Cutting fluid recovery device for metal connecting piece machining

A metal connector, recycling device technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools and other directions, can solve the problems of low processing accuracy, high cost, poor quality, etc., to achieve good recycling quality, convenient operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

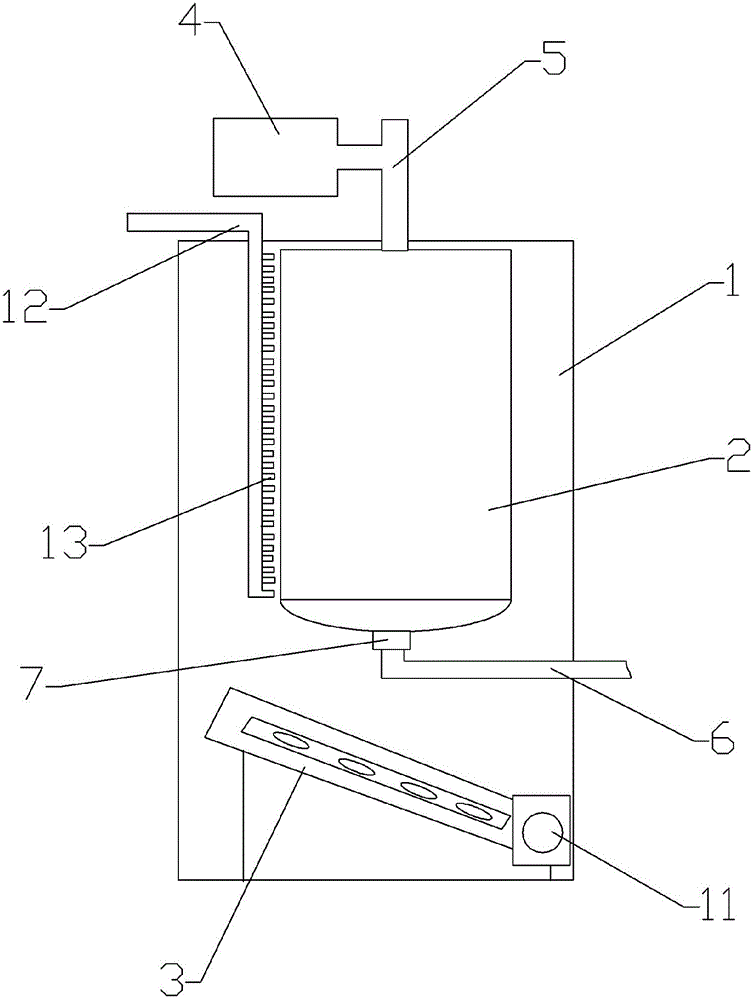

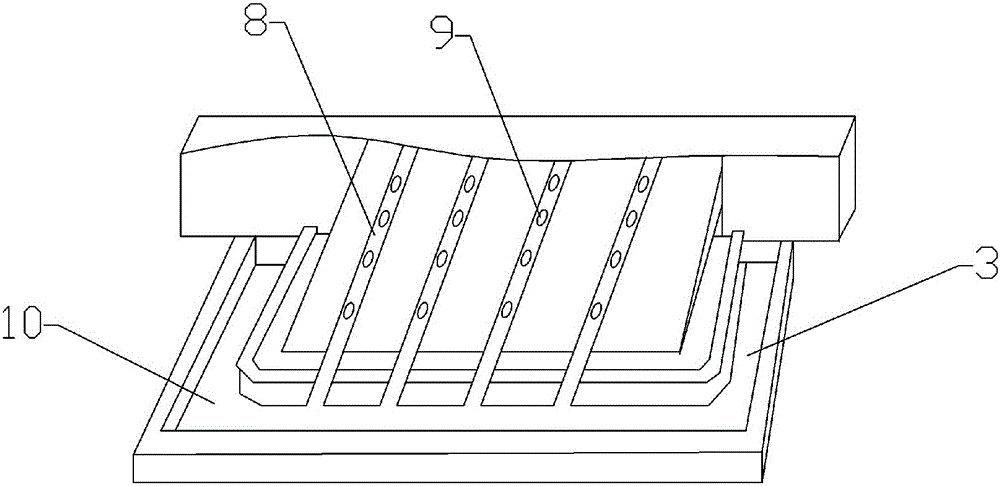

[0014] The reference signs in the drawings of the description include: housing 1, centrifugal roller 2, inclined platform 3, motor 4, rotating shaft 5, feed pipe 6, sealing ring 7, longitudinal drainage groove 8, magnet 9, collection groove 10, Drain pipe 11, recoil water pipe 12, nozzle 13.

[0015] The embodiment is basically as attached figure 1 , attached figure 2 Shown: The cutting fluid recovery device for processing metal connectors, including a casing 1, a centrifugal roller 2 and an inclined platform 3 located below the centrifugal roller 2 are arranged in the casing 1, and the side of the centrifugal roller 2 is a screen-like dense hole, the centrifugal roller 2 is connected with a rotating shaft 5 with a motor 4, and the bottom of the centrifugal roller 2 is connected with a feed pipe 6, and the connection between the centrifugal roller 2 and the feed pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com