Hydrate process and apparatus for separating gas mixture continuously

A technology of mixed gas and separation method, which is applied in the direction of separation method, carbon compound, and dispersed particle separation, etc., and can solve problems such as low recovery rate, reduced system separation capacity, and reduced pressure of hydrate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

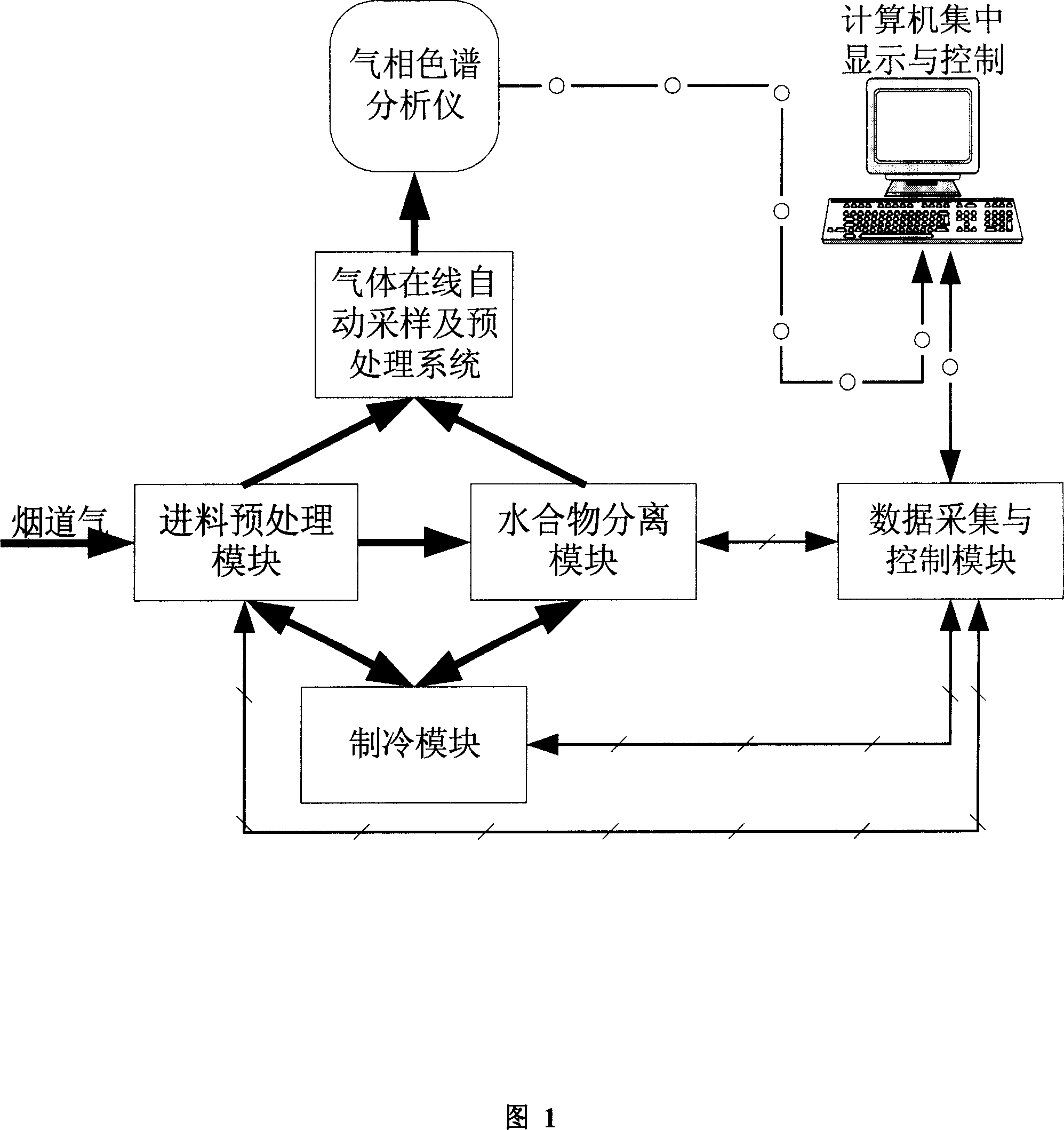

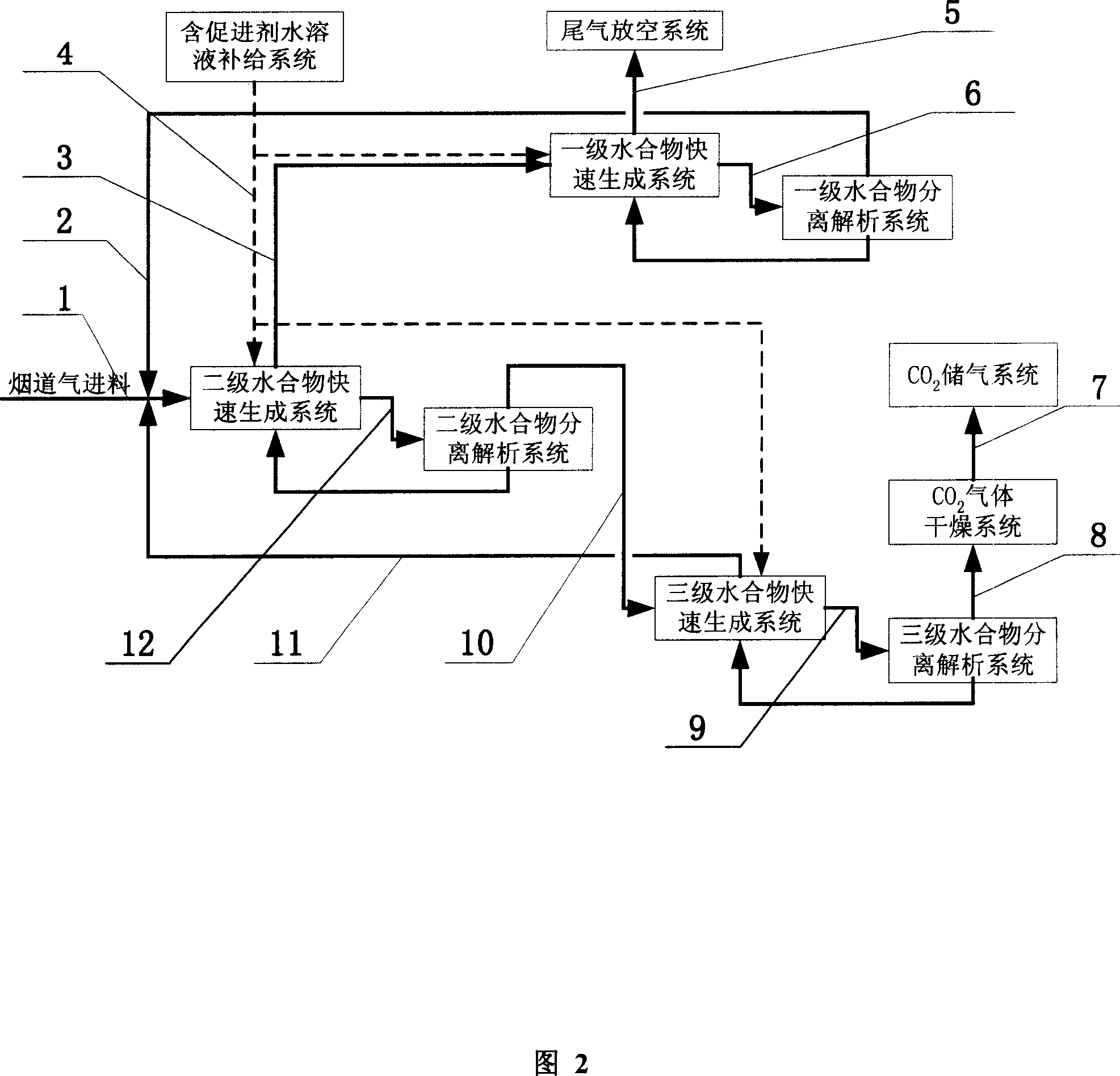

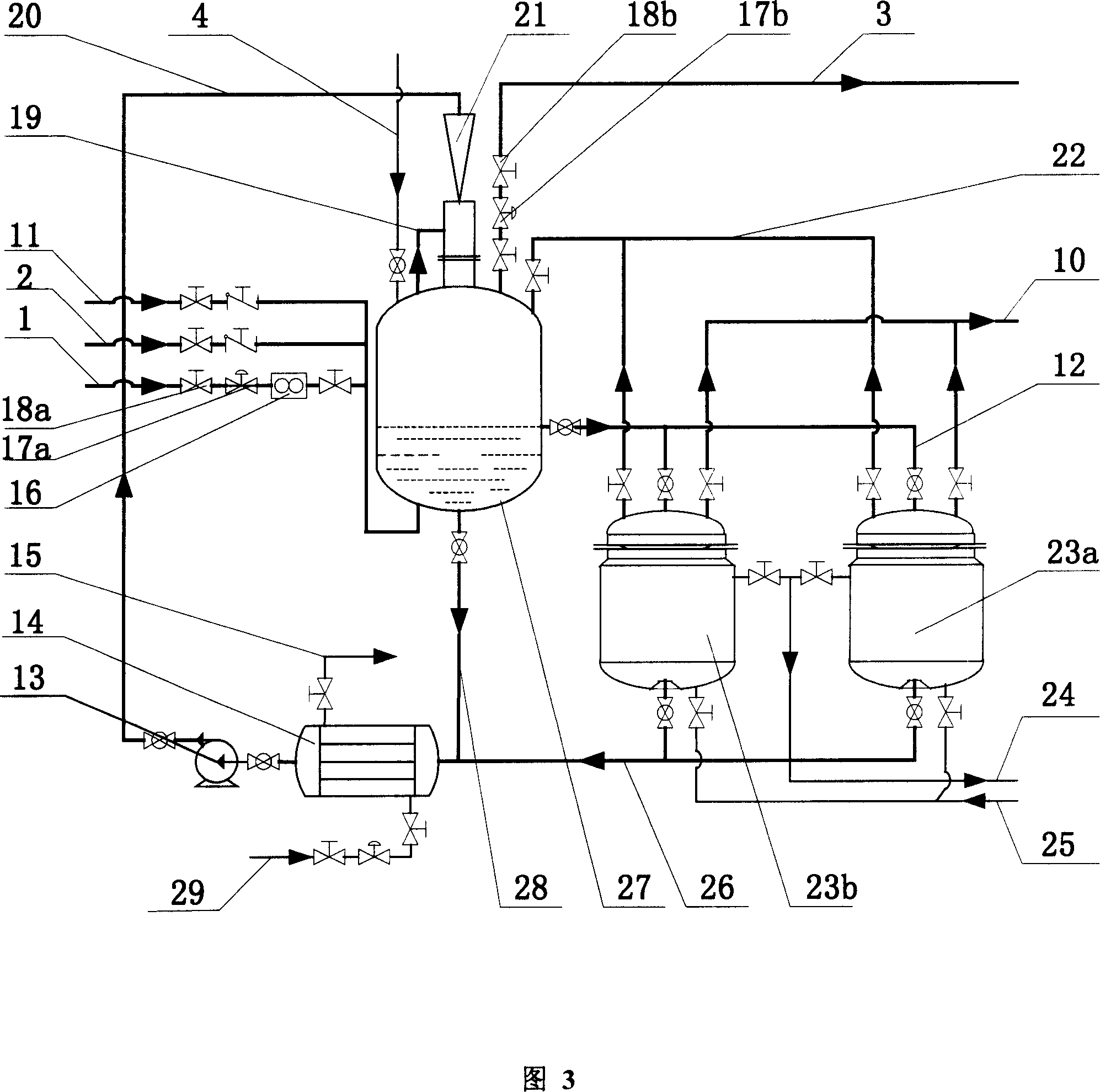

[0059] As shown in Figures 1, 2, and 3, after the flue gas is pretreated by water washing, drying, compression, and pre-cooling, the CO in the flue gas 2The molar concentration is about 18%, the pressure is about 2.0MPa, and the temperature is 4°C. The pretreated flue gas enters the secondary hydrate synthesis through the flue gas feed pipe 1, the feed regulating valve 18a, and the flow meter 16. Kettle 27; aqueous solution containing 1.0% accelerator sodium lauryl sulfate is added to primary, secondary, and tertiary hydrate synthesis kettles through aqueous solution supply system and aqueous solution supply pipeline 4; The aqueous agent solution is cooled to 2°C through the liquid phase circulation pipe 28 of the secondary hydrate synthesis tank to the heat exchanger 14, and then enters the microbubble jet full-mix reactor 21 through the circulation pump 13 and the liquid inlet pipe 20 of the microbubble jet full-mix reactor The flue gas in the gas-phase region at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com