Carbon quantum dot-modified bismuth tungstate/ordered macroporous fluorine-doped tin oxide composite photocatalyst, and preparation method and application thereof

A technology of fluorine-doped tin oxide and carbon quantum dots, which is applied in the direction of physical/chemical process catalysts, oxygen/ozone/oxide/hydroxide, oxygen preparation, etc., can solve the problems that limit the application of cadmium-based quantum dots, and achieve Effects of reduced recombination rate, high catalytic performance, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

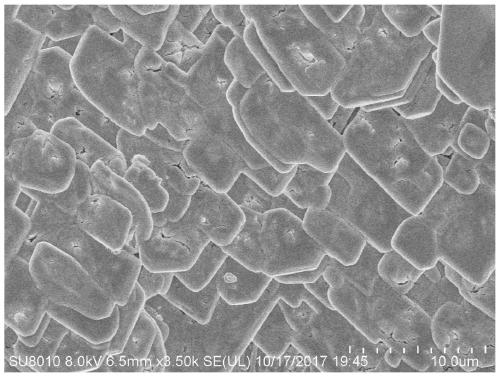

Embodiment 1

[0040] 1. Prepare a fluorine-doped tin oxide film with an ordered macroporous three-dimensional space structure on a conductive substrate:

[0041] (1) Concentrated sulfuric acid and hydrogen peroxide solution are prepared with piranha solution at a volume ratio of 3:1, and the newly prepared piranha solution is soaked in FTO conductive glass for more than 2 hours to remove organic impurities on the surface of the conductive glass. After soaking, use deionized water Rinse several times until the solution pH = 7, remove and dry under nitrogen flow.

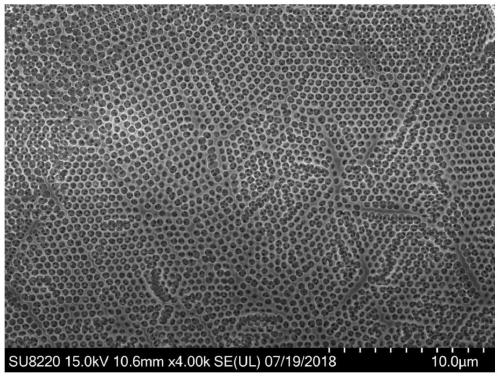

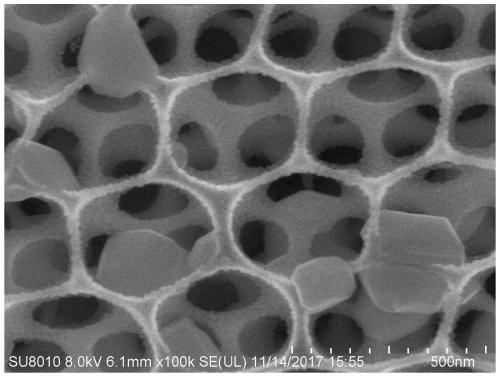

[0042] (2) Polystyrene monodisperse bead (d≈450nm) solution is sonicated for 2 minutes, take 1ml of the solution and put it in 40ml pentahydrate ethanol, put the clean FTO glass obtained above into a glass vial containing polystyrene monodisperse bead solution , the polystyrene monodisperse bead solution just submerged the FTO conductive glass with its rough conductive surface facing outward.

[0043] Transfer the glass vial conta...

Embodiment 2

[0061] The difference between this example and Example 1 is that when using the in-situ synthesis method to synthesize bismuth tungstate, the number of soaking cycles is 20, and the other steps are exactly the same, marked as 20-CQD / Bi 2 WO 6 @mac - FTO.

Embodiment 3

[0063] The difference between this example and Example 1 is that when using the in-situ synthesis method to synthesize bismuth tungstate, the number of soaking cycles is 40 times, and the other steps are exactly the same, marked as 40-CQD / Bi 2 WO 6 @mac - FTO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com