Molecular distillation apparatus

A molecular distillation and cylinder technology, applied in molecular distillation and other directions, can solve the problems of molecular structure, product quality impact, high requirements for mechanical parts, only one motor speed, etc., to reduce energy consumption, improve purity and quality, The effect of film thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

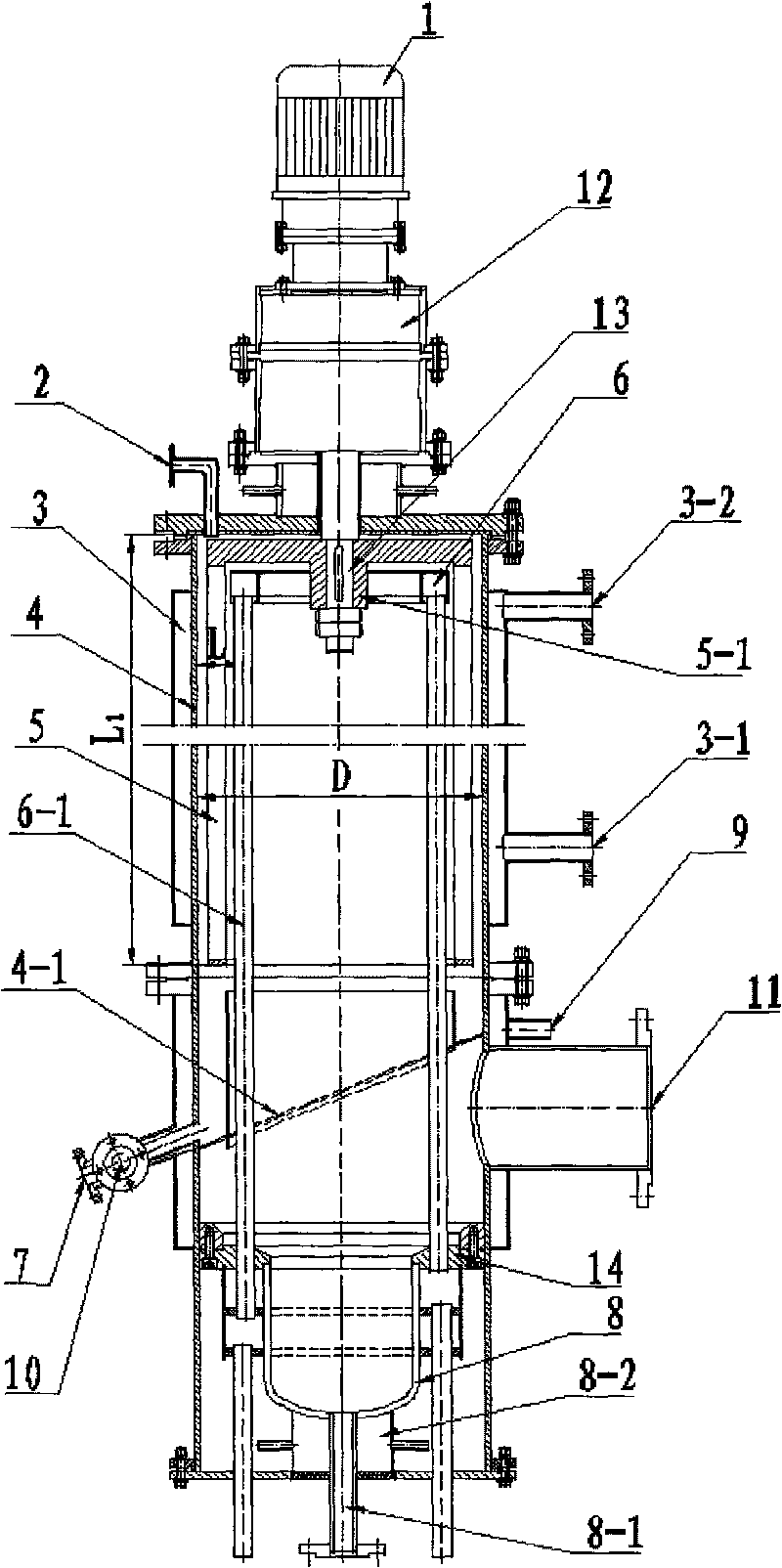

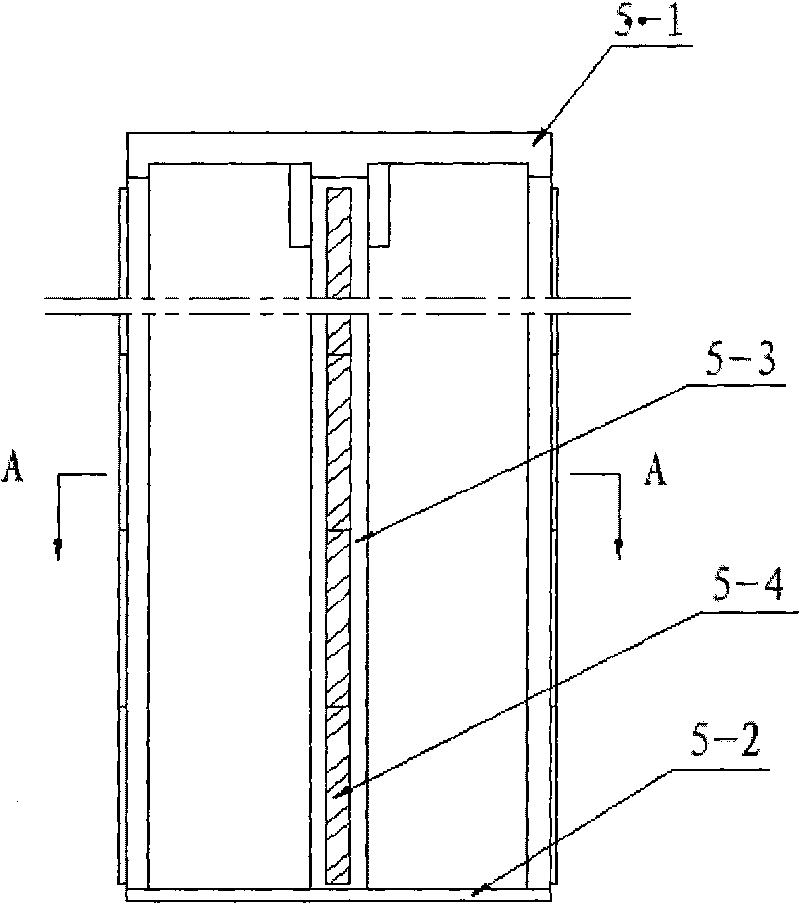

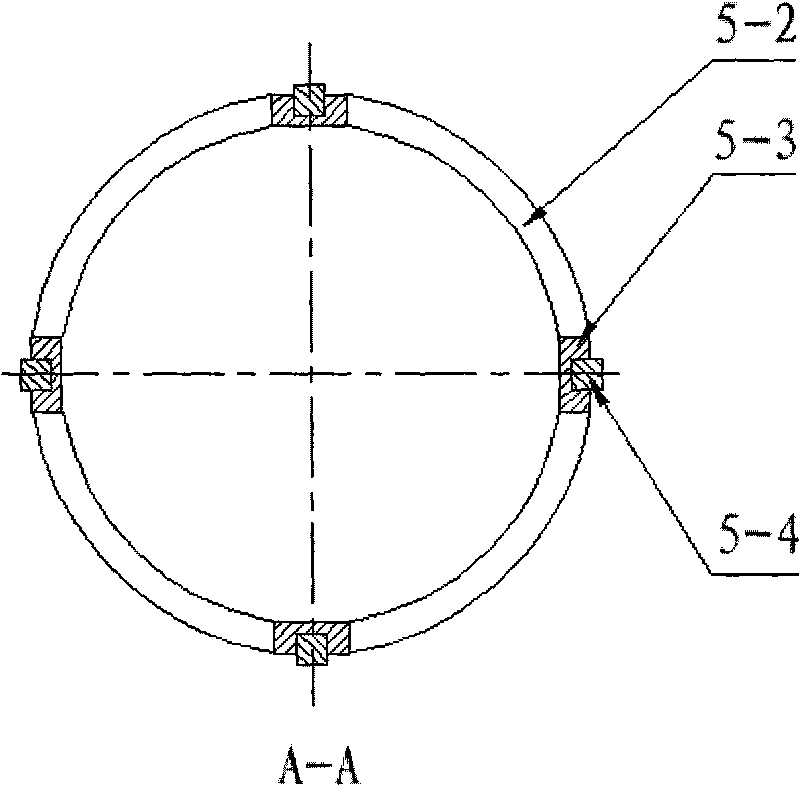

[0021] Such as figure 1 As shown, the present invention includes a motor 1, a material inlet 2, a jacket 3, a cylinder 4, a rotating cage device 5, a condensation pipe assembly 6, a heavy oil outlet 7, a light oil collection tank 8, a saturated steam inlet 9, and a saturated steam outlet 10 , Vacuum port 11.

[0022] The motor 1 is a two-speed motor with a speed of 86r / min and 130r / min. It is connected to the rotating shaft 13 through a coupling and a reduction mechanism 12. The rotating shaft 13 passes through the end cover of the cylinder body 4 and the upper flange of the cage device 5 5-1, and fixedly connected with the rotating shaft through the key and lock nut. A condensation pipe assembly 6 is installed inside the tumbler device 5, and the condensation pipe assembly 6 is a cylindrical device surrounded by a plurality of condensation pipes 6-1. There is a jacket 3 on the periphery of the cylinder body 4, and the heat transfer oil inlet 3-1 and the heat transfer oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com