Preparation method of Mo or Fe doped Zn1-xIn2S4 catalyst for photocatalytic nitrogen fixation and ammonia synthesis

A zn1-xin2s4, photocatalytic technology, applied in the direction of ammonia preparation/separation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low efficiency of nitrogen fixation and synthesis of ammonia, interference with the accuracy of photocatalytic nitrogen fixation and synthesis of ammonia yield, etc. , to achieve the effects of simple preparation method and process flow, improved efficiency and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

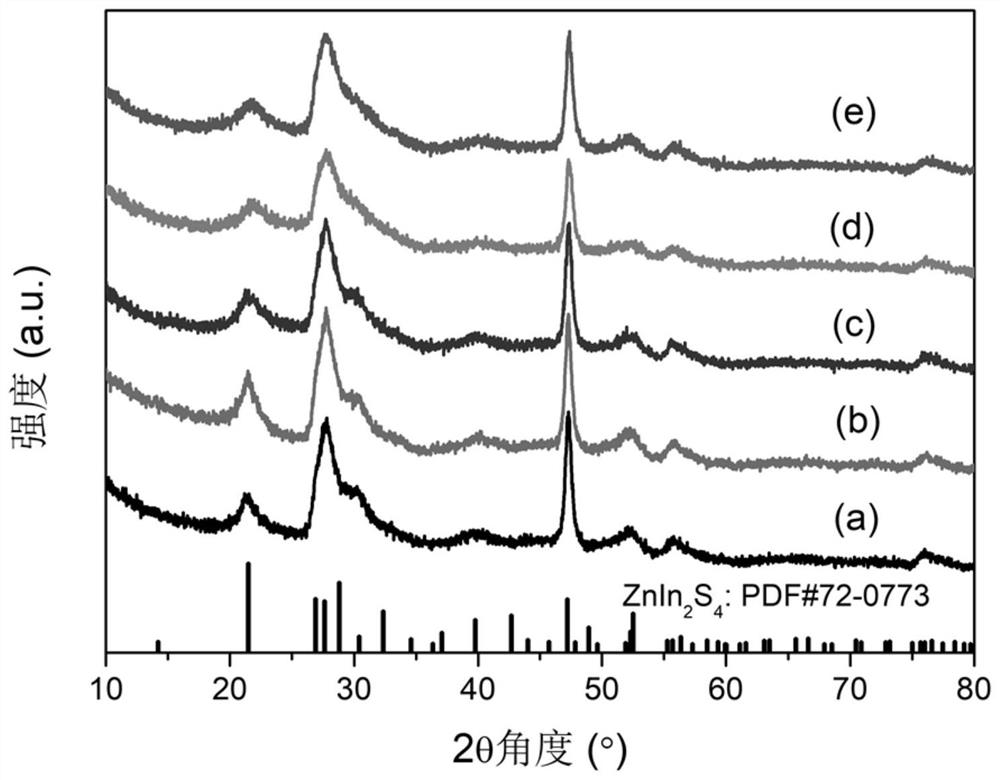

[0031] Example 1 Pure ZnIn 2 S 4 Preparation of Photocatalytic Nitrogen Fixation Catalyst

[0032] Under magnetic stirring conditions, 0.0744g (ie 0.25mmol) of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 0.1504g (0.5mmol) of indium nitrate (In(NO 3 ) 3 ), 0.2420g (ie 2mmol) of L-cysteine were dissolved in 30mL of deionized water, and after magnetic stirring for 10 minutes, the mixed solution was transferred to a hydrothermal reaction kettle, and put into the blast drying together with the hydrothermal reaction kettle In the box, hydrothermal reaction at 180°C for 18 hours, after cooling to room temperature, a yellow-green precipitate was obtained, and the yellow-green precipitate was washed with deionized water and ethanol by centrifugation, repeated washing 3 times, and dried in a blast drying oven at 60°C All night, get pure ZnIn 2 S 4 Photocatalytic nitrogen fixation catalyst.

Embodiment 2

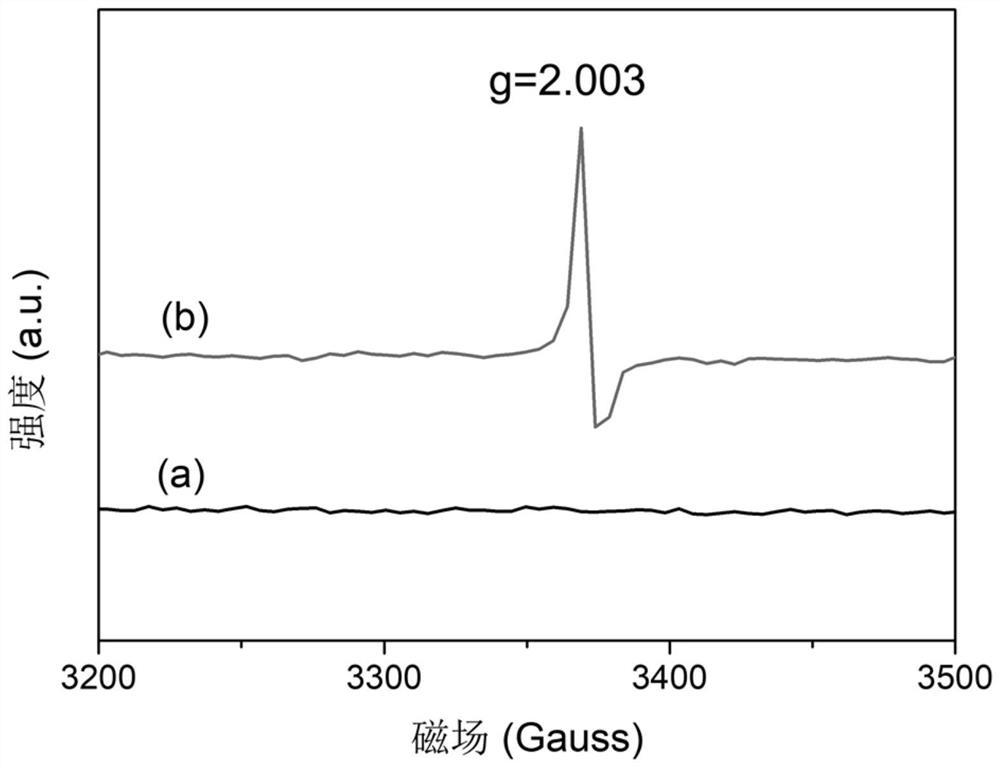

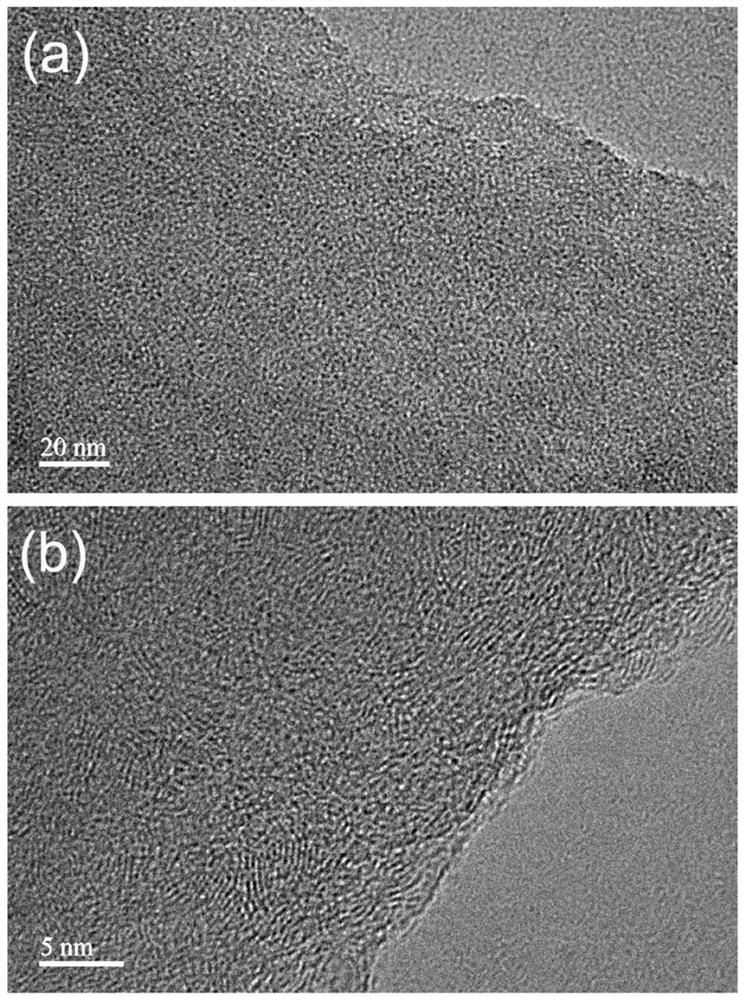

[0033] Example 2 Zn containing Zn vacancies 1-x In 2 S 4 Preparation of Photocatalytic Nitrogen Fixation Catalyst

[0034] Under magnetic stirring conditions, 0.0595g (ie 0.2mmol) of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 0.1504g (0.5mmol) of indium nitrate (In(NO 3 ) 3 ), 0.2420g (ie 2mmol) of L-cysteine were dissolved in 30mL of deionized water, and after magnetic stirring for 10 minutes, the mixed solution was transferred to a hydrothermal reaction kettle, and put into the blast drying together with the hydrothermal reaction kettle In the box, 200 °C hydrothermal reaction for 18 hours, after cooling to room temperature, a yellow-green precipitate was obtained, and the yellow-green precipitate was washed with deionized water and ethanol by centrifugation, repeated washing 3 times, and dried in a blast drying oven at 60 °C Over night, get Zn with Zn vacancies 1-x In 2 S 4 Photocatalytic nitrogen fixation catalyst.

Embodiment 3

[0035] Example 3 1% Fe 3+ Doped with Zn 1-x In 2 S 4 Preparation of Photocatalytic Nitrogen Fixation Catalyst

[0036] Under magnetic stirring conditions, 0.0595g (ie 0.2mmol) of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 0.1504g (0.5mmol) of indium nitrate (In(NO 3 ) 3 ), 0.2420g (ie 2mmol) of L-cysteine were dissolved in 30mL deionized water, and then 0.0021g (ie 0.005mmol) of iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), after magnetic stirring for 10 minutes, transfer the mixed solution to a hydrothermal reaction kettle, put it into a blast drying oven together with the hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 18 hours. After cooling to room temperature, a yellow For the green precipitate, wash the yellow-green precipitate by centrifugation with deionized water and ethanol in turn. After repeated washing for 3 times, dry it overnight at 60°C in a blast drying oven to obtain 1% Fe 3+ Doped with Zn 1-x In 2 S 4 Phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com