Gas-liquid-solid multi-effect separator

A solid-liquid separator, gas-liquid-solid technology, used in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as single function, incomplete gas-liquid separation, and inability to effectively separate solid and oil impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

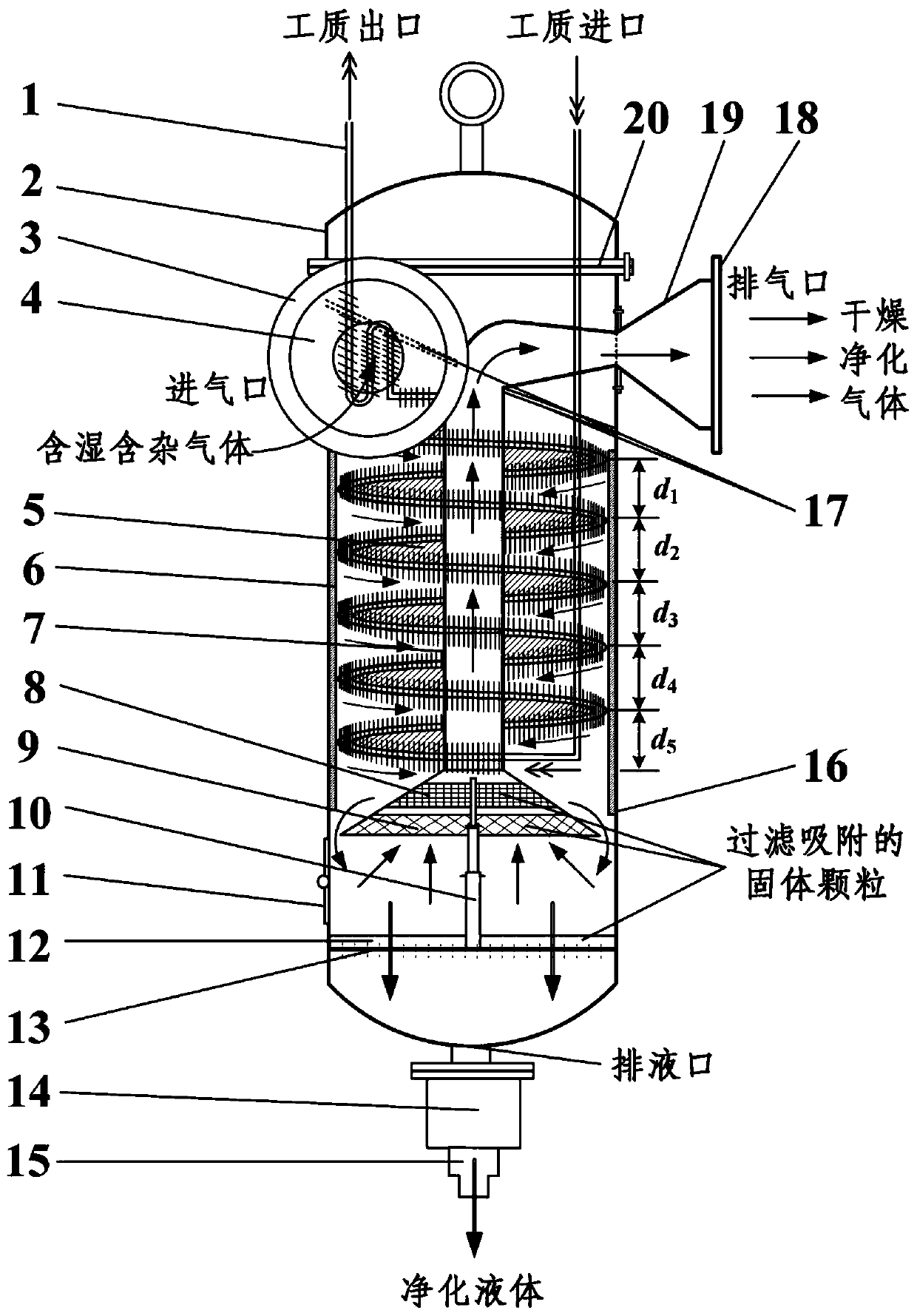

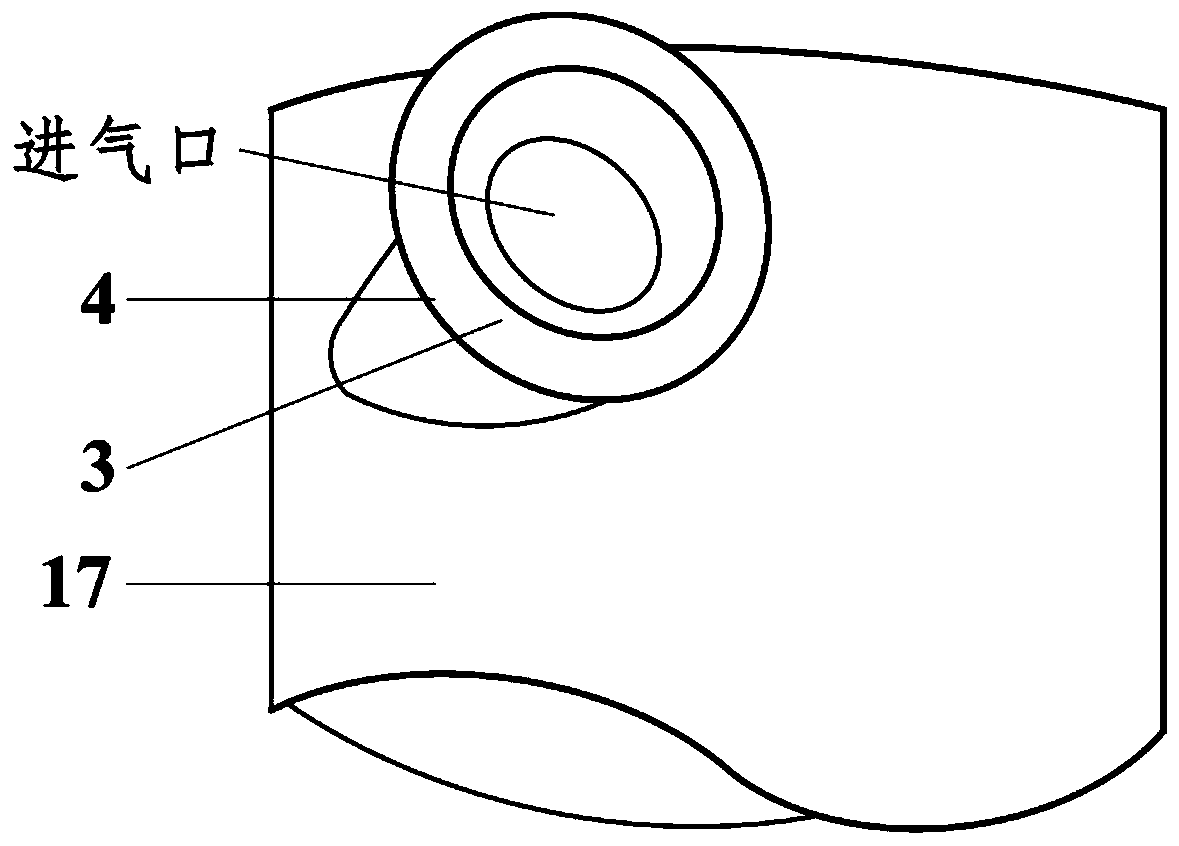

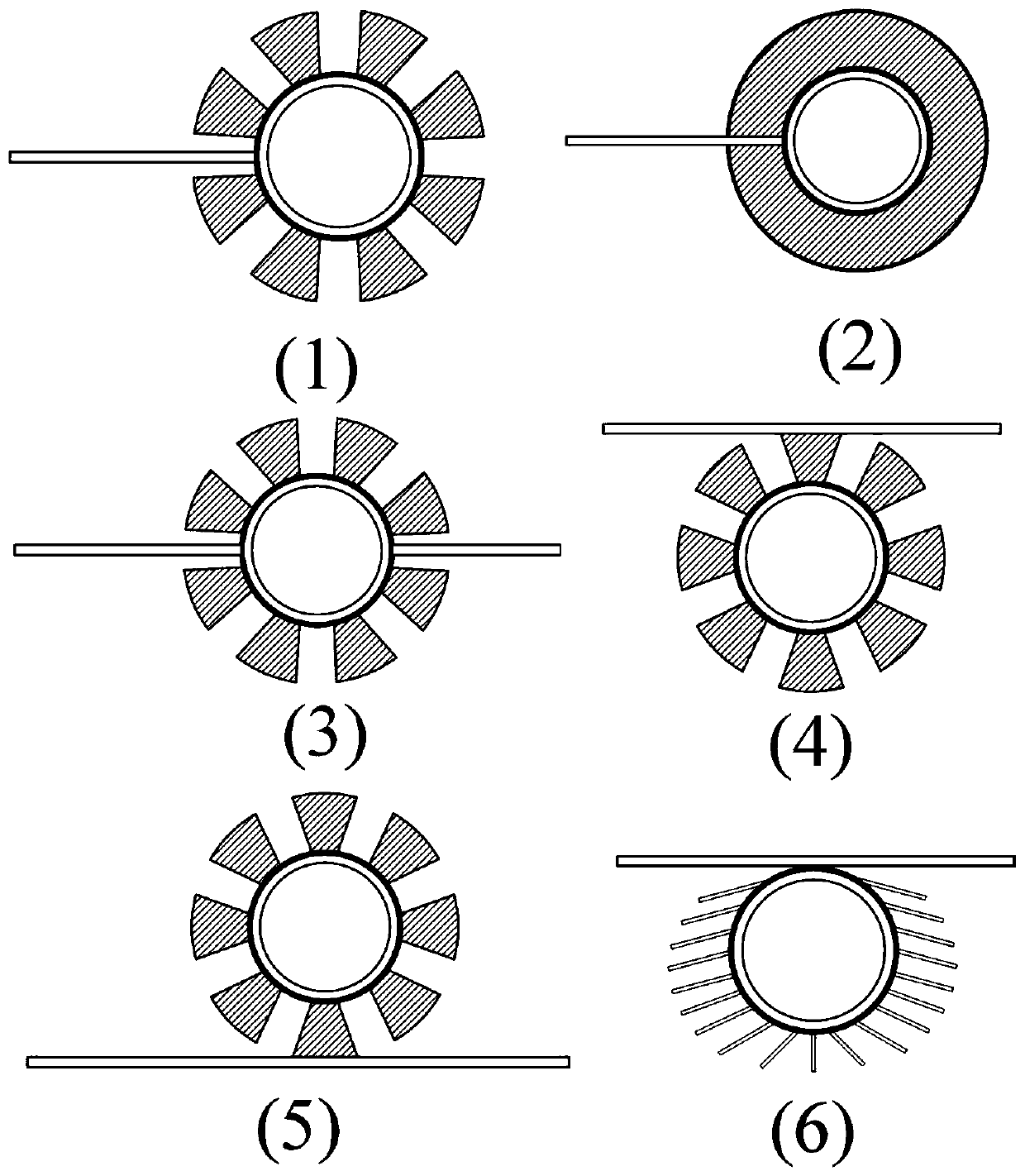

[0039] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a gas-liquid-solid multi-effect separator, including a housing, an inlet pipe, an exhaust pipe, a reversing plate, a spiral plate, a reversing pipe, a heat exchanger, a filter screen, a filter Adsorber and solid-liquid separator; the intake pipe 4 is a tapered reducing pipe, which is arranged on the upper part of the shell 16 and is tangent to the circumference of the shell 16 to realize tangential air intake and acceleration; the spiral plate 5 is provided with a heat exchange The device 1 is set between the reversing tube 7 and the shell 16, and is fixed on the reversing tube 7. The gas-liquid separation is realized during the flow of the gas along the spiral plate; the heat exchanger 1 is a finned heat exchange tube, which increases the gas The liquid separation area and the heat dissipation area accelerate the gas collision and cooling and dehumidification; the filter screen 9 is s...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment lies in that the horizontal section of the reversing tube is different. like Figure 4 As shown, in this embodiment, the horizontal pipe part of the reversing pipe is a pipe with equal cross-section, and the structures and beneficial effects of other parts not described are the same as those in Embodiment 1. The advantage of this embodiment is that the equal-section pipe is easy to manufacture.

Embodiment 3

[0060] The difference between this embodiment and the first embodiment lies in that the position of the intake pipe and the structure of the reversing pipe are different. like Figure 5 As shown, in this embodiment, the intake pipe is located on one side of the housing and is coaxial with the exhaust pipe; the reversing pipe only has a vertical section, and the purified gas directly enters through the reversing pipe, which is composed of the housing, the reversing plate and the upper end cover. In the large space cavity, and then discharged through the exhaust pipe. Other structures and beneficial effects not described are the same as those in Embodiment 1. The advantage of this embodiment is that the intake pipe and the exhaust pipe are coaxial, and the processing is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com