Gas-hydrate-separation bubbling reinforcing device gas-hydrate-separation purifying reinforcing device based on the same and gas purifying reinforcing method

A technology for hydration separation and strengthening devices, which is applied in chemical instruments and methods, chemical methods for reacting liquids and gaseous media, chemical/physical/physical-chemical nozzle reactors, etc. Hydration and separation effect is not obvious and other problems, to achieve the effect of improving resource utilization, easy transformation and upgrading, and speeding up the separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 7

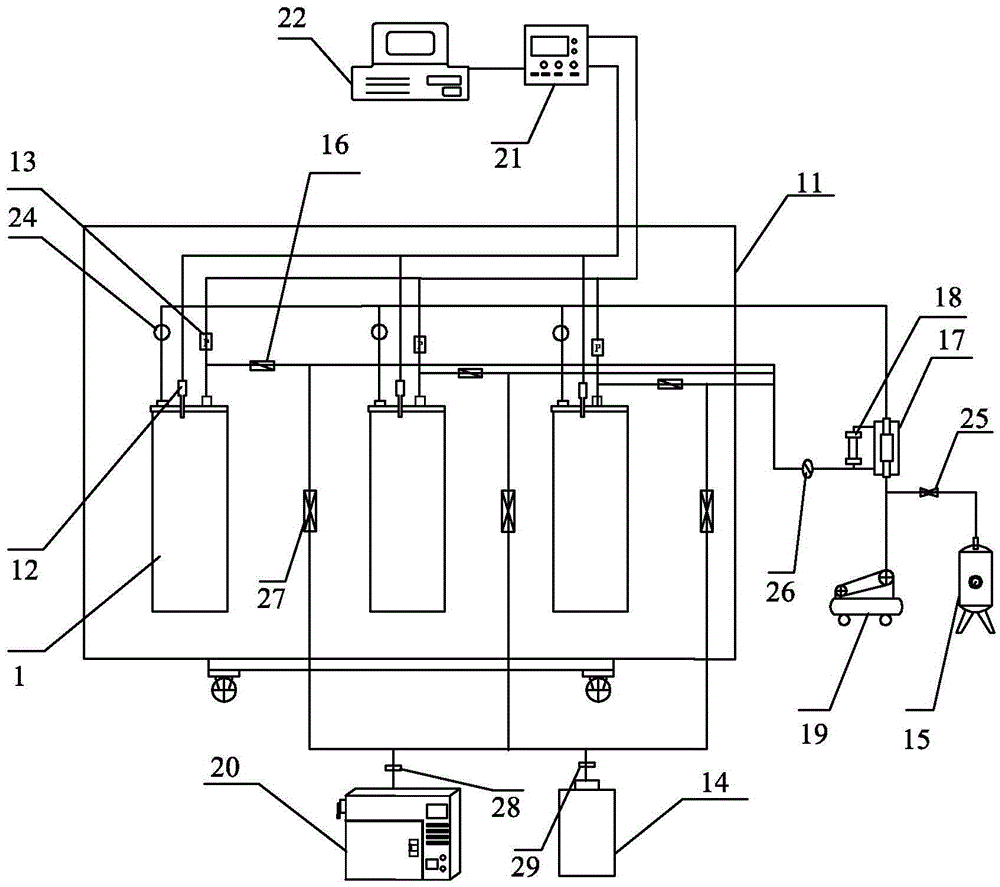

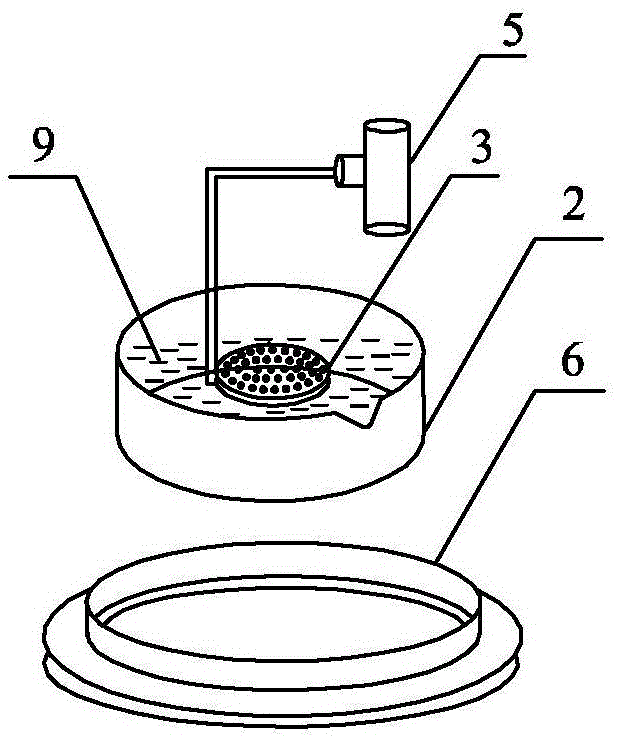

[0054] Embodiment 7. According to Embodiment 4, 5 or 6, the gas purification and strengthening method of the gas hydration separation and purification strengthening device based on the gas hydration separation bubbling strengthening device, in this embodiment,

[0055] The purification and strengthening method comprises the following steps:

[0056] Step 1: Check the air tightness of the gas hydration separation and purification strengthening device based on the gas hydration separation bubbling strengthening device;

[0057] Step 2, close the intake stop valve 24, open the intake stop valve for 10min-15min, and remove the air in the gas hydration separation purification and strengthening device;

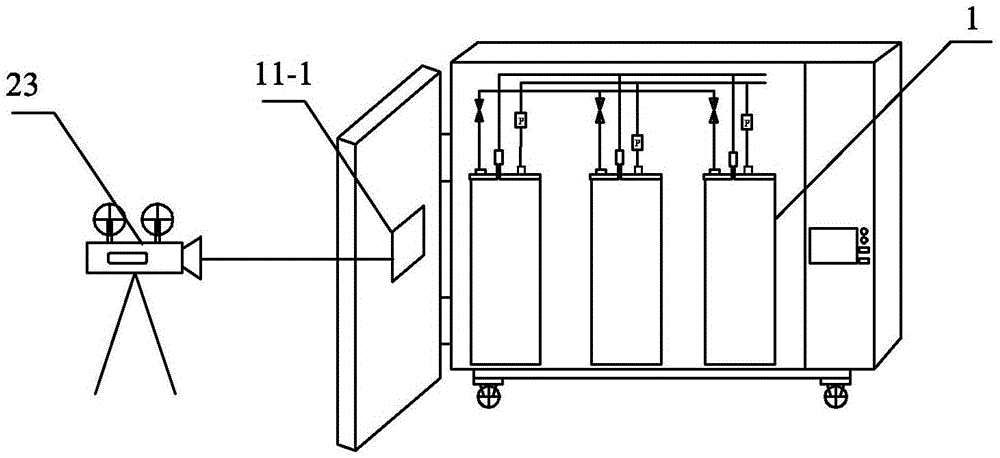

[0058] Step 3, setting the temperature in the temperature control box 11 to be lower than the temperature value when the methane hydrate is formed; the temperature value when the methane hydrate is formed represents the corresponding phase equilibrium temperature value when the meth...

specific Embodiment approach 8

[0064] Specific embodiment 8. This specific embodiment is a further description of the gas purification and strengthening method of the gas hydration separation and purification strengthening device based on the gas hydration separation and bubbling strengthening device described in the specific embodiment 7. In this embodiment, in step 1 Check the air tightness of the gas hydration separation, purification and strengthening device based on the gas hydration separation and bubbling strengthening device. The gas hydration separation, purification and strengthening device is filled with 2MPa gas, and the pressure sensor 13 and the industrial computer 22 are used to monitor the change of the gas pressure in the hydration reactor in real time. The gas hydration separation and purification strengthening device of the hydration separation bubbling strengthening device has good air tightness.

[0065] In the present invention, the accelerator solution is composed of a kinetic acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com