Filler extraction tower for gradient fractionating separation of large phase ratio system, and extraction method thereof

A technology of fractional separation and extraction tower, which is applied in the direction of liquid solution solvent extraction, etc., and can solve the problem of unsuitable emulsification extraction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

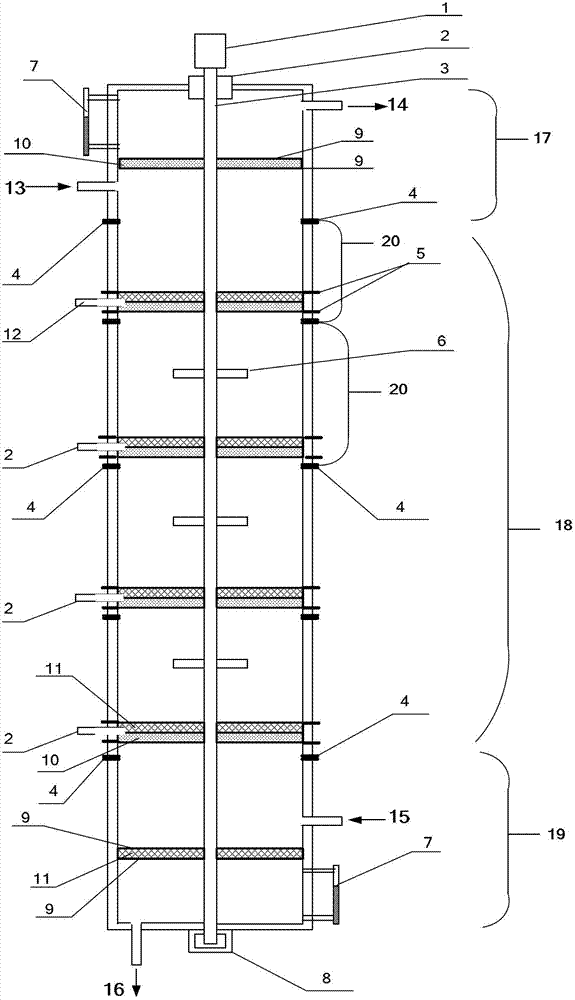

[0065] Such as figure 1 As shown, a packed extraction tower with a gradient fractionation separation of a large phase-easy emulsification system, the middle section of the tower body 18 is composed of four sub-cylinders 20, and the hydrophobic fillers from top to bottom are: silicone rubber, Polytetrafluoroethylene, polyacrylonitrile, phenolic resin, polypropylene, and hydrophilic fillers from top to bottom are: glass powder, ceramic powder, hydrophilic polyurethane foam, stainless steel wire mesh, nickel-titanium alloy wire mesh, extraction system The light phase is nonane, the heavy phase is polyethylene glycol aqueous solution, and the phase volume ratio of the light and heavy two phases countercurrent is 1:100. The light phase is used as the dispersed phase, which flows in from the light phase material inlet 15, and the heavy phase flowing countercurrently downwards in the tower is stirred and mixed in the middle section cylinder 18. During the process of upward flow, the...

Embodiment 2

[0067] Such as figure 1 As shown, a packed extraction tower with a gradient fractionation separation of a large phase-easy emulsification system, the middle section of the tower body 18 is composed of four sub-cylinders 20, and the hydrophobic fillers from top to bottom are: silicone rubber, Polytetrafluoroethylene, polyacrylonitrile, phenolic resin, polypropylene, and hydrophilic fillers from top to bottom are: glass powder, ceramic powder, hydrophilic polyurethane foam, stainless steel wire mesh, nickel-titanium alloy wire mesh, extraction system The light phase is a kerosene solution of 30% by volume of trialkylphosphine oxide, and the heavy phase is an aqueous ammonium sulfate solution of polyethylene glycol with a weight percentage of 20%. The heavy phase is used as the dispersed phase, and it flows in from the heavy phase material inlet 13, and the light phase flowing upwards countercurrently in the tower is stirred and mixed in the middle section cylinder 18. In the pr...

Embodiment 3

[0069] Such as figure 1 As shown, a packed extraction tower with a gradient fractionation separation of a large phase-easy emulsification system, the middle section of the tower body 18 is composed of four sub-cylinders 20, and the hydrophobic fillers from top to bottom are: silicone rubber, Polytetrafluoroethylene, polyacrylonitrile, phenolic resin, polypropylene, and hydrophilic fillers from top to bottom are: glass powder, ceramic powder, hydrophilic polyurethane foam, stainless steel wire mesh, nickel-titanium alloy wire mesh, extraction system The light phase is nonane, the heavy phase is polyethylene glycol aqueous solution containing phenol, nitrophenol, p-nitrophenol, and o-nitrophenol, and the phase volume ratio of light and heavy two-phase countercurrent is 1:50. The light phase is used as the dispersed phase, which flows in from the light phase material inlet 15, and the heavy phase flowing countercurrently downwards in the tower is stirred and mixed in the middle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com