Composite photocatalyst and preparation method and application thereof

A catalyst and composite light technology, applied in the field of materials, can solve the problems of weak photoetching resistance, uneven distribution, and unsatisfactory photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

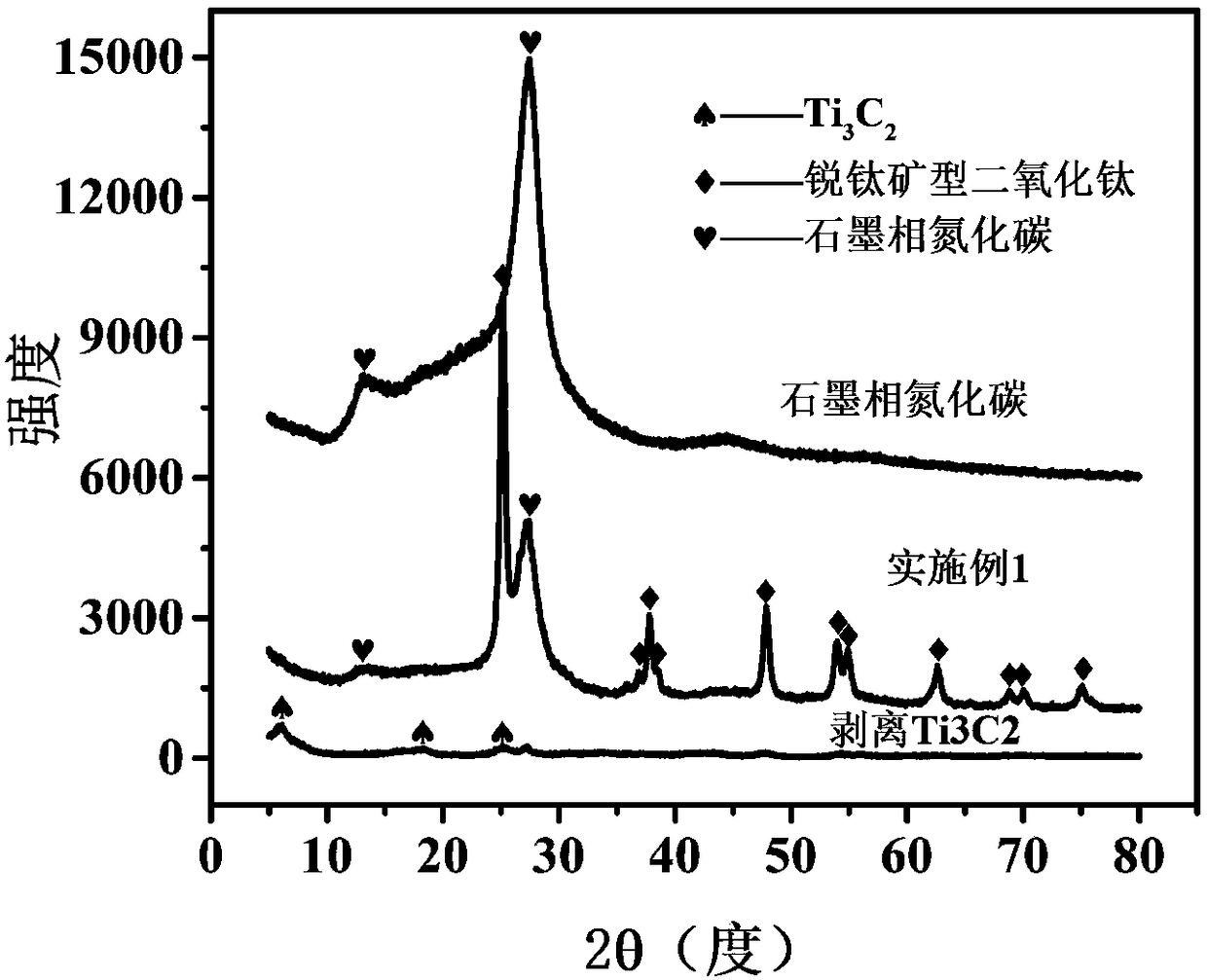

[0025] The invention provides a preparation method of a composite photocatalyst, comprising the following steps: carbon nitride of graphite phase, stripping Ti 3 C 2 The suspension and water are sequentially mixed, freeze-dried and calcined to obtain the composite photocatalyst. In the present invention, the graphite phase carbon nitride, exfoliated Ti 3 C 2 The usage ratio of water and water is preferably 0.2g:0.0125-0.2g:10-40ml, more preferably 0.2:0.02-0.15:15-35ml, most preferably 0.2:0.05:30ml. In the present invention, the stripped Ti 3 C 2 The concentration and dosage of the suspension are not particularly limited, as long as the stripped Ti 3 C 2 The mass ratio of carbon nitride to graphite phase is 0.0125-0.2:0.2.

[0026] The present invention is to described graphite phase carbon nitride, exfoliated Ti 3 C 2 The method of mixing the suspension and water is not particularly limited, and a mixing method well known to those skilled in the art can be used. In...

Embodiment 1

[0045] 30g of urea was subjected to thermal polycondensation reaction at 500°C for 2h to obtain graphite phase carbon nitride.

[0046] Dissolve 1.5g LiF in 15ml HCl solution with a concentration of 6mol / L, add 1.5g Ti 3 AlC 2 powder, and stirred in a water bath at 60°C for 24 hours to obtain an etching product;

[0047] The obtained etching product was repeatedly centrifuged and cleaned until the supernatant was neutral, and the Ti 3 C 2 Stripped into a single layer, and finally centrifuged at 3500rpm at low speed for 1h to separate the stripped and non-striped samples to obtain the stripped Ti 3 C 2 suspension.

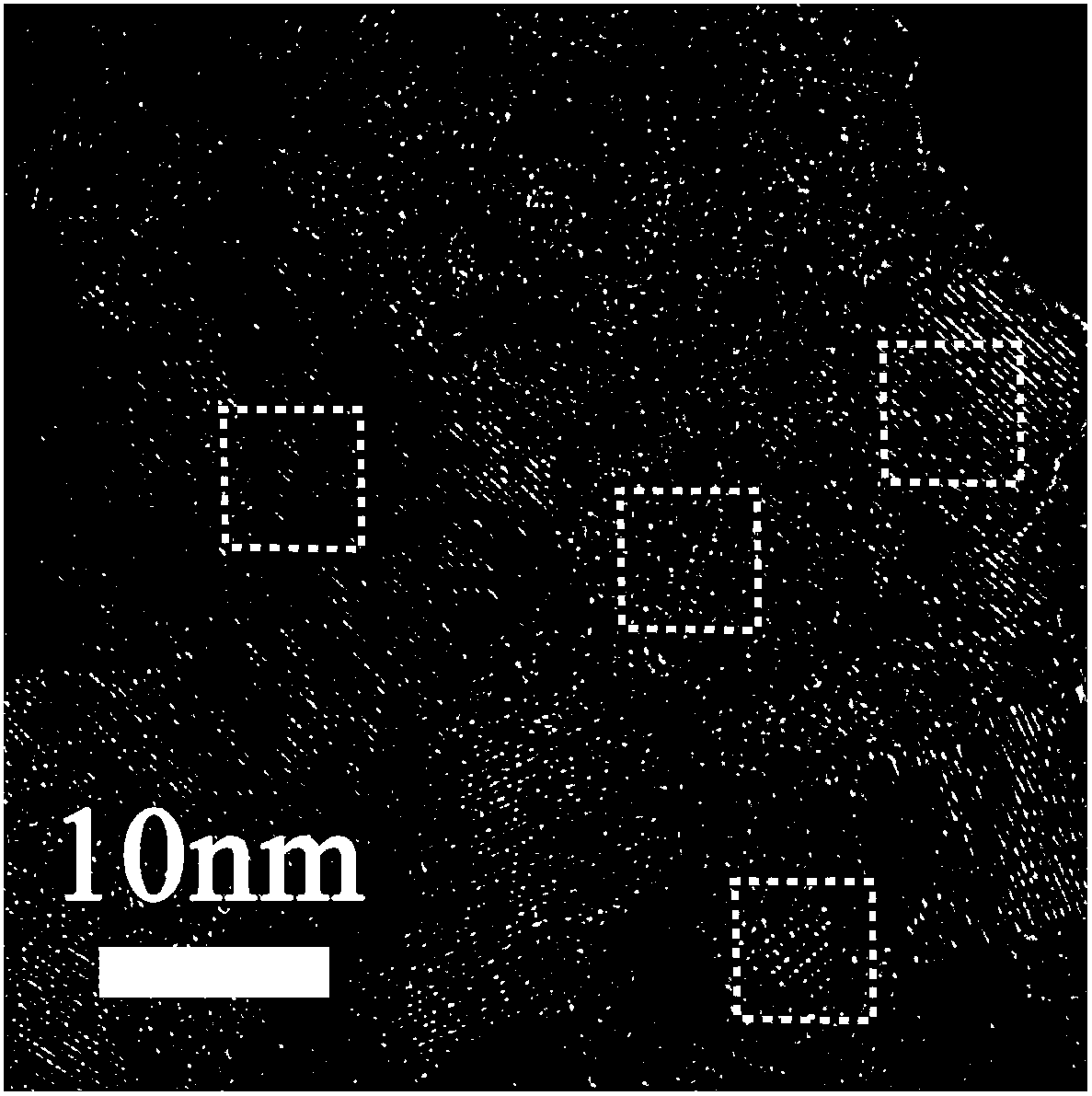

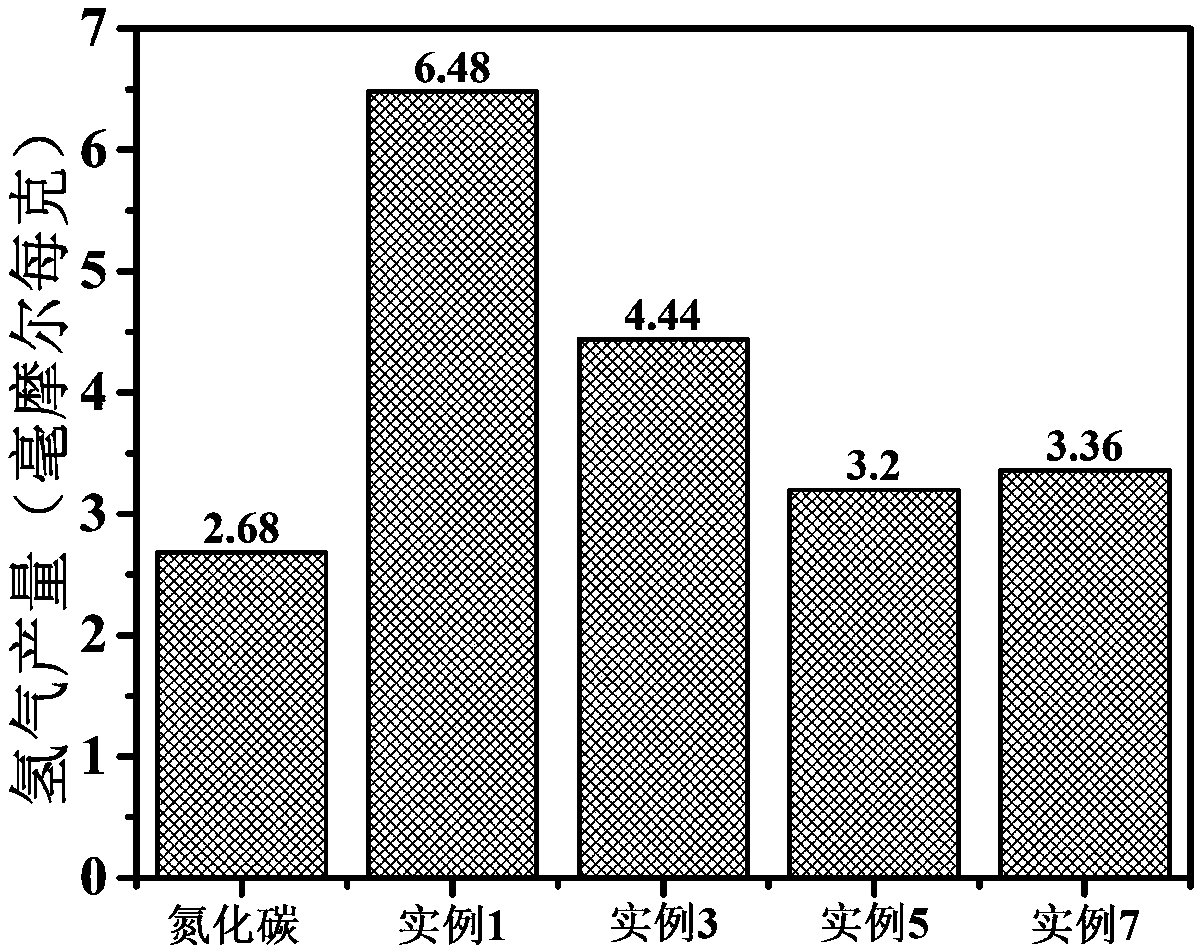

[0048] Mix 0.2 g of graphitic carbon nitride and 20 ml of exfoliated Ti at a concentration of 2.5 mg / ml 3 C 2 The suspension was mixed, and 30ml of deionized water was added to keep the total volume of the system at 50ml; the mixed solution was sonicated at 80W for 30min, stirred for 30min, and freeze-dried to obtain a freeze-dried product; the freeze-dried p...

Embodiment 2

[0056] 0.2 g of graphitic carbon nitride and 40 ml of exfoliated Ti at a concentration of 2.5 mg / ml 3 C 2 The suspension was mixed, and 10ml of deionized water was added to keep the total volume of the system at 50ml; the mixed solution was sonicated at 80W for 30min, then stirred for 30min, and freeze-dried to obtain a freeze-dried product; the freeze-dried product was roasted at 350°C for 1 hour to obtain The composite photocatalyst; the composite photocatalyst includes the following components in weight percentage: titanium dioxide nanoparticles 30.41%, stripping Ti 3 C 2 9.01%, graphite phase carbon nitride 60.58%;

[0057] The same test method as in Example 1 was used to measure the photocatalytic water splitting hydrogen production performance of the composite photocatalyst. The test results were: the measured hydrogen production was 1.36 mmol / g, and the pure carbon nitride was 2.68 mmol / g.

[0058] The graphitic phase of carbon nitride and exfoliated Ti 3 C 2 The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com