Sawdust waste recycling and ash removing device for furniture manufacturing

A technology for waste recycling and furniture manufacturing, which is applied in the direction of separating solids from solids with airflow, solid separation, and screening, etc. It can solve problems affecting the quality of recycling, increase the drop distance, improve the efficiency of impurity separation, and increase The effect of the effect of the dispersed feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

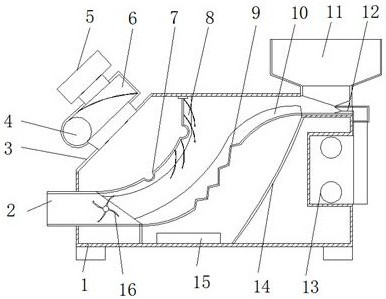

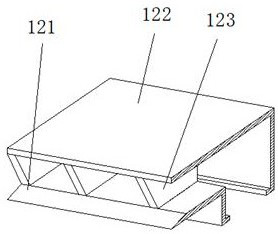

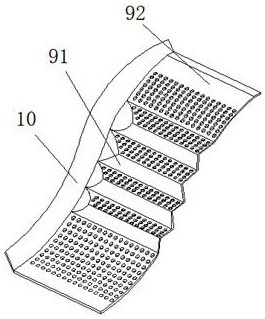

[0027] refer to Figure 1-5 , a device for recycling sawdust waste for furniture manufacturing, comprising a housing 1, a feed hopper 11 and a cover 3 are fixedly installed on the top of the housing 1, and an air pump 13 and a rectangular air pump 13 are fixedly installed at both ends of the housing 1 The discharge pipe 2 of the structure, the side bottom end of the housing 1 is fixedly equipped with a cleaning pipe 15, the end of the housing 1 is provided with a rectangular groove, and the inside of the rectangular groove is fixedly installed with an exhaust mechanism 12, and the exhaust mechanism 12 The bottom end communicates with the air outlet of the air pump 13 through a pipeline, and the air outlet of the exhaust mechanism 12 is located at the feeding end of the feed hopper 11, between the bottom end of the end of the discharge pipe 2 and the top end of the inner wall of the housing 1 A filter screen mechanism 9 is fixedly installed, and an isolation screen mechanism 7 ...

Embodiment 2

[0037] refer to Figure 1-5 , a device for recycling sawdust and waste materials used in furniture manufacturing. Compared with Embodiment 1 in this embodiment, a rotating rod is installed inside the discharge pipe 2 through a drive motor and a bearing, and a plurality of arcs are fixedly installed on the outside of the rotating rod. shaped structure of the scraper 16.

[0038] When this embodiment is in use, waste materials such as sawdust and wood shavings processed in the device fall into the inner discharge pipe 2 for unloading, and the nozzle can be blocked by the installed scraper 16 during the unloading process to prevent air The bottom is circulated, and during the discharge process, the rotating scraper 16 can be used to push to the outside in turn, which improves the stability of the discharge, avoids clogging, and improves the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com