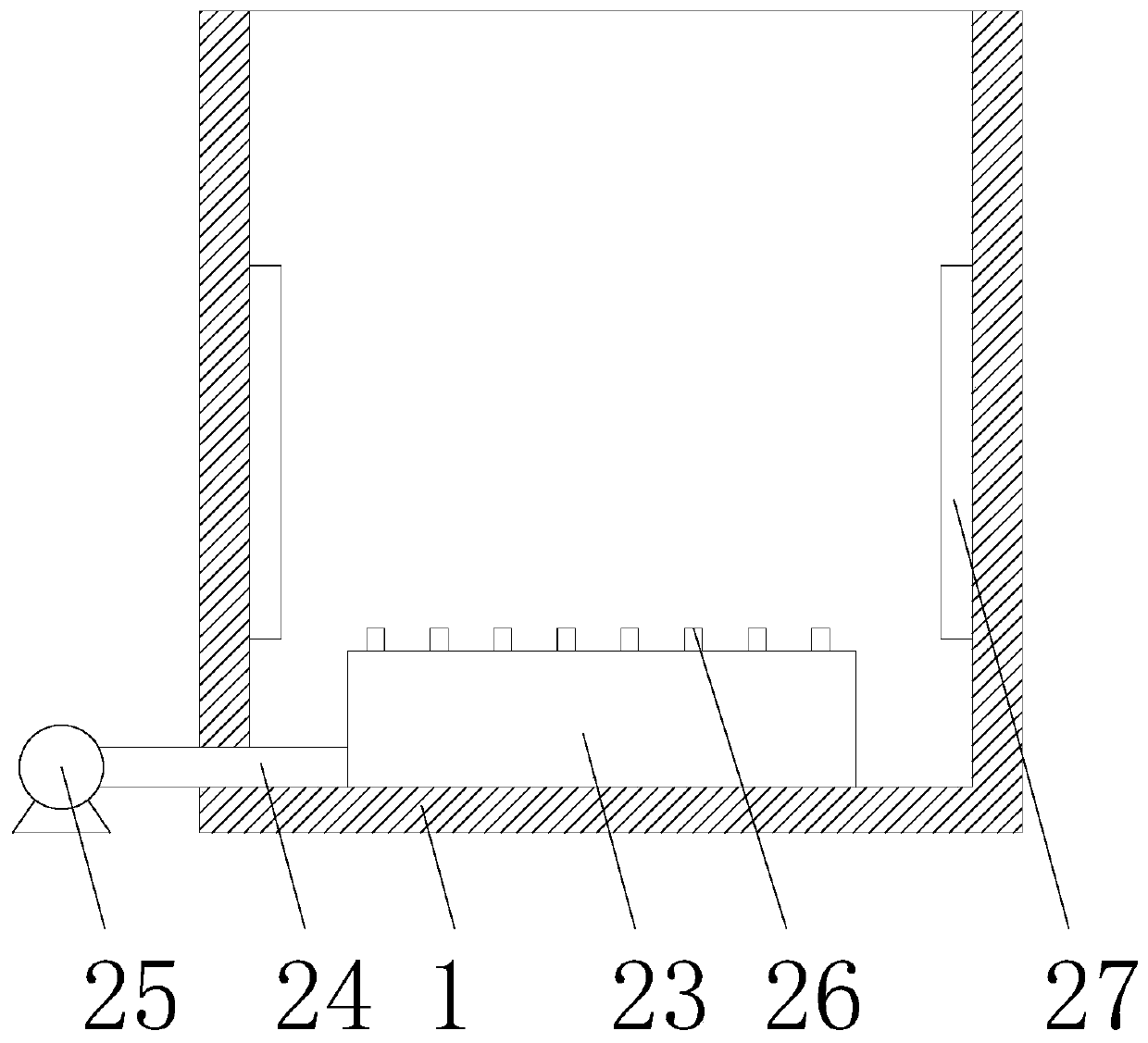

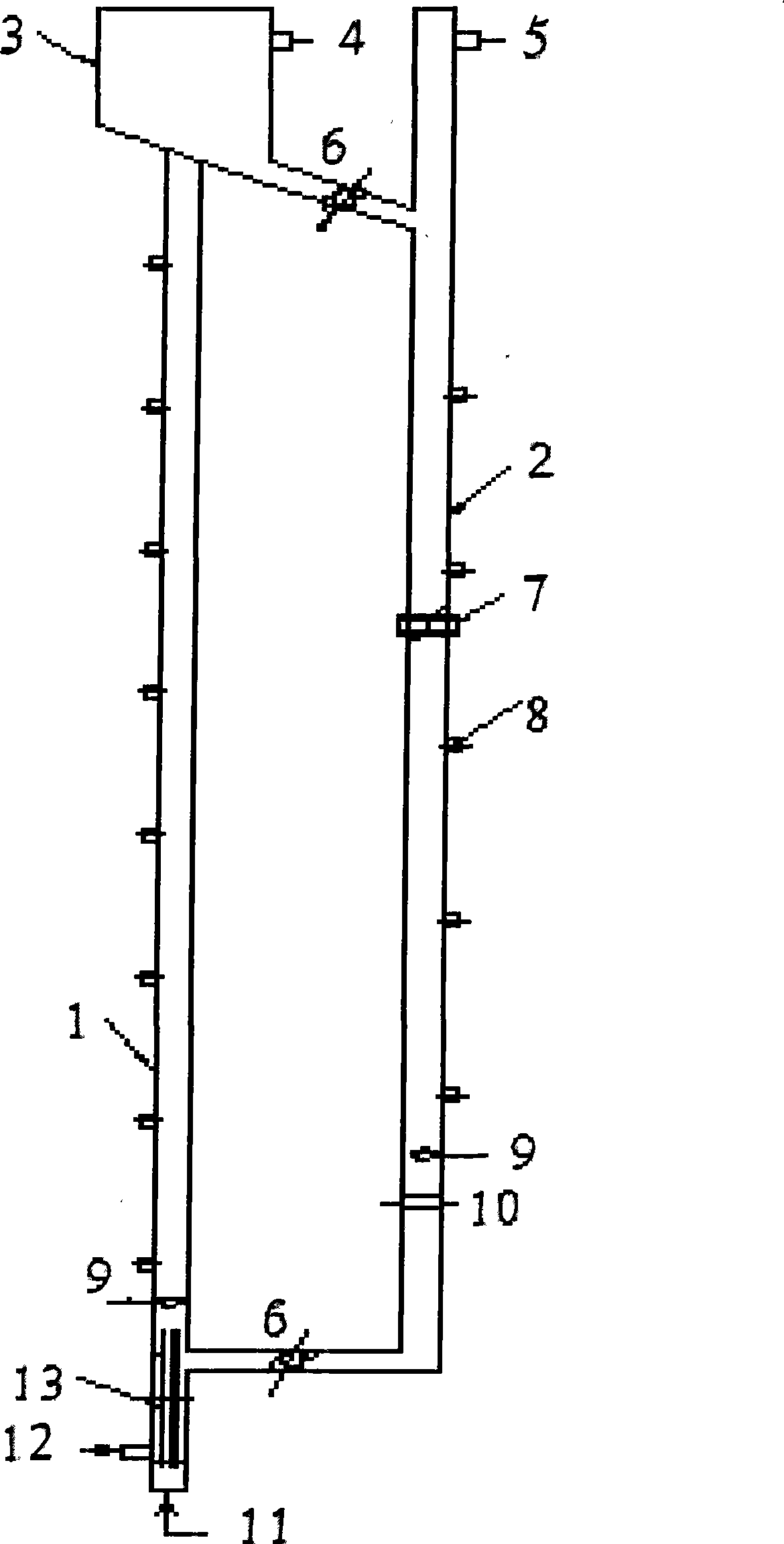

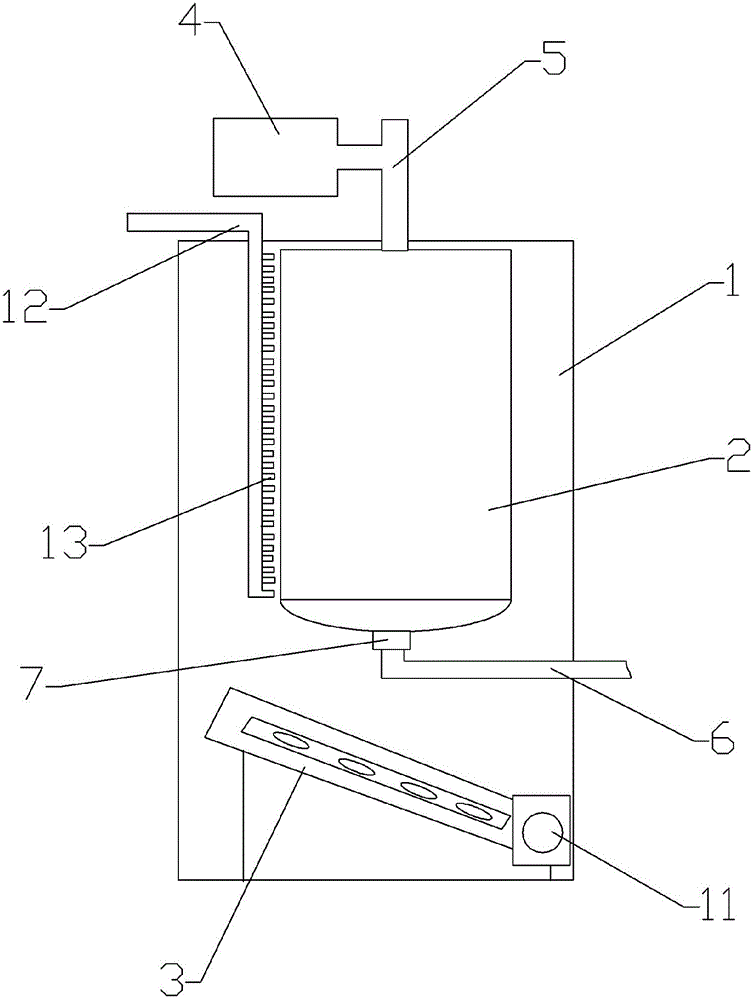

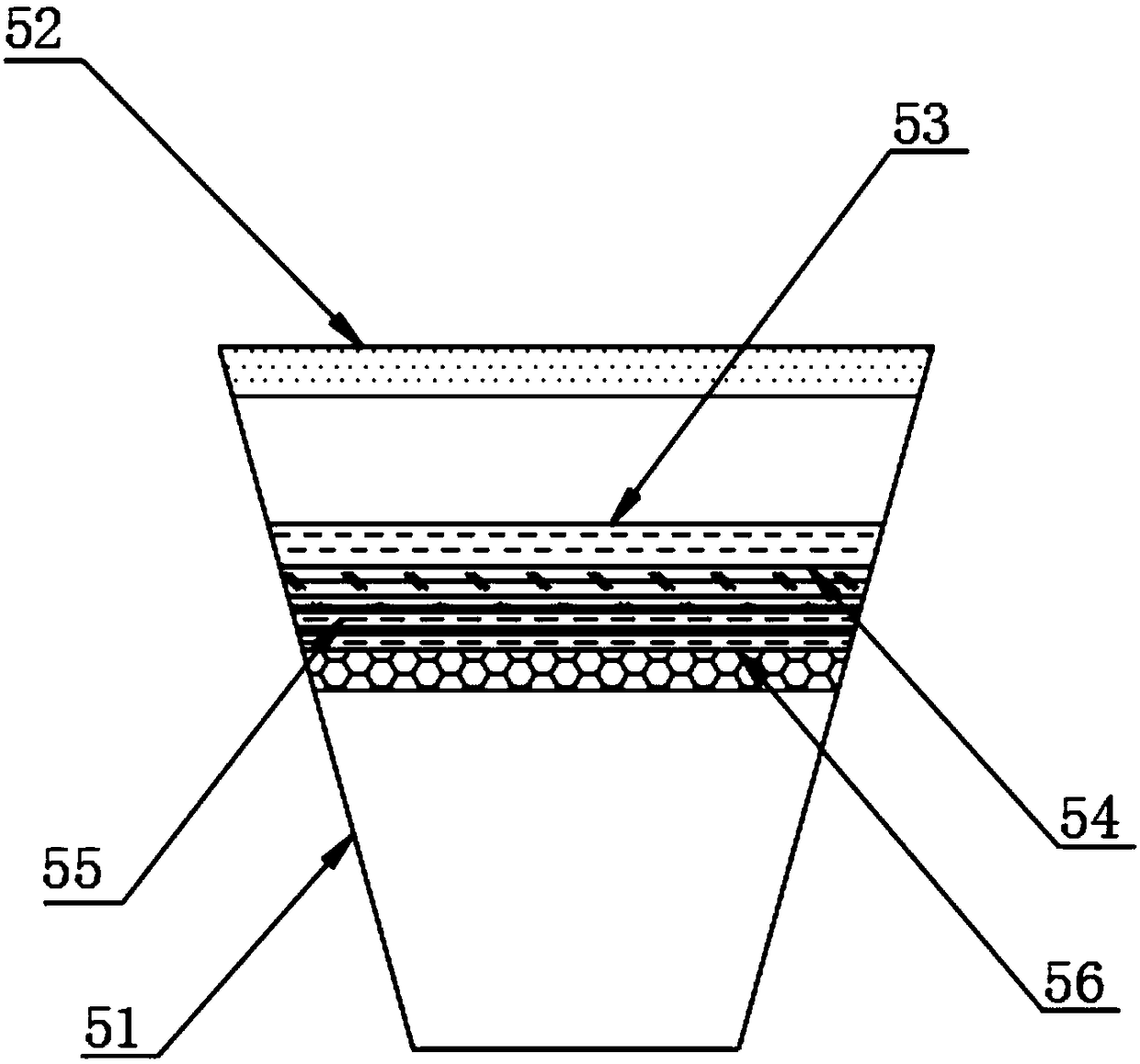

Solar in-situ reinforced vapor extracting system for restoring soil organic pollutants

ActiveCN105234166AReduce residual concentrationIncrease temperatureContaminated soil reclamationGas phaseWater cycling

The invention relates to a solar in-situ reinforced vapor extracting system for restoring soil organic pollutants. The solar in-situ reinforced vapor extracting system comprises a pipeline of a vapor extracting pipe 4, a water circulating system pipeline buried in organic pollutant soil, a solar heat collecting system 1, a heat insulating water tank 2, a gas purifying system and a soil water replenishing system, wherein the water circulating system pipeline is communicated with the solar heat collecting system 1 on the ground so as to form a solar circulating water heating system, the water circulating system pipeline is communicated with the heat insulating water tank 2 so as to form a heat insulating water tank heat storage circulating water system, and the solar heat collecting system 1 is communicated with the heat insulating water tank 2 so as to form a solar and heat insulating water tank combination circulating water heating system; pumps 12 and 13 and valves 7, 8, 9, 10 and 11 are arranged on pipelines of the solar circulating water heating system, the heat insulating water tank heat storage circulating water system and the solar and heat insulating water tank combination circulating water heating system; and the pipeline of the vapor extracting pipe 4 is communicated with the gas purifying system on the ground. The system utilizes solar reinforced in-situ vapor extraction to restore the soil organic pollutants, is compact, is convenient to operate and saves energy.

Owner:中钢集团天澄环保科技股份有限公司

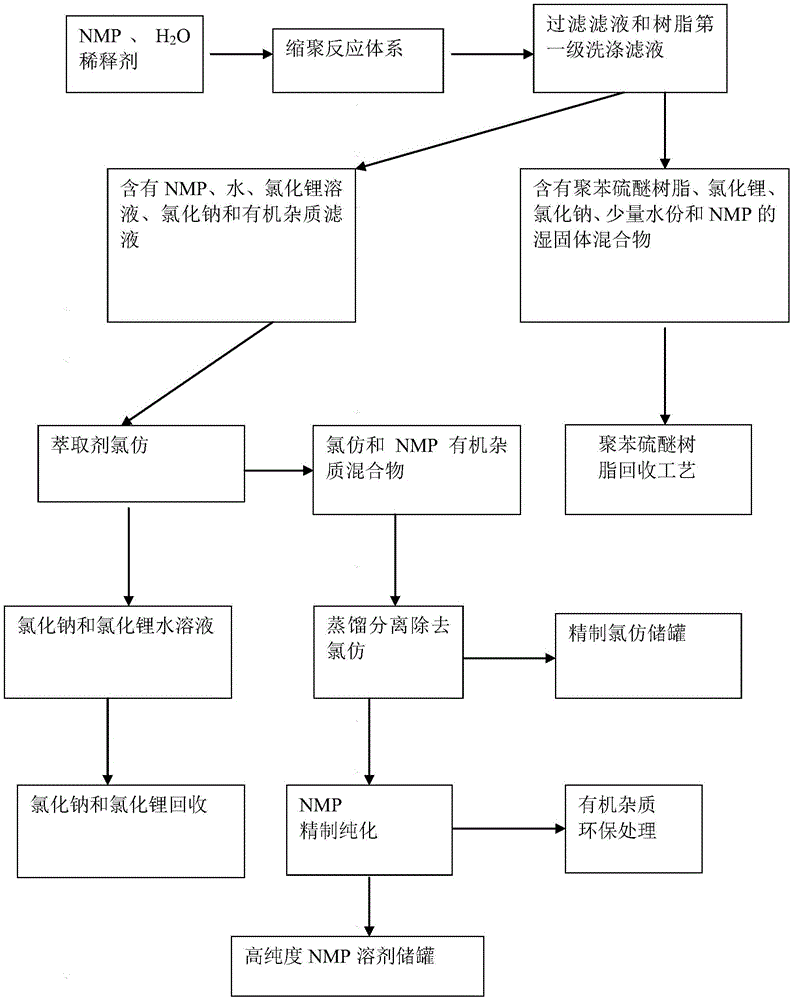

Solvent recycling technology adopted in polyphenylene sulfide production

The invention relates to a solvent recycling technology adopted in polyphenylene sulfide production. According to the technology, sodium sulfide and paradichlorobenzene which contain a certain amount of crystallization water are adopted as raw materials, lithium chloride is adopted as cosolvent, and N-methyl pyrrolidone is adopted as solvent, so that polyphenylene sulfide resin is synthecized; after a polycondensation reaction is completed, the solvent for synthesizing and producing the polyphenylene sulfide resin is recycled, meanwhile, a certain amount of fresh NMP solvent and oxygen-free deionized water need to be added to a polycondensation reaction system to dissolve the cosolvent and a by-product (sodium chloride) generated in the synthesis technological process, thereby a mixture system containing the polyphenylene sulfide resin, NMP, the cosolvent, the by-product and organic impurities is formed, and immediately the mixture system is input into a centrifugal machine for solid-liquid separation. According to the solvent recycling technology, the high boiling point solvent and the oxygen-free deionized water are adopted as diluent of the polycondensation reaction system, and the solvent recycling technology aims at lowering the viscosity of the polycondensation reaction system, raising the velocity of solid-liquid separation, further raising the production rate of the polyphenylene sulfide resin, lowering production cost of whole polyphenylene sulfide resin, shortening the washing process flow at the same time and reducing equipment investment of the washing process flow.

Owner:何展潮

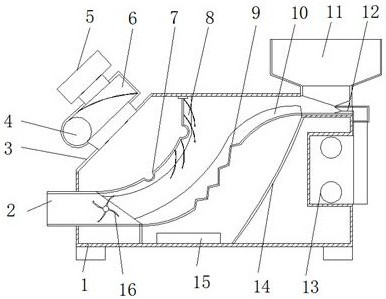

Sawdust waste recycling and ash removing device for furniture manufacturing

InactiveCN111842151AImprove purification efficiencyIncrease separation rateSievingGas current separationWood shavingsAir pump

The invention discloses a sawdust waste recycling and ash removing device for furniture manufacturing, and relates to the technical field of furniture production. The sawdust waste recycling and ash removing device aims to solve the problems that most of processing wastes such as sawdust and wood shavings are directly discarded on the ground for convenience, sand grains, dust and the like are mixed in the sawdust, the wood shavings and the like in the utilization process, and the recycling quality is influenced. The sawdust waste recycling and ash removing device specifically comprises a shell, a feeding hopper and a sealing cover are fixedly installed on the top of the shell, an air pump and a discharging pipe of a rectangular structure are fixedly installed at two ends of the shell correspondingly, and a cleaning pipe is fixedly installed at the bottom end of a side face of the shell. According to the sawdust waste recycling and ash removing device, the dust, the sand grains and thelike are separated from the sawdust and the wood shavings under the action of airflow, the sand grains and the like are filtered through a filter screen plate mechanism, the dust and the like penetrate through the filter screen plate mechanism along with air flowing to enter a filtering mechanism, and fall into an ash discharging pipe through separation of the filtering mechanism, continuous ash removing and impurity removing operation is carried out, and the purification efficiency of wastes such as the sawdust and the wood shavings is remarkably improved.

Owner:周祥

Method for preparing sugar-free and smell-free pumpkin powder

The invention relates to food processing technologies and in particular relates to a method for preparing sugar-free and smell-free pumpkin powder. The method comprises the following steps: with fresh old mature pumpkins as raw materials, mixing and processing by virtue of a colloid grinding pulping process, a biological enzymatic hydrolysis and smell removal technology, an ultrasonic flocculation effect and a low-temperature sedimentation solid-liquid separation process. According to the method, the smell of the pumpkins is removed and the mouth feel and the solubility of the pumpkin powder are improved. The pumpkin powder prepared by the method is high in soluble dietary fiber content, low in sugar content and suitable for patients with diabetes and hypertension, can serve as a raw material for a mixing process in the food industry and also can be processed and eaten according to personal taste. The method has the characteristics of low cost, low energy consumption and low heat-sensitive nutrition loss.

Owner:BIOTECH RES INST HEILONGJIANG ACADEMY OF AGRI SCI

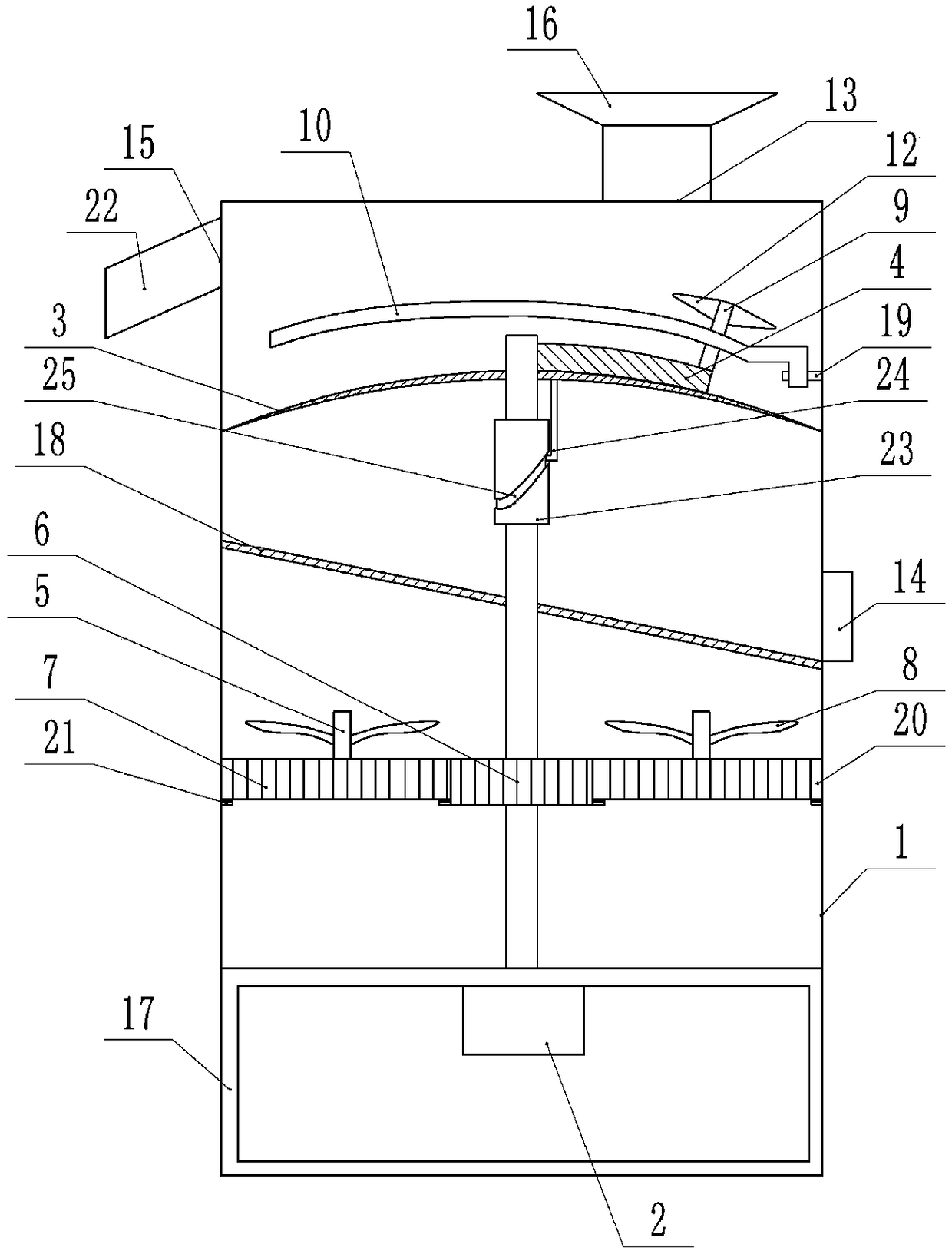

Cassia seed screening device

ActiveCN108499674AIncrease separation rateGood peeling effectGrain treatmentsEngineeringFood processing

The invention belongs to the technical field of food processing equipment and in particular discloses a cassia seed screening device which comprises a case, wherein a motor provided with an upward output shaft is arranged at the lower part of the case; a screening plate, a guide plate, a discharge hole and a screening waste hole are arranged on the case; a transverse rod is arranged in a position,above the screening plate, of the output shaft; a feeding hole is formed in the upper part of the case; the case is a cylindrical case; the case is provided with convex teeth in a circumferential direction below the guide plate; the output shaft is provided with a first gear which is fixedly connected with the output shaft and is arranged in a position below the guide plate; a plurality of secondgears are arranged between the first gear and the case; the second meshes are meshed with both the first gear and the convex teeth; first vertical shafts which are fixedly connected with the second gears are arranged on the second gears; fans which are fixedly connected with the first vertical shafts are arranged on the first vertical shafts. The device is mainly used for screening cassia seeds,and the problem that product waste can be caused since fruit peel is not well crushed can be solved.

Owner:凤冈县万福食品有限责任公司

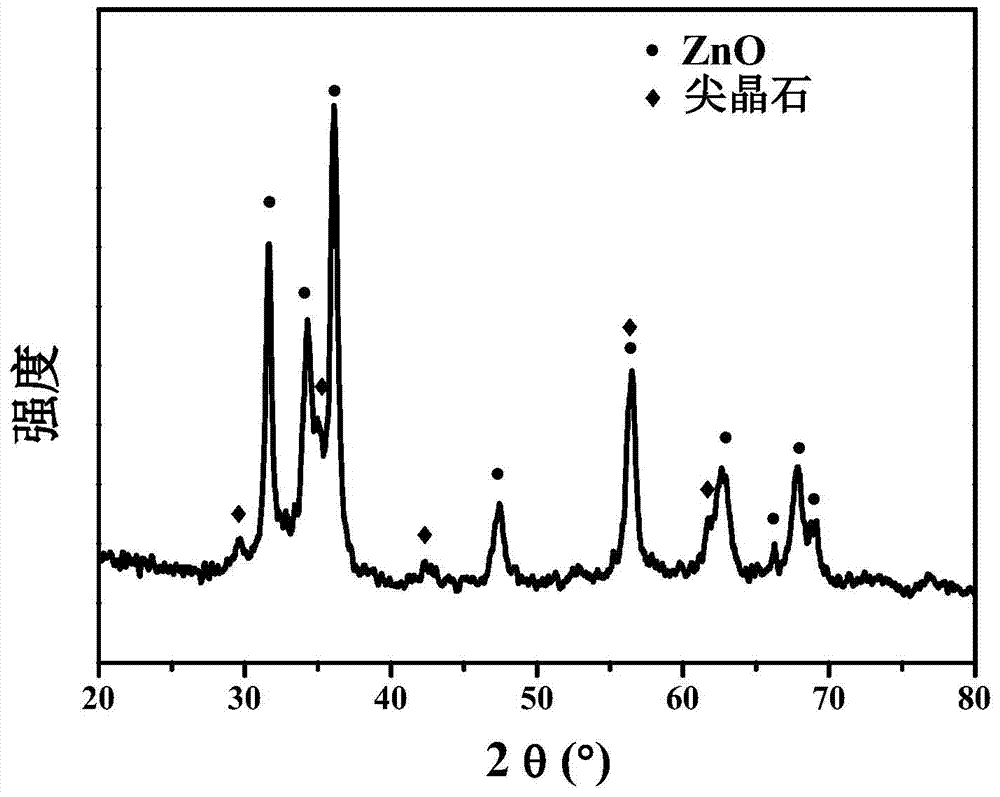

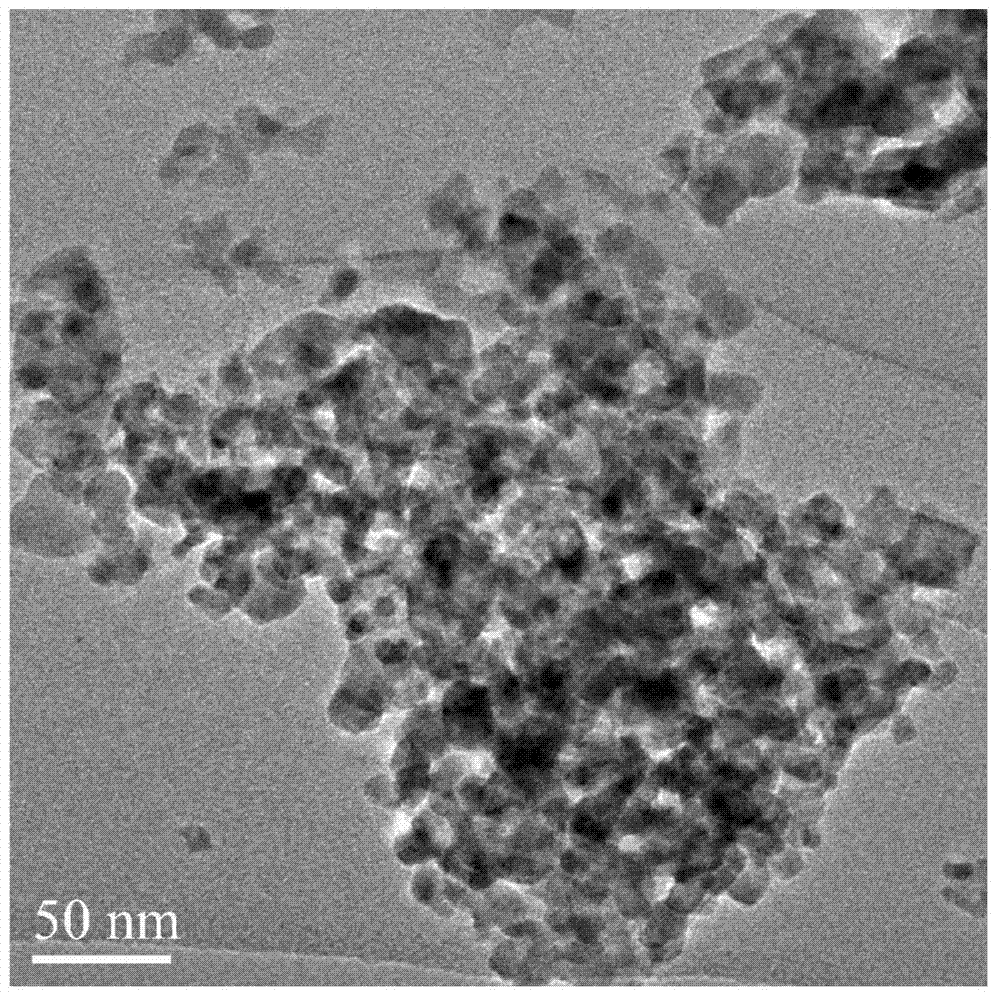

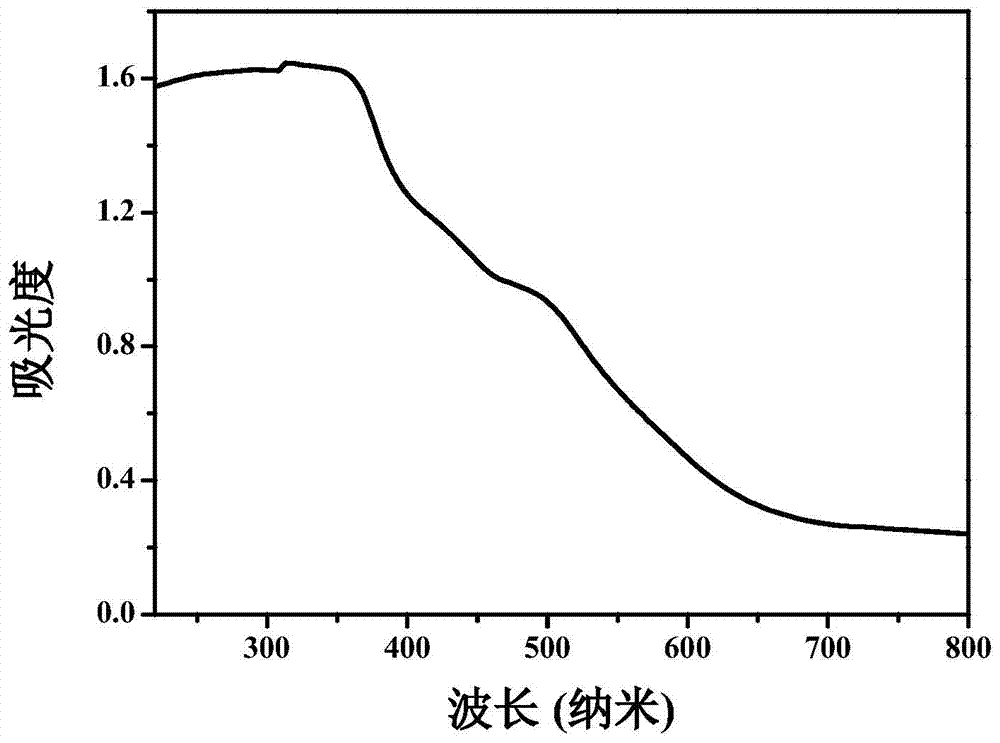

Heterojunction type ternary composite semiconductor photocatalyst and preparation method thereof

InactiveCN104841440AProper band structureIncrease separation rateWater/sewage treatment by irradiationWater contaminantsHeterojunctionElectronic band structure

The invention discloses a heterojunction type ternary composite semiconductor photocatalyst and a preparation method thereof. A constant-pH coprecipitation method is adopted to prepare ternary layered double hydroxides as a precursor, and finally a ternary heterojunction composite semiconductor is obtained by high-temperature roasting. The preparation technology is simple and convenient, the obtained material is provided with a proper energy band structure, current carrier separation and migration rates can be effectively improved, visible light is efficiently used, the relative amount of metal ions is selectively regulated and controlled to prepare a series of ternary heterojunction composite semiconductors, a high-activity photocatalyst is screened out, and good dye degradation ability is shown under the visible light. A visible light catalytic degradation reaction rate constant of the ternary heterojunction composite semiconductor to methylene blue is 1.6 to 4.1 times of that of a binary composite semiconductor, and the ternary heterojunction composite semiconductor has higher catalytic activity and good universality in the aspect of dye degradation under visible light.

Owner:BEIJING UNIV OF CHEM TECH

Method capable of photocatalytically degrading dyes to prepare copper-loaded nano titanium dioxide chitosan composite microspheres in microfluidic mode

ActiveCN108855233AIncrease profitLarge catalytic surface areaWater/sewage treatment by irradiationWater treatment compoundsIonChemistry

The invention discloses a method capable of photocatalytically degrading dyes to prepare copper-loaded nano titanium dioxide chitosan composite microspheres in a microfluidic mode. The method comprises the steps: adding a tetrabutyl titanate solution into an acid solution, mixing to form nano titanium dioxide gel, utilizing an organic solvent to mixing the nano titanium dioxide gel with amine terminated hyperbranched polymer to obtain mixed liquor, then adding a copper ion solution into the mixed liquor, drying to obtain copper-loaded nano titanium dioxide powder, adding the copper-loaded nanotitanium dioxide powder and chitosan into the acid solution to be mixed to obtain a dispersion phase, mixing sorbitan fatty acid ester with a hydrocarbon mixture to obtain a continuous phase, mixingthe dispersion phase with the continuous phase in a microfluidic mode and drying to obtain the copper-loaded nano titanium dioxide chitosan composite microspheres. According to the method disclosed bythe invention, the composite microspheres are prepared in the microfluidic mode, so that a material utilization rate is high; the microspheres have large self catalyzing surface areas and high catalytic activity, can effectively reduce dye concentration, reduce toxic components in dye wastewater and protect environment and water resources.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

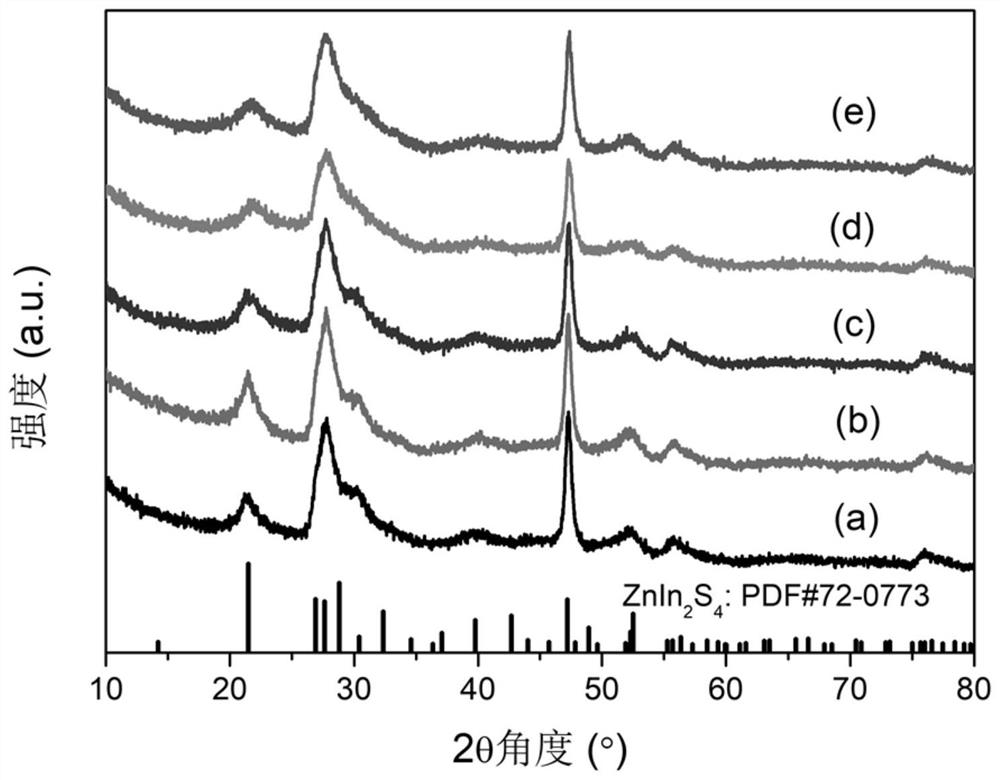

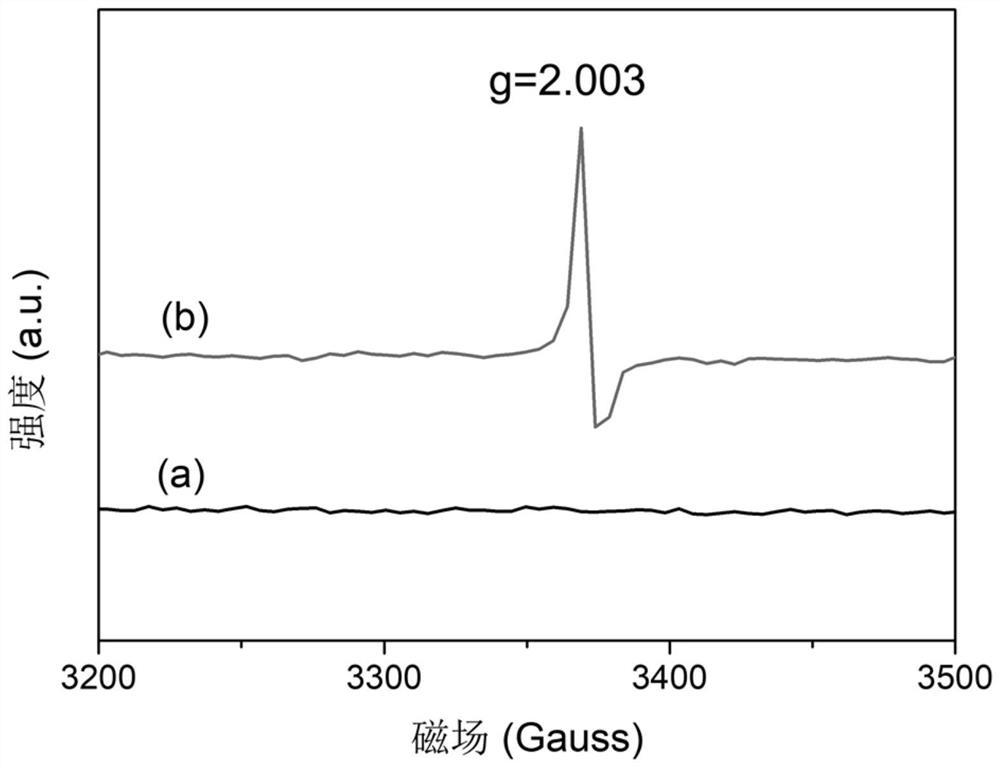

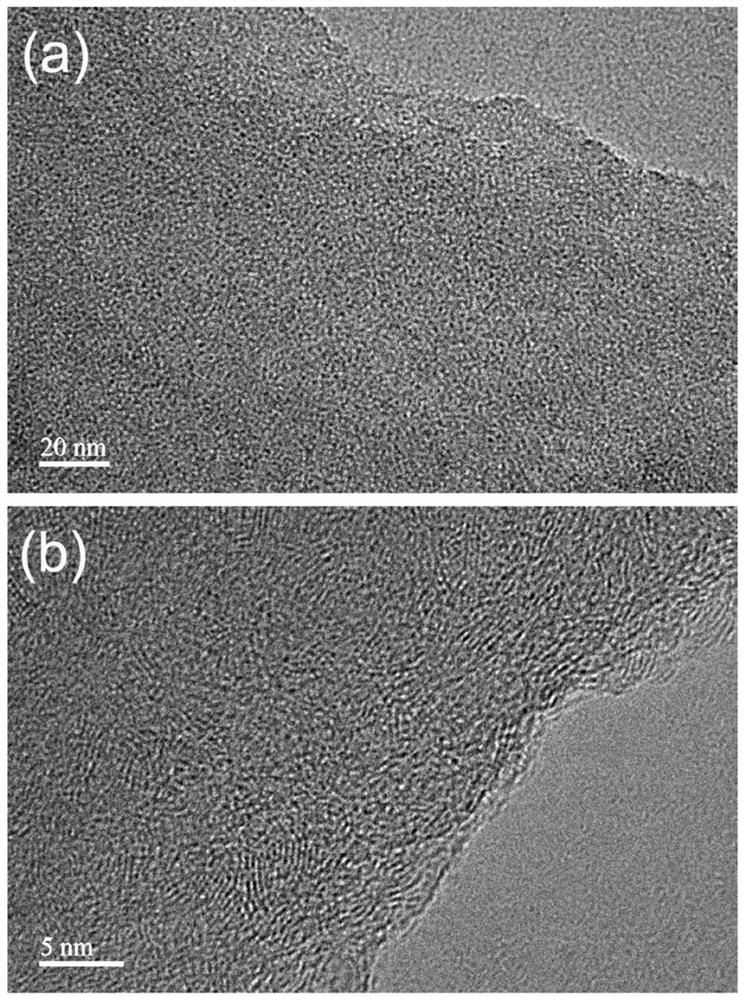

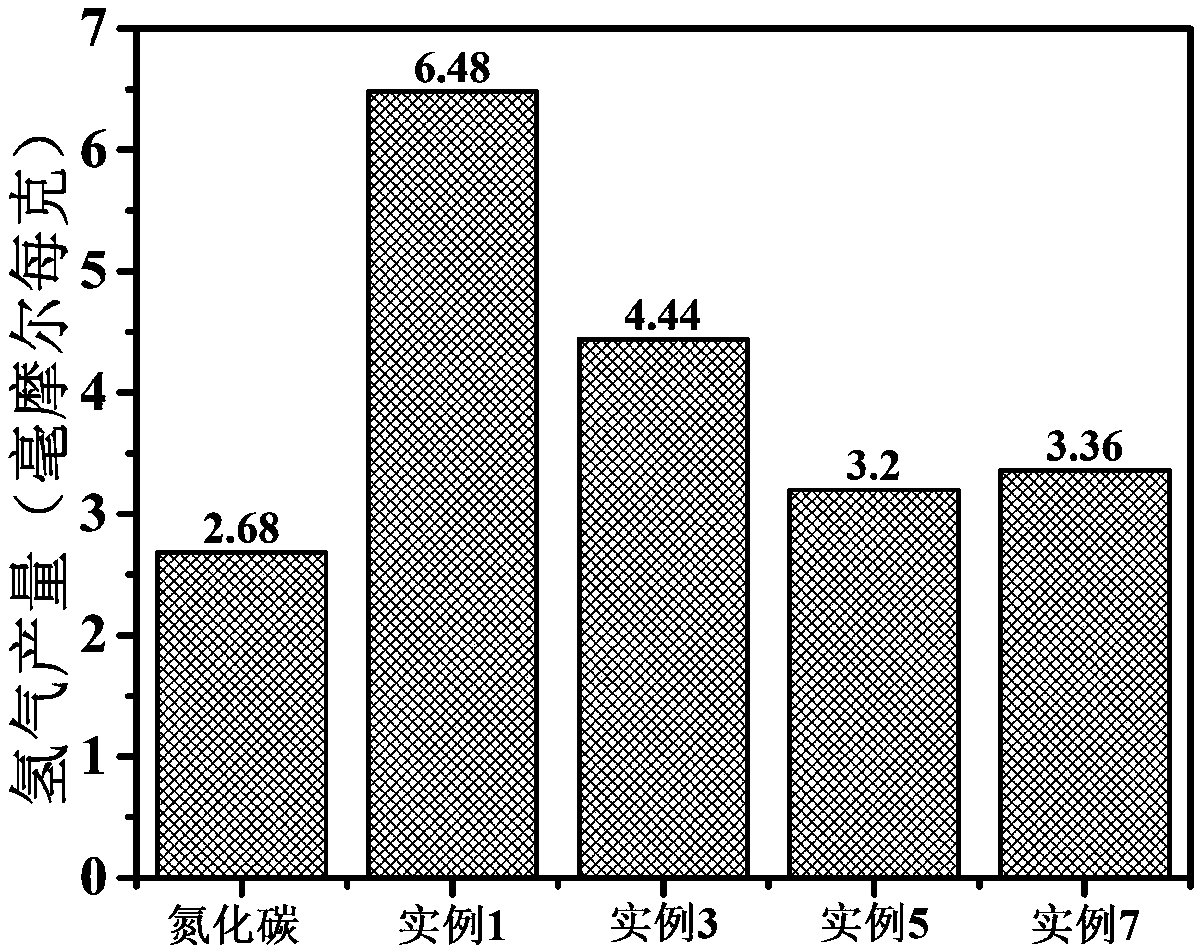

Preparation method of Mo or Fe doped Zn1-xIn2S4 catalyst for photocatalytic nitrogen fixation and ammonia synthesis

PendingCN112264049AImprove efficiencyImprove performancePhysical/chemical process catalystsBulk chemical productionHydration reactionPtru catalyst

The invention discloses a preparation method of a Mo or Fe doped Zn1-xIn2S4 catalyst for photocatalytic nitrogen fixation and ammonia synthesis. The method comprises the following steps: dissolving zinc nitrate hexahydrate, indium nitrate and L-cysteine into deionized water under a magnetic stirring condition, adding an inorganic salt containing molybdenum or iron, conducting magnetic stirring, transferring a mixed solution into a hydrothermal reaction kettle, putting the hydrothermal reaction kettle into a blast drying oven together, and conducting drying to obtain a precursor; and carrying out hydrothermal reaction for 15-24 hours, conducting cooling to room temperature to obtain a yellow-green precipitate, washing the yellow-green precipitate with deionized water and ethanol in sequence, repeatedly carrying out centrifugal washing for 3-5 times, and conducting drying in a blast drying oven at the temperature of 60-100 DEG C for the whole night to obtain the Mo or Fe doped Zn1-xIn2S4photocatalytic nitrogen fixation catalyst. The Mo or Fe doped Zn1-xIn2S4 photocatalytic nitrogen fixation catalyst provided by the invention is high in nitrogen fixation efficiency and simple in preparation method, and has a good application prospect.

Owner:YANCHENG INST OF TECH

Oil-water separation system device for oil-water mixed liquid

InactiveCN110237571AEasy to separateImprove separation efficiencyLiquid separation auxillary apparatusFiltration circuitsOil waterGravity separation

The invention discloses an oil-water separation system device for an oil-water mixed liquid. The device comprises a separation box, the end surfaces of the left and right sides of the separation box are provided with pipeline components, and the interior of the separation tank is provided with an oil-water separation zone and a clear water zone; and the oil-water separation zone and the clear water zone are separated by a partition plate, the clear water zone is located at the right side of the oil-water separation zone, the lower section of the partition plate is provided with a communication opening, and the interior of the oil-water separation zone is provided with an oil removing mechanism and an air floatation mechanism. According to the oil-water separation system device for the oil-water mixed liquid provided by the invention, the air-floating mechanism, oil-absorbing sponges and a scraping plate are arranged, so that the oil-water separation efficiency and effect are improved, the device is prevented from being clogged, and the problems of lower gravity separation efficiency and a poorer separation effect are solved.

Owner:新疆中金科瑞新能源发展股份有限公司

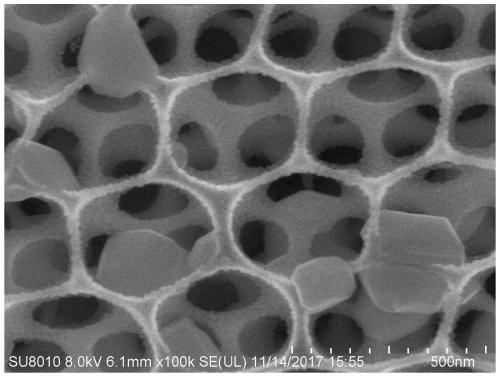

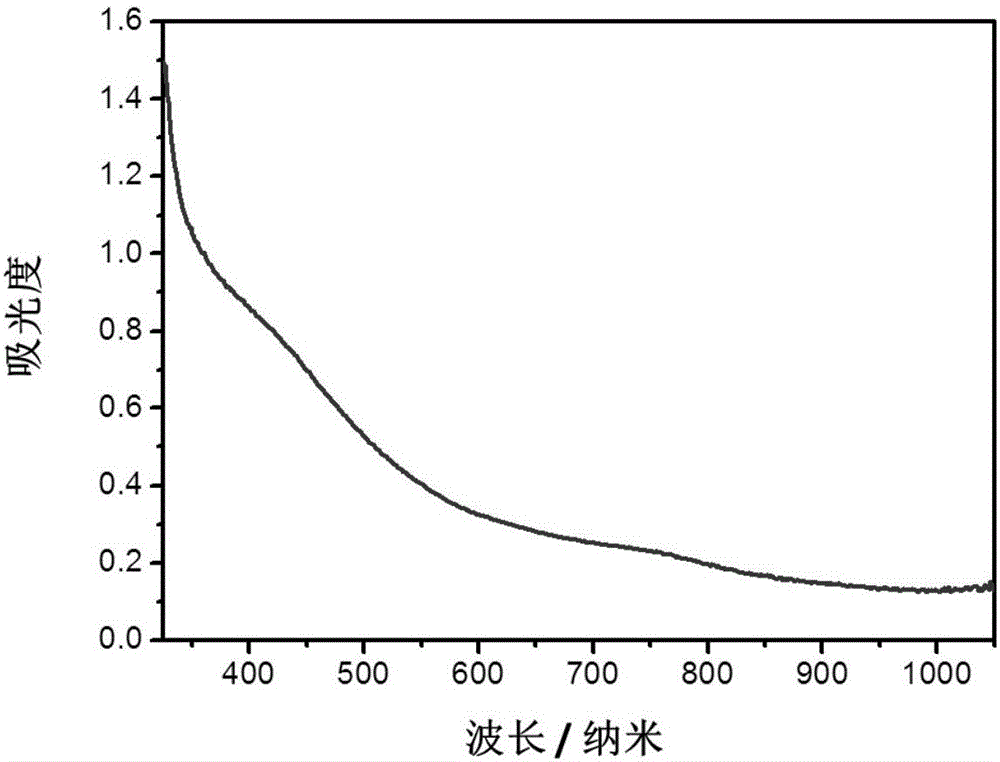

Carbon quantum dot-modified bismuth tungstate/ordered macroporous fluorine-doped tin oxide composite photocatalyst, and preparation method and application thereof

ActiveCN110252352AReduce compound rateIncrease separation rateMaterial nanotechnologyPhysical/chemical process catalystsComposite filmTungstate

The invention discloses a carbon quantum dot modified bismuth tungstate / ordered macroporous fluorine-doped tin oxide composite photocatalyst, and a preparation method and application thereof, belonging to the technical field of photocatalysis of solar-photoelectrochemical conversion. The composite photocatalyst is prepared by preparing a fluorine-doped tin oxide film with a three-dimensional ordered porous space structure on a conductive substrate, allowing bismuth tungstate to grow on the film to prepare a bismuth tungstate / ordered macroporous fluorine-doped tin oxide composite film, soaking the bismuth tungstate / ordered macroporous fluorine-doped tin oxide composite film in a carbon quantum dot solution and carrying out vacuum drying. The carbon quantum dot-modified bismuth tungstate / ordered macroporous fluorine-doped tin oxide composite film has high specific surface area, high electrical conductivity and high photocatalytic activity, and can be used as a photoanode material for solar-photoelectrochemical conversion equipment. The preparation method of the invention has the advantages of simple process, mild reaction conditions, easy control, and good application prospects.

Owner:GUANGDONG UNIV OF TECH

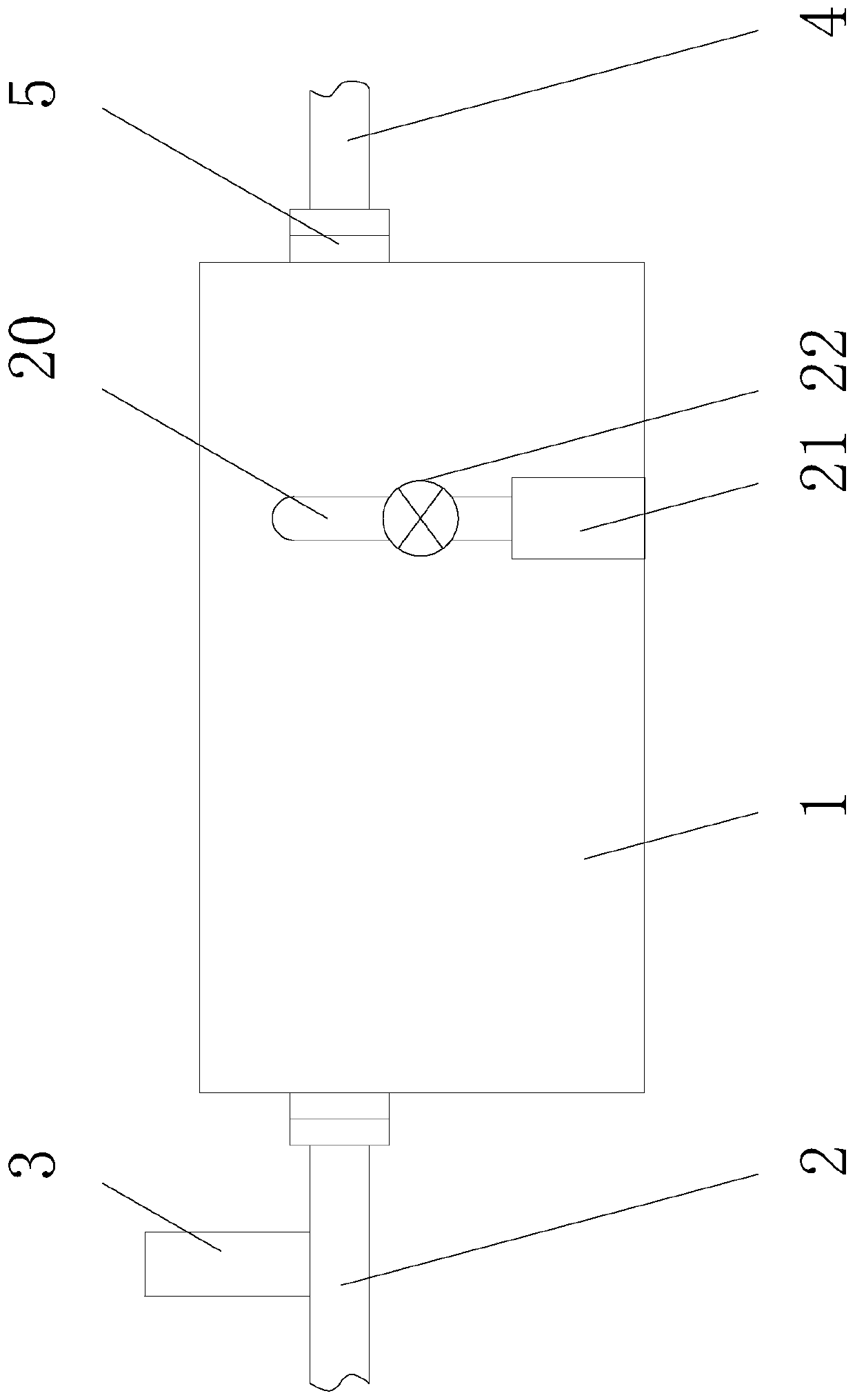

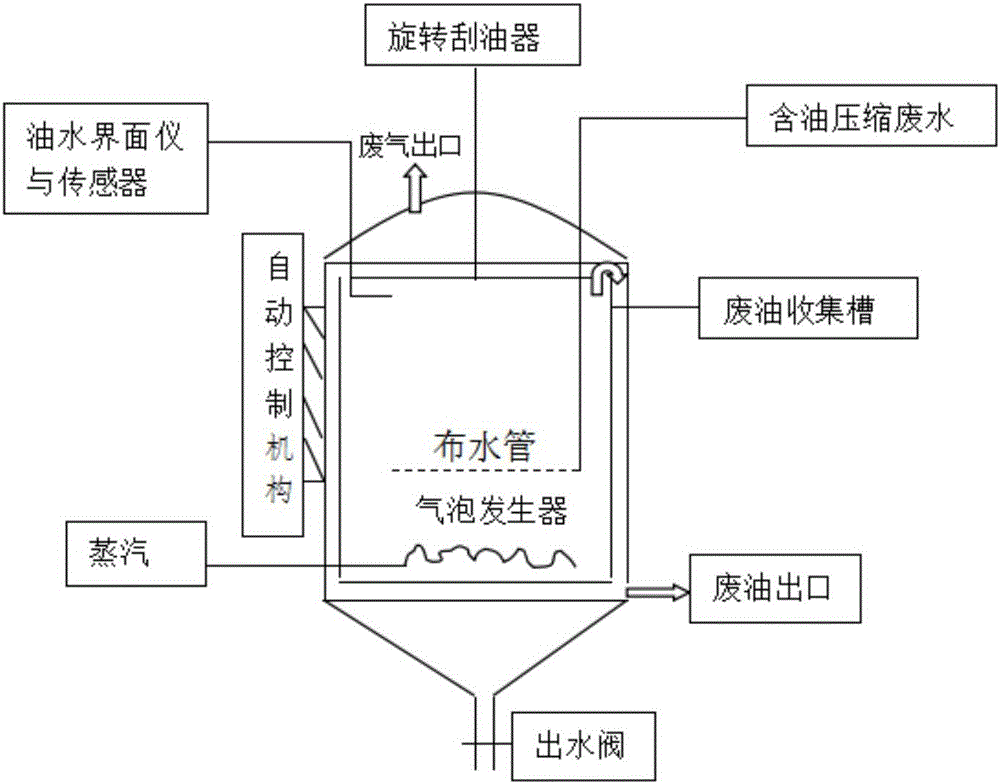

Kitchen waste oil-water separation apparatus and oil-water separation method thereof

PendingCN106673095AImprove oil-water separation rateImprove oil recycling rateFatty/oily/floating substances removal devicesWater/sewage treatment by heatingAutomatic controlMicro bubble

The invention discloses a kitchen waste oil-water separation apparatus. The kitchen waste oil-water separation apparatus comprises a vertical tank body, wherein an oil-water interface measurement instrument, a temperature sensor, a rotating oil scraper and a waste oil collection groove are arranged inside the tank body; a waste water inlet and a waste gas outlet are formed in the top of the tank body; a steam inlet and a waste oil outlet communicated with the waste oil collection groove are formed in the bottom of the side wall of the tank body, a micro-bubble generator connected with the steam inlet is also arranged inside the tank body, and bubbles are generated from steam by virtue of the micro-bubble generator to enable an oil component of oil-containing compressed waste water in the tank body to float; the floating oil component is scraped by the rotating oil scraper into the waste oil collection groove and then discharged by virtue of the waste oil outlet; and the bottom of the tank body is provided with a water outlet valve, the oil-water separation apparatus is also provided with an automatic control mechanism, and the automatic control mechanism is respectively electrically connected with the oil-water interface measurement instrument, the temperature sensor and the micro-bubble generator so as to automatically control the oil-water separation. The invention also discloses a method for separating oil and water of kitchen wastes by utilizing the kitchen waste oil-water separation apparatus.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

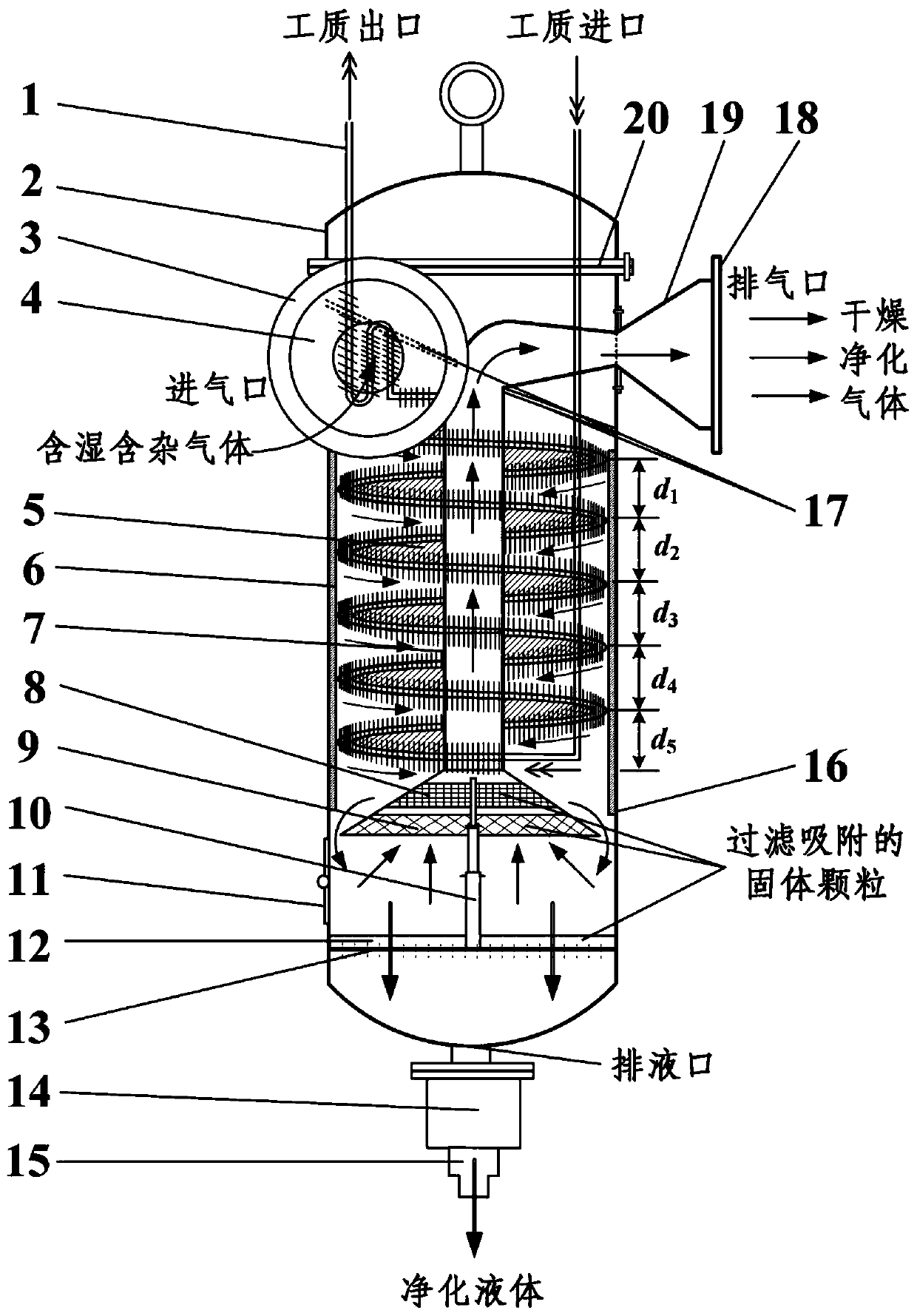

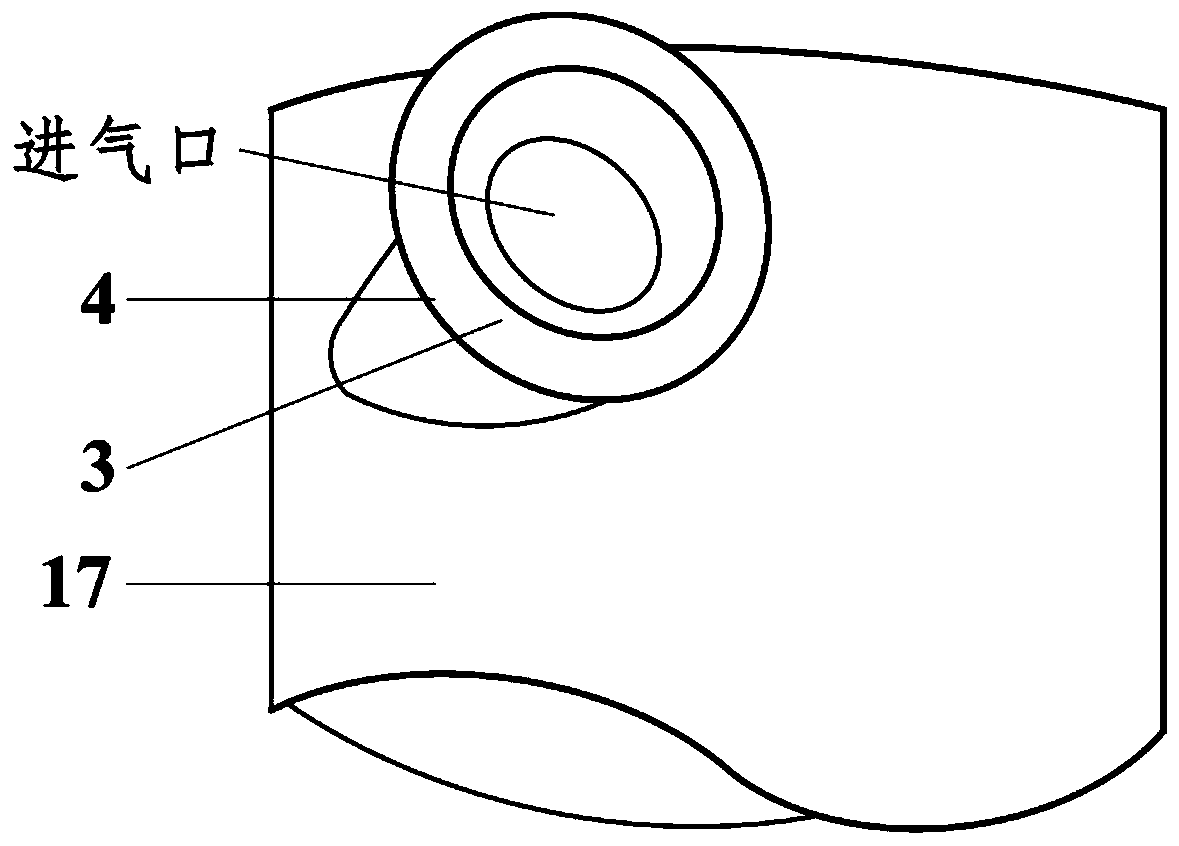

Gas-liquid-solid multi-effect separator

The invention relates to the technical field of filtration, purification and purification, and discloses a gas-liquid-solid multi-effect separator which comprises a shell, a gas inlet pipe, a gas outlet pipe, a spiral plate, a reversing pipe, a heat exchanger, a filter screen mesh, a filter adsorber and a solid-liquid separator, wherein the tapered gas inlet pipe is arranged at the upper part of the shell and is tangent to the circumference of the shell to realize tangential gas inlet and gasflow acceleration; the heat exchanger is arranged on the spiral plate and fixed to the reversing pipe,and gas-liquid separation is achieved in the flowing process of gas along the spiral plate; the heat exchanger is a finned tube type heat exchange tube and is used for accelerating gas cooling and dehumidification; the filter screen mesh and the filter adsorber are sequentially arranged at the lowermost end in the reversing pipe from top to bottom and are used for filtering and adsorbing liquid and solid in the gas; the solid-liquid separator is arranged at the lower part of the shell to realize solid-liquid separation; the horizontal section of the reversing pipe is a diverging and reducing pipe, and the diverging type gas outlet pipe is arranged on the other side of the shell and is coaxial with the gas inlet pipe. The gas-liquid-solid multi-effect separator provided by the invention realizes thorough separation and purification of gas and liquid, and is high in separation efficiency and reliable and stable in work.

Owner:QINGDAO UNIV OF SCI & TECH

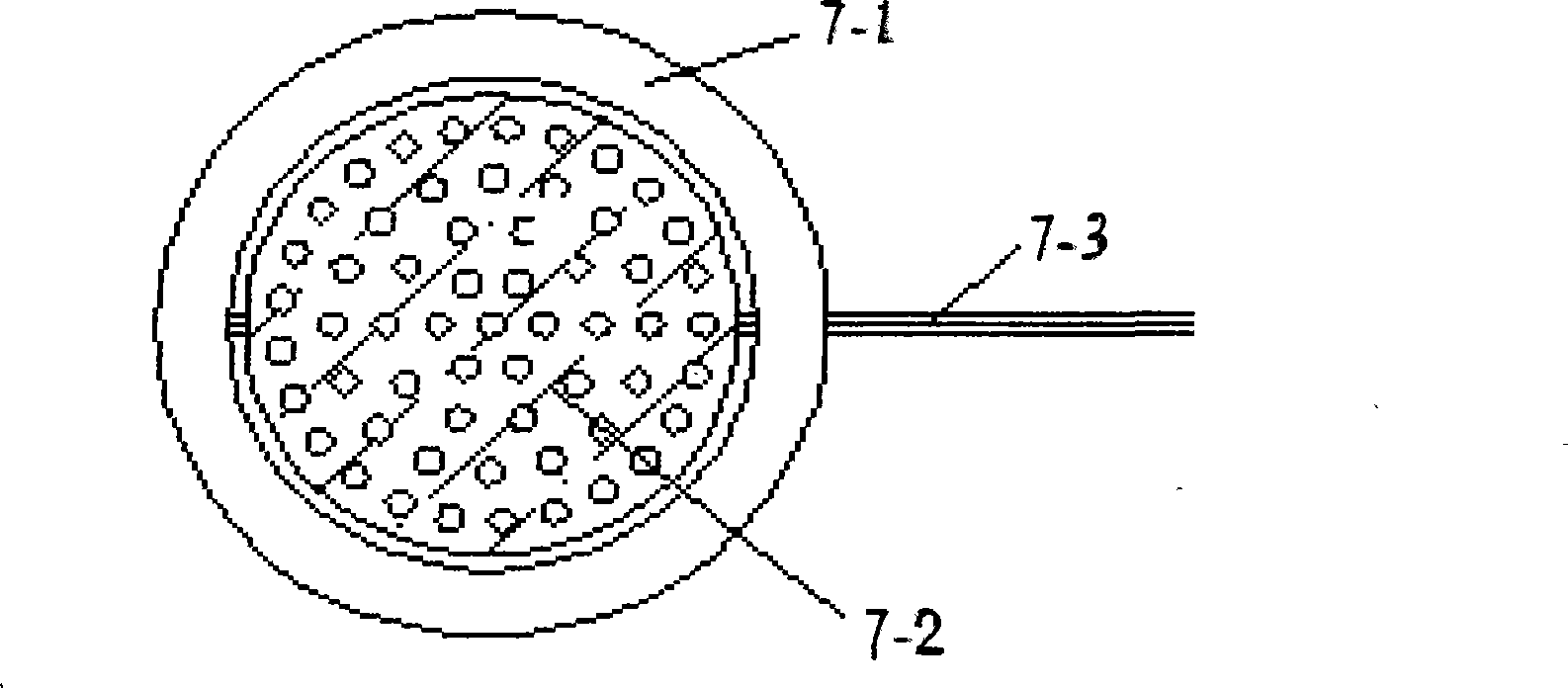

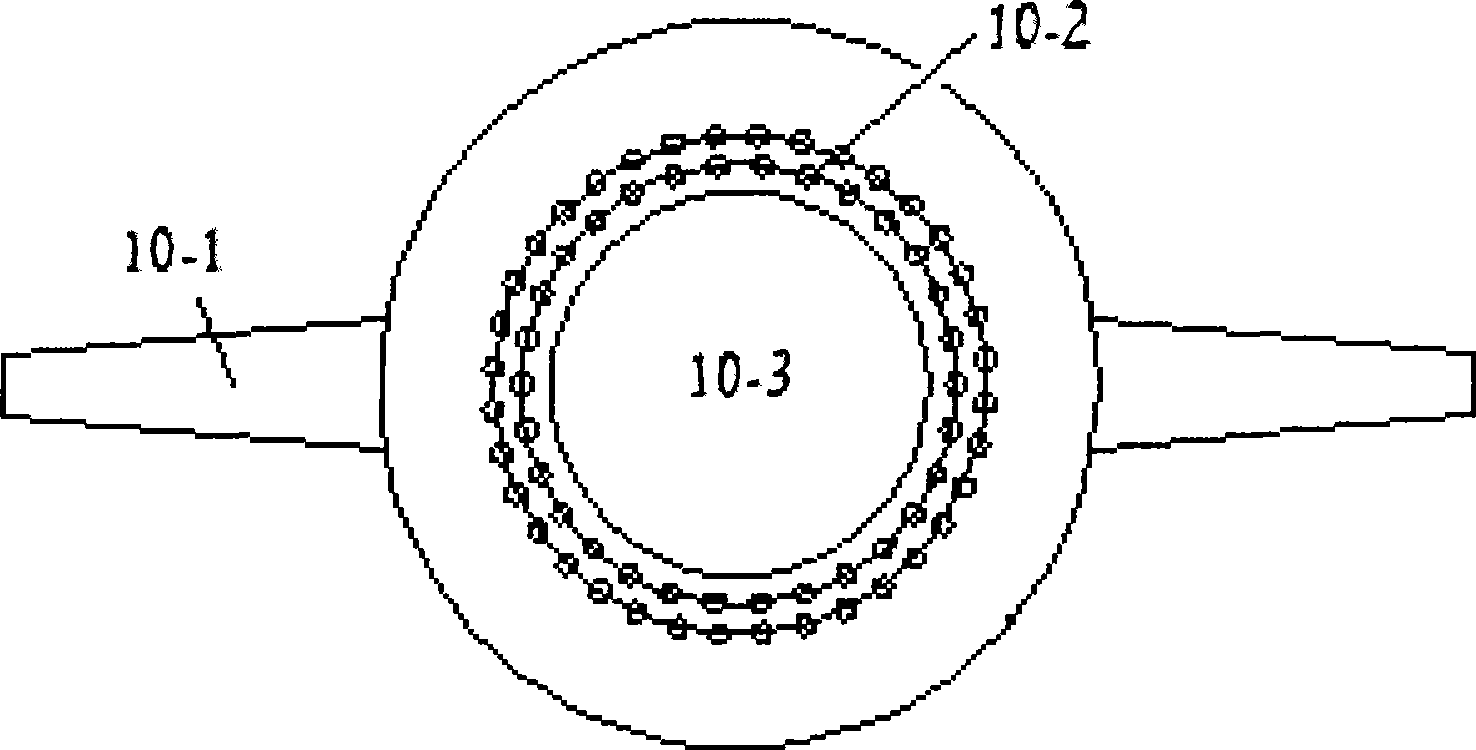

Gas-liquid-solid circulating fluidized bed adsorptive separation device and operation method

InactiveCN101485939AAchieve the effect of separation, concentration and refinementImprove adsorption capacityIon-exchange process apparatusIon exchange beds cleaning/rinsingMass transfer resistanceDesorption

The invention relates to an adsorptive separation device of a gas-liquid-solid circulating fluidized bed and an operation method thereof. The adsorptive separation device comprises an ascending bed, a descending bed, gas distributors, liquid distributors, a liquid-solid separator and circulating pipes; the lower part of the ascending bed is connected with the lower part of the descending bed through a lower circulating pipe; the upper part of the ascending bed is connected with the liquid-solid separator; the liquid-solid separator is connected with the descending bed through an upper circulating pipe; the lower parts of the ascending bed and the descending bed are provided with the gas distributor respectively; one liquid distributor is arranged under each gas distributor; the ascending bed and the descending bed are provided with a sampling port; and the upper and lower circulating pipes are provided with flushing fluid flowing pipelines. The method comprises: carrying out reverse flow adsorption operation on the descending bed of the gas-liquid-solid circulating fluidize bed, and simultaneously carrying out parallel flow desorption operation on the ascending bed. The motion of air bubbles is favorable for reducing the thickness of a liquid membrane on the surfaces of adsorptive particles, and reduces mass transfer resistance of the liquid membrane. The gas-liquid-solid circulating fluidize bed is an efficient adsorptive separation device system for separating Chinese medicinal herb such as gingko flavone.

Owner:TIANJIN UNIV

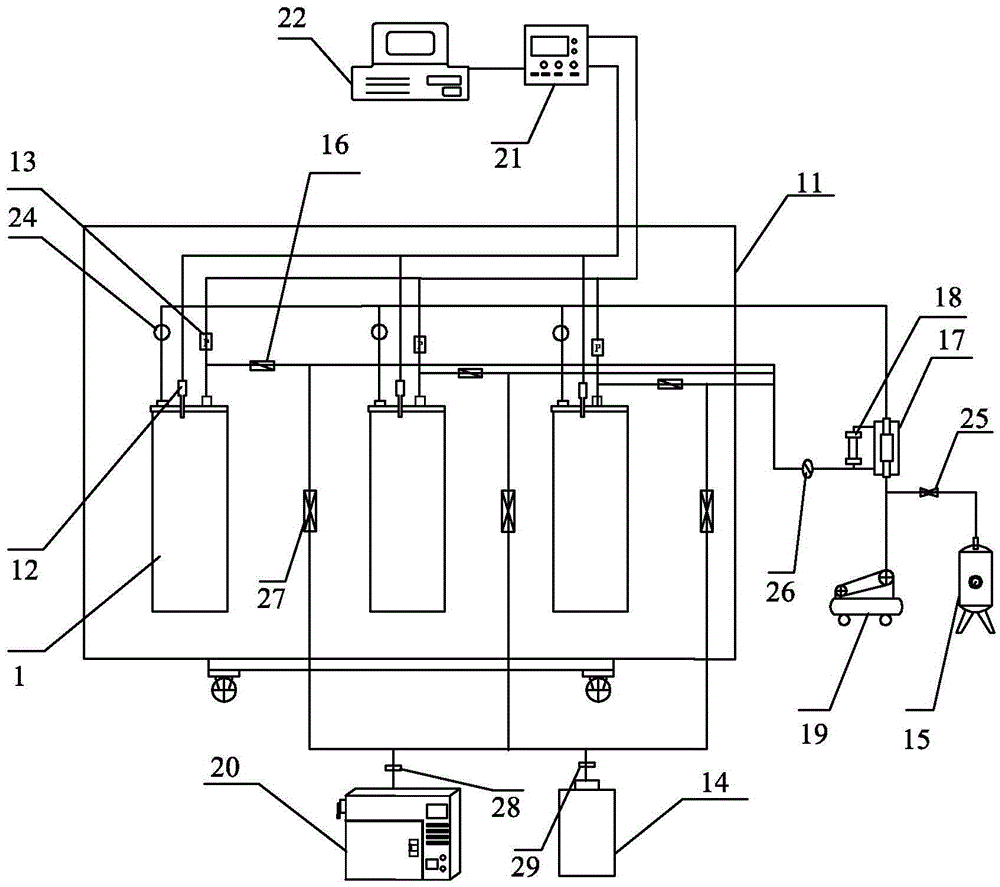

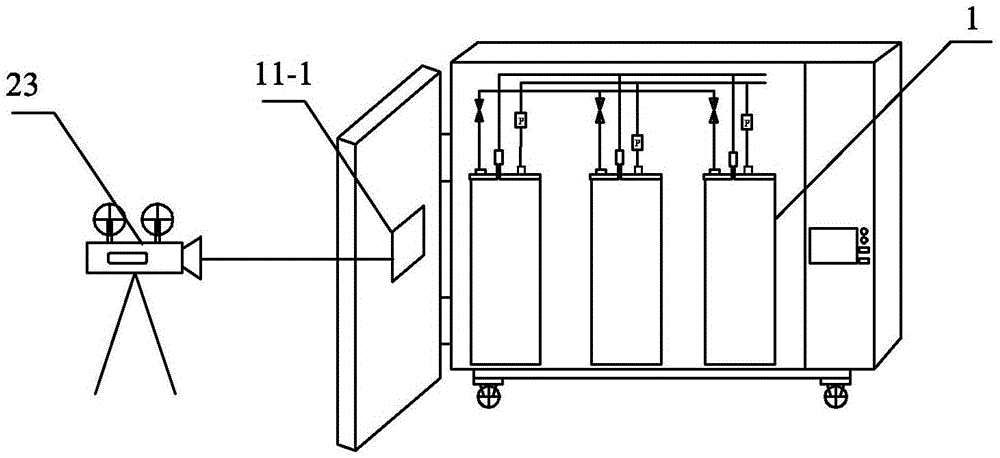

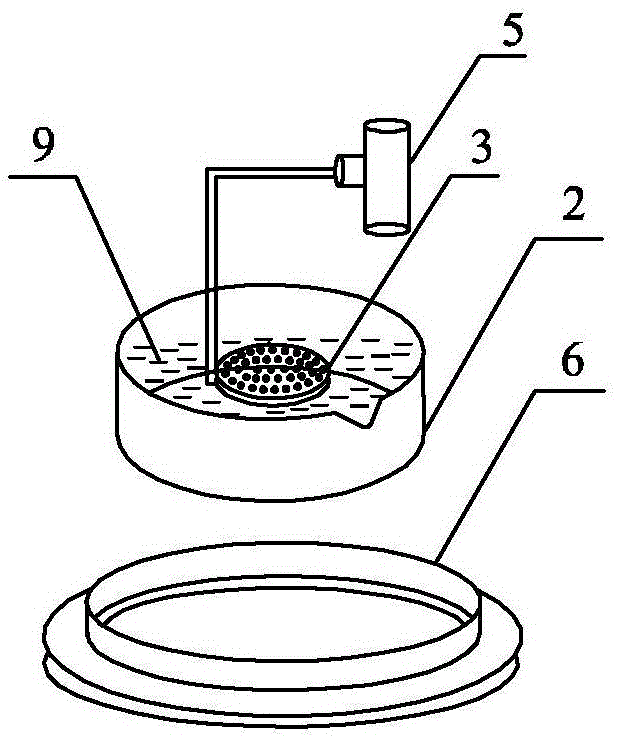

Gas-hydrate-separation bubbling reinforcing device gas-hydrate-separation purifying reinforcing device based on the same and gas purifying reinforcing method

ActiveCN105567362AIncrease concentrationHigh recovery rateGaseous fuelsChemical/physical/physico-chemical nozzle-type rreactorsTemperature controlData acquisition

The method discloses a gas-hydrate-separation bubbling reinforcing device, a gas-hydrate-separation purifying reinforcing device based on the same and a gas purifying reinforcing method, and relates to the field of coal. The problems that the gas-hydrate-separation rate is low, and the separation concentration and the methane recovery rate are low are solved. By means of the gas-hydrate-separation bubbling reinforcing device, the contact area between gas and an accelerant solution is greatly increased, the content of the gas entering a liquid phase is increased, the separation rate is accelerated, and the gas-hydrate separation concentration and the methane recovery rate are increased. According to the gas-hydrate-separation purifying reinforcing device and the purifying reinforcing method, the temperature is adjusted through a temperature control box, the pressure and the temperature of the gas in a hydrate reaction kettle are monitored through pressure sensors and temperature sensors in real time, and are stored and observed through an industrial personal computer and a data acquisition device in real time, the temperature of the temperature control box and the operating sequence of the device can be conveniently adjusted in time, and the gas-hydrate-separation purifying reinforcing device and the purifying reinforcing method are suitable for purifying other kinds of gas.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method used for extracting hemicellulose with low pigment content

The invention discloses a method used for extracting hemicellulose with low pigment content. According to the method, corn straws are taken as raw materials; the method comprises the following steps: first, soaking the corn straws respectively with deionized water and ethyl alcohol to remove hydrophilic polysaccharide and fat soluble pigments, then removing lignin in the straws with sodium chlorite, extracting with aqueous alkali at the temperature of 80-120 DEG C, and finally, adding ethyl alcohol to deposit the hemicellulose. The extracted hemicellulose is in claybank, and the content of the impurity lignin is about 2%, and therefore, the quality of the hemicellulose of the corn straws can be obviously improved; meanwhile, the corn straws can be ungreased in a large volume, so as to provide the application basis for the industrialization of the hemicellulose.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

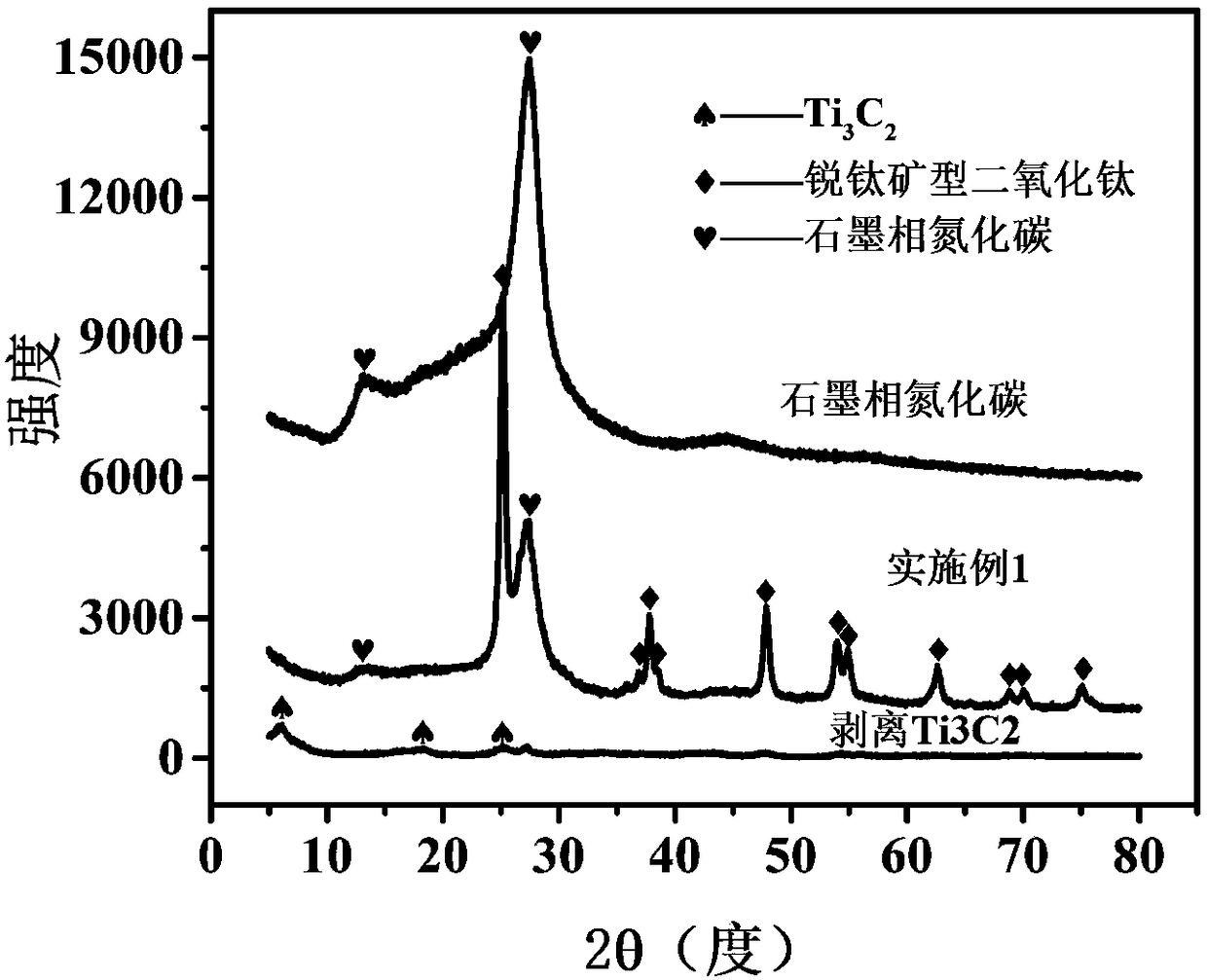

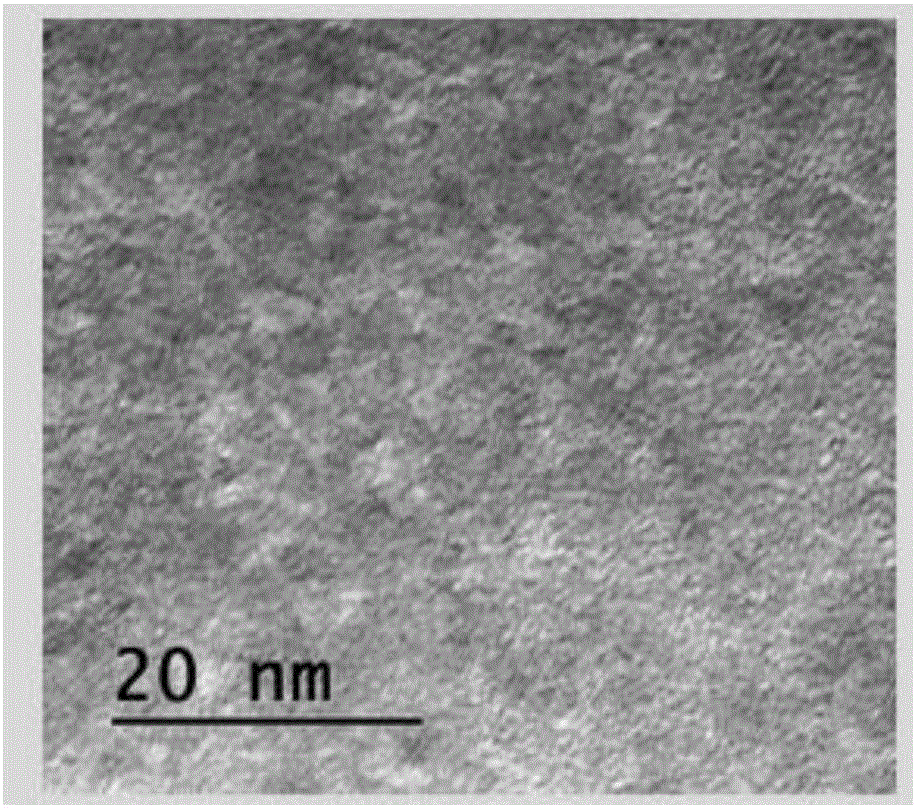

Composite photocatalyst and preparation method and application thereof

InactiveCN108525700AEvenly distributedIncrease separation ratePhysical/chemical process catalystsHydrogen productionTitanium dioxide nanoparticlesNanometre

The invention provides a preparation method of a composite photocatalyst and belongs to the technical field of material. The preparation method comprises the steps of mixing graphite-phase carbon nitride, stripped Ti3C2 suspension and water, lyophilizing the mixture, and calcining to obtain the composite photocatalyst, wherein calcining temperature is 300-400 DEG C. Stripped Ti3C2 is used as a precursor for titanium dioxide nanoparticles such that titanium dioxide nanoparticles from the stripped Ti3C2 by oxidation are distributed more evenly on the surface of the graphite-phase carbon nitride;therefore, the composite photocatalyst has heterogenous structure and improved visible light catalysis.

Owner:YANSHAN UNIV

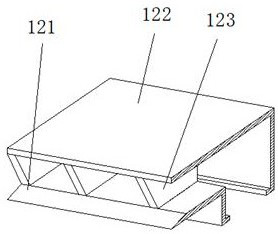

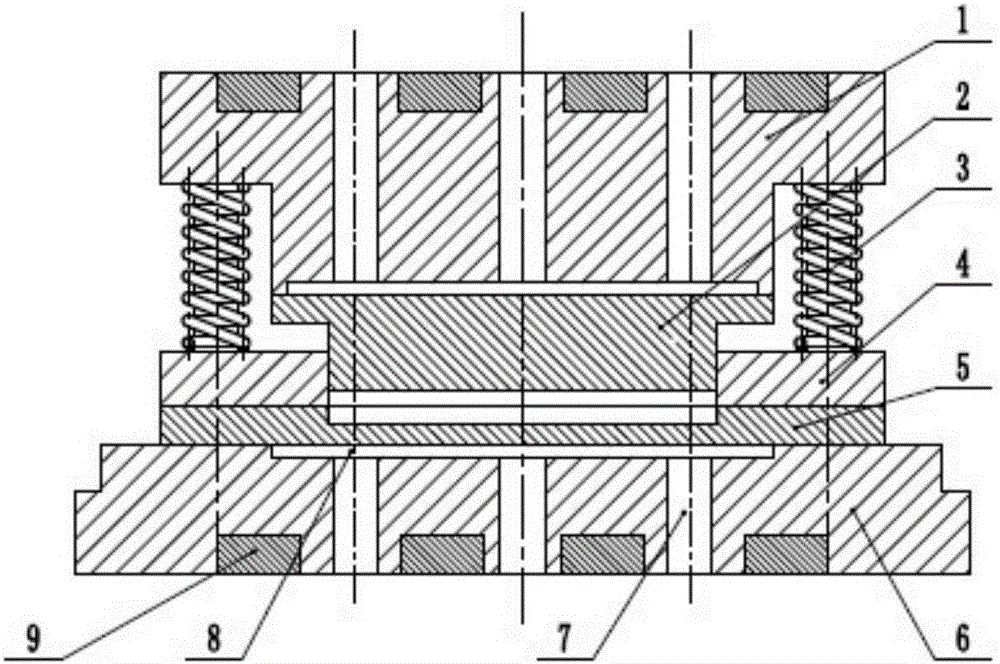

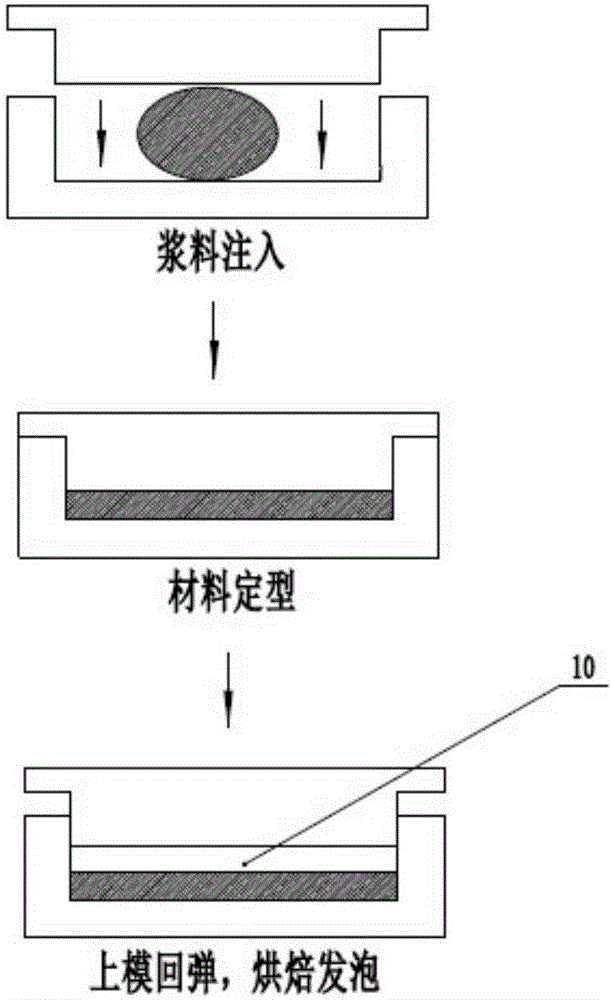

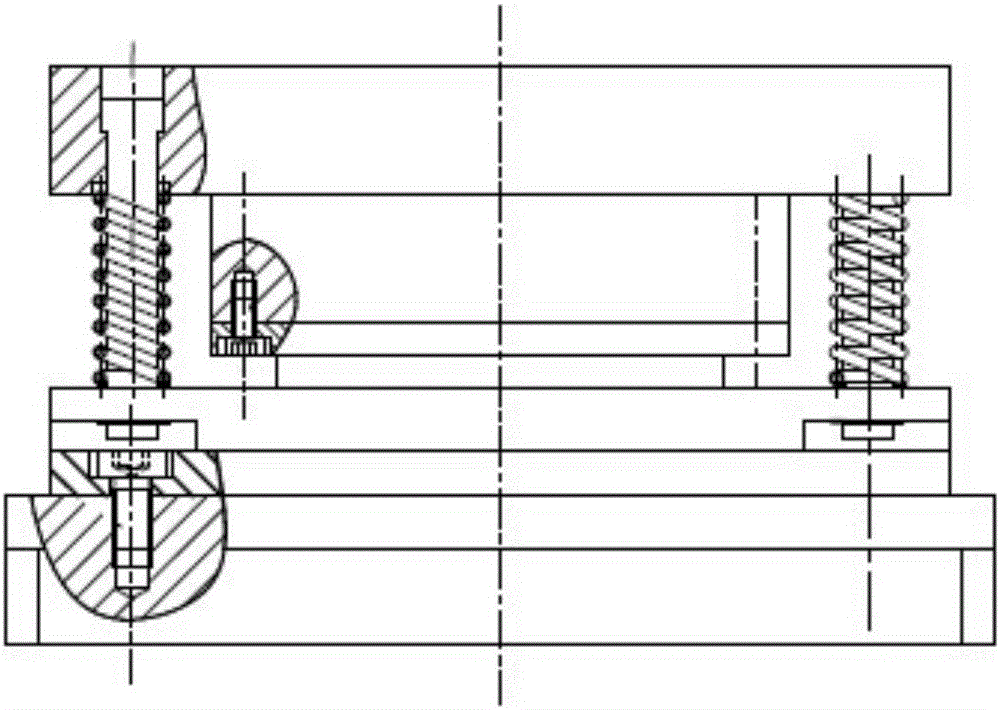

Monolateral cavity freestyle foaming mould

The invention discloses a monolateral cavity freestyle foaming mould, which comprises an upper mould and a lower mould, wherein a groove for storing a biologic material is arranged in the surface of the lower mould; the upper mould can be partially embedded into the groove; one of the upper mould or the lower mould can move relative to the other one so as to extrude the biologic material, so that the biologic material is formed in the groove; one of the upper mould or the lower mould is connected with a moving mechanism; the upper mould is separated from the groove under the action of the moving mechanism after the setting time of extruding the biologic material by the upper mould and the lower mould, and the biologic material is foamed freely. According to the monolateral cavity freestyle foaming mould, the product drying time is greatly reduced, the original slurry dosage of the product is reduced, the product bubble quality is improved, the buffer performance is improved, meanwhile, the material raw material use cost and the product manufacturing production cost are reduced, and the monolateral cavity freestyle foaming mould has a favorable actual effect, and has a favorable reference significance on mould production at present.

Owner:SHANDONG UNIV

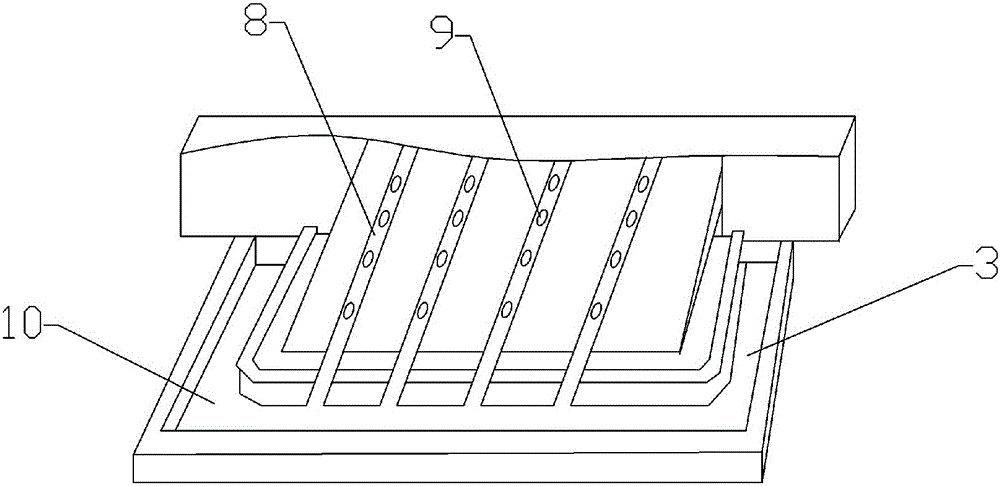

Cutting fluid recovery device for metal connecting piece machining

InactiveCN105108574ASimple structureEasy to operateMaintainance and safety accessoriesEngineeringMetal

The invention discloses a cutting fluid recovery device for metal connecting piece machining. The cutting fluid recovery device for metal connecting piece machining comprises a shell. A centrifugal roller and an oblique platform located below the centrifugal roller are arranged in the shell. Cribriform dense holes are formed in the side face of the centrifugal roller. The centrifugal roller is connected with a rotating shaft with a motor, and the bottom of the centrifugal roller is communicated with a feeding pipe. A plurality of longitudinal flow guide grooves are formed in the oblique platform. A plurality of magnets are fixed on the inner wall of each longitudinal flow guide groove. A collection groove is formed in the lower end of the oblique platform. The longitudinal flow guide grooves are communicated with the collection groove. The two ends of the collection groove are each connected with a fluid drain pipe penetrating through the shell. The cutting fluid recovery device for metal connecting piece machining is capable of separating out cutting fluid quickly, good in recovery quality and high in efficiency.

Owner:CHONGQING ZUOEN FURNITURE

Preparation method of black titanium dioxide nano thin film

ActiveCN106622247AExpand the photoresponse rangeBroad absorption spectrumCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogen atmosphere

The invention belongs to the technical field of preparation of nano thin films and relates to a preparation method of a black titanium dioxide nano thin film. A technological process comprises three steps including preparation of nanoparticles, preparation of the nano thin film and thickness control of the nano thin film; black titanium dioxide nanoparticles are prepared from titanium tetraisopropoxide and nickel nitrate; the black titanium dioxide nanoparticles are deposited on a stainless steel substrate by adopting an electrophoretic deposition method so as to prepare the black titanium dioxide nano thin film; nickel ion doping is coupled with hydrogen atmosphere heat treatment modification, and effective active sites can be formed on the surface of titanium dioxide by doping nickel ions, and separation of photo-induced electrons and holes is accelerated; the catalytic activity of the titanium dioxide is improved and hydrogen atmosphere heat treatment can expand a photo-response region of the titanium dioxide; white titanium dioxide is turned into black titanium dioxide; the technological process is simple, low in production cost, rapid in deposition speed and high in film-forming quality; an application environment is environmentally friendly and commercialized requirements are met.

Owner:青岛西交蓝海科技有限公司

Efficient oil-water separation device for chemical engineering

InactiveCN108744605AIncrease separation rateEasy to handle and utilizeLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesOil waterVolumetric Mass Density

The invention discloses an efficient oil-water separation device for chemical engineering. The efficient oil-water separation device comprises a device shell, wherein a rotating disk is arranged at the bottom of the inner wall of the device shell; a motor is arranged at the bottom of the rotating disk; the rotating disk is connected with the motor in a transmission manner; a separation shell is fixedly arranged at the top of the rotating disk; a material inlet is formed in the top of the device shell; a filter device is connected to the bottom of the material inlet; rotating shafts are arranged on two sides of the filter device; a water storage chamber is arranged on one side of the device shell. By the arrangement of the rotating disk and the separation shell, the motor works to drive therotating disk to rotate, so as to drive the separation shell on the surface of the rotating disk to rotate; oil-water mixed liquid in the separation shell slides on the inner wall of the separation shell under the action of centrifugal force; as oil and water have different densities, the oil moves to the top of the mixed liquid and the water moves to the bottom of the mixed liquid during rotation; the oil leaves the separation shell after passing through the filter plate, so that the quick separation work of the oil-water mixed liquid is completed.

Owner:FOSHAN KEFENG CULTURE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com