Kitchen waste oil-water separation apparatus and oil-water separation method thereof

A technology of waste oil and separation device, applied in separation method, oil/oily substance/float removal device, liquid separation, etc., can solve the problem of low oil recovery rate of kitchen waste and single oil-water separation technology separation The problem is that the effect is low and the oil in the water is enriched, so as to improve the oil-water separation effect, improve the oil-water separation rate, and improve the oil recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

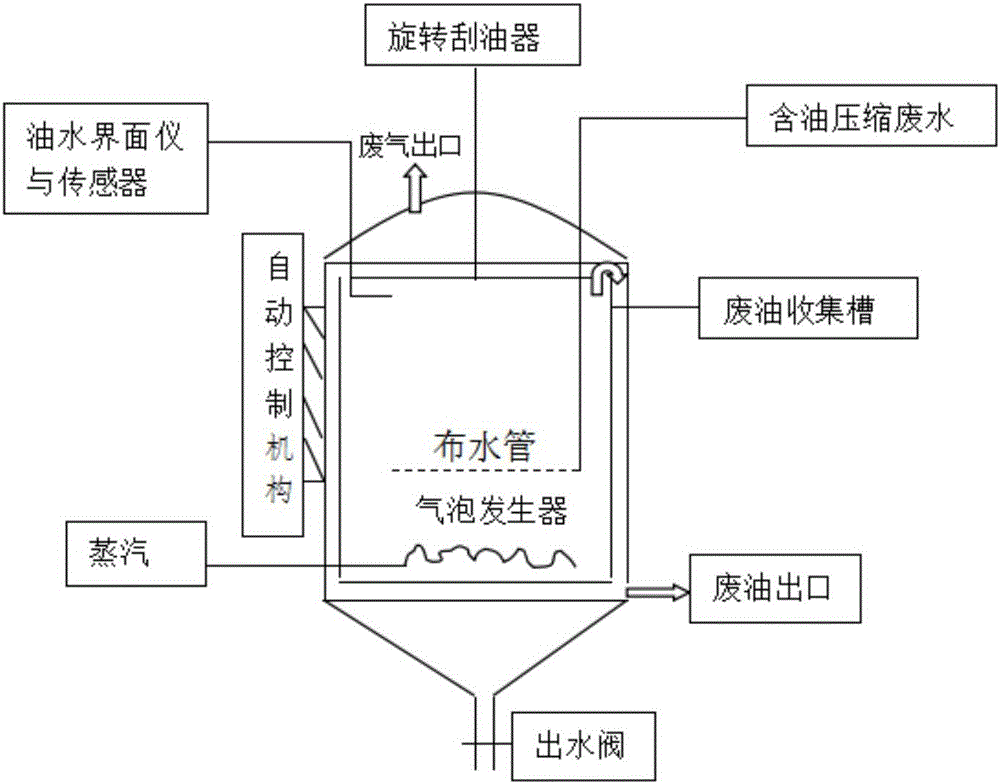

[0028] Such as figure 1 As shown, the kitchen waste oil-water separation device provided in this embodiment includes a vertical tank for storing oil-containing compressed waste water, and the inside of the tank is equipped with an oil-water interface measuring instrument, a temperature sensor, a rotary oil scraper, waste oil Collection tank; the top of the tank is provided with a waste water inlet and a waste gas outlet, the waste water inlet is connected to a water distribution pipe for oily compressed waste water to pass into the tank, and the waste gas outlet is used to connect to the deodorization system of the biological filter; the side of the tank body The bottom of the wall is provided with a steam inlet and a waste oil outlet connected to the waste oil collection tank. A micro-bubble generator connected to the steam inlet is provided inside the tank. The steam generates bubbles through the micro-bubble generator to compress the oil contained in the tank. The oil in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com