Graphene nitrogen carbide quantum dot modified ZnS micrometer composite material as well as preparation method and application thereof

A technology of graphene nitrogen and composite materials, which is applied in the field of ZnS micro-composite materials modified by graphene nitrogen carbon quantum dots and its preparation, can solve the problems of complicated preparation methods and easy agglomeration of quantum dots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention at first provides a kind of preparation method of the ZnS micro-composite material of graphene carbonized nitrogen quantum dot modification, and this method comprises:

[0032] Step 1: Preparation of ZnS(en) 0.5 Nanosheets, specifically: adding zinc salt and thiourea into ethylenediamine, stirring, the stirring time is preferably 30 minutes, and then hydrothermally reacting at 180-200°C for 10-24 hours, the reaction temperature is preferably 180°C, the reaction time is preferably 18h, after cooling, washing and drying, ZnS(en) can be obtained 0.5 Nanosheets; the zinc salt is preferably zinc chloride, zinc nitrate or zinc acetate; the mass ratio of the zinc salt to thiourea is preferably 272.6:304; the washing is preferably the reactant with ethanol and water Wash each for 2-3 times, the drying temperature is preferably 60-80°C, and the drying time is preferably 10-12h;

[0033] Step 2: Add the amino compound into the porcelain boat, put it in a t...

Embodiment 1

[0042] Example 1g-C 3 N 4 Preparation of QDs

[0043] Add 100 mg of melamine into the porcelain boat, put it in a tube furnace, heat at 550 ° C for 4 hours under nitrogen atmosphere, and the heating rate is 2.5 ° C per minute to obtain the bulk phase g-C 3 N 4 Yellow powder, mix 100mg g-C 3 N 4 The powder was dissolved in 50mL deionized water and stirred for 60min, then transferred to a 100mL reactor and reacted at 200°C for 6h to obtain a light yellow g-C 3 N 4 QDs transparent solution.

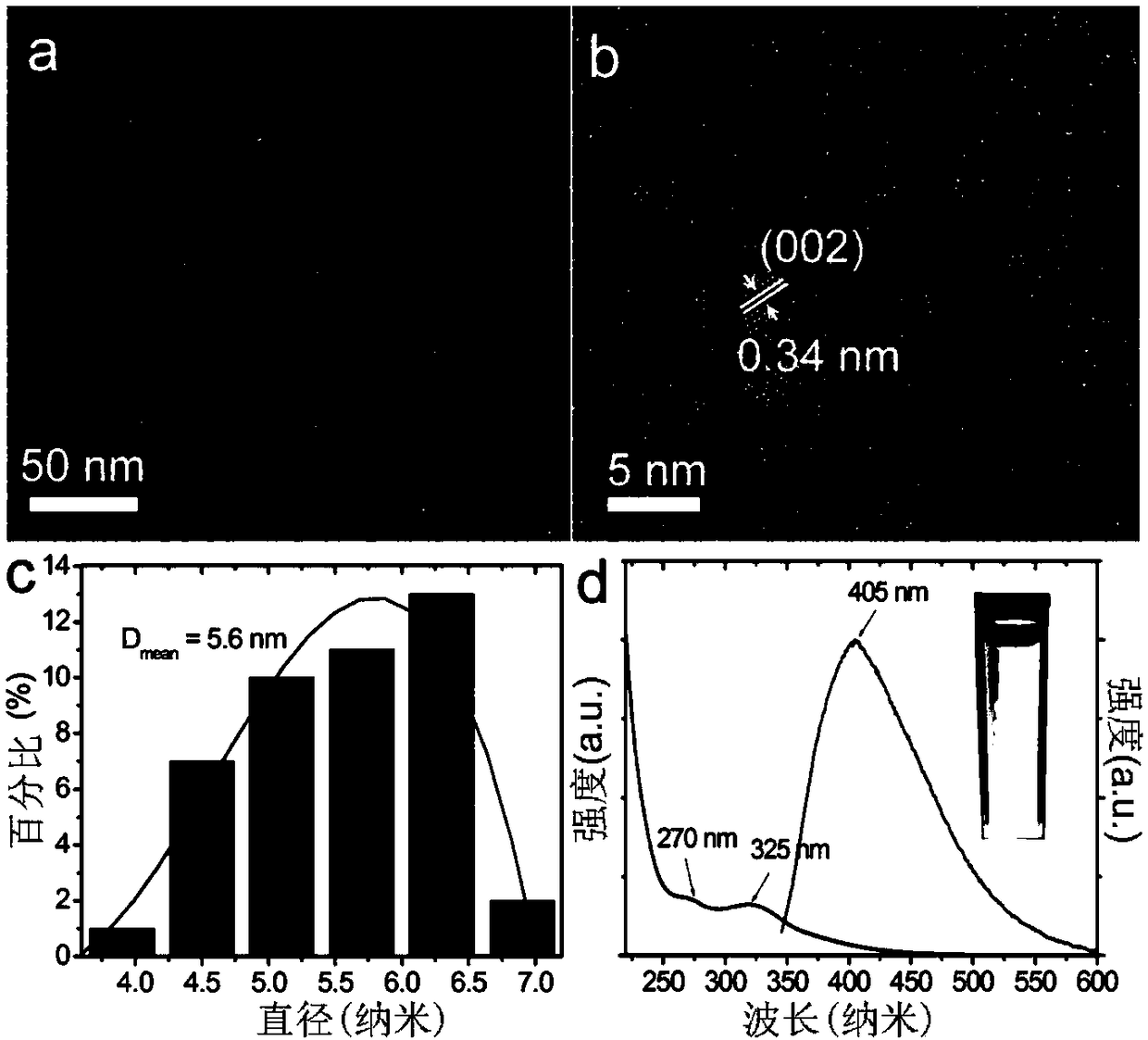

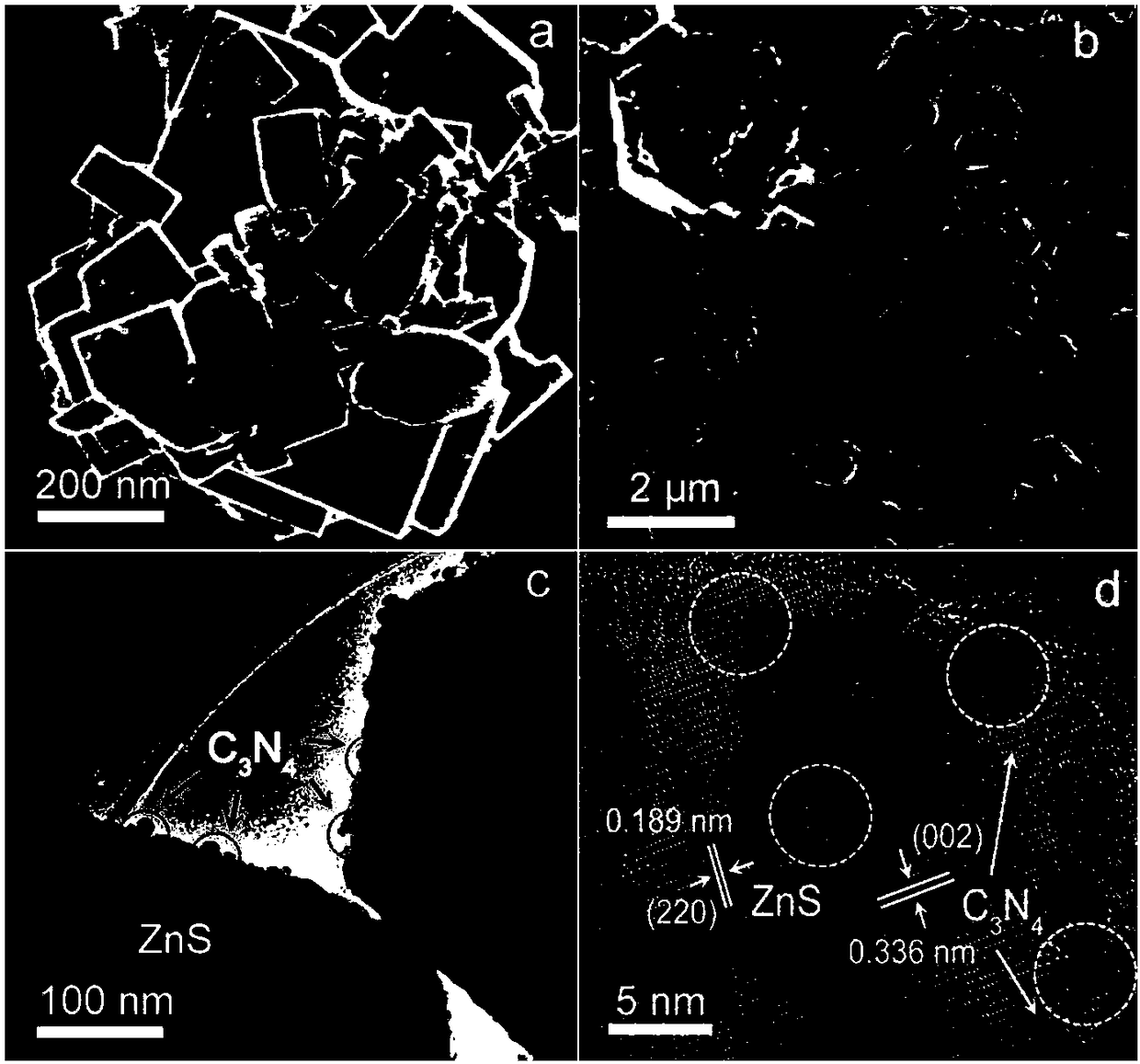

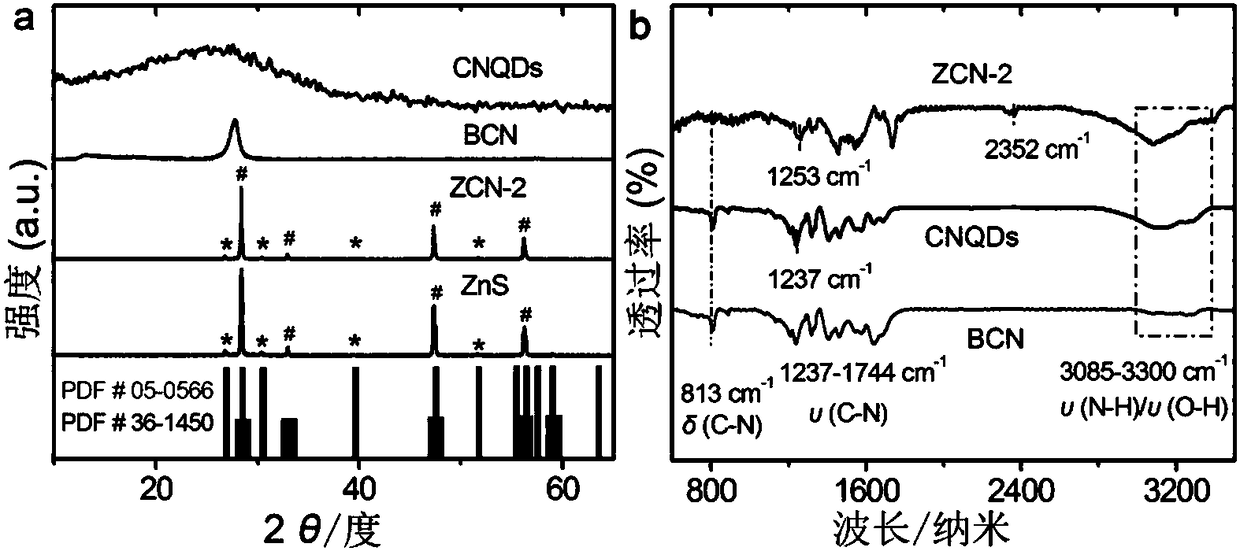

[0044] figure 1 g-C prepared for Example 1 3 N 4 Transmission (a), high-resolution photo (b), size distribution (c) and absorption and fluorescence curves (d) of QDs; from figure 1 It can be seen that g-C 3 N 4 QDs have good dispersion, and the crystal lattice is obvious in high-resolution photos, indicating good crystallinity, with an average particle diameter of 5.6nm, blue light emission, absorption and fluorescence, and bulk g-C 3 N 4 Compared with the obvious blue shift, i...

Embodiment 2

[0046] 1. Preparation of ZnS(en) 0.5

[0047] First 272.6mg ZnCl 2 and 304mg of thiourea were added to 60mL of ethylenediamine, stirred for 30min, hydrothermally reacted at 180°C for 18h, cooled to room temperature, washed with ethanol and water for 2-3 times, and dried at 60°C for 12h.

[0048] 2. Preparation of bulk g-C 3 N 4

[0049] Add 100 mg of melamine into the porcelain boat, put it in a tube furnace, heat at 550 ° C for 4 hours under nitrogen atmosphere, and the heating rate is 2.5 ° C per minute to obtain the bulk phase g-C 3 N 4 yellow powder.

[0050] 3. Synthesis of ZCN-0.5

[0051] Take the above ZnS(en) 0.5 Nanosheets and g-C 3 N 4 Powder, where ZnS(en) 0.5 Nanosheets and g-C 3 N 4 The molar ratio of the powder is 1.0:0.5, mixed and stirred for 60 minutes, heated in a reactor at 200°C for 6 hours, then transferred to a dialysis bag for dialysis for 24 hours, and the resulting product was freeze-dried to obtain ZCN-0.5.

[0052] Photocatalytic hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com