Carbon dioxide industrial-scale separation and purification system and method in mixture gas by hydrate method

A technology for decomposing mixed gases and hydrates, applied in chemical instruments and methods, chemical industry, carbon compounds, etc., can solve problems such as unfavorable energy saving and comprehensive utilization of energy, large number of separation equipment, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

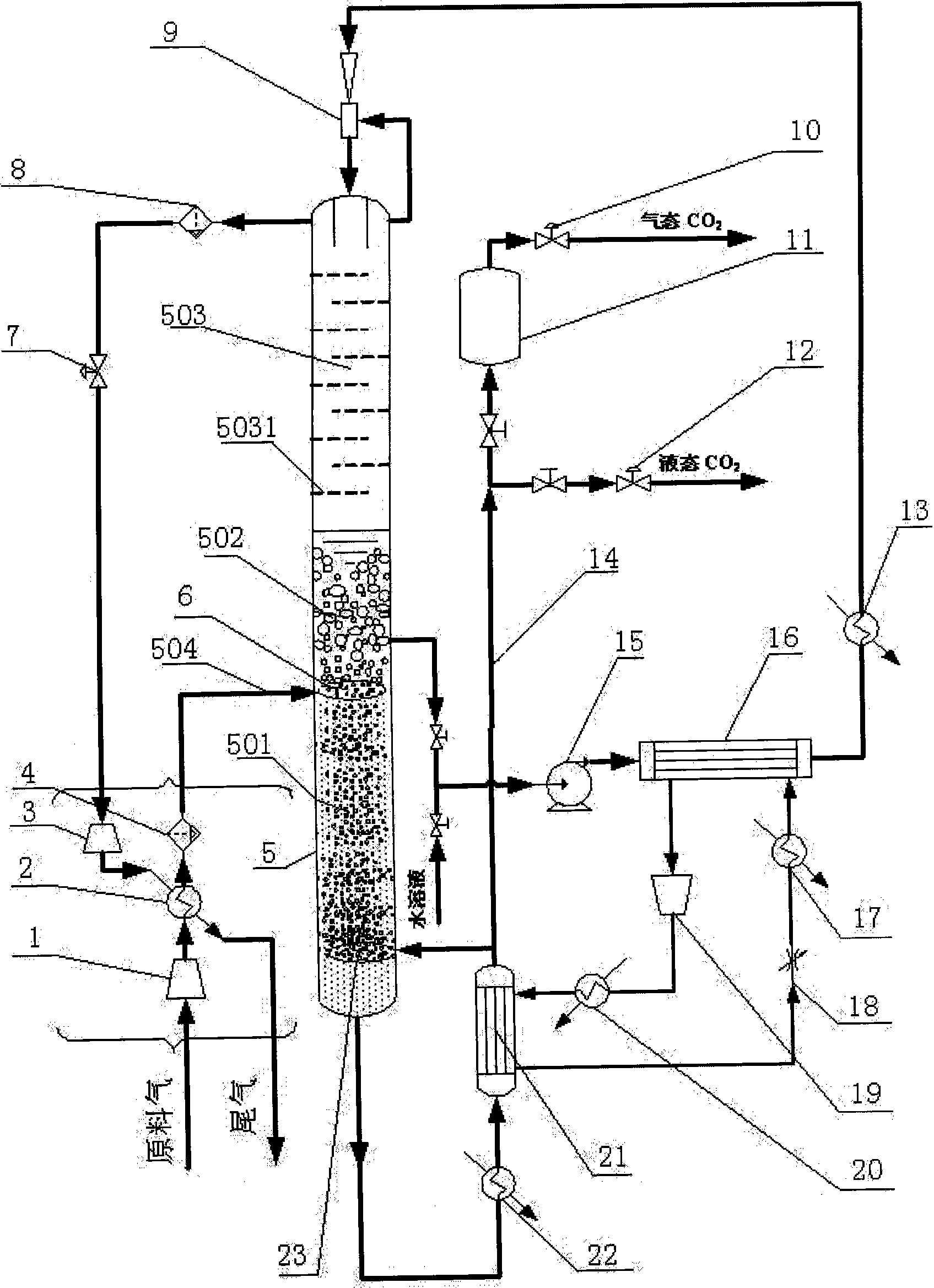

[0035] see figure 1 As shown, the flow rate is 100kmol / h, the pressure is 1bar, and the temperature is 373.15K raw gas (power plant flue gas), its CO 2 The molar concentration of the flue gas is 17%, and the flue gas is compressed by the three-stage feed gas compressor 1, cooled by the four-stage inter-stage heat exchanger 2, pretreated by the three-stage inter-stage gas-liquid separator 4, and then passes through the porous feed from the feed gas inlet 504 The sparger 6 enters the hydrate separation tower 5, the flue gas pressure reaches 24.46bar, and the temperature is 280.25K; the circulation pump 15 is used to inject an aqueous solution containing an accelerator with a tetrabutylammonium bromide (TBAB) content of 7.5% into the hydrate separation tower, make CO 2 The displacement fractionation zone 501 and the bubbling reaction zone 502 are filled with an aqueous solution containing an accelerator; the pretreated flue gas enters the hydrate separation tower 5 for hydration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com