Preparation method for Pt@CeO2/3DCN composite photocatalyst applied to photocatalytic reduction of CO2

A composite light and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high electron-hole recombination rate, unfavorable agglomeration and full contact, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

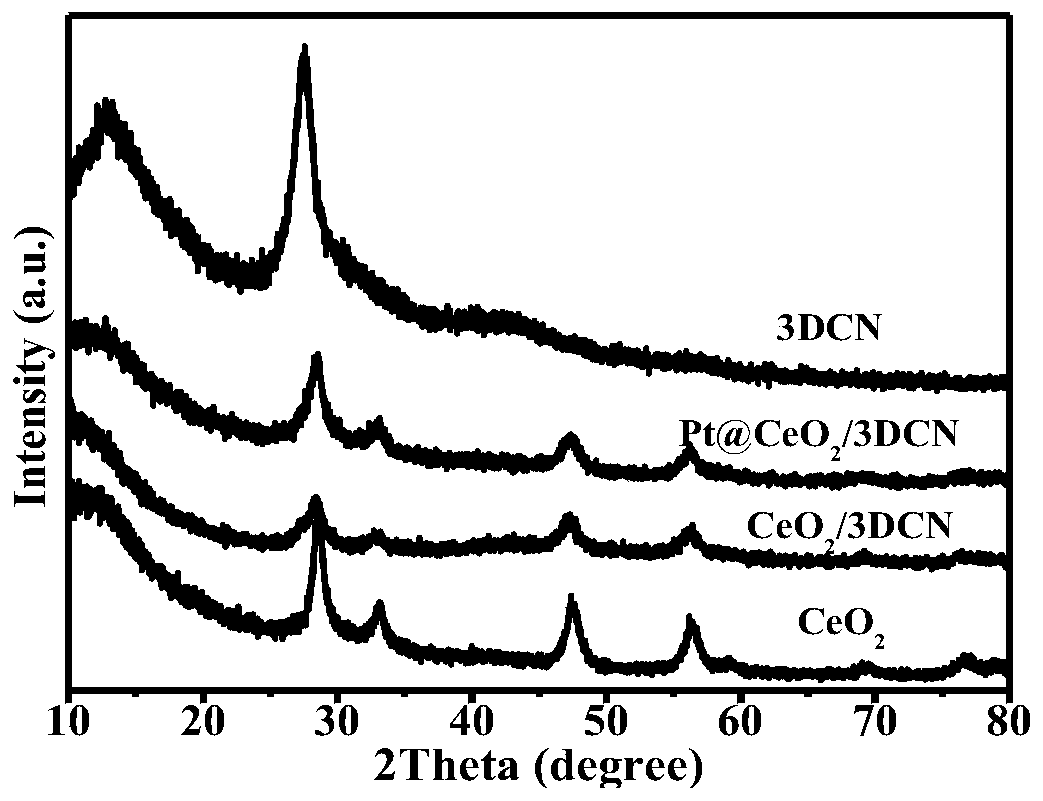

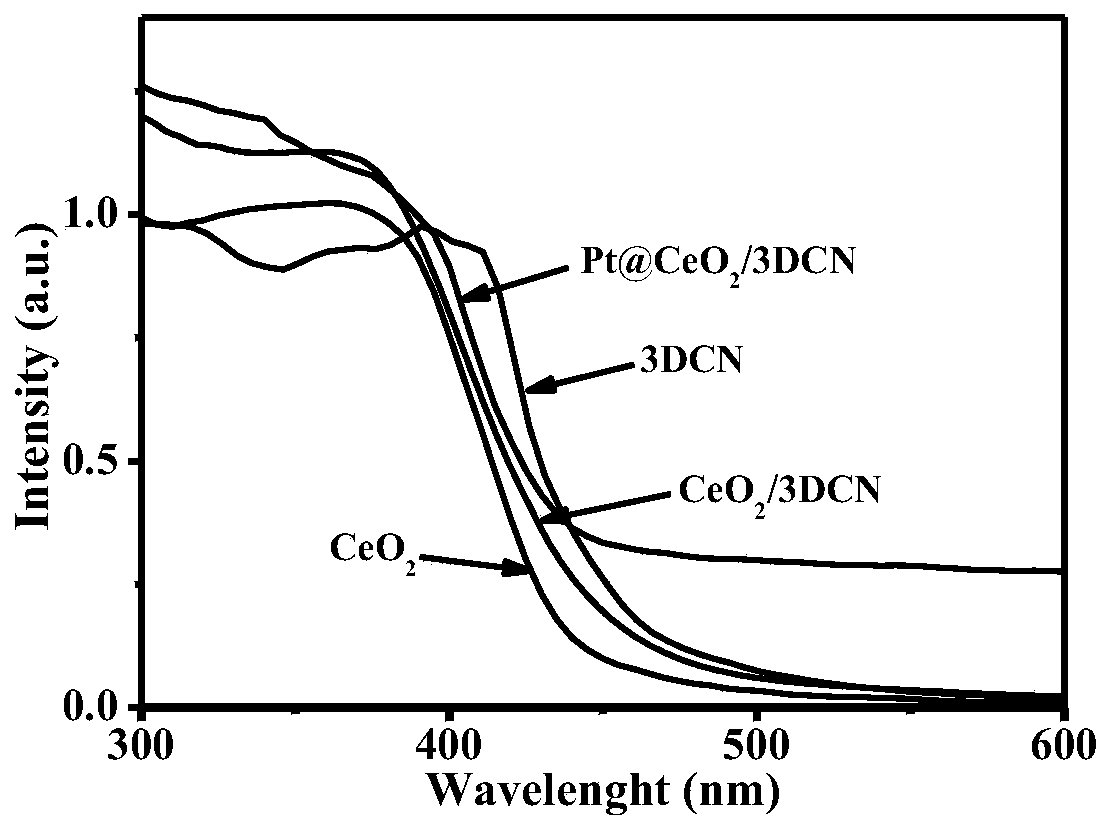

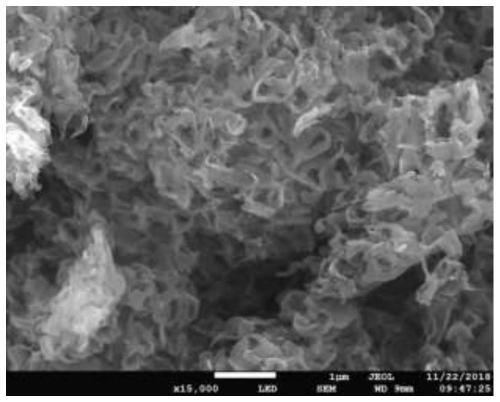

[0032] (1) Preparation of three-dimensional porous carbon nitride (3DCN):

[0033] Put melamine into a crucible with a cover, then place the crucible in a muffle furnace at 500°C for calcination for 2 hours, and collect g-C in block form after cooling down. 3 N 4 ; then 2g block g-C 3 N 4 With 2g ammonium bicarbonate (NH 4 HCO 3 ) were ground and mixed, and put into a tube furnace for calcination at 200° C. for 2 h. After cooling down, the obtained sample was washed and dried to obtain three-dimensional porous carbon nitride (3DCN).

[0034] (2)CeO 2 / 3DCN composite photocatalyst preparation:

[0035] Weigh 0.19g of cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.5g of 3DCN dispersed in deionized water, stirred at room temperature, transferred to an oven for drying after stirring, and put the dried sample into a muffle furnace for calcination at 300°C for 2h to obtain CeO 2 / 3DCN composite photocatalyst.

[0036] (3) Pt@CeO 2 / 3DCN composite photocatalyst pr...

Embodiment 2

[0040] (1) Preparation of three-dimensional porous carbon nitride (3DCN):

[0041] Put melamine into a crucible with a cover, then place the crucible in a muffle furnace at 550°C for calcination for 2 hours, and collect g-C in block form after cooling down. 3 N 4 ; then 2g block g-C 3 N 4 With 4g ammonium bicarbonate (NH 4 HCO 3 ) were ground and mixed, put into a tube furnace for calcination at 300° C. for 2 h, and after cooling down, the obtained sample was washed and dried to obtain three-dimensional porous carbon nitride (3DCN).

[0042] (2)CeO 2 / 3DCN composite photocatalyst preparation:

[0043] Weigh 0.38g of cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.5g of 3DCN dispersed in deionized water, stirred at room temperature, transferred to an oven for drying after stirring, and put the dried sample into a muffle furnace for calcination at 350°C for 2h to obtain CeO 2 / 3DCN composite photocatalyst.

[0044] (3) Pt@CeO 2 / 3DCN composite photocatalyst pr...

Embodiment 3

[0048] (1) Preparation of three-dimensional porous carbon nitride (3DCN):

[0049] Put melamine into a crucible with a cover, and then place the crucible in a muffle furnace at 600°C for calcination for 2 hours. After cooling down, collect g-C 3 N 4 ; then 2g block g-C 3 N 4 With 6g ammonium bicarbonate (NH 4 HCO 3 ) were ground and mixed, put into a tube furnace for calcination at 350° C. for 2 h, and after cooling down, the obtained sample was washed and dried to obtain three-dimensional porous carbon nitride (3DCN).

[0050] (2)CeO 2 / 3DCN composite photocatalyst preparation:

[0051] Weigh 0.57g of cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.5g of 3DCN dispersed in deionized water, stirred at room temperature, transferred to an oven for drying after stirring, and put the dried sample into a muffle furnace for calcination at 400°C for 2h to obtain CeO 2 / 3DCN composite photocatalyst.

[0052] (3) Pt@CeO 2 / 3DCN composite photocatalyst preparation:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com