Method capable of photocatalytically degrading dyes to prepare copper-loaded nano titanium dioxide chitosan composite microspheres in microfluidic mode

A technology of nano-titanium dioxide and composite microspheres, which is applied in the field of photocatalytic degradation materials preparation, can solve the problems of complex components, poor hydrophilicity, high organic content, etc., to protect the environment and water resources, reduce toxic components, and have a large catalytic surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

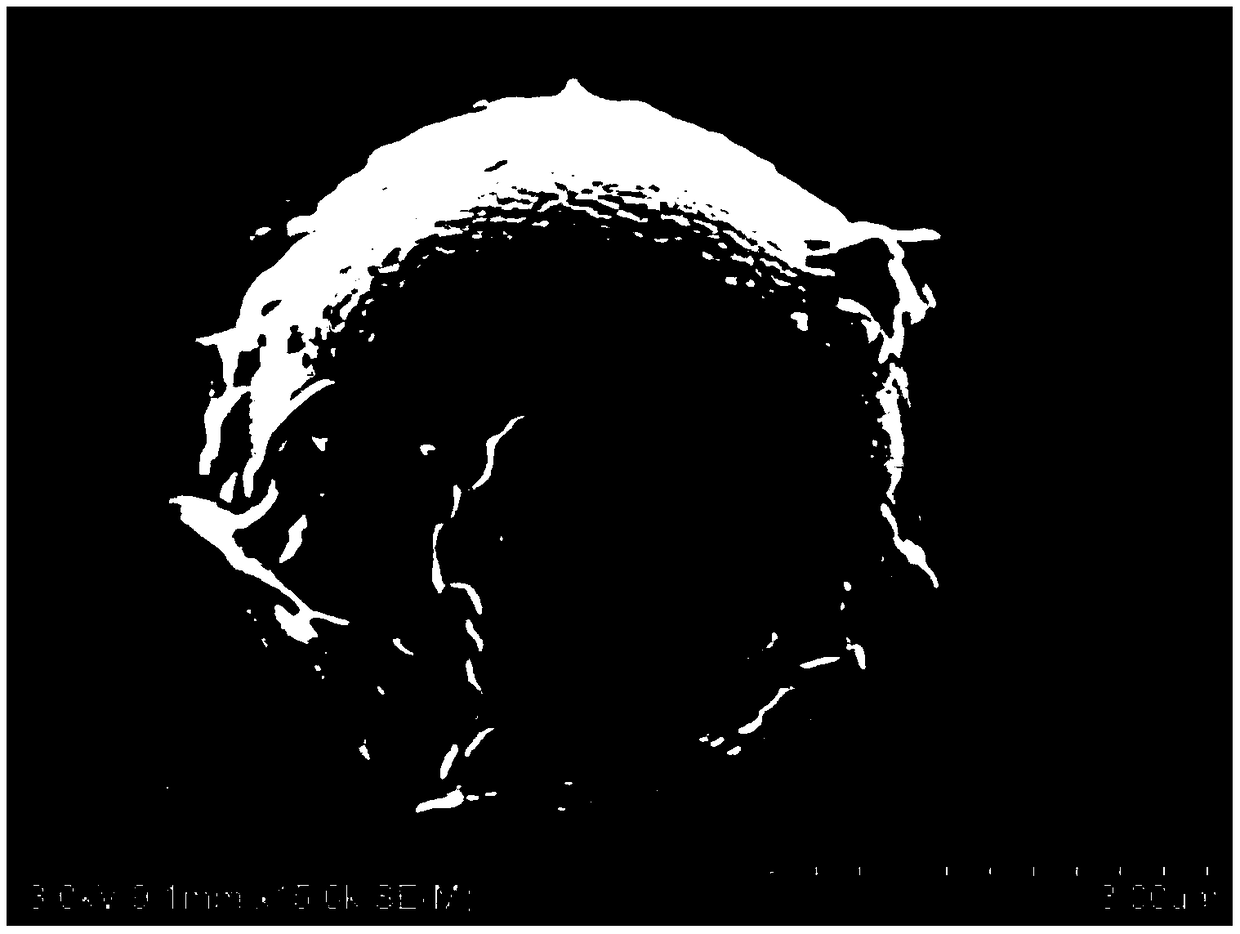

Image

Examples

Embodiment 1

[0047] Weigh 11g of tetrabutyl titanate and add 37ml of absolute ethanol, ultrasonically oscillate for 15 minutes, as solution A; measure 11ml of deionized water and 12ml of glacial acetic acid, add 38ml of absolute ethanol as solution B, put it into a three-necked flask, and Stir in a water bath at 23°C. Pour liquid A into the constant pressure funnel, and slowly drop it into liquid B by adjusting the switch. This process lasts for about 2.2 hours, during which the solution gradually turns blue. After dripping, continue to stir for 50 minutes, then transfer to a petri dish and let it stand until a gel is formed.

[0048] Take by weighing 12g of the prepared nano-titanium dioxide gel and put it into a three-necked flask, take the 120g / L amino-terminated hyperbranched polymer (HBP-NH2) 10ml and 40ml of absolute ethanol prepared in the laboratory for proportioning and mixing and transfer Put it into a constant pressure funnel, degumming at 23 degrees Celsius, then add 0.7ml of ...

Embodiment 2

[0052] Weigh 9g of tetrabutyl titanate and add 32ml of absolute ethanol, ultrasonically oscillate for 8 minutes, as solution A; measure 8ml of deionized water and 8ml of glacial acetic acid, add 32ml of absolute ethanol as solution B, put them into a three-necked flask, and Stir in a 17°C water bath. Pour liquid A into the constant pressure funnel, and adjust the switch to slowly drip into liquid B. This process lasts for about 1.8 hours, during which the solution gradually turns blue. After the dripping is finished, continue to stir for 30 minutes, then transfer to a petri dish, and let it stand until a gel is formed.

[0053] Weigh 9g of the prepared nano-titanium dioxide gel and put it into a three-necked flask, take the 90g / L amino-terminated hyperbranched polymer (HBP-NH2) 6ml and 44ml of absolute ethanol prepared in the laboratory for proportioning and mixing and transfer Put it into a constant pressure funnel, degumming at 16 degrees Celsius, then add 0.5ml of copper s...

Embodiment 3

[0057] Weigh 10g of tetrabutyl titanate and add 37ml of absolute ethanol, ultrasonically oscillate for 11 minutes, as solution A; measure 11ml of deionized water and 9ml of glacial acetic acid, add 35ml of absolute ethanol as solution B, put them into a three-necked flask, and Stir in a 20°C water bath. Pour liquid A into the constant pressure funnel, and slowly drop into liquid B by adjusting the switch. This process lasts for about 2.1 hours, during which the solution gradually turns blue. After dripping, continue to stir for 35 minutes, then transfer to a petri dish and let it stand until a gel is formed.

[0058] Weigh 10g of the prepared nano-titanium dioxide gel and put it into a three-necked flask, take the 110g / L amino-terminated hyperbranched polymer (HBP-NH2) 8ml and 42ml of absolute ethanol prepared in the laboratory and carry out proportioning and mixing and transfer Put it into a constant pressure funnel, degumming at 25 degrees Celsius, then add 0.55ml of copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com