Solvent recycling technology adopted in polyphenylene sulfide production

A technology of polyphenylene sulfide and polyphenylene sulfide resin is applied in the field of improving the production process of polyphenylene sulfide, and can solve the problems of being uncomplimentable, high requirements, and low catalyst recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

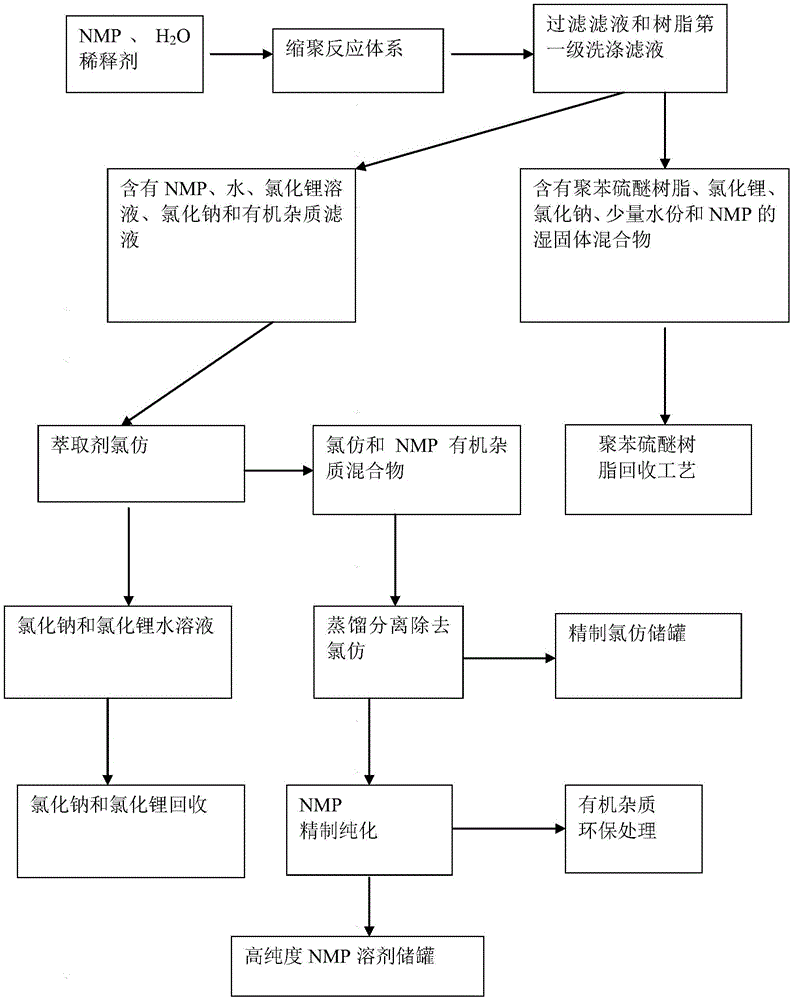

Image

Examples

Embodiment 1

[0024] After the polycondensation reaction is completed, it is necessary to add fresh NMP solvent and oxygen-free deionized water to the polycondensation reaction system to dissolve the co-solvent and by-product-sodium chloride in the synthesis process, wherein the amount of NMP solvent added is 1.1mol / molNa 2 S, the addition of anaerobic deionized water is 8.6mol / molNa 2 S, NMP and H in which the co-solvent and NaCl are completely soluble 2 O, thereby forming a solution mixture containing polyphenylene sulfide resin, NMP, cosolvent, and by-products, and the mixture is input into a centrifuge for solid-liquid separation to obtain a solution containing 30wt% H 2 O and the polyphenylene sulfide resin solid mixture of a small amount of NMP, contain NMP, water, co-solvent and by-product in the filtrate; and the mixed system of organic impurity solution; in the mixed system, the total amount of 6.9mol / molNa 2 The chloroform of S, wherein NMP is carried out effectively extraction,...

Embodiment 2

[0026] After the polycondensation reaction is completed, it is necessary to add fresh NMP solvent and oxygen-free deionized water to the polycondensation reaction system to dissolve the co-solvent and by-product-sodium chloride in the synthesis process, wherein the amount of NMP solvent added is 1.6mol / molNa 2 S, the addition of anaerobic deionized water is 5.8mol / molNa 2S, NMP and H in which the co-solvent and NaCl are completely soluble 2 O, thereby forming a solution mixture containing polyphenylene sulfide resin, NMP, cosolvent, and by-products, and the mixture is input into a centrifuge for solid-liquid separation to obtain a solution containing 30wt% H 2 O and the polyphenylene sulfide resin solid mixture of a small amount of NMP, contain NMP, water, co-solvent and by-product in the filtrate; and the mixed system of organic impurity solution; in this mixed system, the total amount of 9.6mol / molNa 2 The chloroform of S, wherein NMP is carried out effectively extraction,...

Embodiment 3

[0028] After the polycondensation reaction is completed, it is necessary to add fresh NMP solvent and oxygen-free deionized water to the polycondensation reaction system to dissolve the co-solvent and by-product-sodium chloride in the synthesis process, wherein the amount of NMP solvent added is 0.2mol / molNa 2 S, the addition of anaerobic deionized water is 6.6mol / molNa 2 S, NMP and H in which the co-solvent and NaCl are completely soluble 2 O, thereby forming a solution mixture containing polyphenylene sulfide resin, NMP, cosolvent, and by-products, and the mixture is input into a centrifuge for solid-liquid separation to obtain a solution containing 30wt% H 2 O and the polyphenylene sulfide resin solid mixture of a small amount of NMP, contain NMP, water, co-solvent and by-product in the filtrate; and the mixed system of organic impurity solution; in this mixed system, the total amount of 7.3mol / molNa 2 The chloroform of S, wherein NMP is carried out effectively extraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com