Efficient oil-water separation device for chemical engineering

An oil-water separation device, high-efficiency technology, applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve the problems of environmental damage, waste of resources, etc., to speed up the separation rate, facilitate processing and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

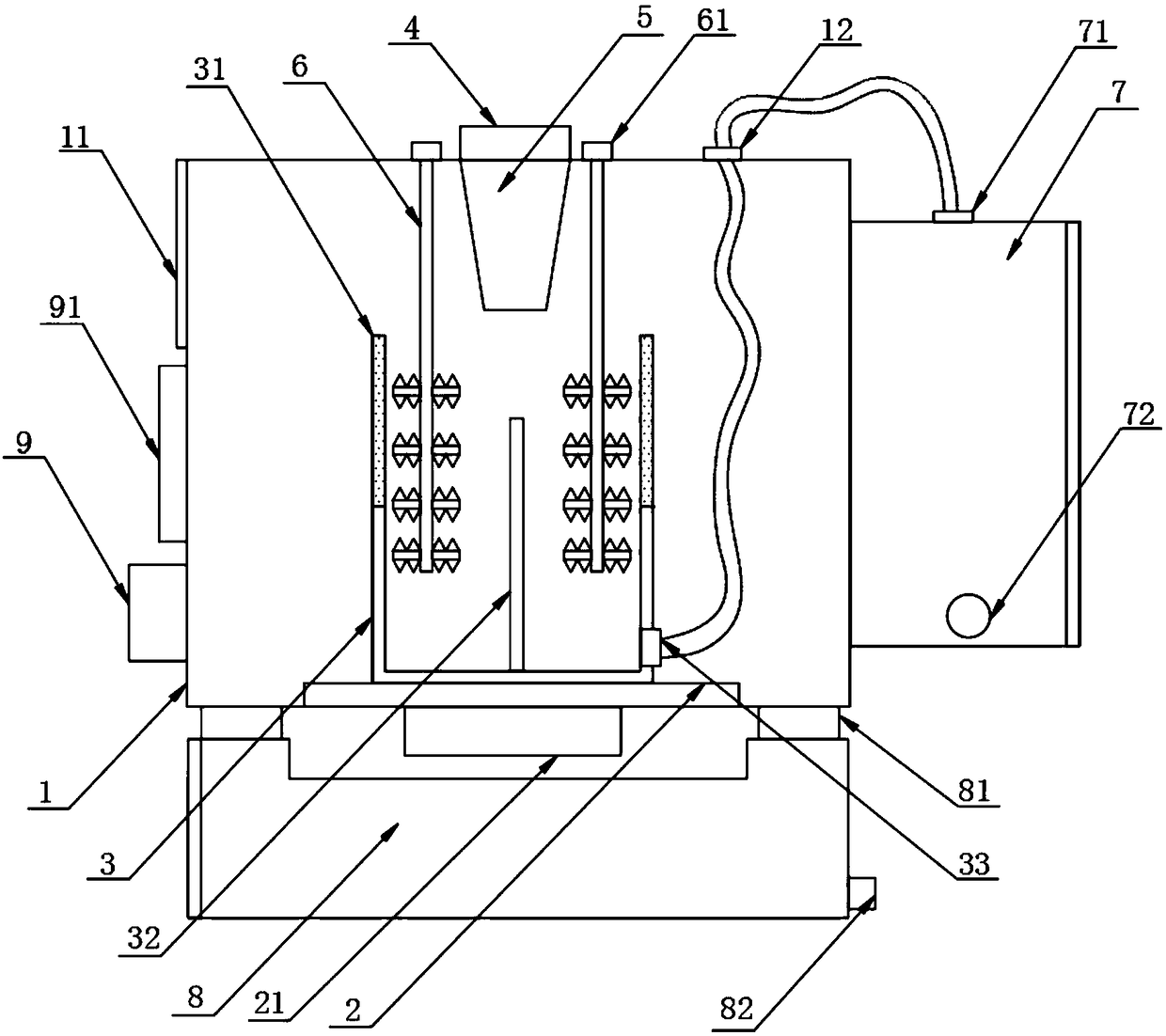

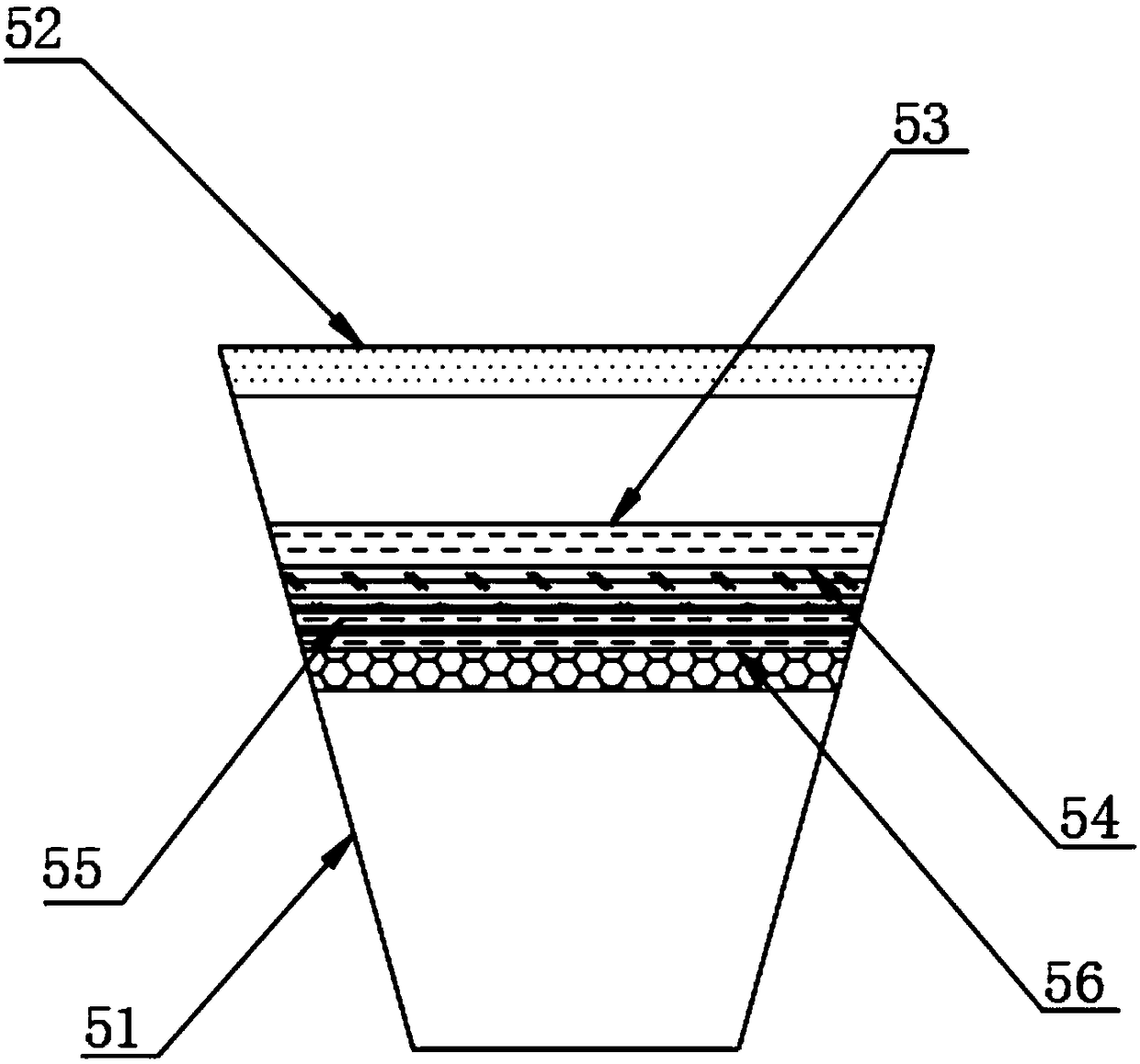

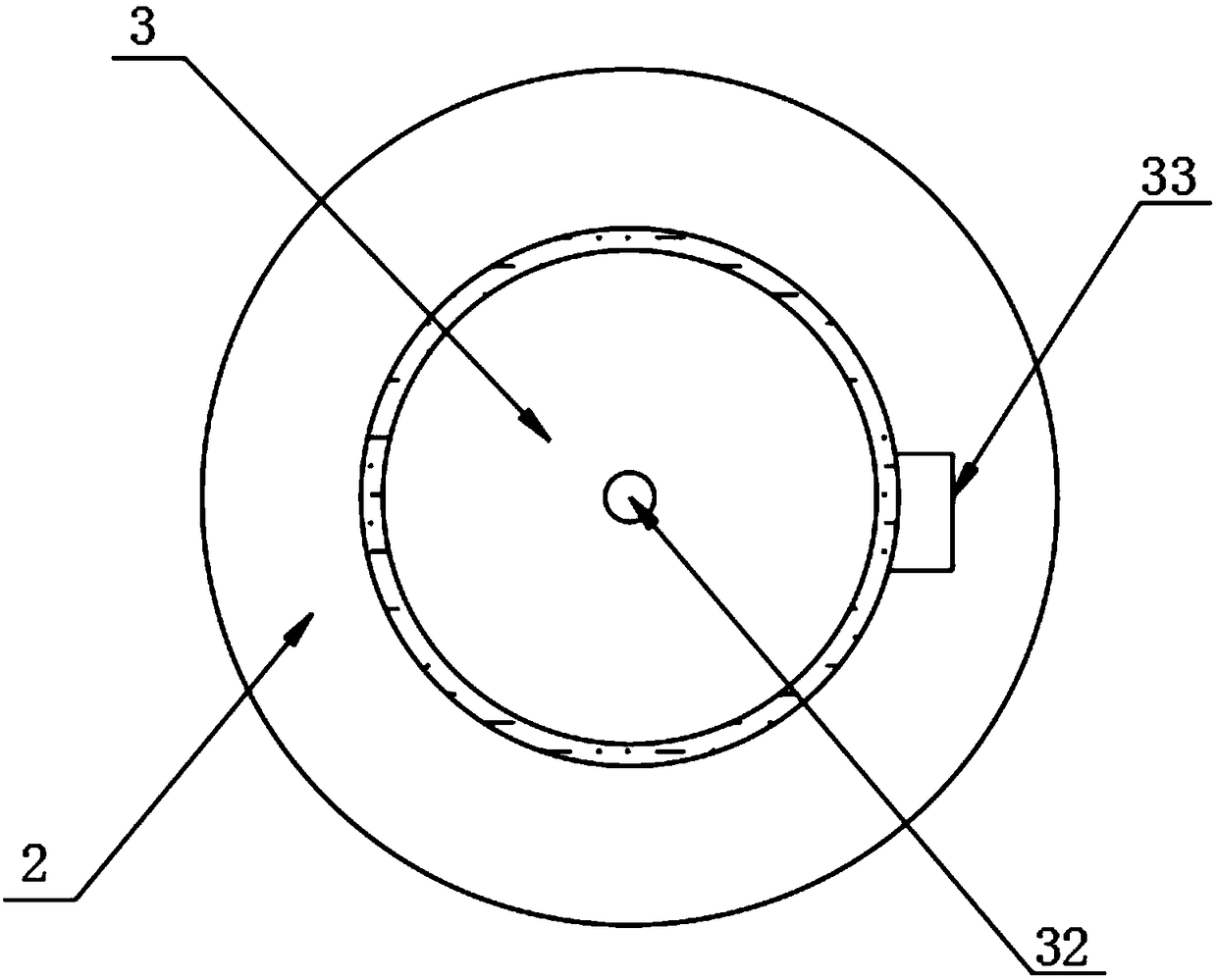

[0022] The present invention provides such as Figure 1-3 The shown high-efficiency oil-water separation device for chemical industry comprises a device casing 1, a rotating disk 2 is arranged at the bottom of the inner wall of the device casing 1, a motor 21 is arranged at the bottom of the rotating disk 2, and the rotating disk 2 is connected to the motor. 21 Transmission connection, the top of the rotating disk 2 is fixed with a separation shell 3, the top of the device shell 1 is provided with a feeding port 4, and the bottom of the feeding port 4 is connected with a filter device 5, and the filter device 5 It includes a filter housing 51, an inner thread 52, a filter screen 53, a filter element 54, an activated carbon adsorption layer 55 and a filter bag filling layer 56. The filter device 5 is provided with a rotating shaft 6 on both sides. A water storage chamber 7 is provided on one side, an oil storage chamber 8 is provided at the bottom of the device housing 1 , and ...

Embodiment 2

[0026] The filter housing 51 is arranged on the top of the inner wall of the device housing 1, and the top of the inner wall of the filter housing 51 is provided with an inner thread 52, and the inner thread 52 is threadedly connected with the feeding port 4. There is a filter screen 53, the bottom of the filter screen 53 is provided with a filter element 54, the bottom of the filter element 54 is provided with an activated carbon adsorption layer 55, and the bottom of the activated carbon adsorption layer 55 is provided with a filter bag filling layer 56, the filter bag is filled with The interior of the layer 56 is filled with nitrifying bacteria.

[0027] The top of the rotating shaft 6 is provided with a motor 61 , the motors 61 are arranged on both sides of the feeding port 4 , the rotating shaft 6 is connected with the motor 61 in a driving manner, and the rotating shaft 6 extends to the interior of the separation housing 3 and the rotating shaft 6 There is a stirring ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com