Patents

Literature

56results about How to "Cut off stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

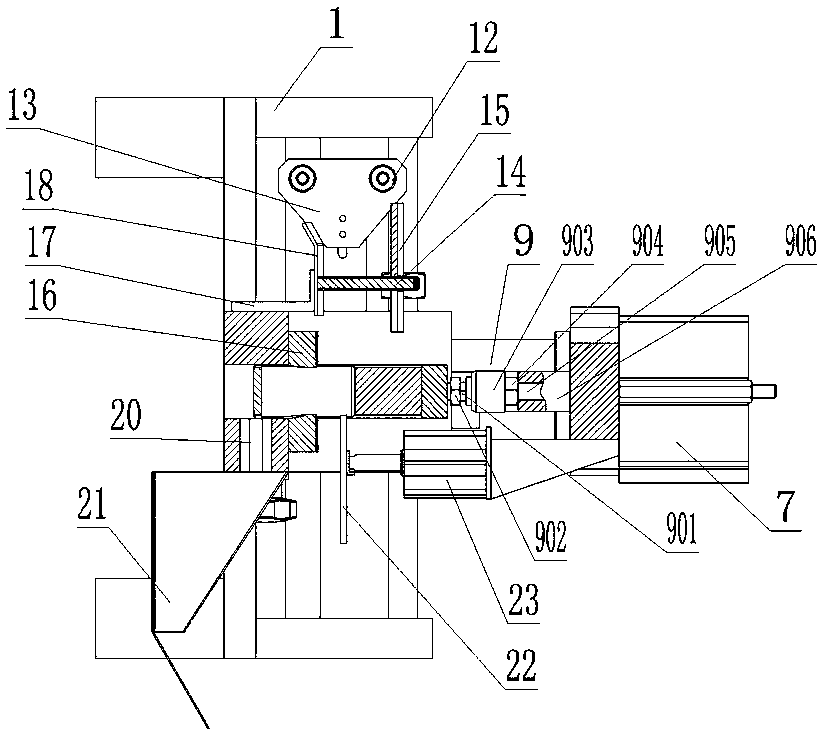

Cutter device for board printing production line

InactiveCN107379043AAvoid adverse effectsGuarantee product qualityMetal working apparatusEngineeringElectromagnetic valve

The invention discloses a cutter device for a board printing production line. Through guide strips, side plates can move frontwards and backwards and cannot be inclined at the same time. Through fastening screws, the side plates can be conveniently fixed and prevented from sliding when working. Through cooperative arrangement of air cylinders, a cutter installation plate, a cutter, tightly pressing rod sleeves, springs and tightly pressing rods, a board can be tightly pressed when cut, and the cutter stably cuts off the board. Through cooperative arrangement of guide grooves and guide sliding blocks, the cutter installation plate can stably and vertically move. Through cooperative arrangement of an air pump, electromagnetic valves and spray heads, chippings can be conveniently blown off. By the adoption of the cutter device for the board printing production line, the horizontal position of the cutter can be arranged at will, the boards can be conveniently cut to have different lengths according to needs, the chippings which may be generated during cutting can be blown off, an adverse influence on the cutting process is avoided, and the product quality is guaranteed.

Owner:江苏韵燕印刷版材有限公司

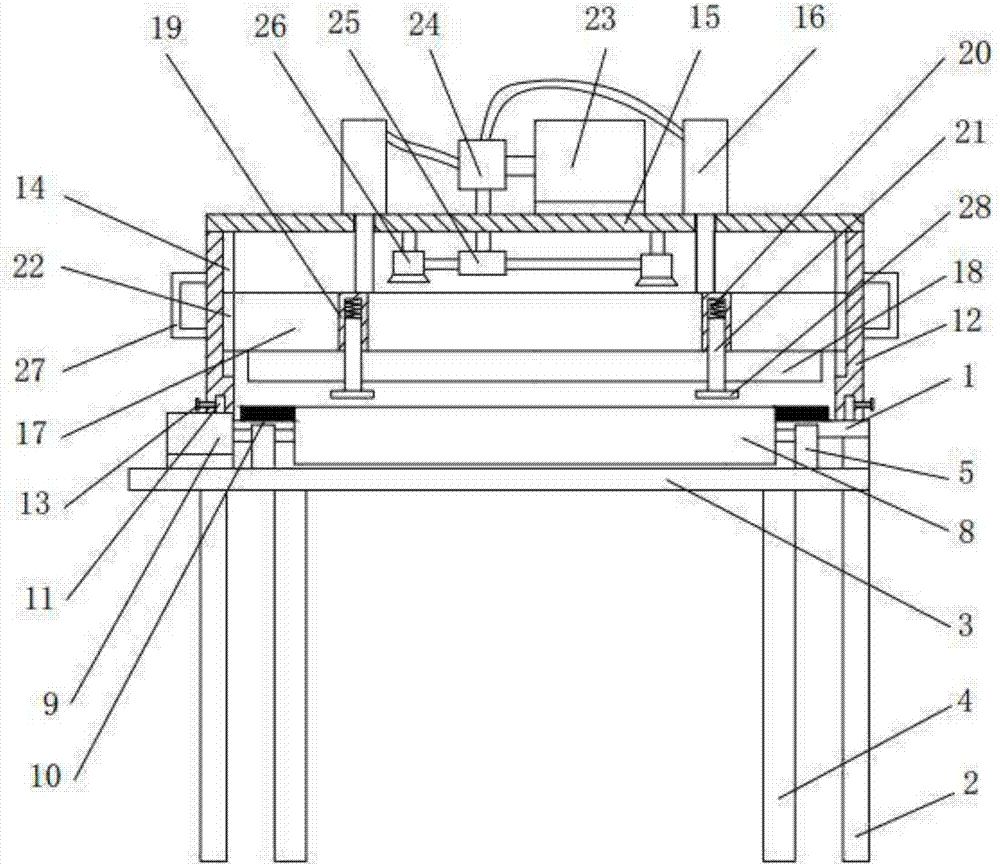

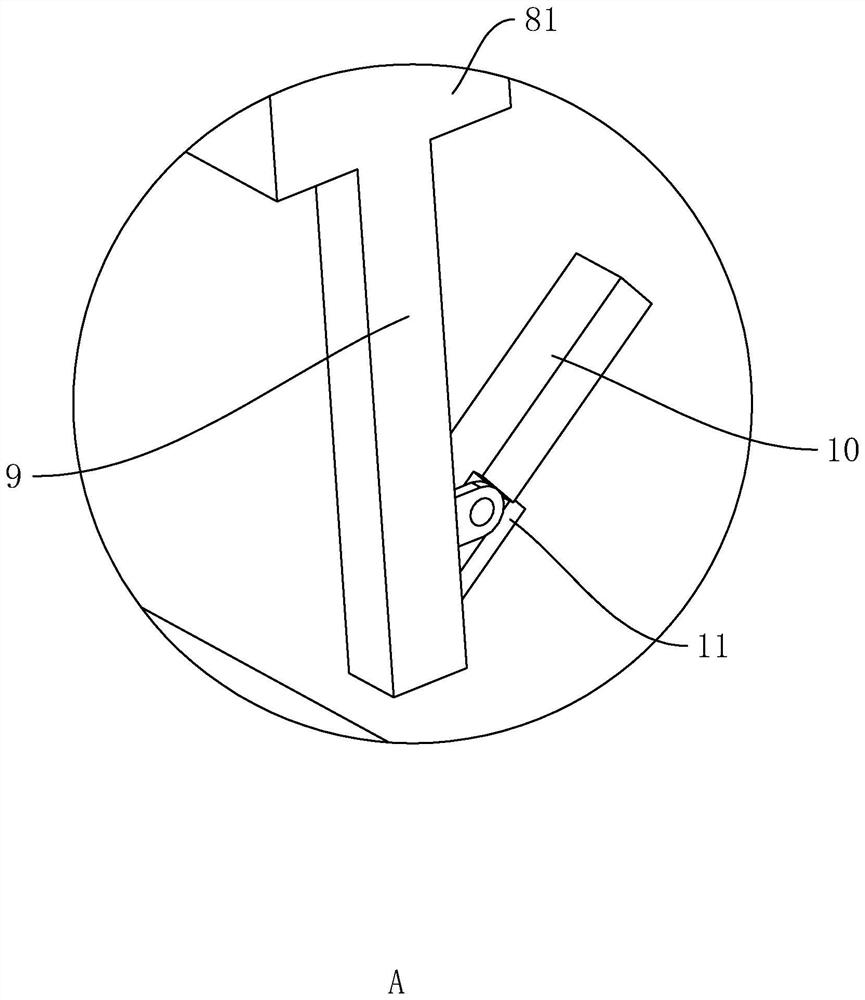

Intelligent numerically-controlled hydraulic sheet shearing machine

PendingCN111774634APlay a role in compressingEasy to move to the leftShearing machinesShearing machine accessoriesStructural engineeringMachine

The invention discloses an intelligent numerically-controlled hydraulic sheet shearing machine, and belongs to the technical field of sheet shearing machines. The machine comprises a base, spring telescopic columns, a conveying mechanism, a fixing frame, a pressing mechanism, a workbench and an extruding mechanism; the base is transversely arranged on a bottom surface; the multiple spring telescopic columns are vertically fixed to the top of the base; the pressing mechanism comprises pressing rods symmetrically arranged on the two sides of a sheet shearing cutter; the workbench is fixed to themiddle of the base, the interior of the workbench is of a hollow structure, the top of the workbench is provided with a sheet shearing opening part, and the rear inner wall of the workbench is provided with a transverse sliding groove; and the extruding mechanism comprises a sliding block arranged in the sliding groove. According to the machine, the inventive concept is ingenious and the practicability is high; when a mounting base moves downwards, the sheet shearing cutter can be driven to move downwards so as to shear a steel sheet, the folded edge of the cut steel sheet can be extruded tobe flat, and burrs at the cut position can be polished; and the application range is wide, and the machine is suitable for application and popularization.

Owner:苏强

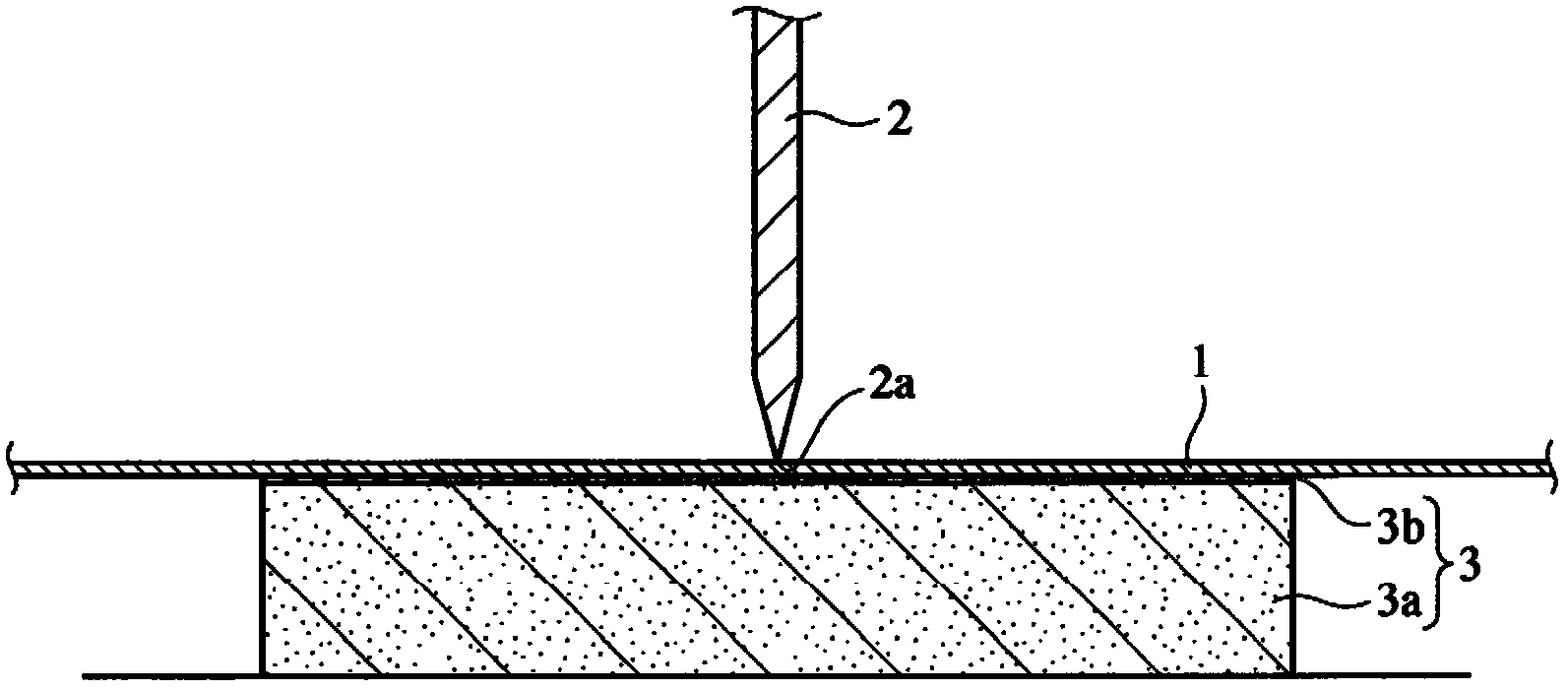

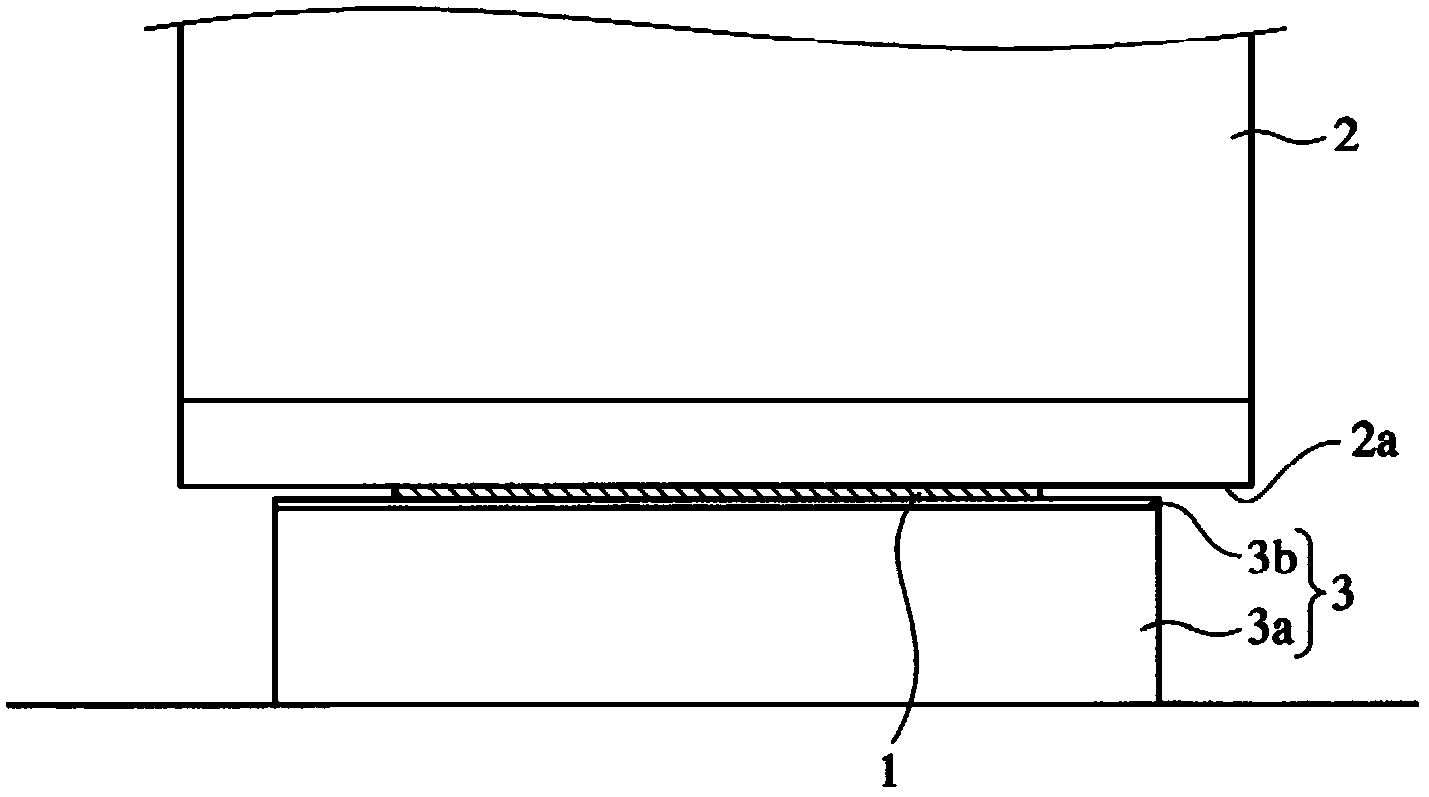

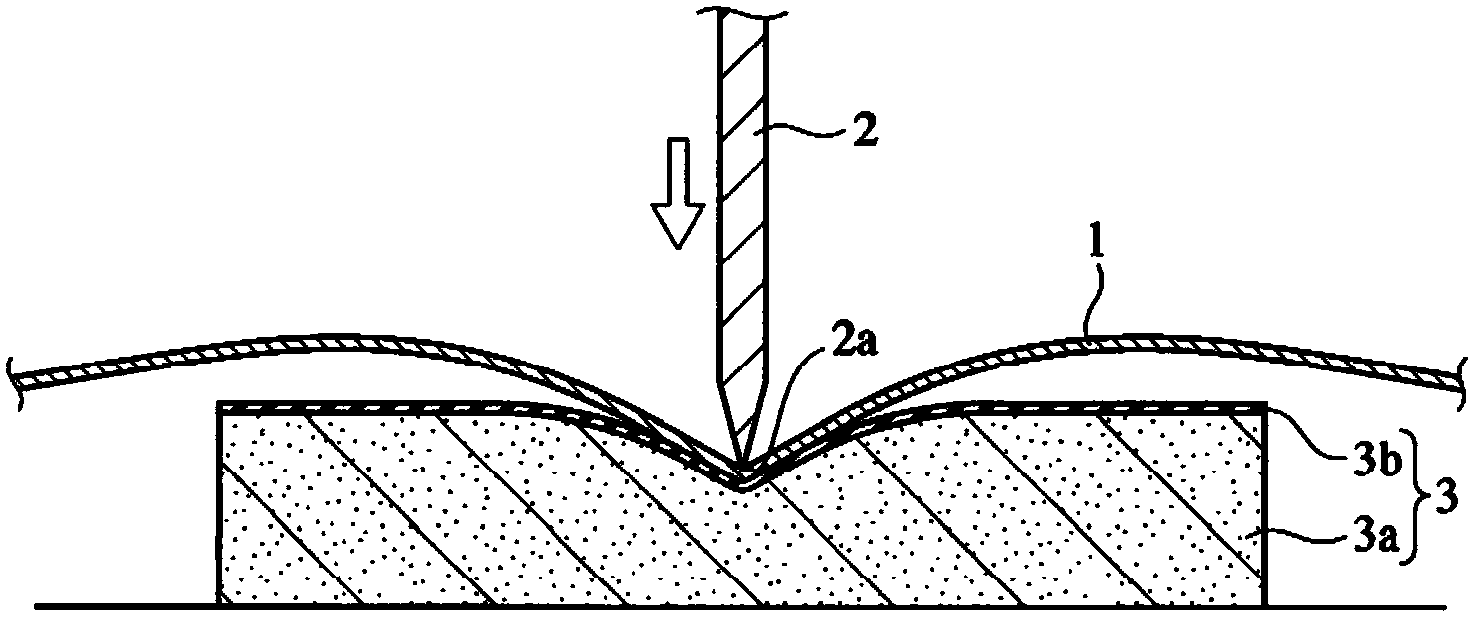

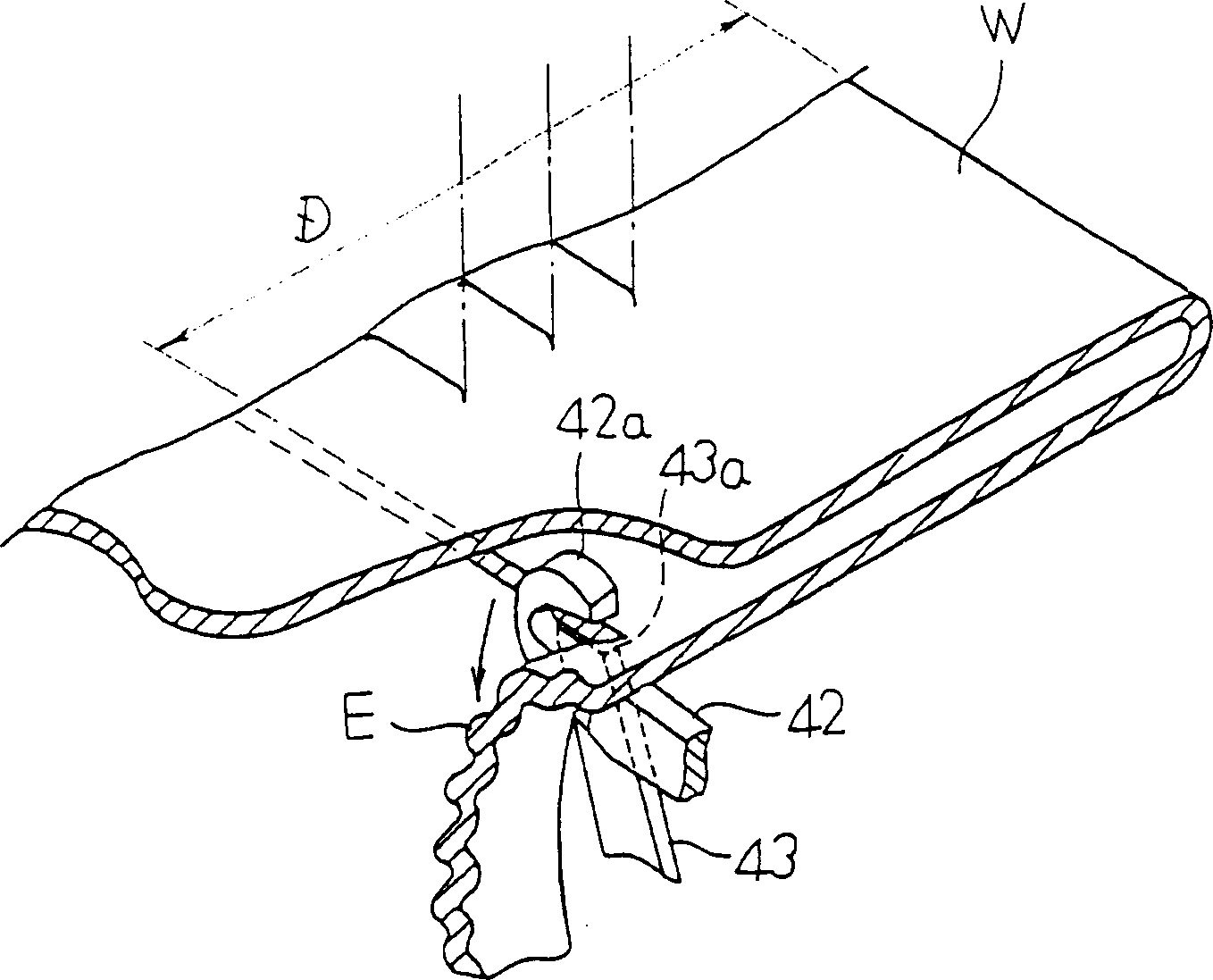

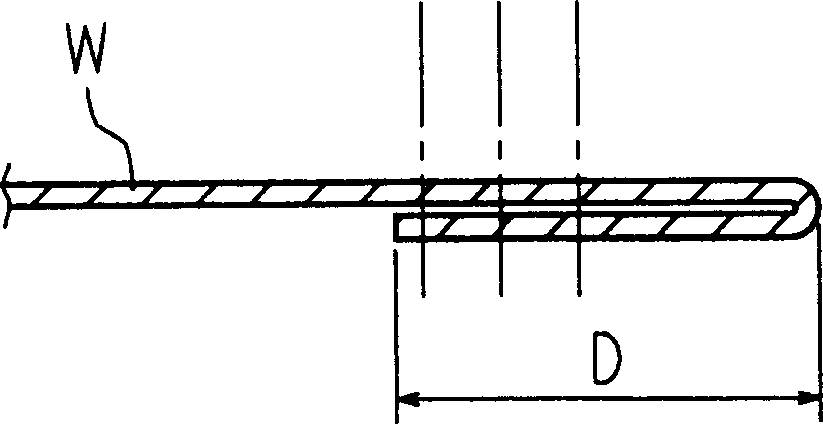

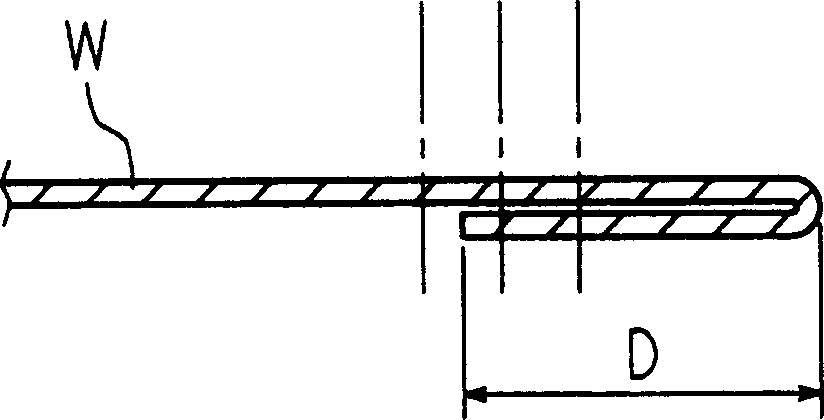

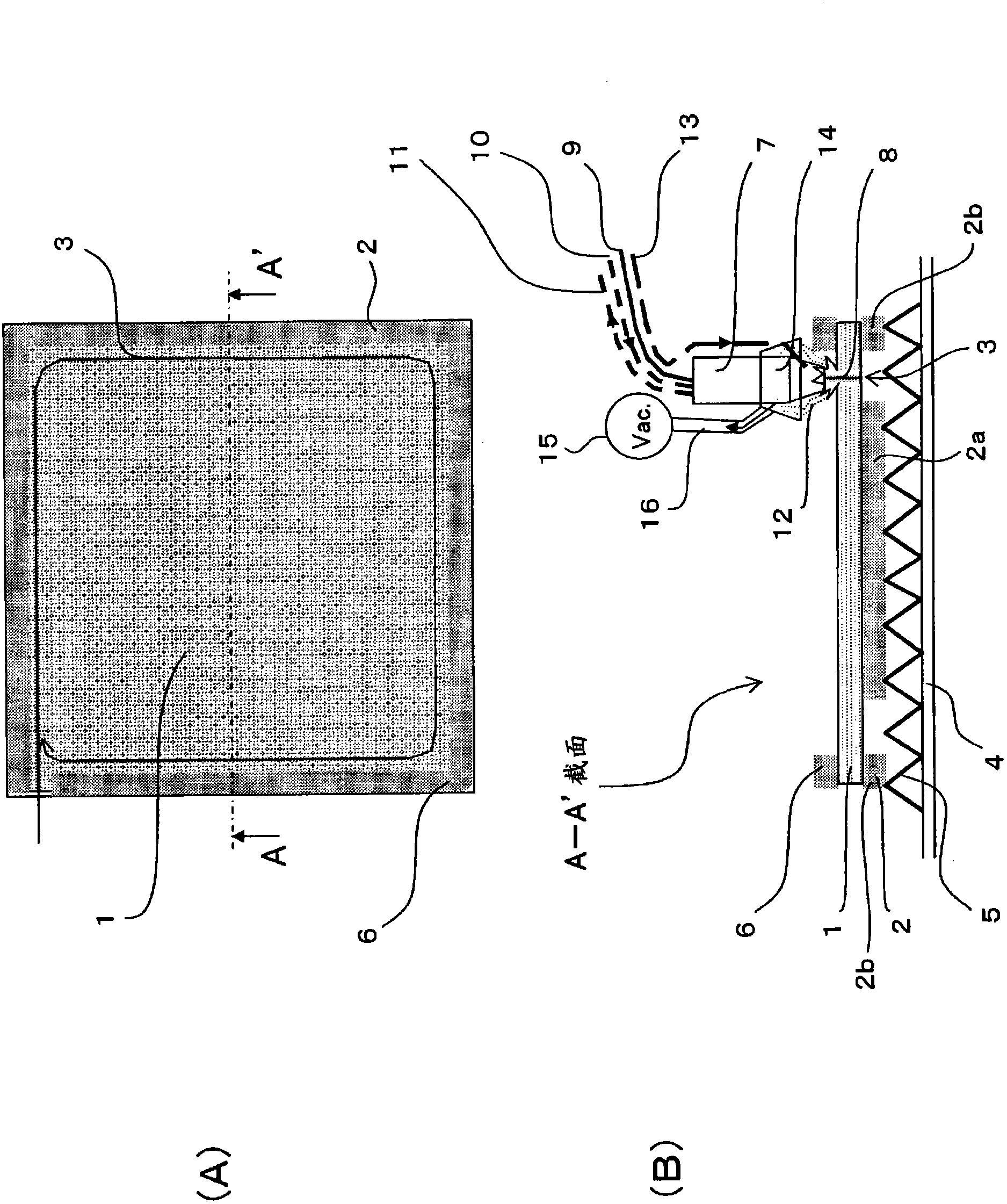

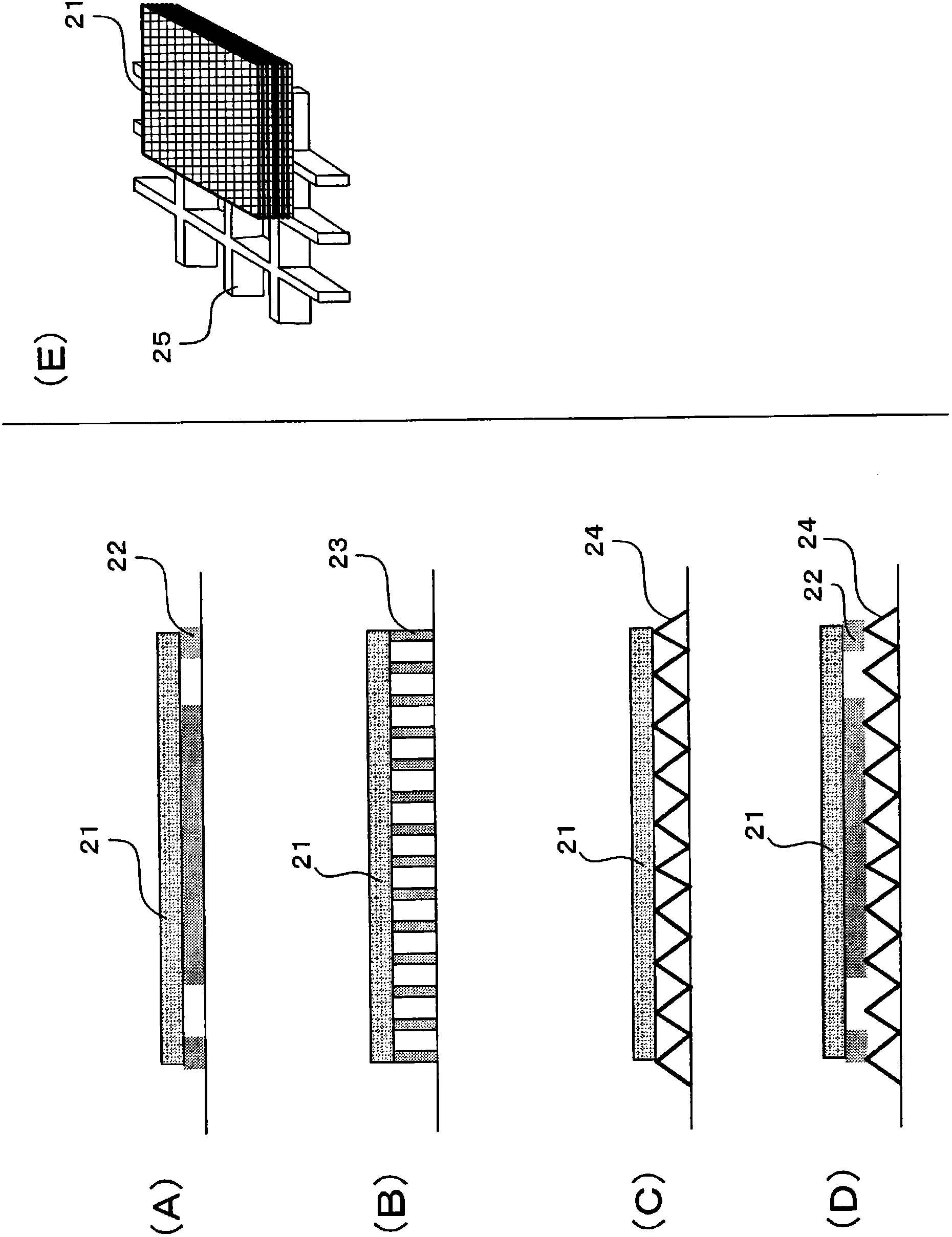

Thin strip of alloy containing initial ultrafine crystals and method for cutting same, and thin strip of nanocrystalline soft-magnetic alloy and magnetic part employing same

ActiveCN103748250AStable pressingReduce wearMagnetic materialsMetal working apparatusNanocrystalline siliconAmorphous matrix

The present invention relates to a method for cutting a thin strip of an alloy that contains initial ultrafine crystals and has a structure in which ultrafine crystal grains having an average grain diameter of 30 nm or smaller have been dispersed in an amorphous matrix phase in an amount of 5-30 vol.%. The method comprises placing the thin strip on a flexible bed that can be sharply deformed by local pressing, bringing the blade of a cutter into horizontal contact with the surface of the thin strip, pressing the cutter against the thin strip, so that a pressure is evenly applied to the thin strip, and thereby bending the thin strip along the blade edge of the cutter to brittlely cut the thin strip.

Owner:HITACHI METALS LTD

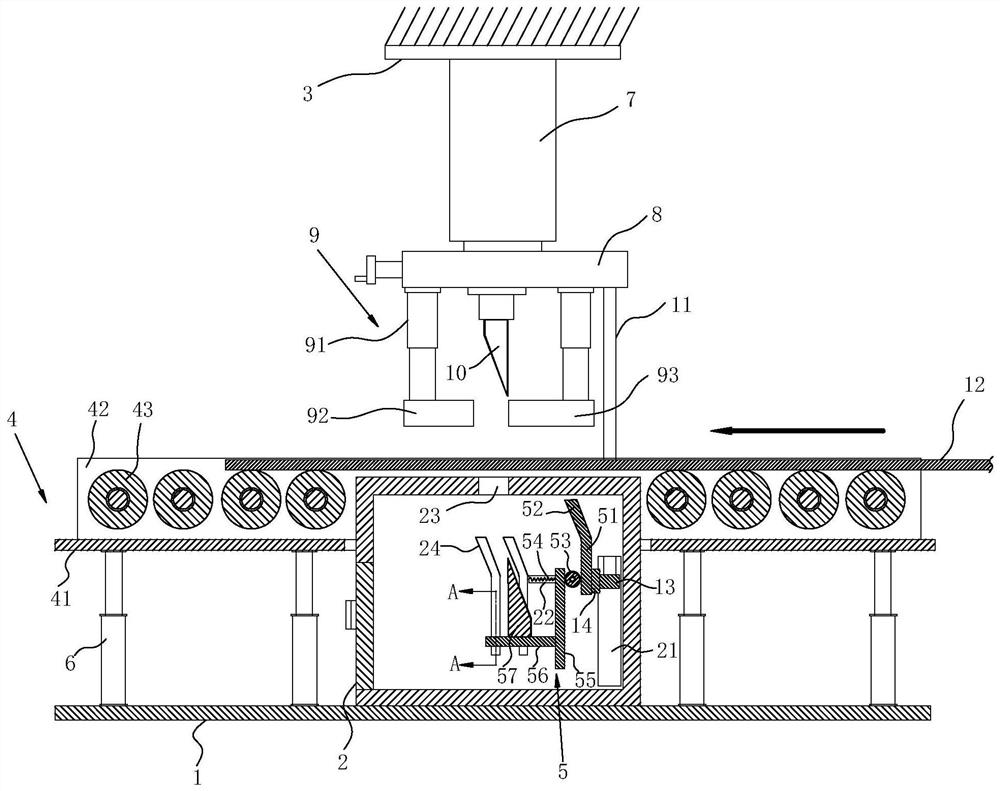

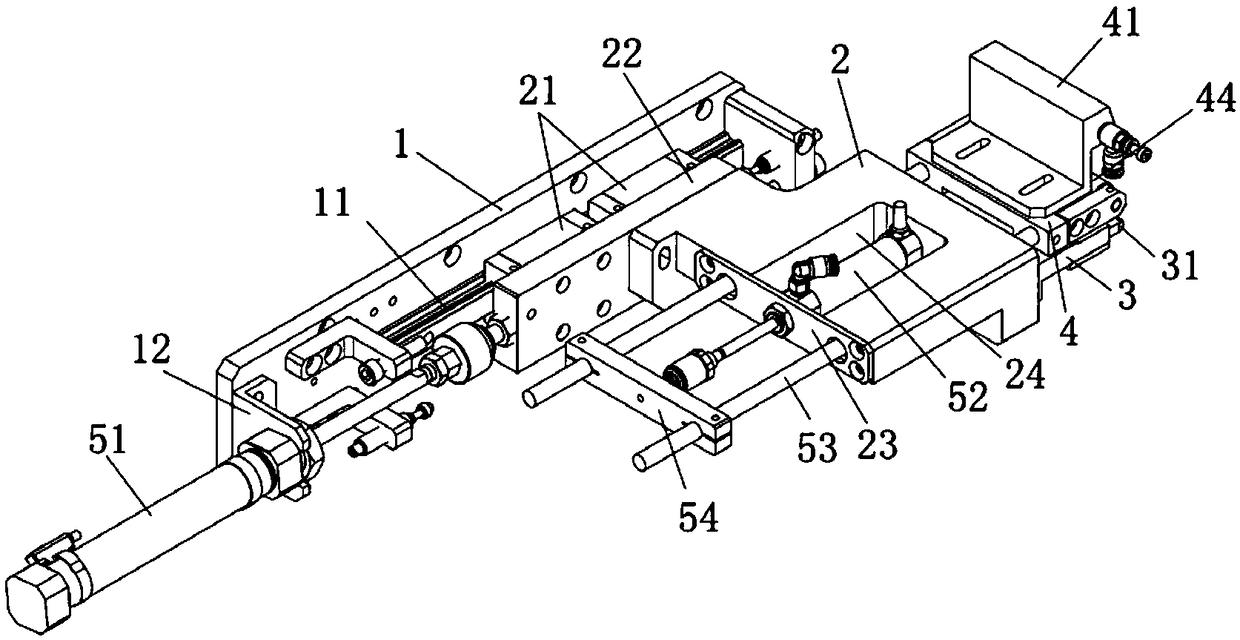

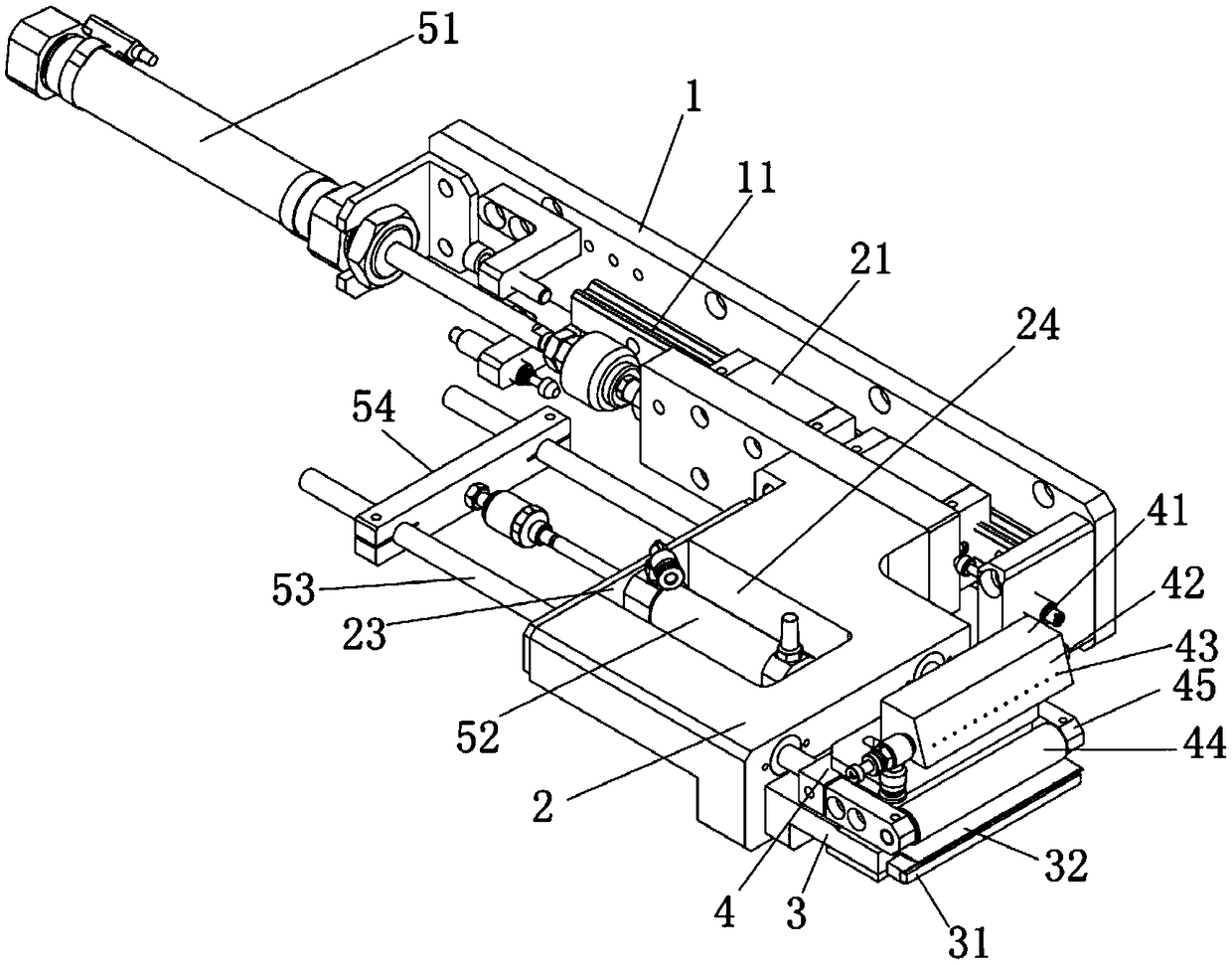

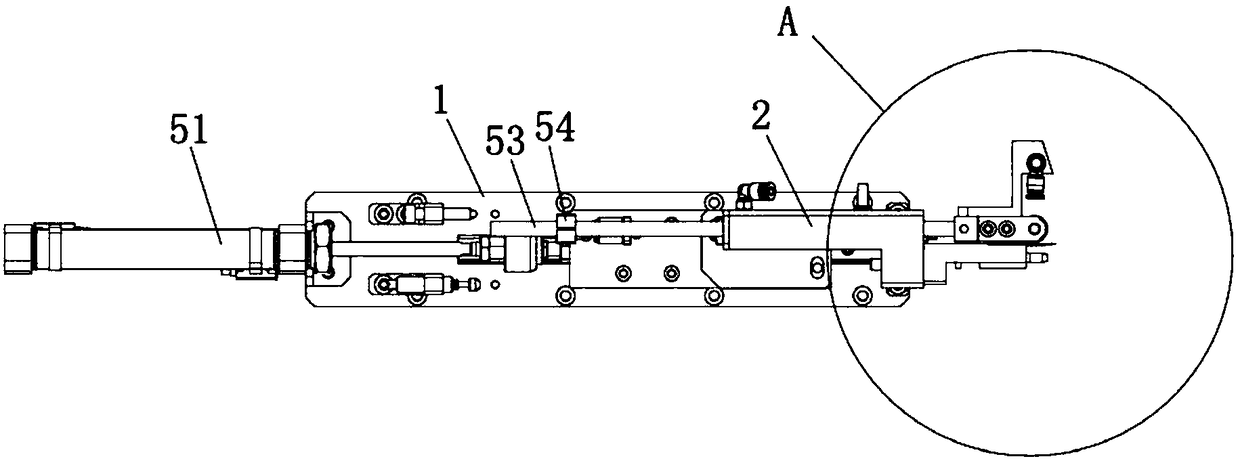

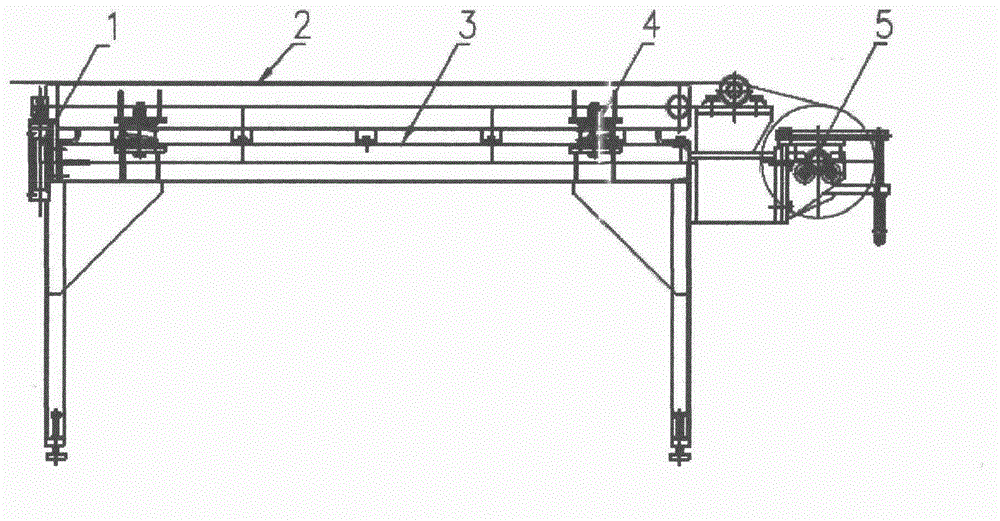

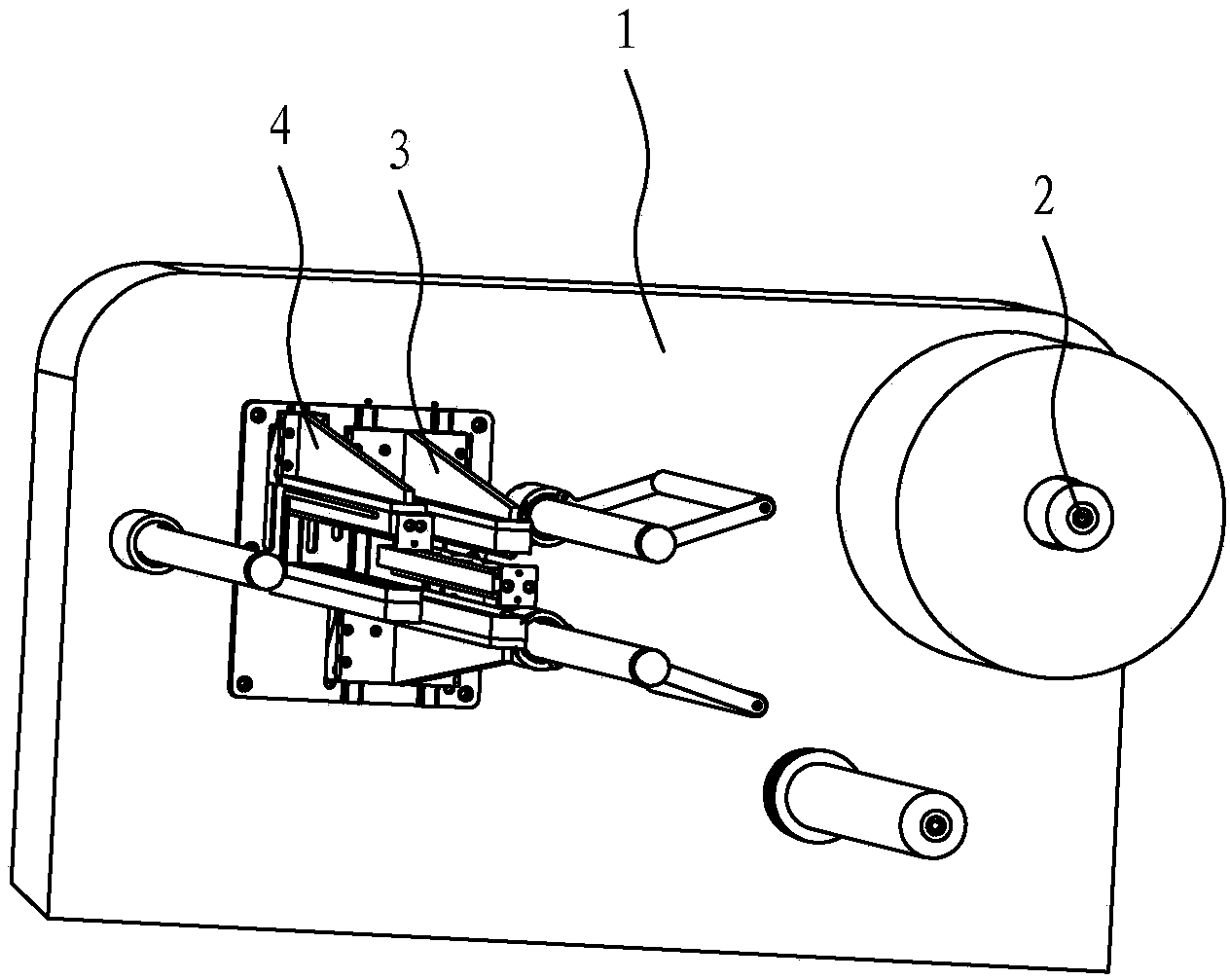

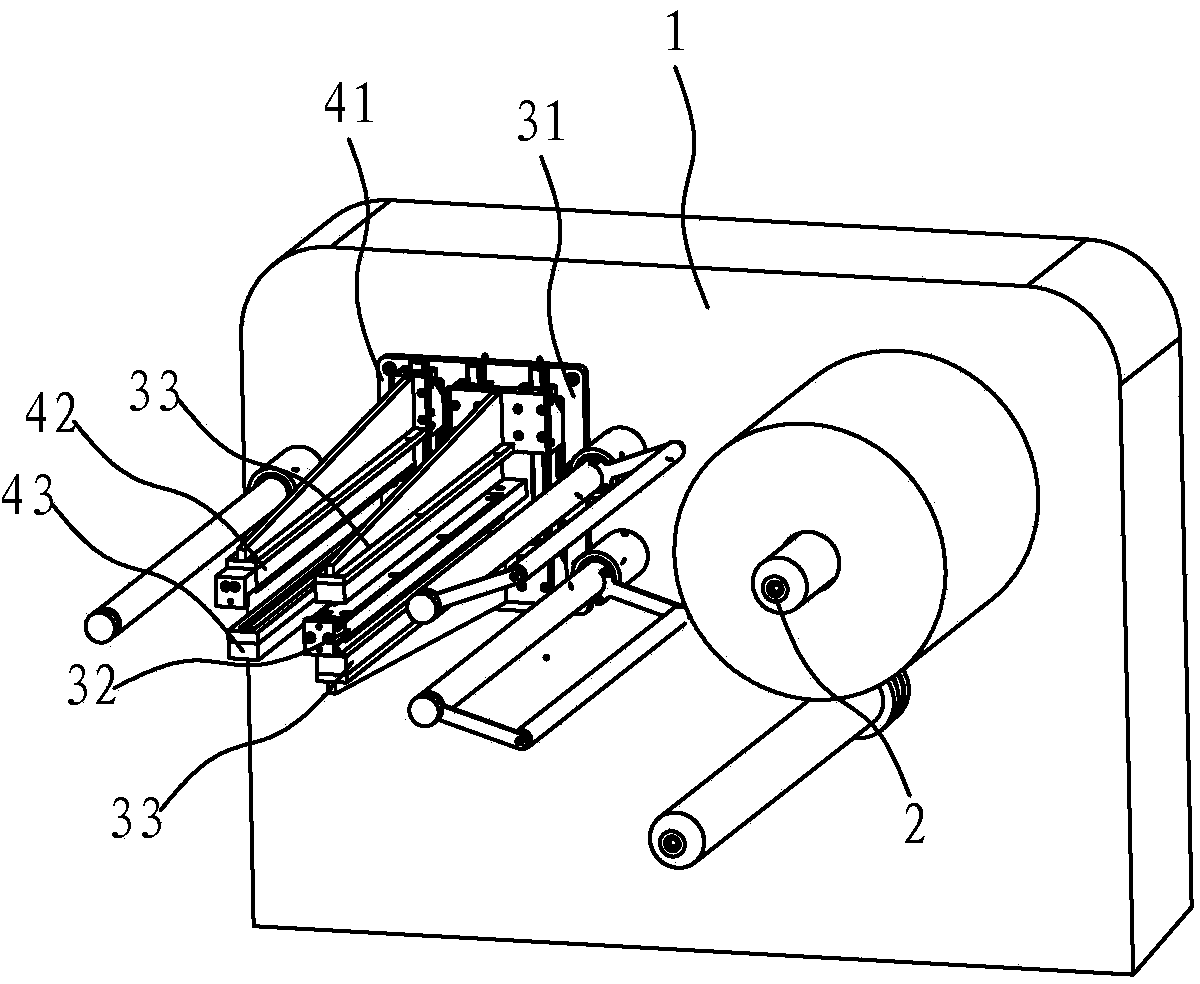

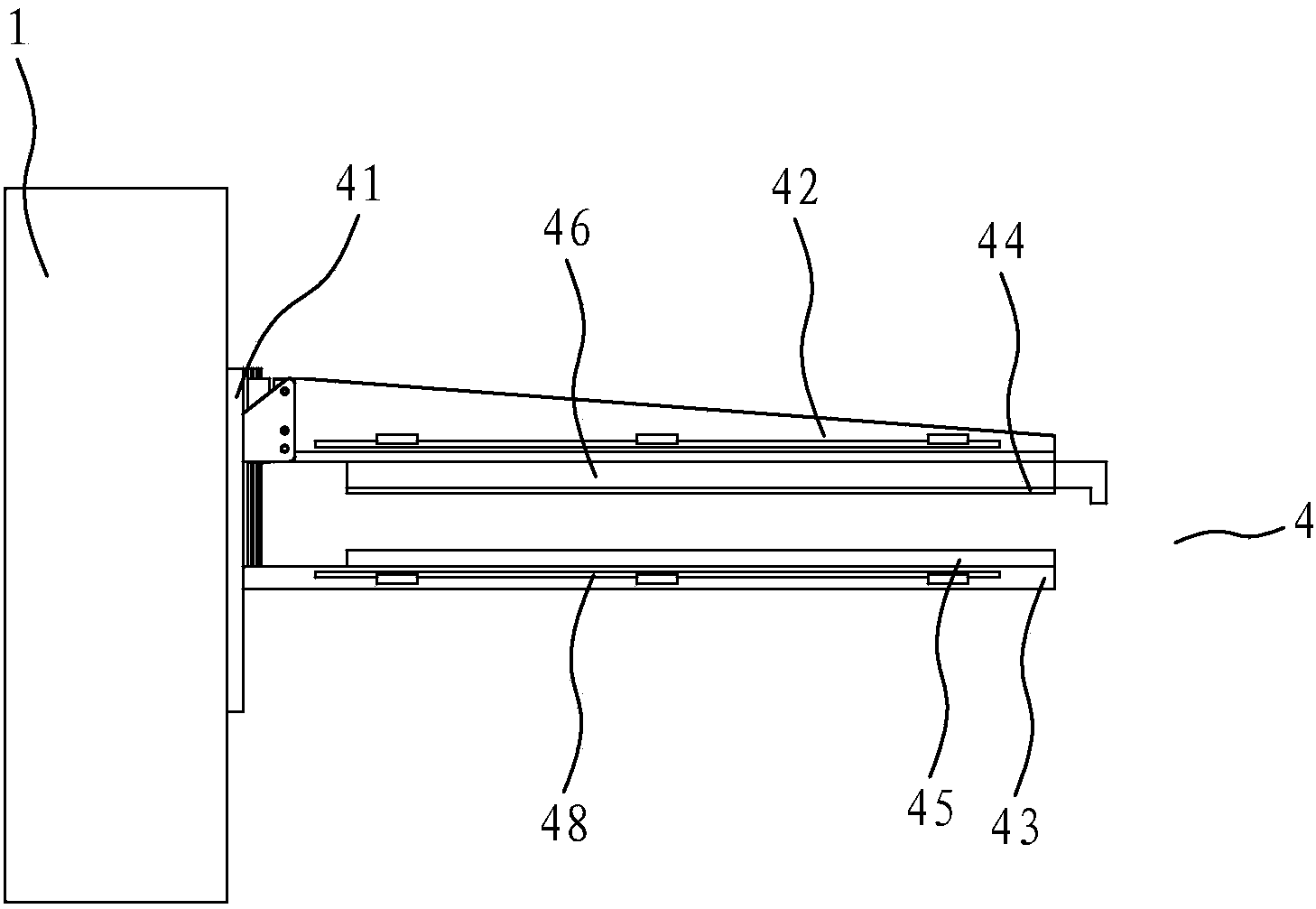

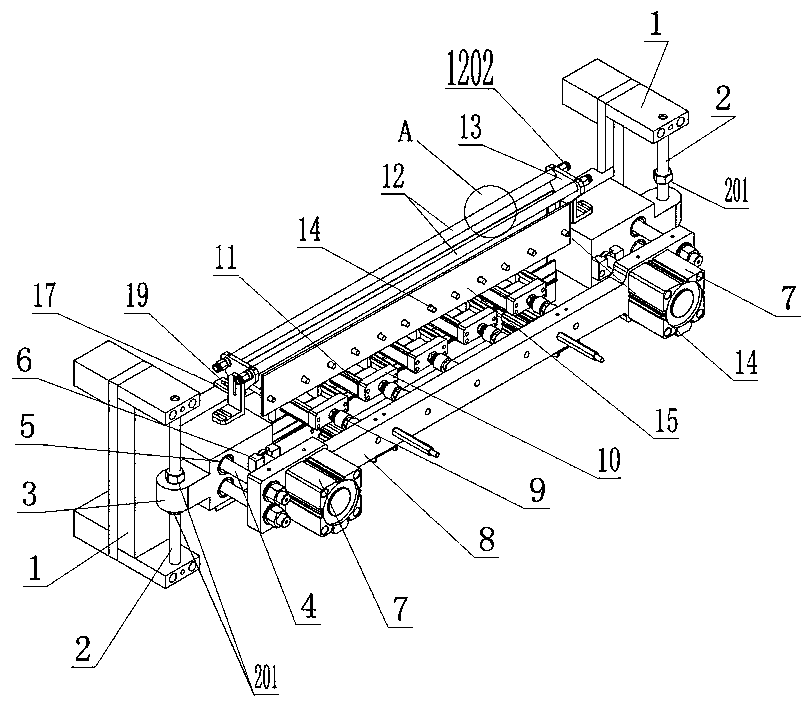

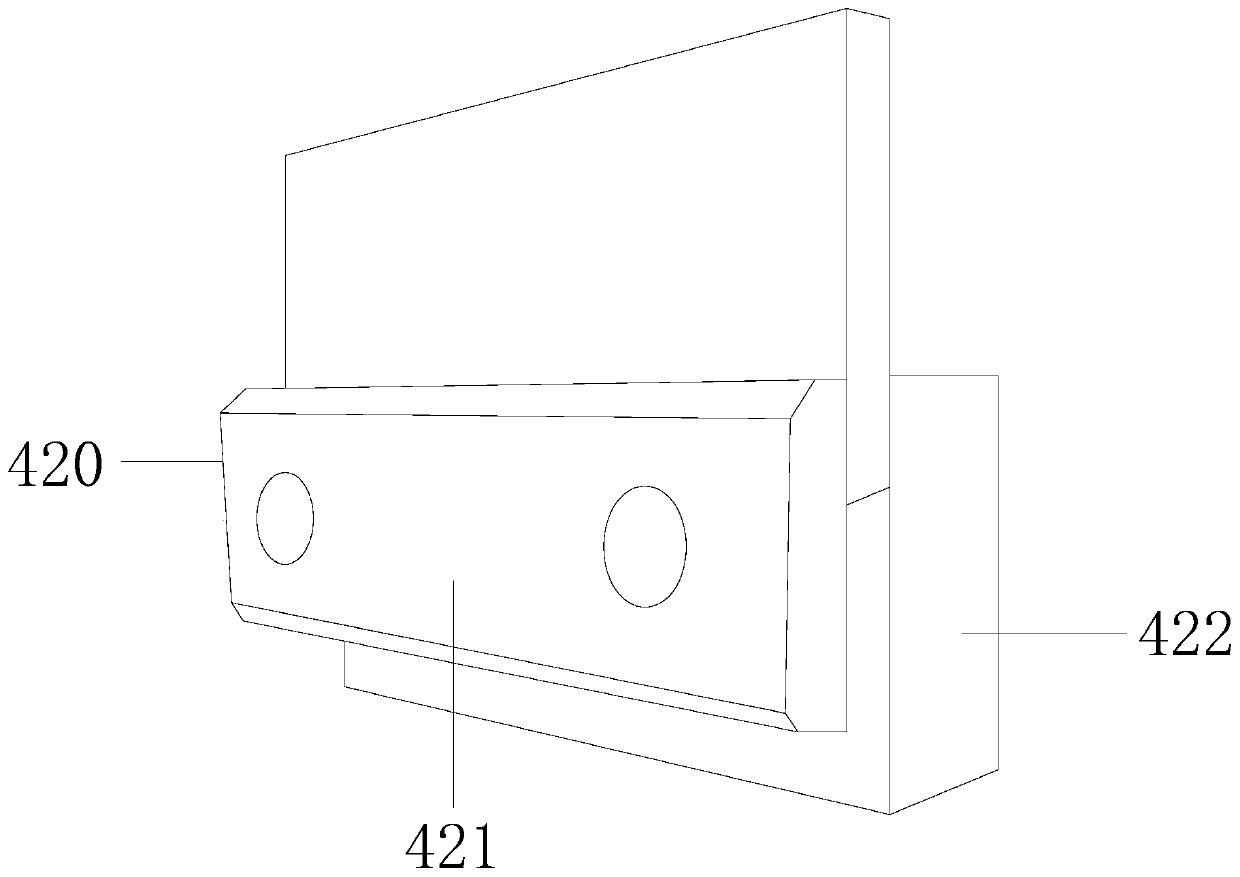

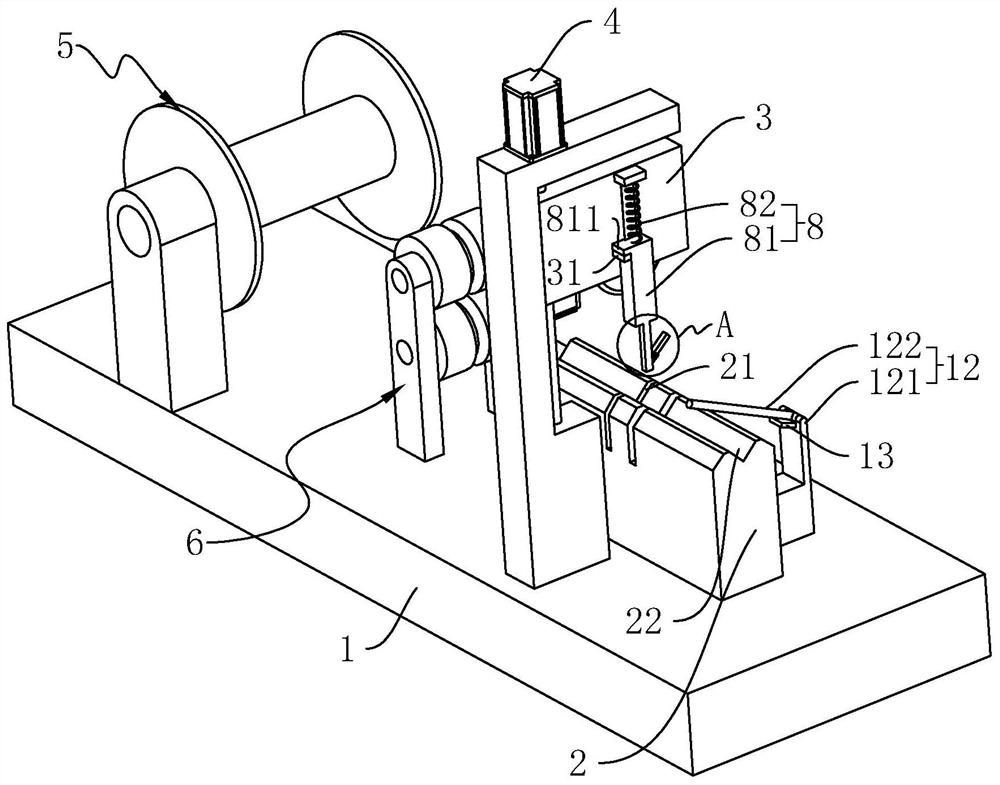

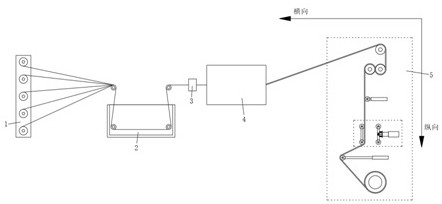

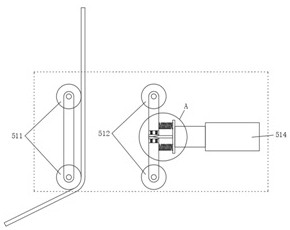

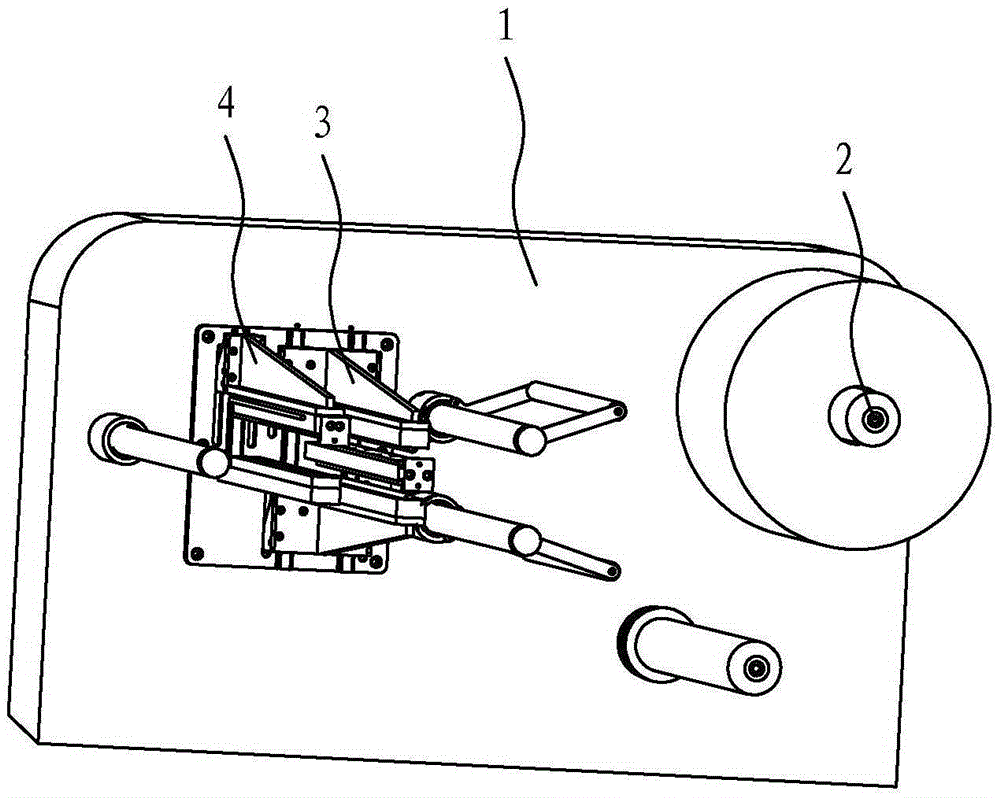

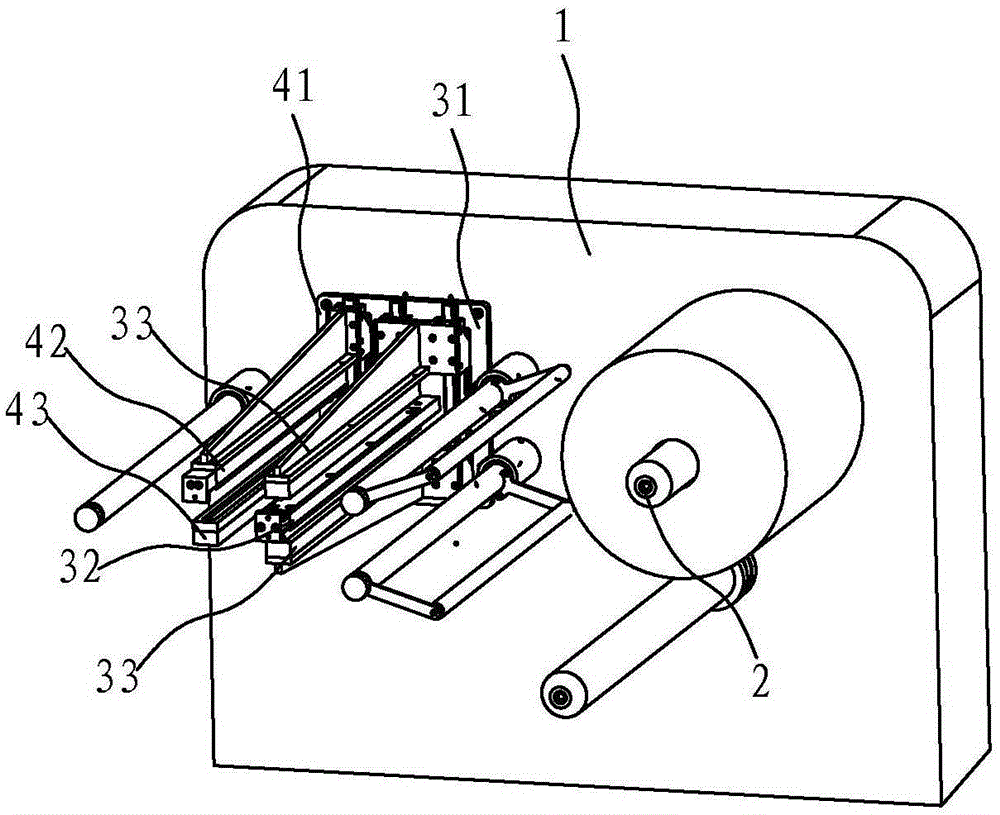

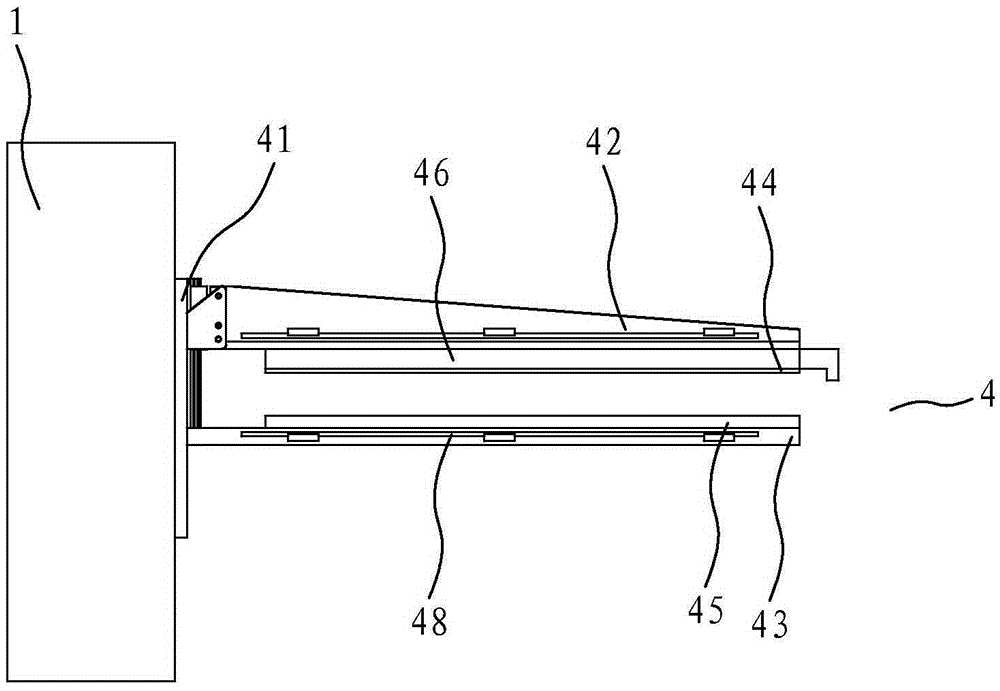

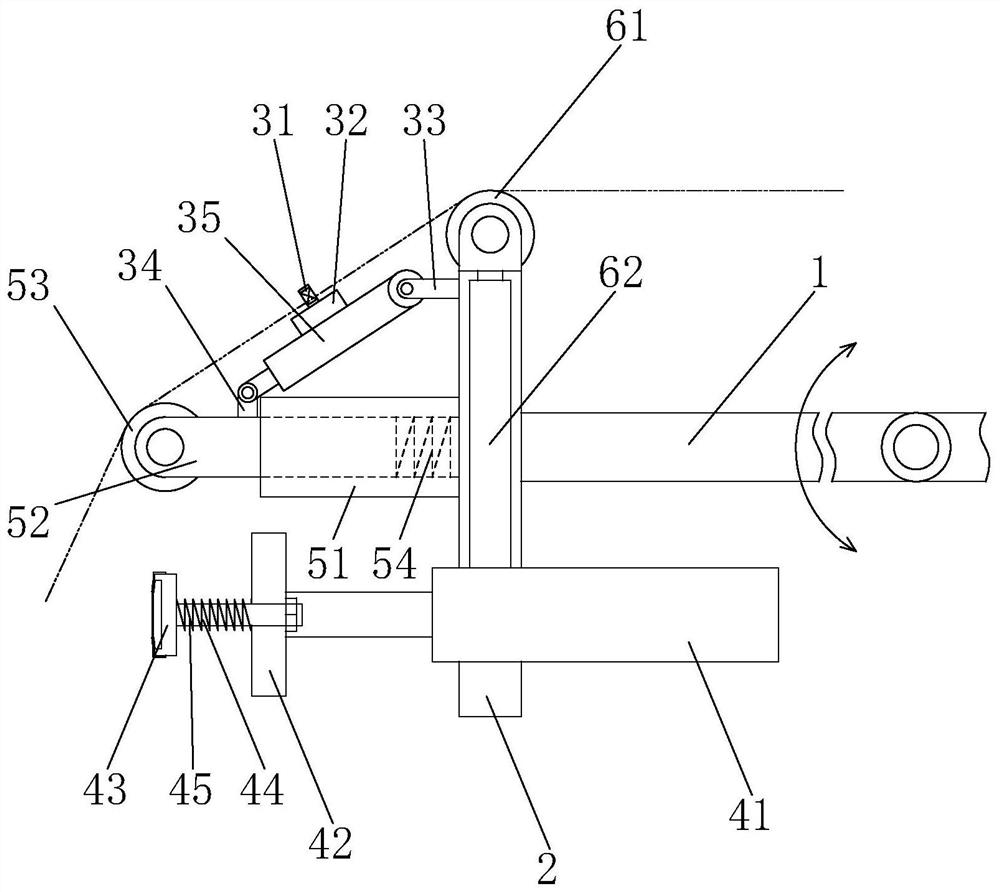

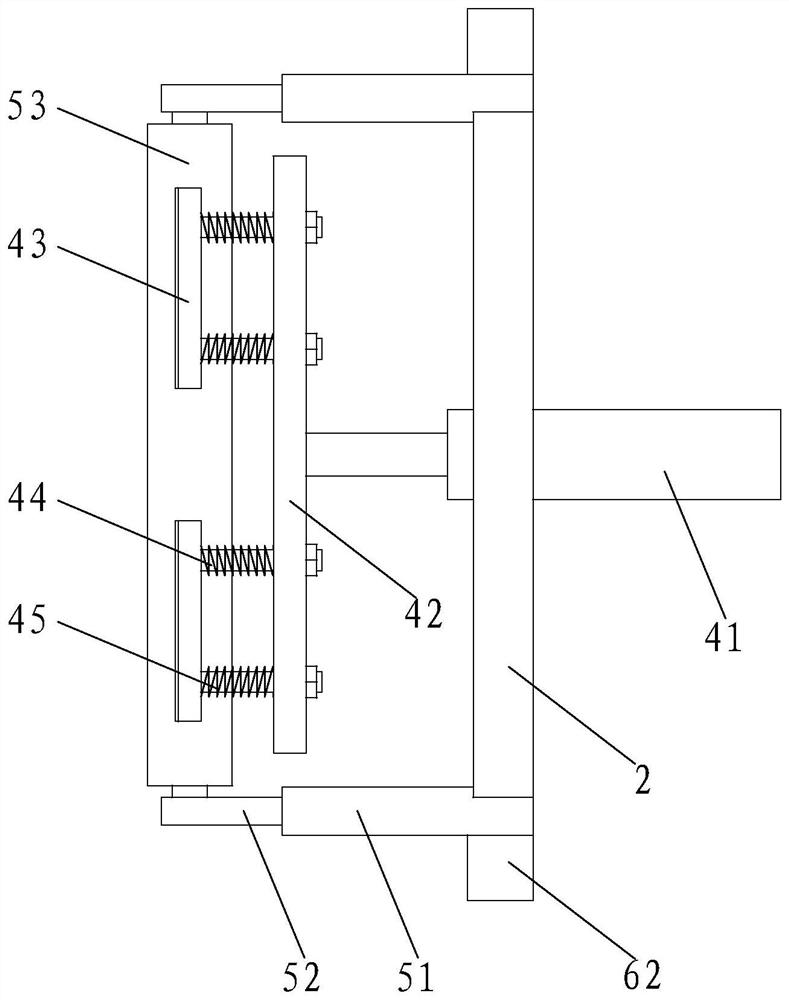

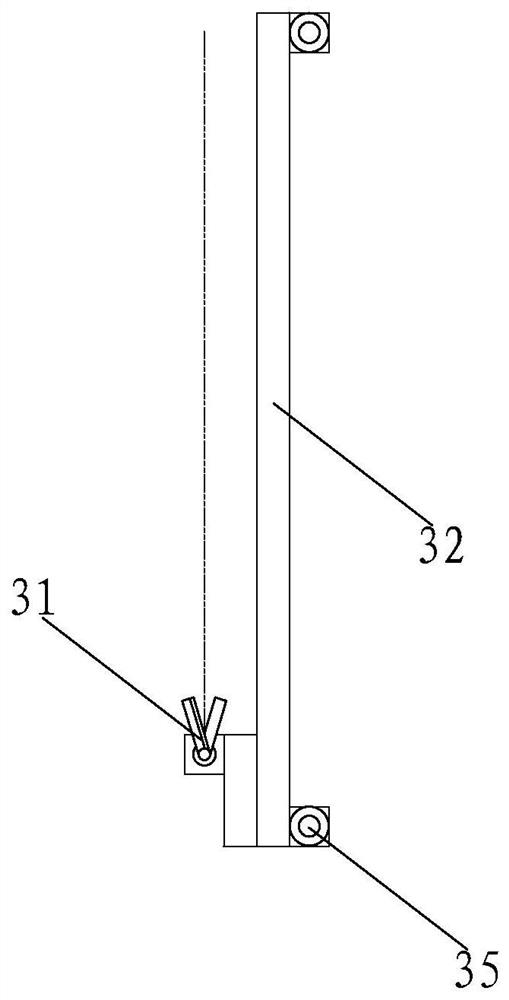

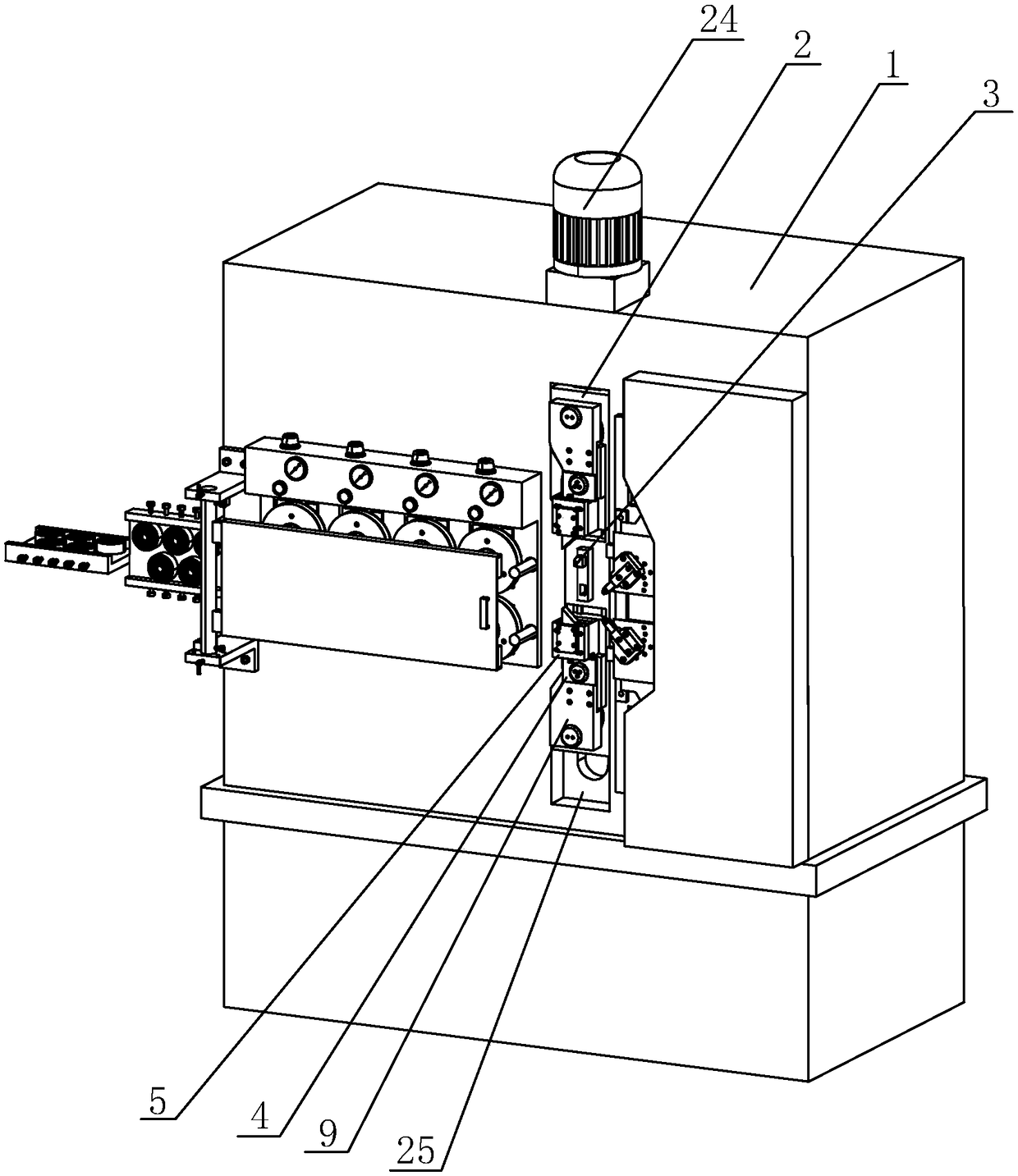

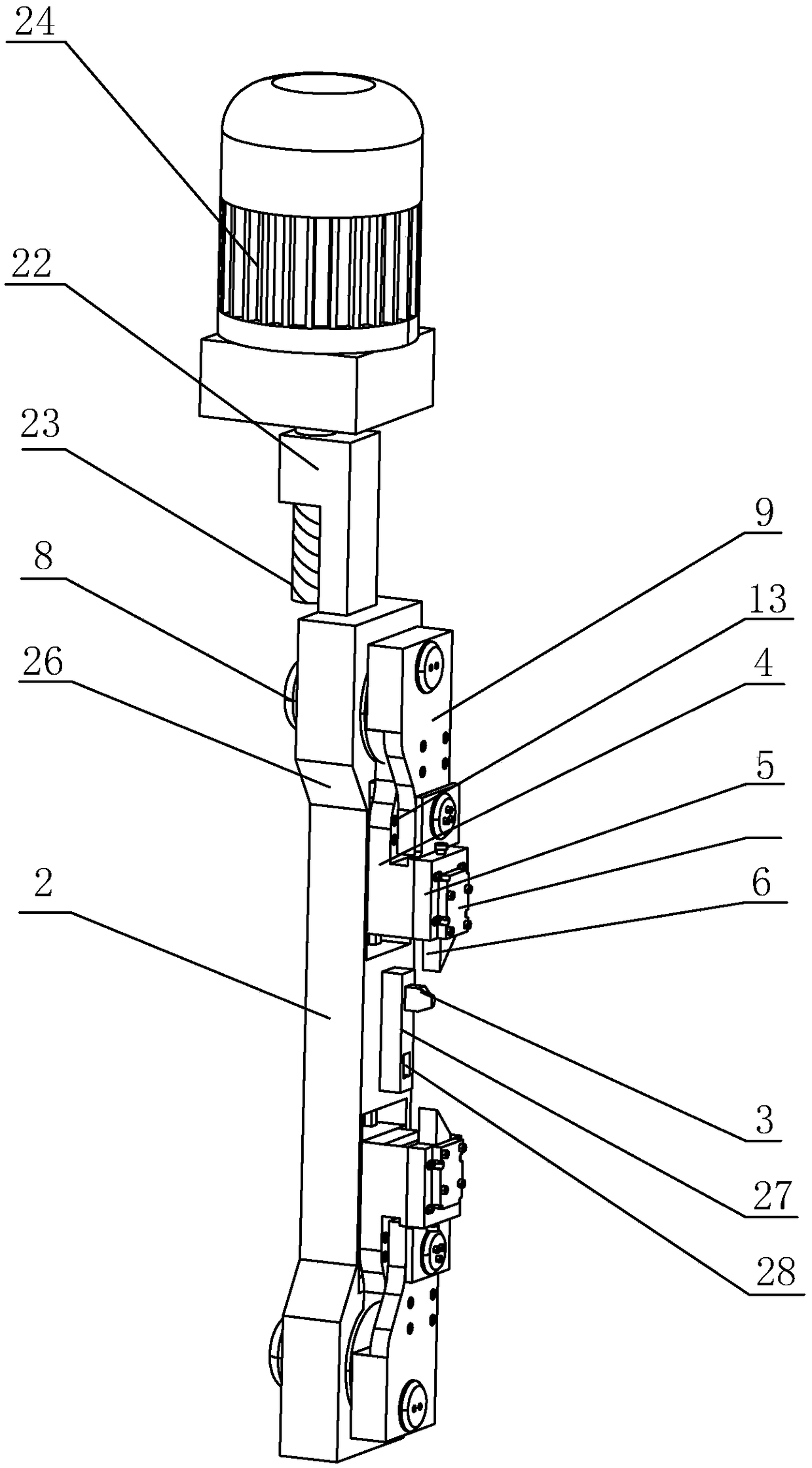

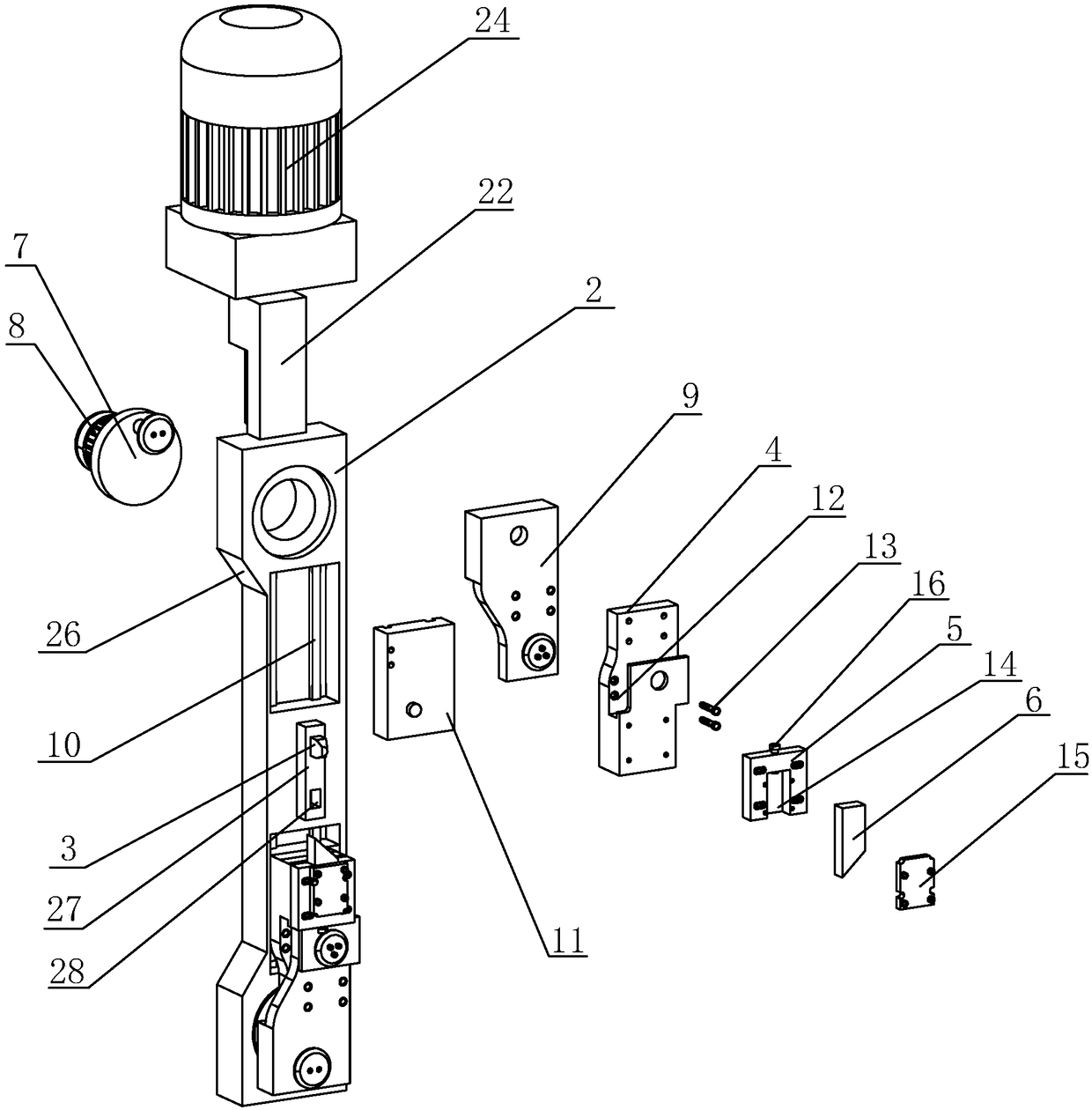

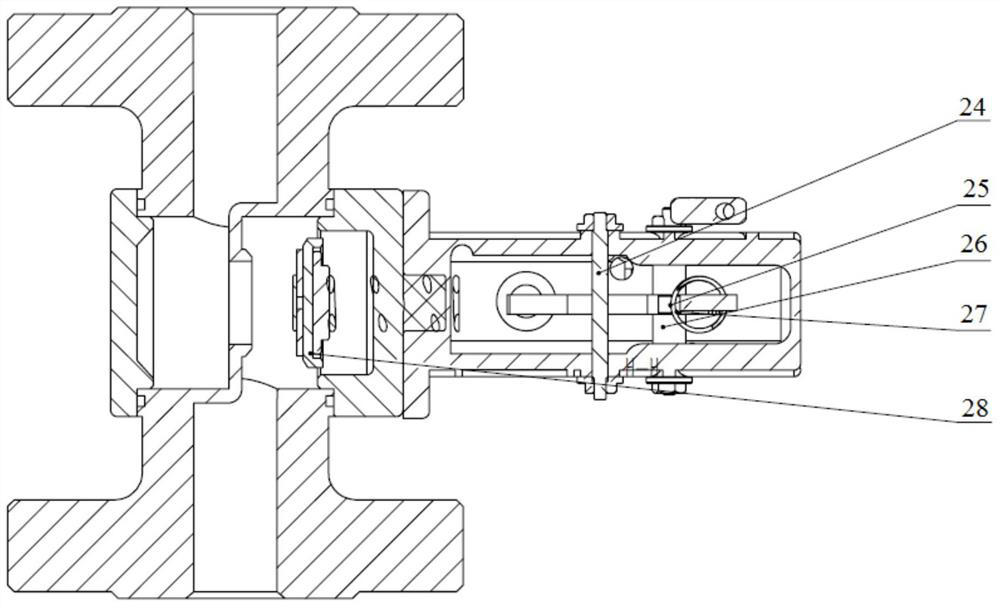

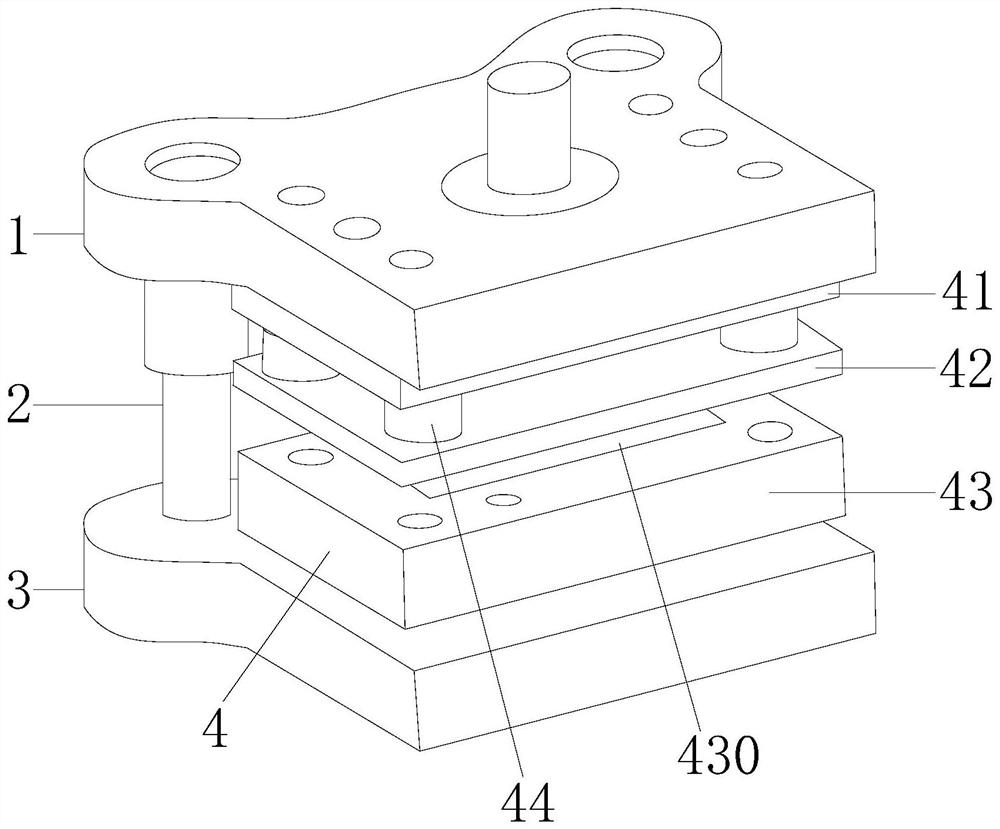

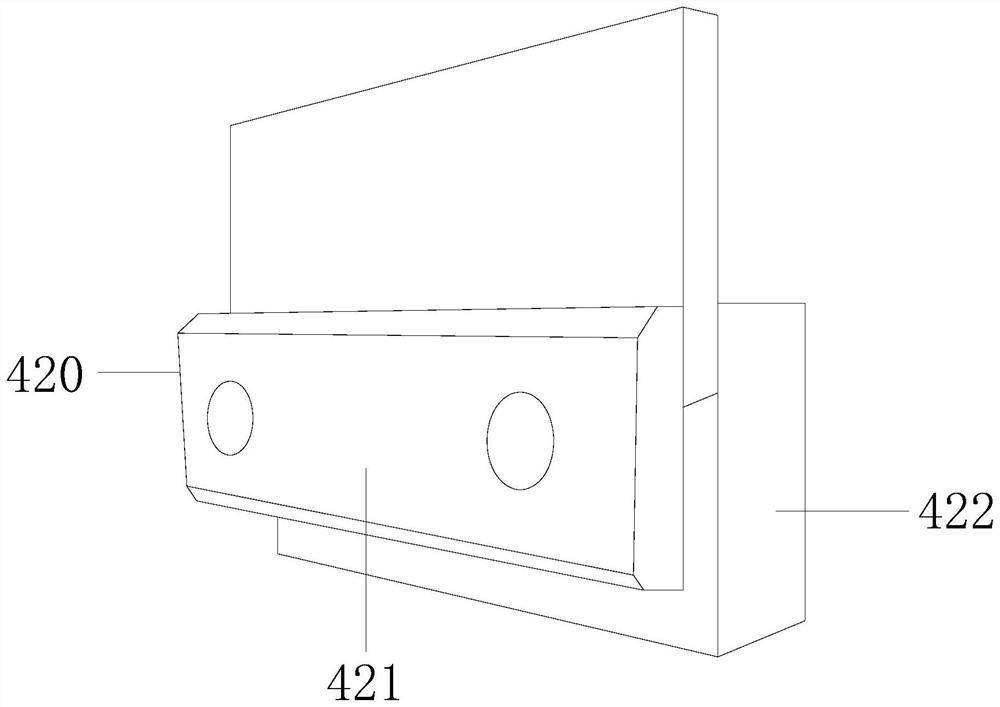

Diaphragm cutting mechanism of lithium battery winding machine

InactiveCN108858307ACut off stabilityCut off accuratelyNon-aqueous electrolyte cellsFinal product manufactureWinding machineEngineering

The invention discloses a diaphragm cutting mechanism of a lithium battery winding machine. The diaphragm cutting mechanism comprises a bracket, a slide seat and a fixing seat. The bracket, the slideseat and the fixing seat are sequentially connected with one another, a support table is arranged on a side of the fixing seat, a cutter for cutting off diaphragms is arranged on the support table, aone-way wheel and a pushing strip are arranged on the upper side and the lower side of the cutter, and a movable seat which is connected with the one-way wheel is arranged on the upper side of the support table, and is provided with a gas blowing seat which is arranged above the one-way wheel; the fixing seat is provided with a movement assembly for driving the movable seat to move on the front side and the rear side of the cutter back and forth; a driving assembly for driving the slide seat to horizontally move is arranged on the bracket. The diaphragm cutting mechanism has the advantages that the diaphragm cutting mechanism is reasonable in structure; the diaphragms on the upper side and the lower side of the cutter can be stably compressed by the one-way wheel and the pushing strip at first and then can be stably and accurately cut off by sawteeth of the cutter, accordingly, the lengths of the diaphragms wound on battery cells are consistent with one another, the consistency and thequality of the battery cells can be improved, and benefits of enterprises can be increased.

Owner:DONGGUAN ZEYUAN MACHINE

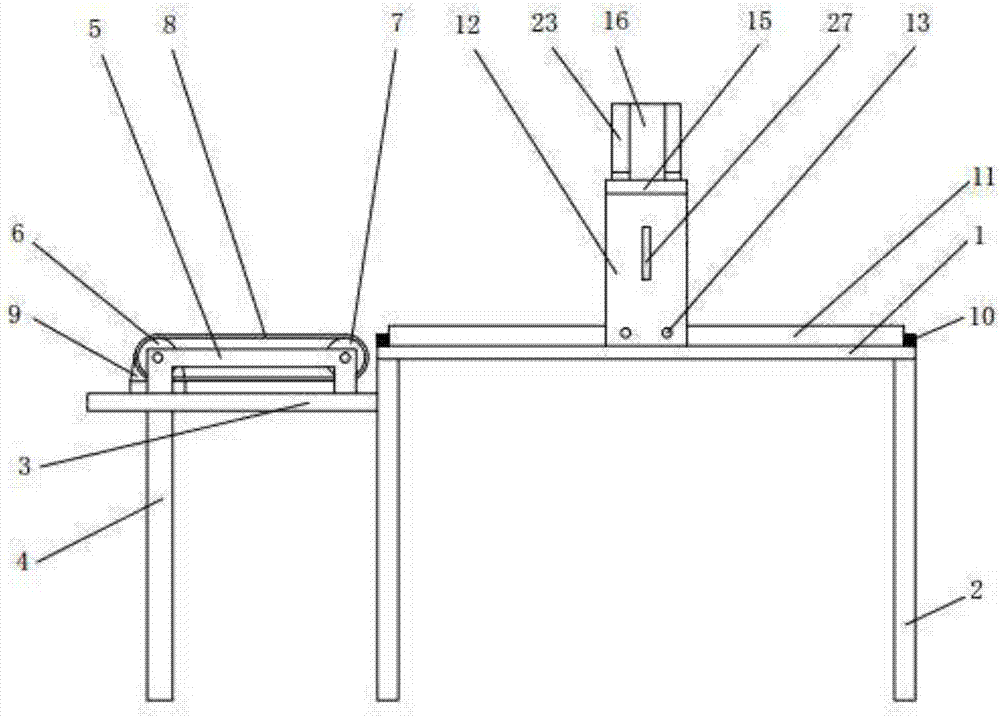

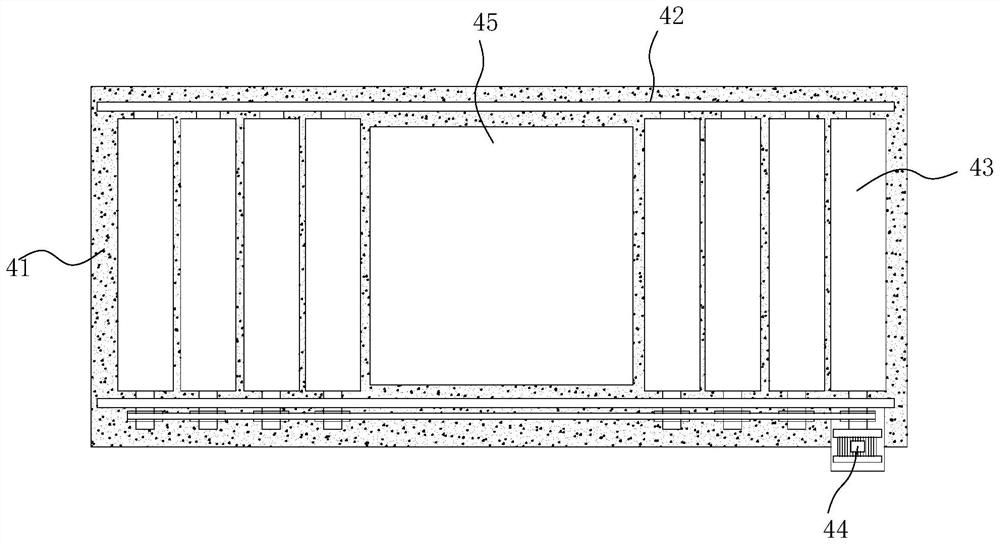

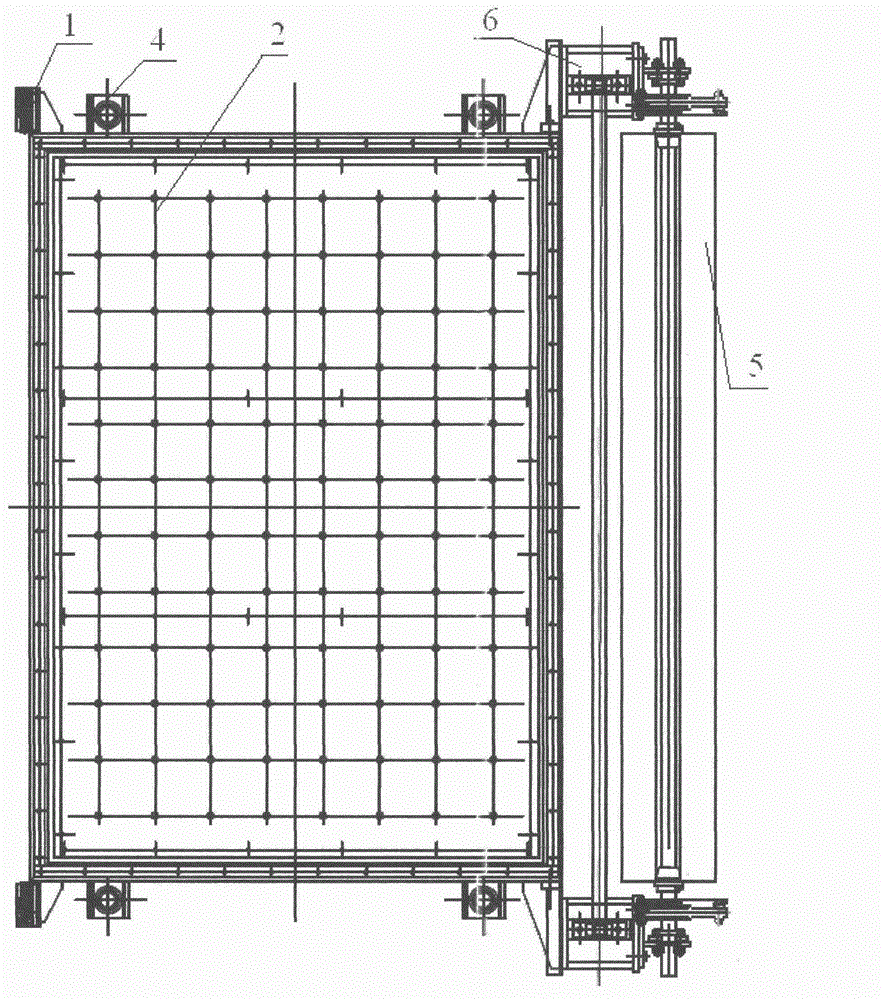

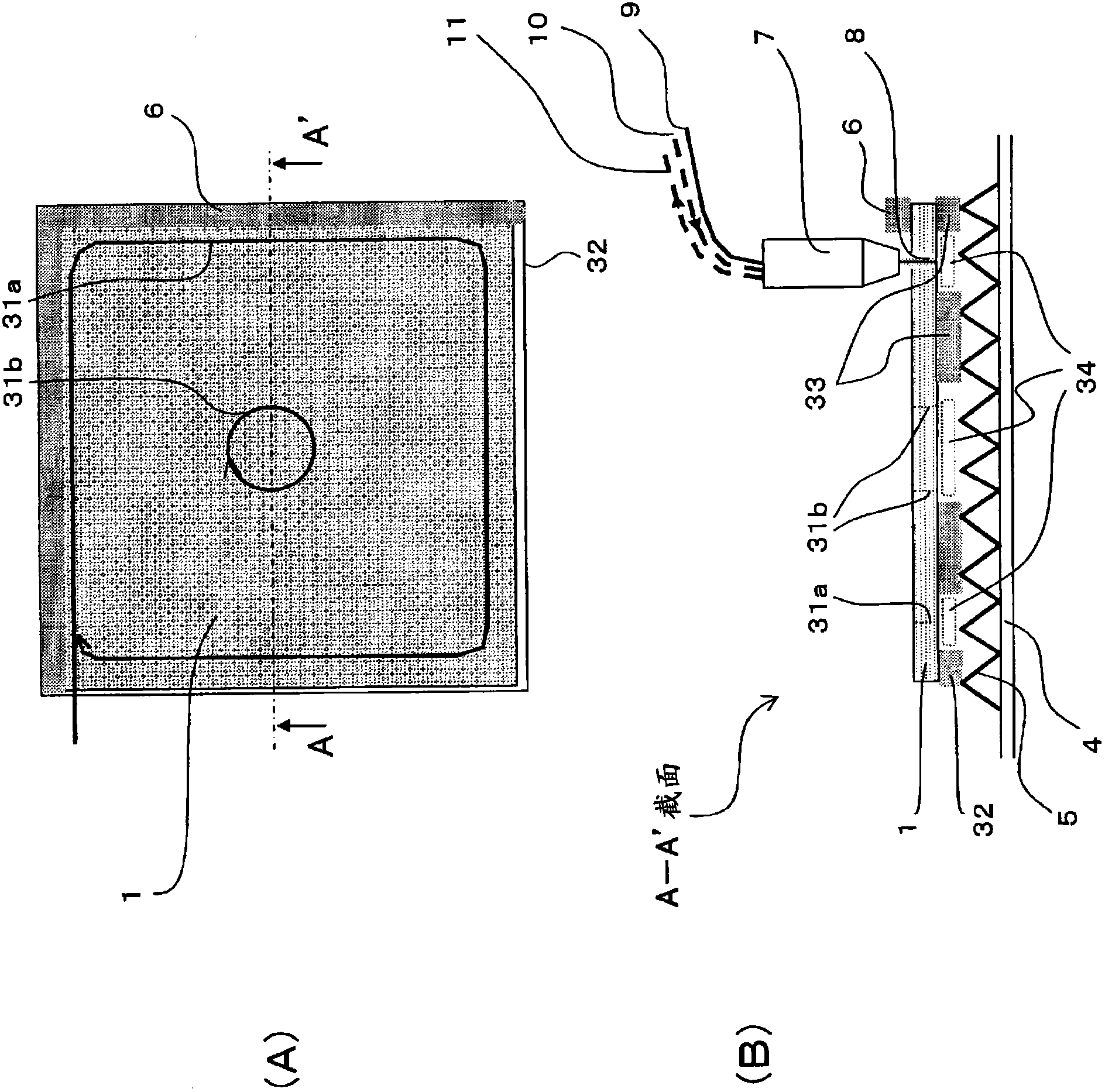

Novel film expanding platform

InactiveCN102941320AHigh degree of automationUnfold stableMoulding machinesControl systemEngineering

The invention relates to a novel film expanding platform, comprising a film cutting mechanism, a film adsorbing frame, a bracket, springs and a thin film supporting roller, wherein the film adsorbing frame is arranged on the bracket; the edge frame of the film adsorbing frame is rectangular; film adsorbing net lines which are vertically and transversely interweaved are arranged inside the film adsorbing frame; the film adsorbing net lines are stuck together at each interweaving point in the film adsorbing frame; the thin film supporting roller is arranged at one side of the film adsorbing frame; the film cutting mechanism is arranged at the other side of the film adsorbing frame; a driving device and a control system are respectively arranged at the two sides of the thin film supporting roller; the springs are arrayed at the two ends of the film adsorbing frame; the springs are arranged between the film adsorbing frame and the bracket along the two ends of the film adsorbing frame through a fixing device; a film covering device and a moving mechanism thereof are arranged above the film adsorbing frame; the film covering device can move on the moving mechanism and a static induction device is arranged at the bottom of the film adsorbing frame; and the control system is respectively connected with the driving device, the static induction device, the film covering device and the film cutting mechanism through signal lines.

Owner:青岛双星铸造机械有限公司

Sewing machine with cloth cutter

InactiveCN1451801AEasily and correctly changeCut off stabilityWorkpiece carriersEngineeringScrew thread

A sewing machine with a cutter, which supports the cutter shaft of the movable cutter, and supports the cutter stand on which the fixed cutter is installed on the base base in a foldable and movable manner in the direction of the shaft length through a support cylinder protruding from one side. On the support frame, on the rear side of the cutting table and the support frame, cooperate with the screw shaft screwed in the screw hole of the sewing machine base, and engage the operation dial set on the screw shaft with the surrounding support tube The engaging groove of the cutting board constitutes an adjustment device, and the shaft screw is screwed in by operating the dial, which can easily and accurately adjust the position of the cutting table in the left and right directions, and can flexibly correspond to the change of the cutting position of the sewn fabric .

Owner:YAMATO SEWING MASCH MFG CO LTD

Device for achieving continuous supply of films automatically

The invention relates to a device for achieving continuous supply of films automatically. The device is simple in structure, high in working efficiency and capable of achieving automation film connection. The device comprises a machine frame, more than two unreeling rollers arranged on the machine frame in a rotary mode, a fusing device arranged in front of the unreeling rollers and used for cutting off the packaging films, a hot melting jointing device arranged in front of the fusing device and used for connecting two packaging films, and an electrical control system, wherein the fusing device comprises a support arranged on the machine frame, a fusing base arranged on the support, and a fusing driving device arranged on the support, two press-fit bases are arranged on the support and located above and below the fusing base respectively, the two press-fit bases can get away from or approach the fusing base under the driving of the fusing driving device, fusing wires communicated with an external power supply are arranged on the upper side and the lower side of the fusing base respectively, and the unreeling rollers, the hot melting jointing device, the fusing wires and the fusing driving device are all connected with the electrical control system.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

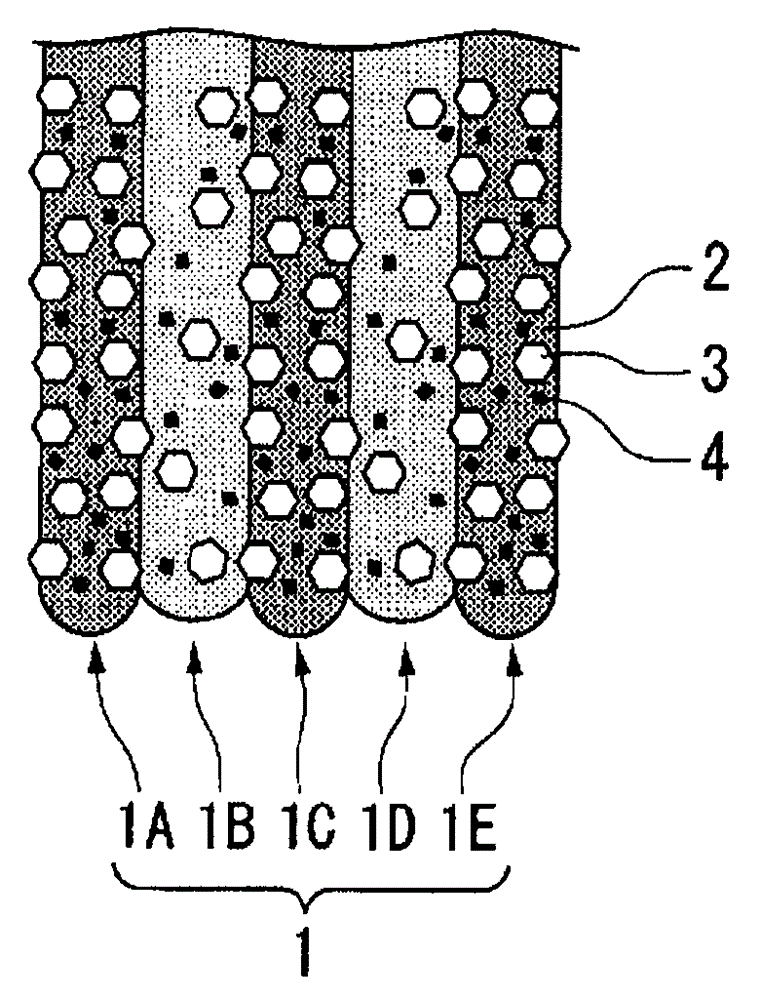

Electroforming thin blade grinding wheel

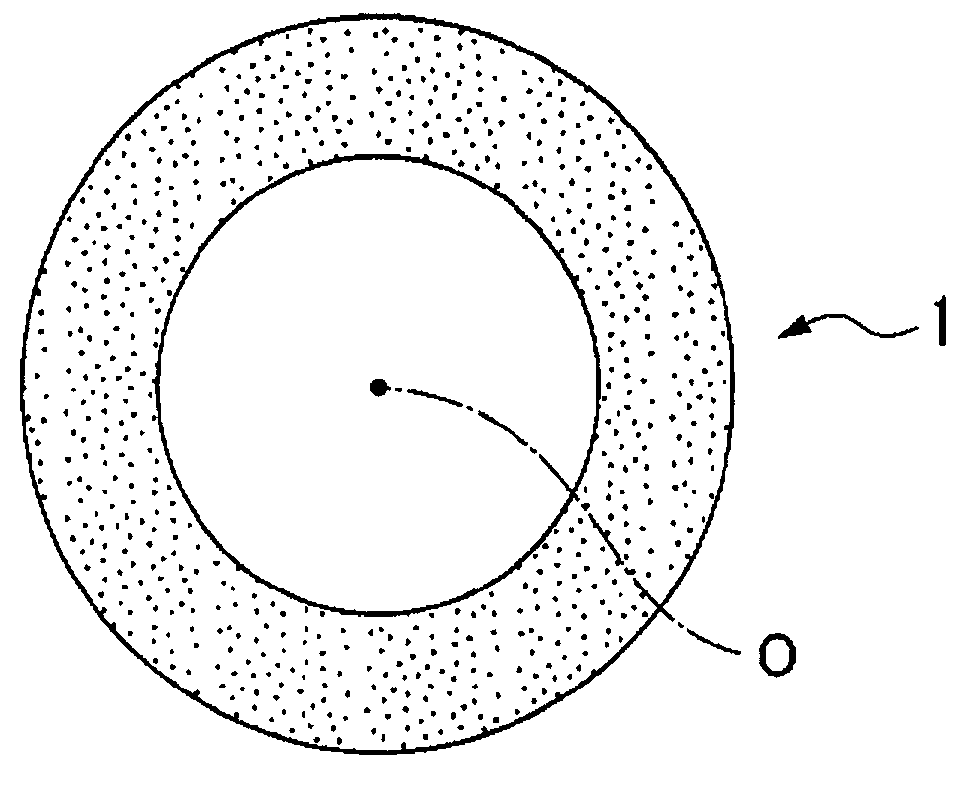

InactiveCN1958239APrevent roundingGood sharpnessBonded abrasive wheelsElectronic materialsEngineering

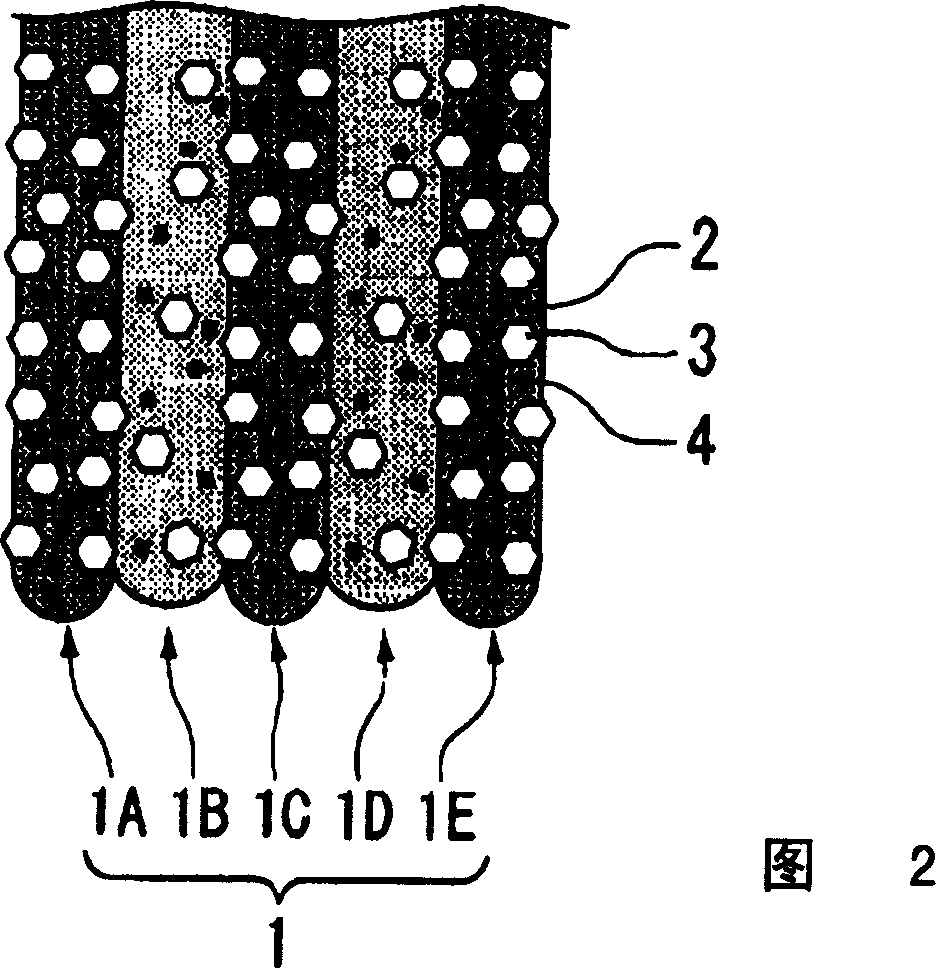

Electroforming thin blade grinding wheel which can be utilized for cutting electronic material components such as QFN, IrDA, LED etc work piece and has advantages that not only preventing burr occurring but also cutting with excellent rectilinear character and high precision, superior abrasion resistance and shell resistance, long service life, and capable of stably keeping high quality of the cut electronic material components. The grinding wheel provided in this invention comprises a thin blade wear particle layer (1) formed by dispersing wear particles in metal coating phase (2). The thin blade wear particle layer (1) has first to fifth wear particle layers (1A-1E) sequentially laminated in layer thickness direction in which wear particle (3) amount of the first, third, fifth wear particle layer (1A,1C,1E) is more than that of the second, fourth wear particle layer (1B,1D).

Owner:TOKYO SEIMITSU

Full-automatic back-sealing multi-row particle packaging machine compound punching and cutting device

The invention discloses a full-automatic back-sealing multi-row particle packaging machine compound punching and cutting device which comprises two standing seats and punching and cutting seats. A screw rod is vertically installed on each standing seat, the two ends of the punching and cutting seats are slidably sleeved on the screw rods, nuts are arranged on the position, at the upper and lower ends of the punching and cutting seats, on the screw rods in a screwed mode correspondingly, and the nuts are used for adjusting and fixing the upper and lower positions of the punching and cutting seats. A plurality of concave dies are horizontally installed on the punching and cutting seats in an uniform distributed mode, and a plurality of plunger chips are arranged on the concave dies in a fitted mode. A row arranging device is arranged above the concave dies, a cooling device is arranged above the row arranging device, a waste collection device is arranged below the concave dies, and an anti-clamping bag device is arranged below the plunger chips. According to the technical scheme, the full-automatic back-sealing multi-row particle packaging machine compound punching and cutting devicehas the advantages of non-clamping bag, one-time cutting, punching easy-to-tear openings and fillets, stable punching and cutting performances, small punching and cutting force, saving compressed air, small impact, stable cutting process, high efficiency, and uniform and beautiful appearance of finished packaging bags after punching and cutting.

Owner:RUIAN SANYANG TECH

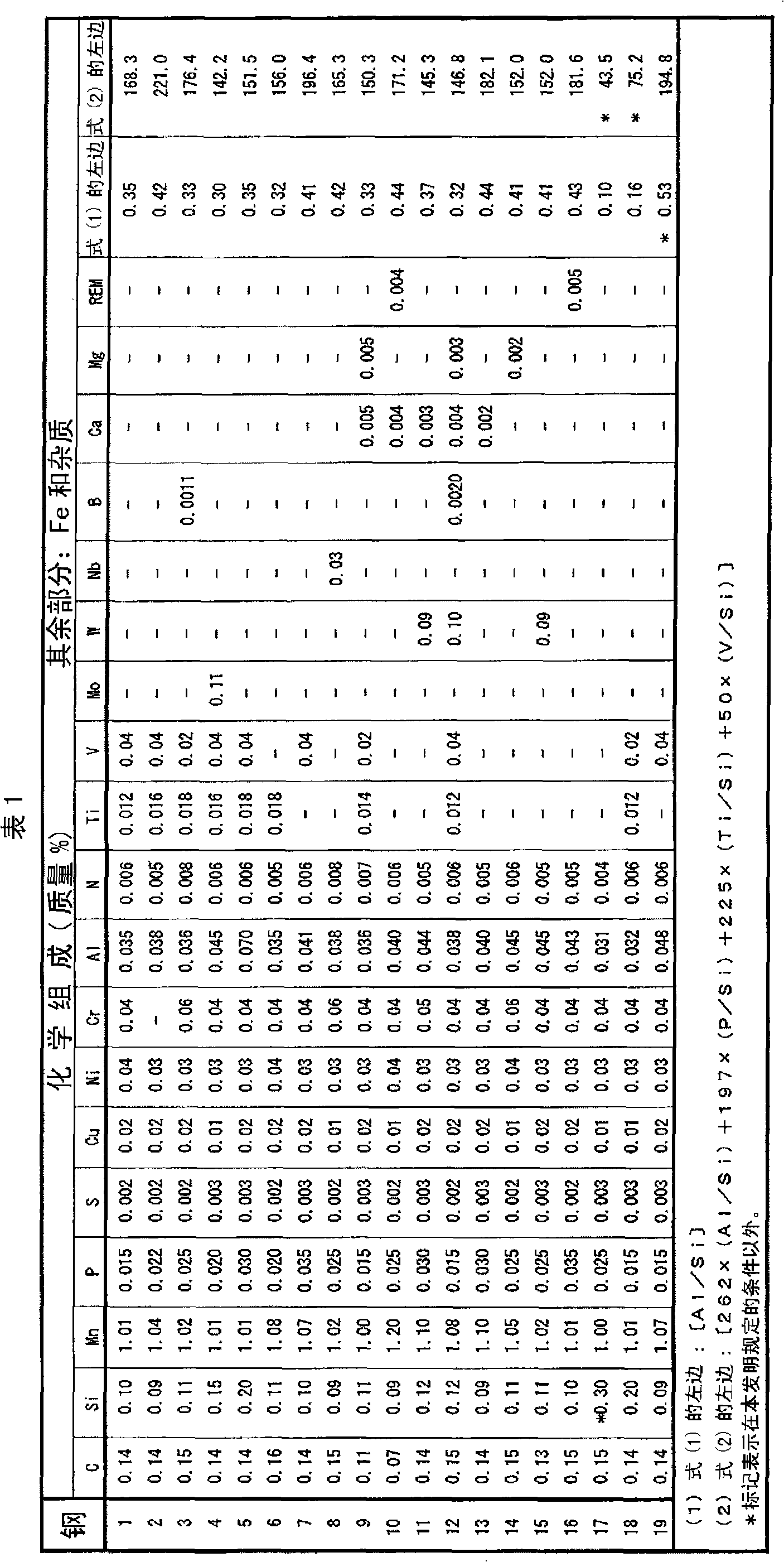

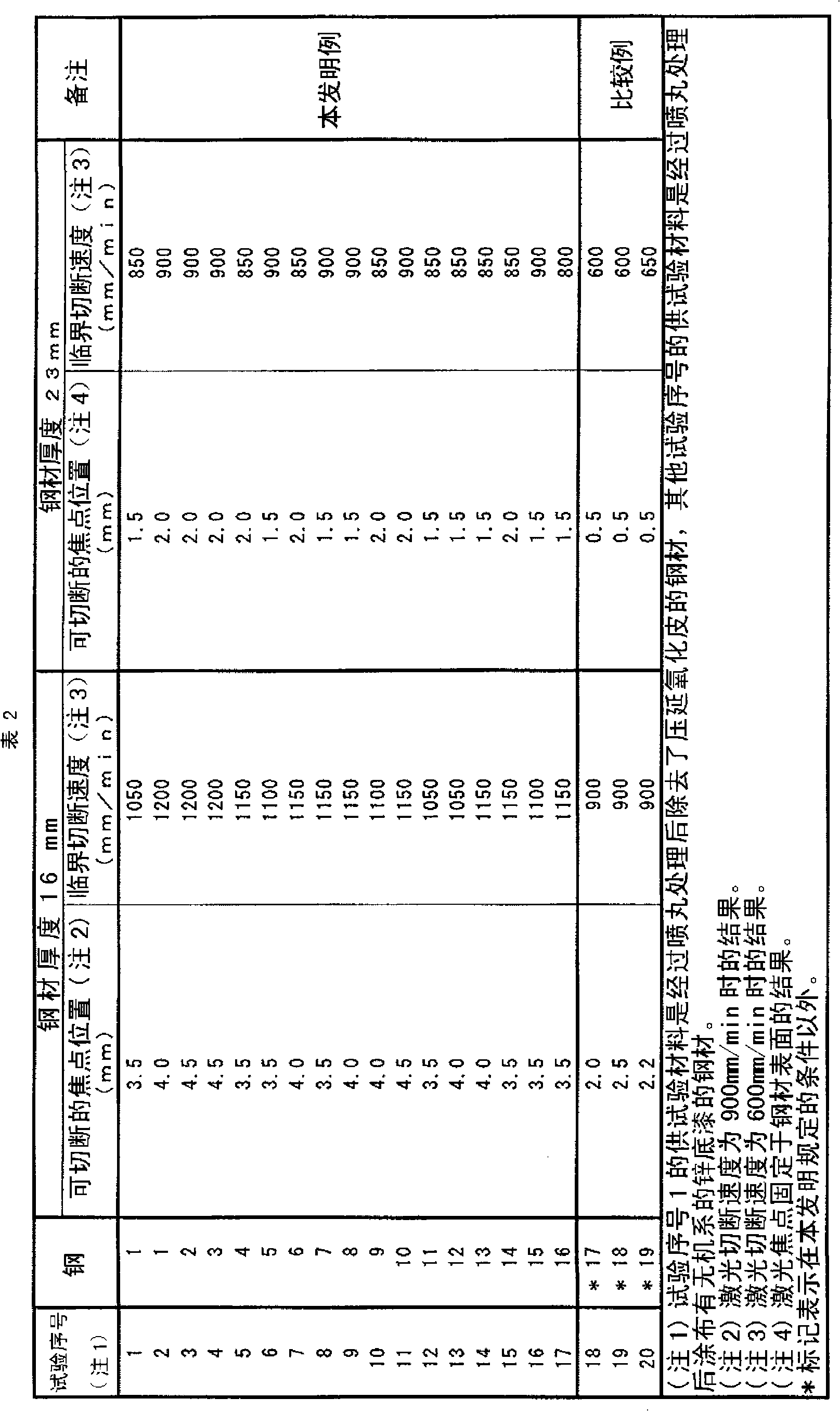

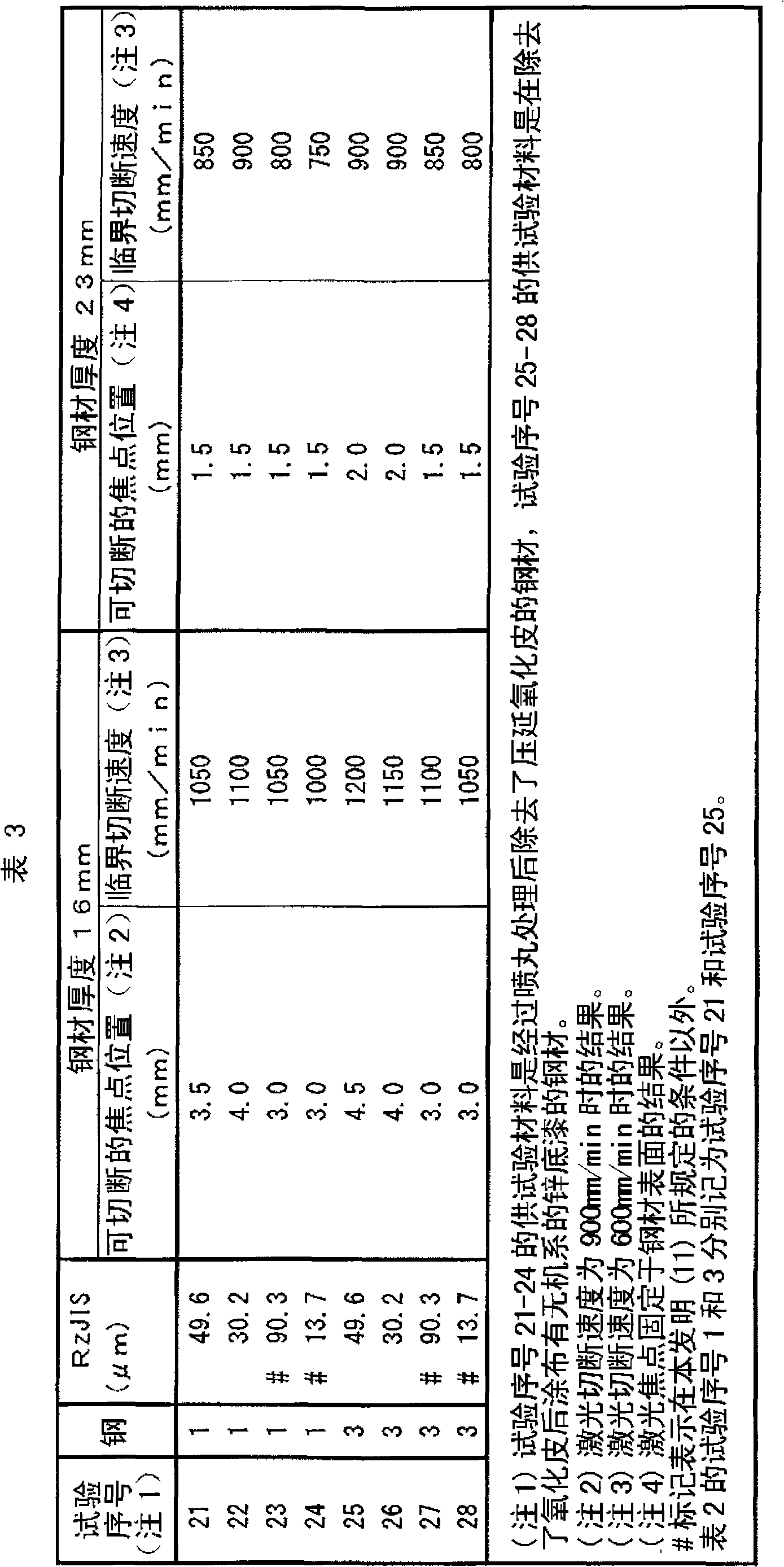

Steel material for thermal cutting with oxygen

A steel material which has been rid of surface scale and which contains Si: 0.08 to 0.20%, Al: more than 0.03% to 0.08%, and one or more of P, Ti and V and satisfies the relationships: ¢Al / Si=0.45! and ¢262(Al / Si)+197(P / Si)+225(Ti / Si) +50(V / Si)>123! wherein each symbol of element represents the content of the element. The steel material permits high-speed stable thermal cutting and is usable as the material for laser beam cutting, plasma arc cutting, and gas cutting. The steel material may have an inorganic zinc primer coat on the surface.

Owner:NIPPON STEEL CORP

Method For Cutting Carbon Fiber Base

ActiveCN102812175ACut off stabilityEliminate heat lossSevering textilesFibre chemical featuresFiberCarbon fibers

Disclosed is a method for laser-cutting a carbon fiber base, e.g., a preform configured of sheets of fabric comprising carbon fibers, characterized by cutting the carbon fiber base under initial conditions which have been set so that the state of the base that is being cut with a laser can be inhibited or prevented from deviating from the desired state. With the method, it is possible to effectively eliminate various problems including dissipation of heat, positional shifting from the focal length range of the laser, and soot, and the carbon fiber base can be stably cut while being kept in the desired state.

Owner:TORAY IND INC

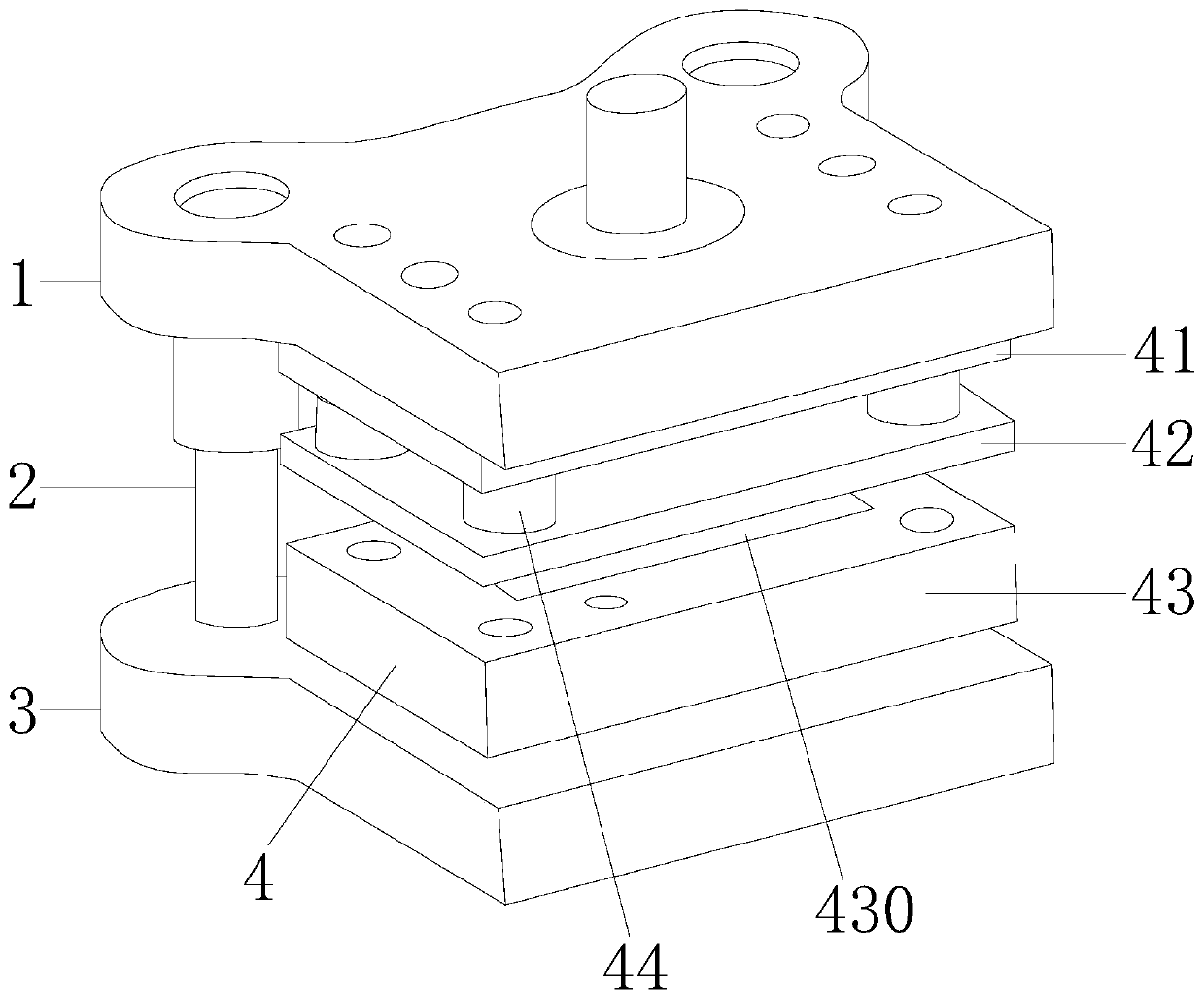

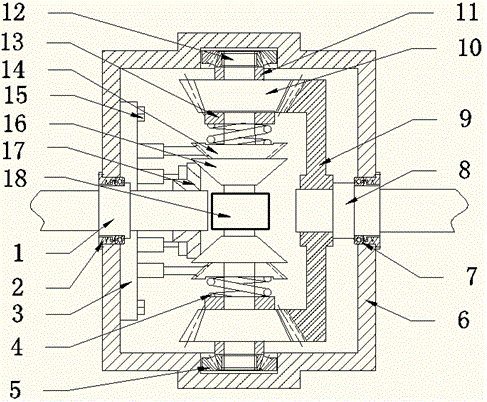

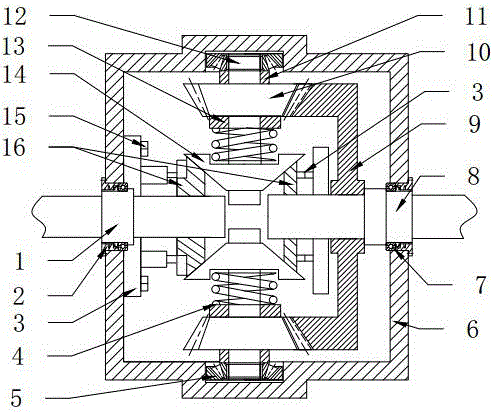

Metal plate stamping mold based on flat demolding

The invention discloses a metal plate stamping mold based on flat demolding. The metal plate stamping mold structurally comprises an upper mold, a mold column and a lower mold, wherein the mold columnis embedded on the upper mold and the lower mold, a stamping structure is arranged between the upper mold and the lower mold, the stamping structure is composed of a top plate, a middle plate, a bottom plate and a plate column, the top plate, the middle plate and the plate column are welded, the middle plate is matched with the bottom plate, and a stripping device is arranged on the bottom plate.According to the metal plate stamping mold, the size of the stripping device can be changed during demolding of a plate, an outer square structure or an inner round structure and an inner square structure can be used for transmission, an adjustable outer square frame moves on an outer square cone round so as to reduce the size of the adjustable outer square frame, an adjustable inner square framemoves on an inner square cone round so as to reduce the diameter of a stretching ring, then the mold and the plate cannot be tightly attached during demolding, and during demolding, the phenomena that the plate is enabled to locally move upwards together with the mold and the plate is slightly deformed are avoided.

Owner:佛山市普瑞生数控钣金有限公司

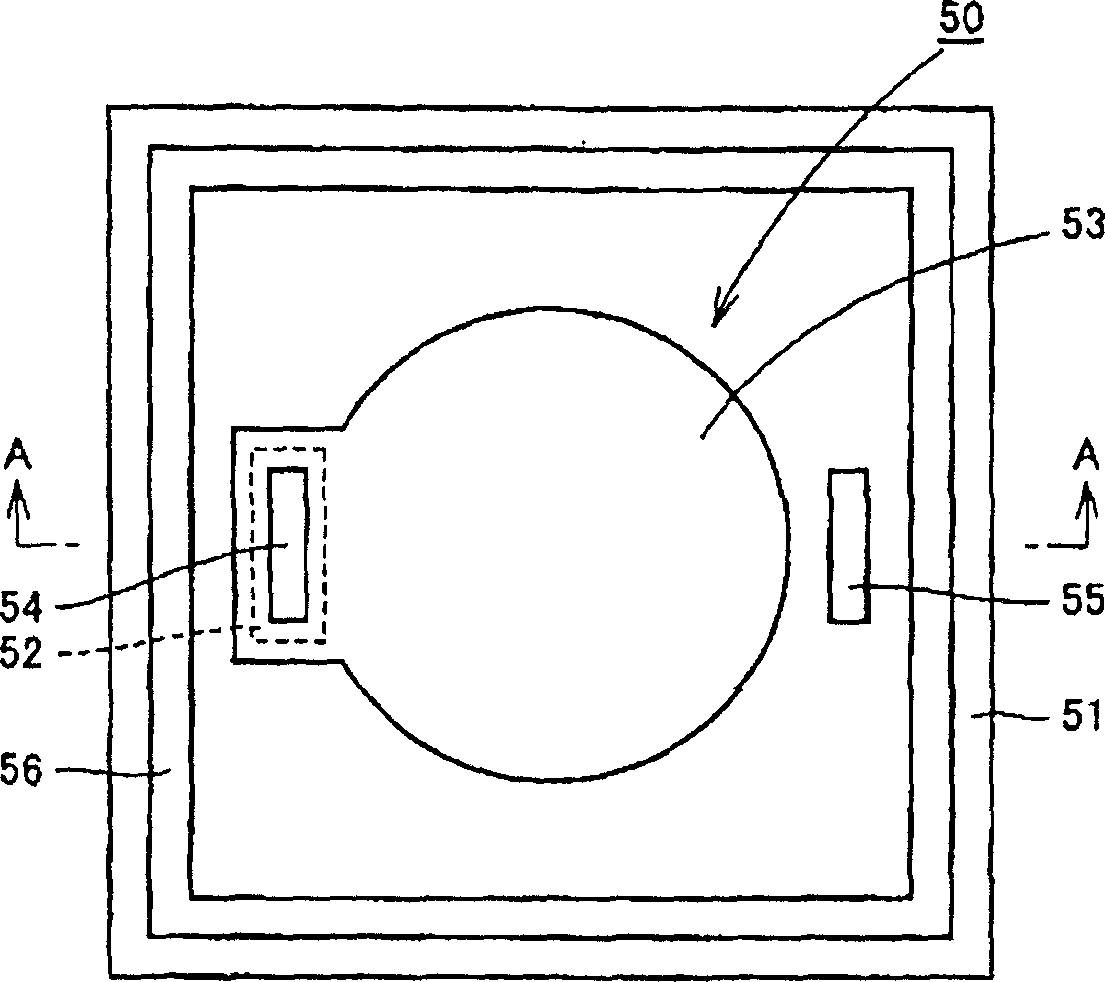

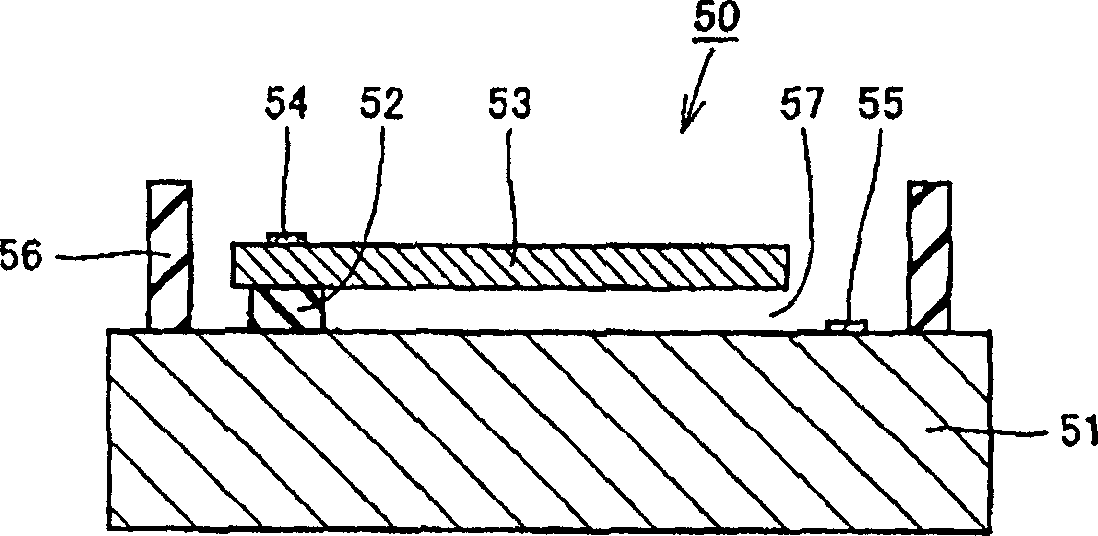

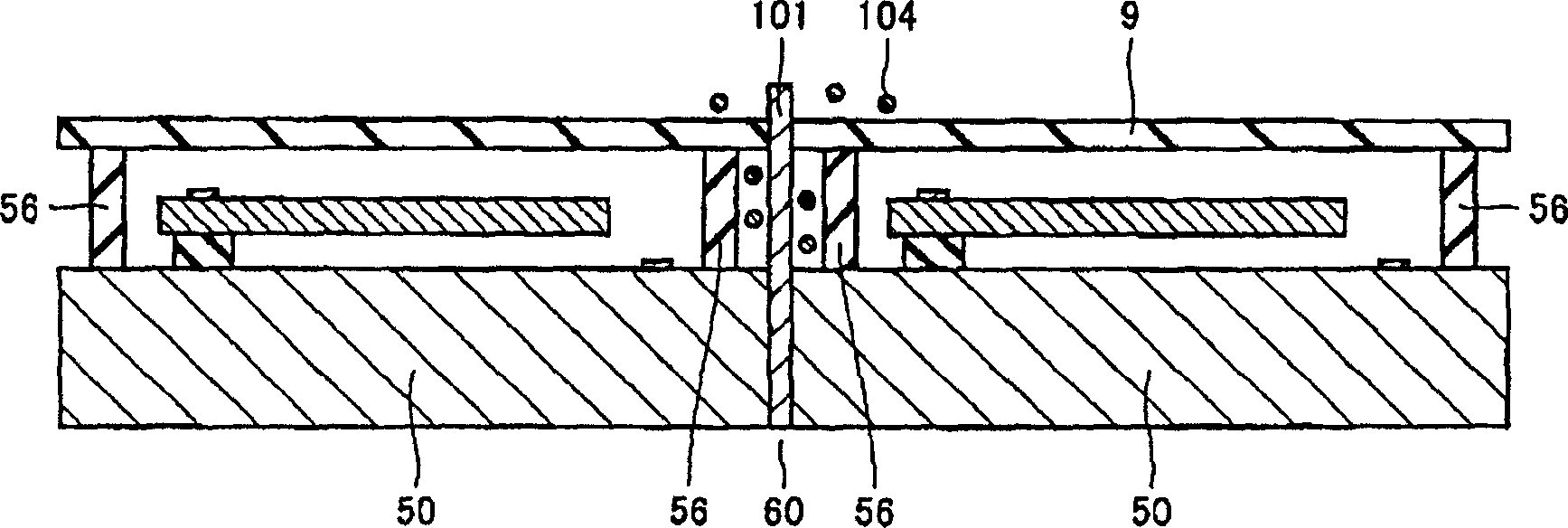

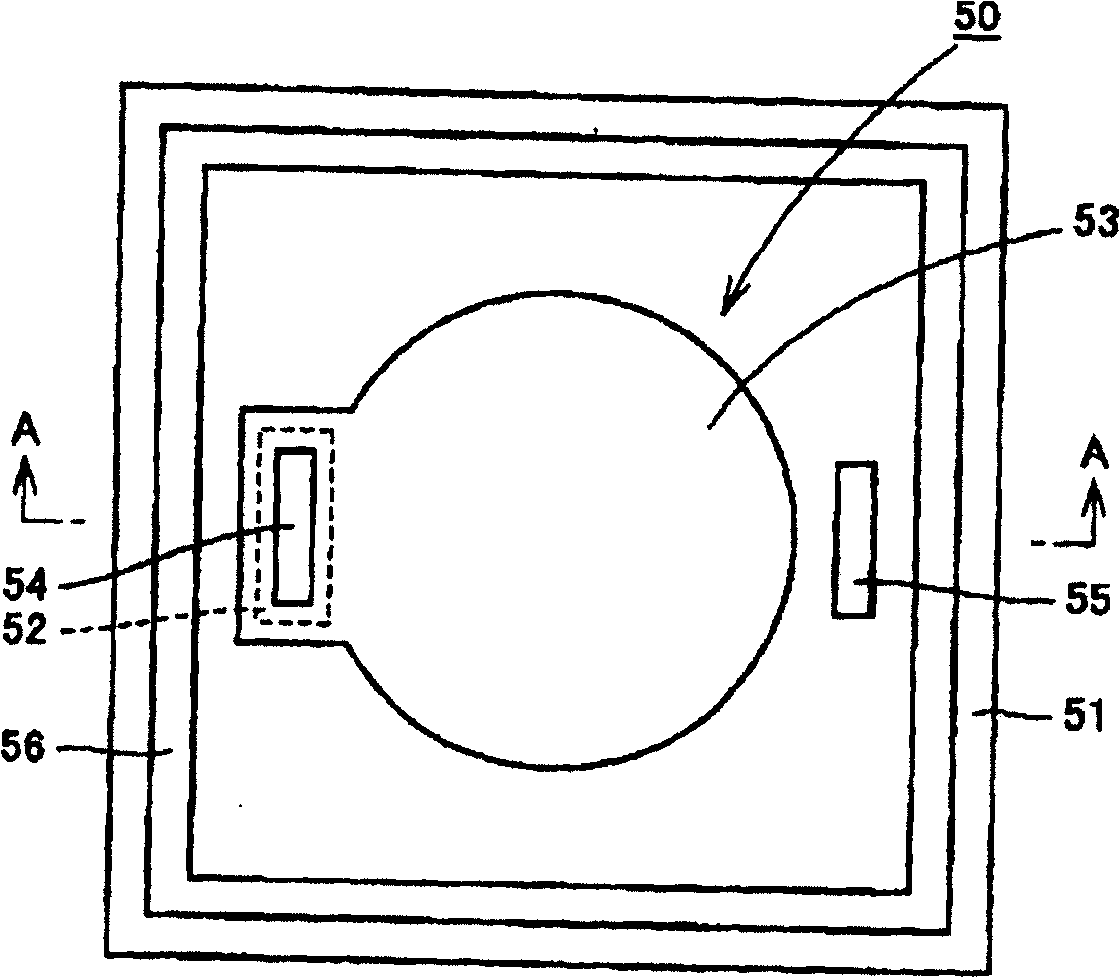

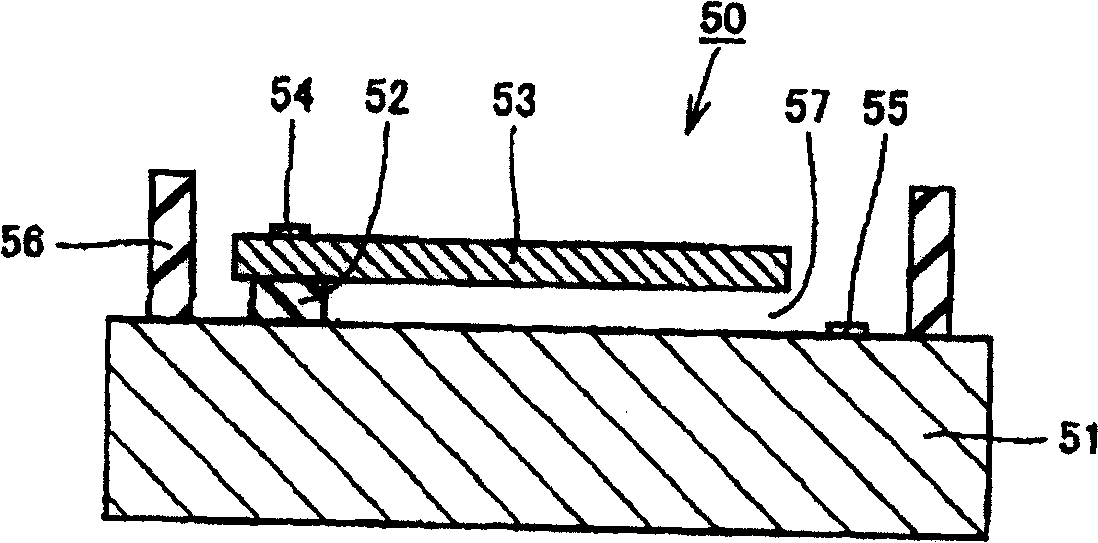

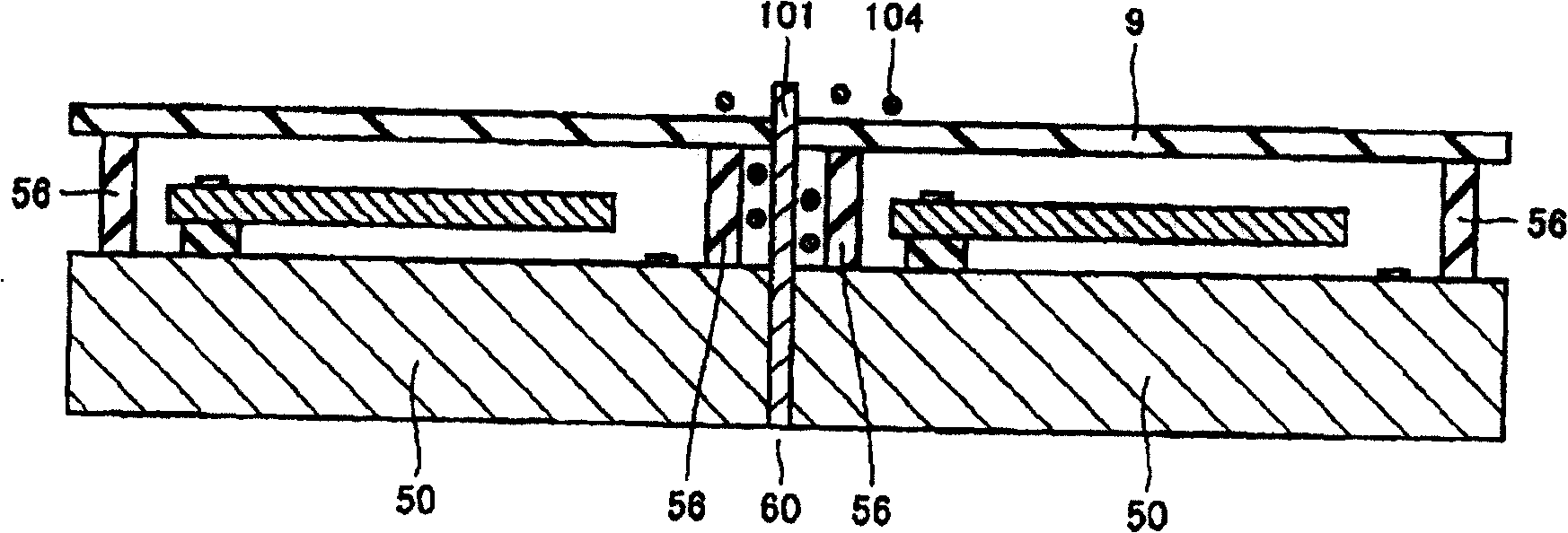

Semiconductor device

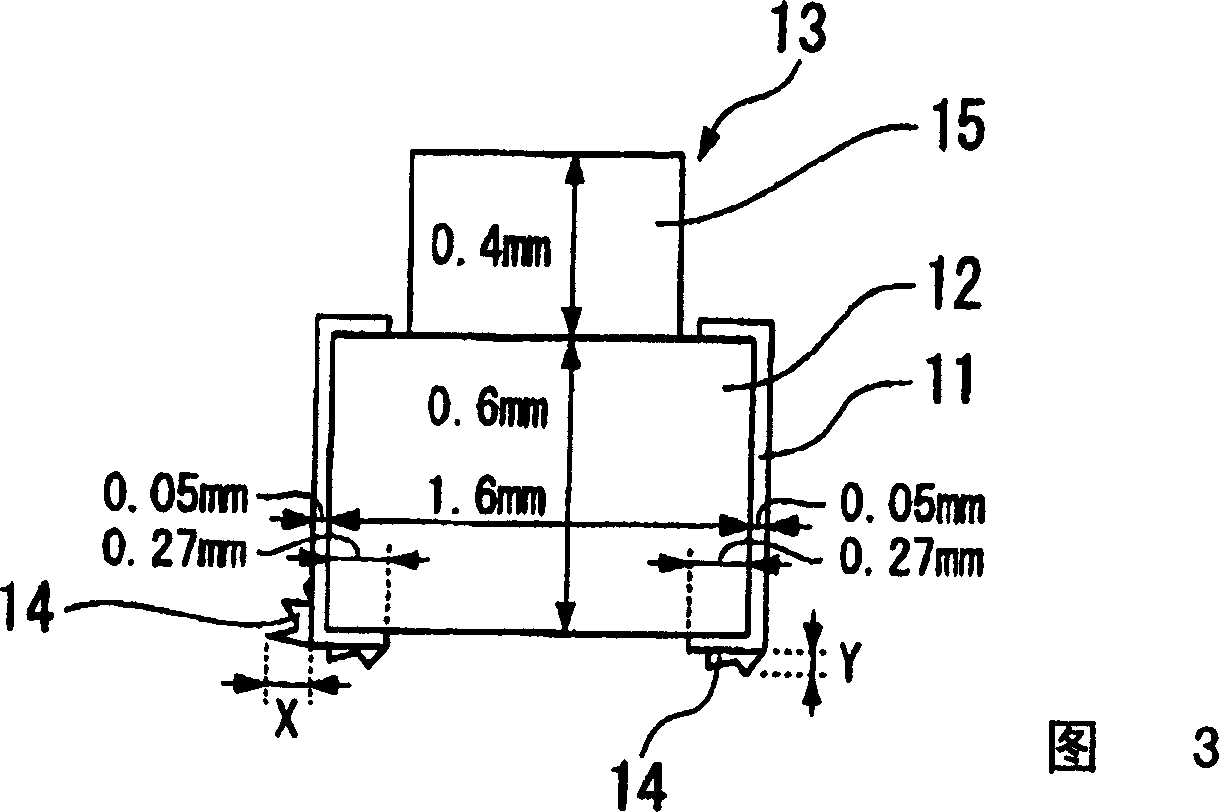

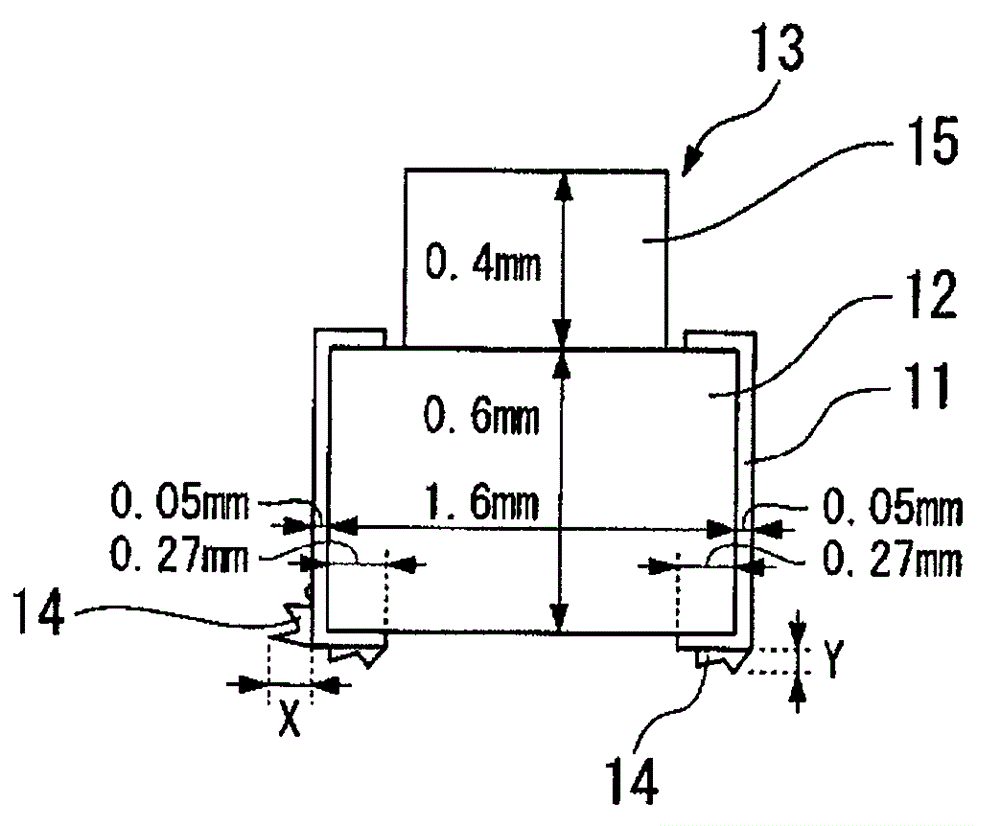

InactiveCN1839467APrevent intrusionCut off stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingForeign matterEngineering

A semiconductor device, wherein a substrate (51) is formed in a rectangular shape with four sides along dicing lines, and a jetty part (56) is formed to surround all the peripheries of an actuator element (50) and electrode pads (54) and (55) for input / output. The jetty part (56) is formed in a rectangular shape with four sides, and each side thereof is continuously extended parallel with each side of the substrate (51). Since the adhesion of a protective tape (9) can be increased by the jetty part (56), foreign matters (104) produced in dicing can be prevented from adhering to the actuator element (50) and the electrode pads (54) and (55).

Owner:TOKYO ELECTRON LTD

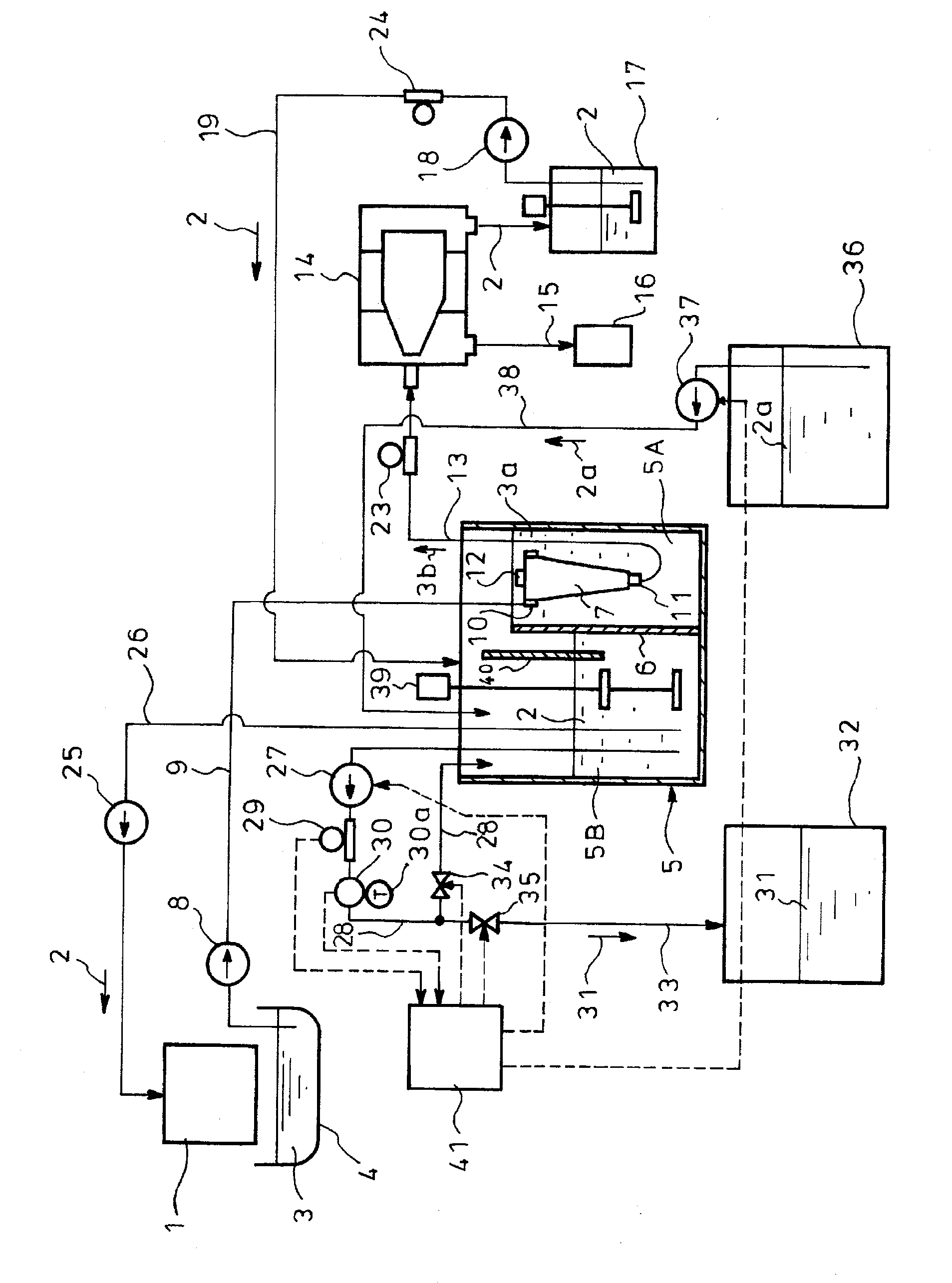

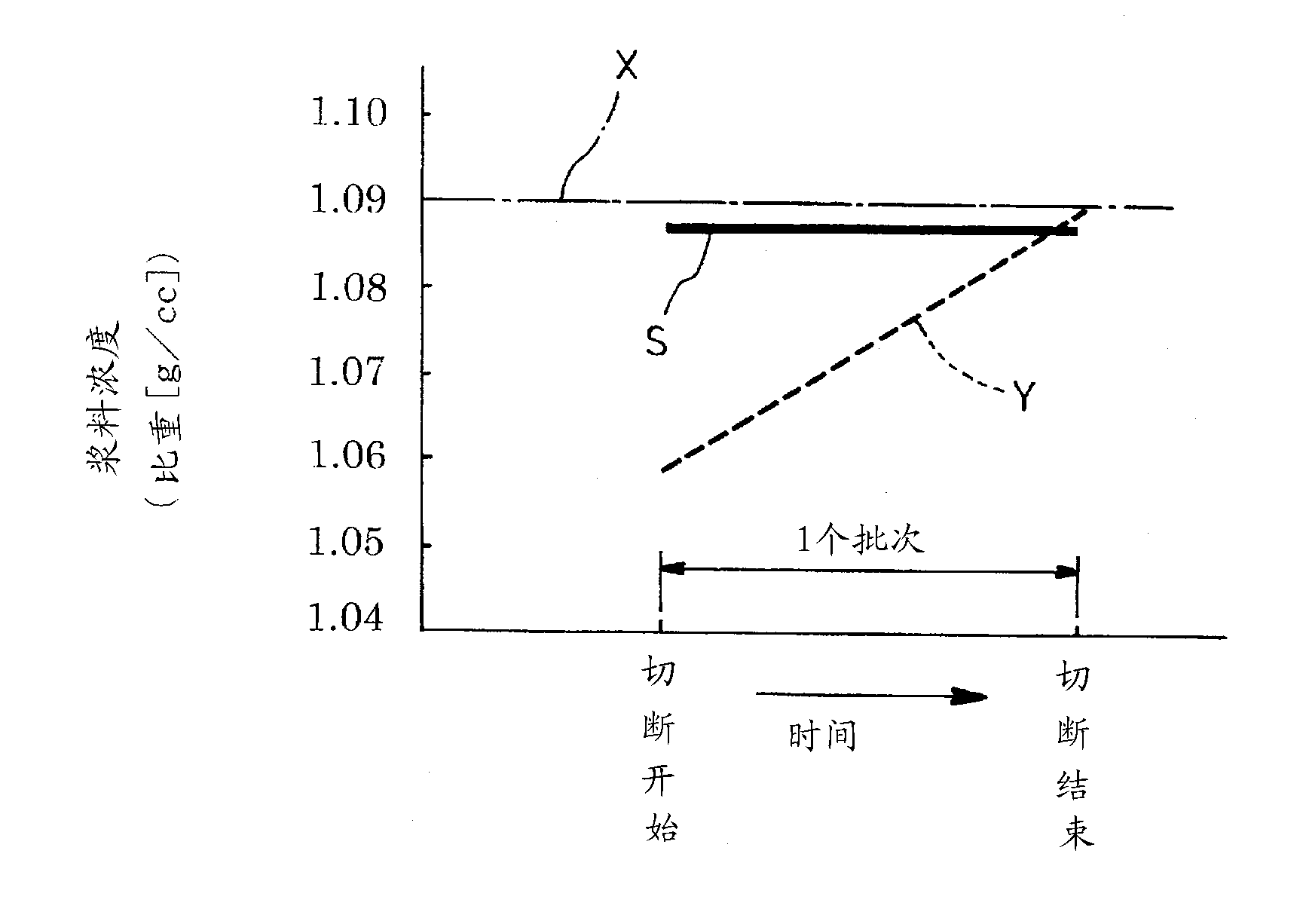

Slurry management device for wire saw

InactiveCN103237628ACut off stabilityStable generationSemiconductor/solid-state device manufacturingWorking accessoriesSpecific gravityCentrifugal separator

A wire saw slurry management device is provided with: a first tank (5A) which receives slurry waste (3); a centrifugal separator (14) into which the slurry waste (3b) from the first tank (5A) is introduced and which isolates the slurry (2); a second tank (5B) which receives the solid-content slurry (2) from the centrifugal separator (14); a slurry supply path (26) which supplies the slurry (2) from the second tank (5B) to a fixed-abrasive wire saw (1); a controller (41) which detects the slurry density using a detection value from a density meter (29) and a viscometer (30), both provided on a circulation flow path (28) for extracting and circulating the slurry (2) from the second tank (5B); a slurry discharge path (33) which discharges some of the slurry (2) from the second tank (5B) as waste slurry (31); and a new slurry supply path (38) which supplies new slurry (2a) to the second tank (5B). The discharge of waste slurry (31) by the slurry discharge path (33) and the supply of new slurry (2a) by the new slurry supply path (38) are implemented in order to maintain a specific density for the slurry density detected using the controller (41).

Owner:IHI ROTATING MACHINERY ENG CO LTD

Cutting-off device for armored cable

ActiveCN112845991AEasy to cut offReduce slippageApparatus for cutting/splicing cablesEngineeringStructural engineering

The invention discloses a cutting-off device for an armored cable, and relates to the technical field of cable cutting-off equipment. The cutting-off device comprises a rack, wherein the rack is provided with a bearing table, and the upper end face of the bearing table is used for storing the cable; and the rack is further provided with a sliding base, the sliding base is located above the bearing table and connected to the rack in a sliding mode in the vertical direction, the sliding base is provided with a cutting-off assembly, and the sliding base moves downwards to enable the cutting-off assembly to cut off the cable on the bearing table. By arranging the bearing table and the cutting-off assembly, the cable can be cut off more conveniently and quickly.

Owner:全通电缆股份有限公司

Film cutting machine

The invention discloses a film cutting machine. The film cutting machine comprises a cutter rest, a cutter cylinder, a cutter, a cutter holder, two guide racks, two guide gears and a guide shaft; thecutter rest is fixedly connected to a machine frame in an across mode; a cylinder block of the cutter cylinder is fixedly mounted at the top of the cutter rest; the rod end of a piston rod of the cutter cylinder downwards penetrates through the cutter rest and then is connected with the upper end of the cutter; the lower end of the cutter extends to the cutter holder; the cutter holder is fixed onthe machine frame; the two guide racks are mounted on the side wall of the cutter; the two guide gears are fixedly arranged on the guide shaft in a sleeving mode and engaged with the two guide rackscorrespondingly; and the guide shaft is rotationally mounted on the cutter rest. Due to the fact that the two guide racks are mounted on the side wall of the cutter, the two guide racks can be engagedwith the two guide gears, thus, the cutter can be stabilized in the film cutting process, and a film is cut more stably and accurately.

Owner:XIAMEN TANUO OPTICAL TECH

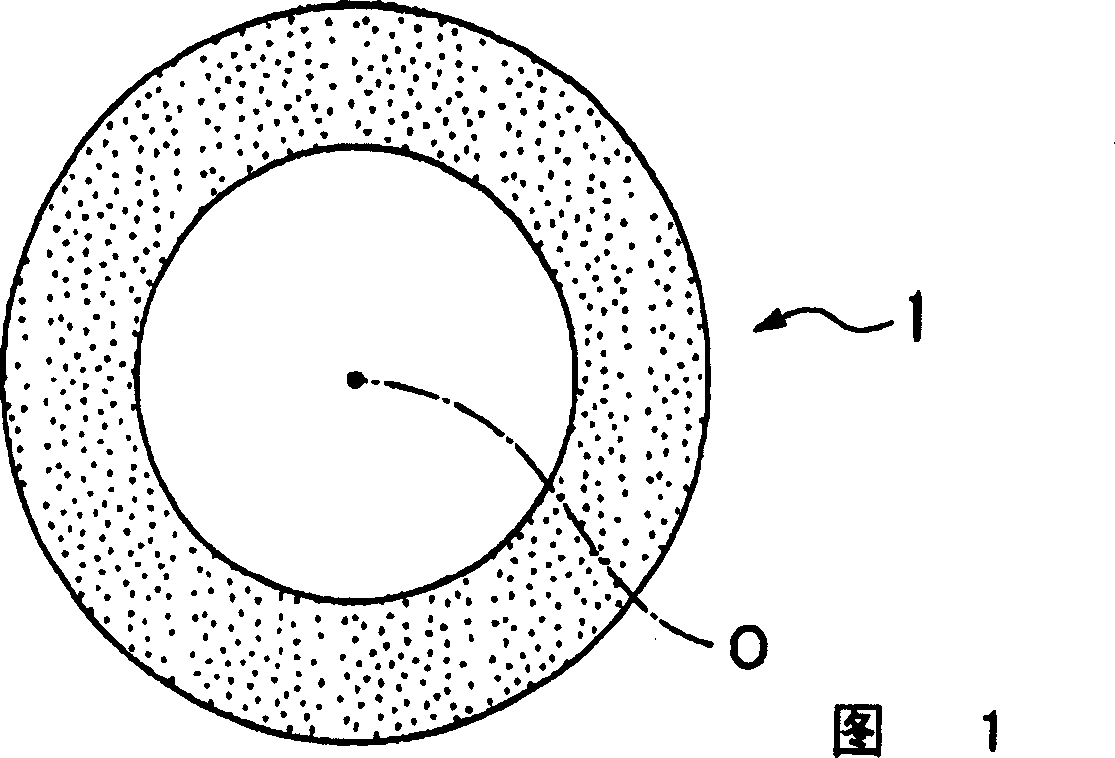

Electroforming thin blade grinding wheel

The present invention provides an electroformed thin edge grinding wheel for use in cutting an electronic material part such as a QFN (quad flat non-leaded package), an optical transmission module (IrDA) or an LED work, not only restraining the generation of burr, but also having high linearity to achieve high-accuracy cutting, further superior in wear resistance and peeling resistance to attain a long life of a grinding wheel and stably maintain a high grade to the cut electronic material part. This electroformed thin edge grinding wheel includes a thin edge abrasive layer 1 formed by dispersing abrasive grains 3 in a metal plated phase 2, wherein the thin edge abrasive grain layer 1 has first to fifth abrasive grain layers 1A to 1E sequentially stacked in the direction of a layer thickness. Among these, the content of abrasive grains 3 in the first, third and fifth abrasive grain layers 1A, 1C, 1E is set larger than that of abrasive grains 3 in the second and fourth abrasive grain layers 1B, 1D.

Owner:TOKYO SEIMITSU

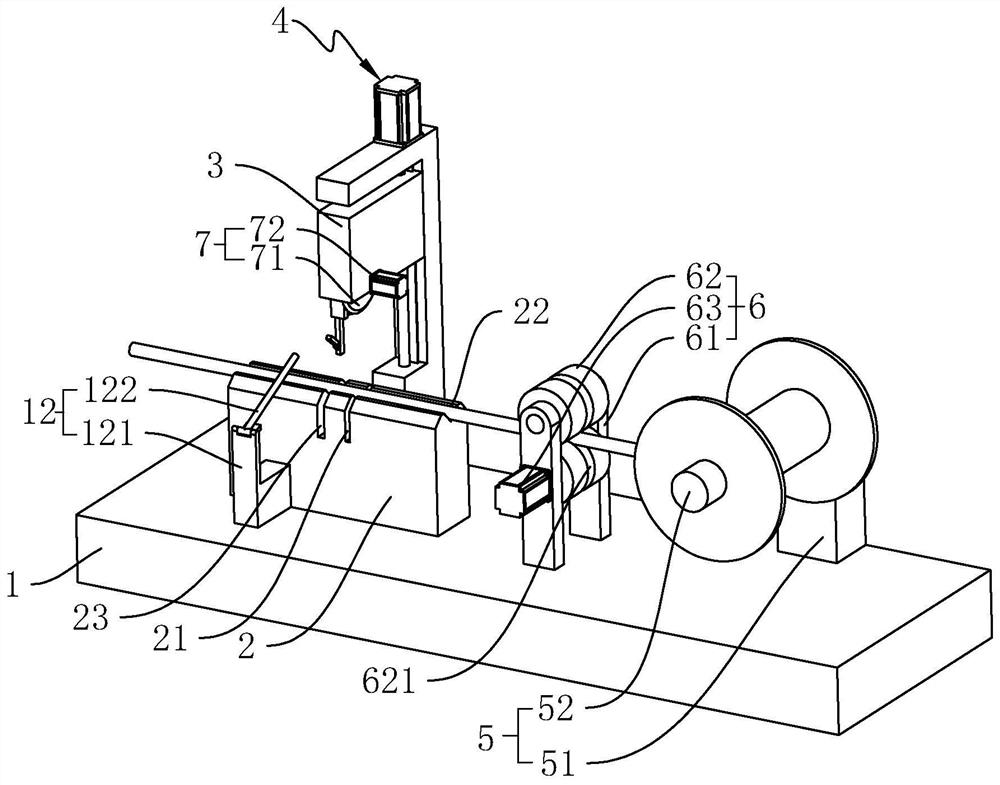

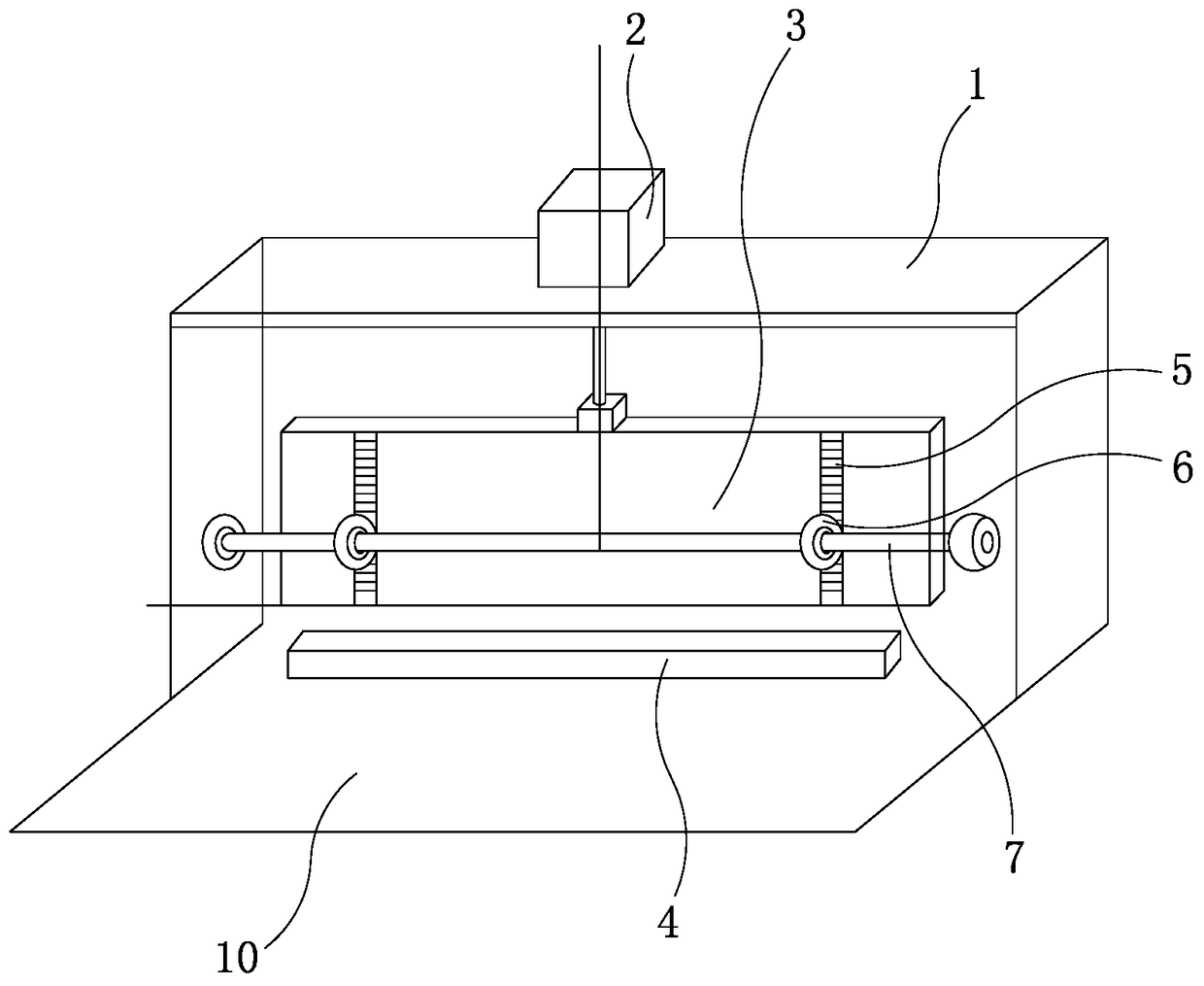

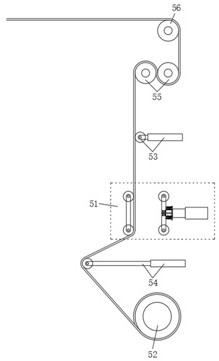

Preparation equipment and preparation method for novel composite fibers for high-altitude operation

ActiveCN113279243AImprove production efficiencyUniform speed windingFilament handlingSevering textilesFiberMaterial storage

The invention discloses preparation equipment and a preparation method for novel composite fibers for a high-altitude operation. The preparation equipment comprises a winding device, wherein the winding device comprises a material cutting assembly, a winding roller, a first material storage mechanism and a second material storage mechanism; the winding roller is located below the material cutting assembly, so that the composite fibers can be vertically conveyed downwards, and the conveying speed of the composite fibers is equal to the winding speed of the winding roller; the first material storage mechanism is arranged above the material cutting assembly, the first material storage mechanism is used for storing materials when the material cutting assembly cuts off the composite fibers and discharging the materials when the material cutting assembly resets after cutting off, and the material storage speed and the material discharging speed are both equal to the conveying speed of the composite fibers; and the second storage mechanism is arranged between the material cutting assembly and the winding roller, the second storage mechanism is used for discharging materials when the material cutting assembly cuts off the composite fibers and storing the materials when the material cutting assembly resets after cutting off, and the material discharging speed and the material storage speed are both equal to the winding speed of the winding roller.

Owner:江苏天华索具有限公司

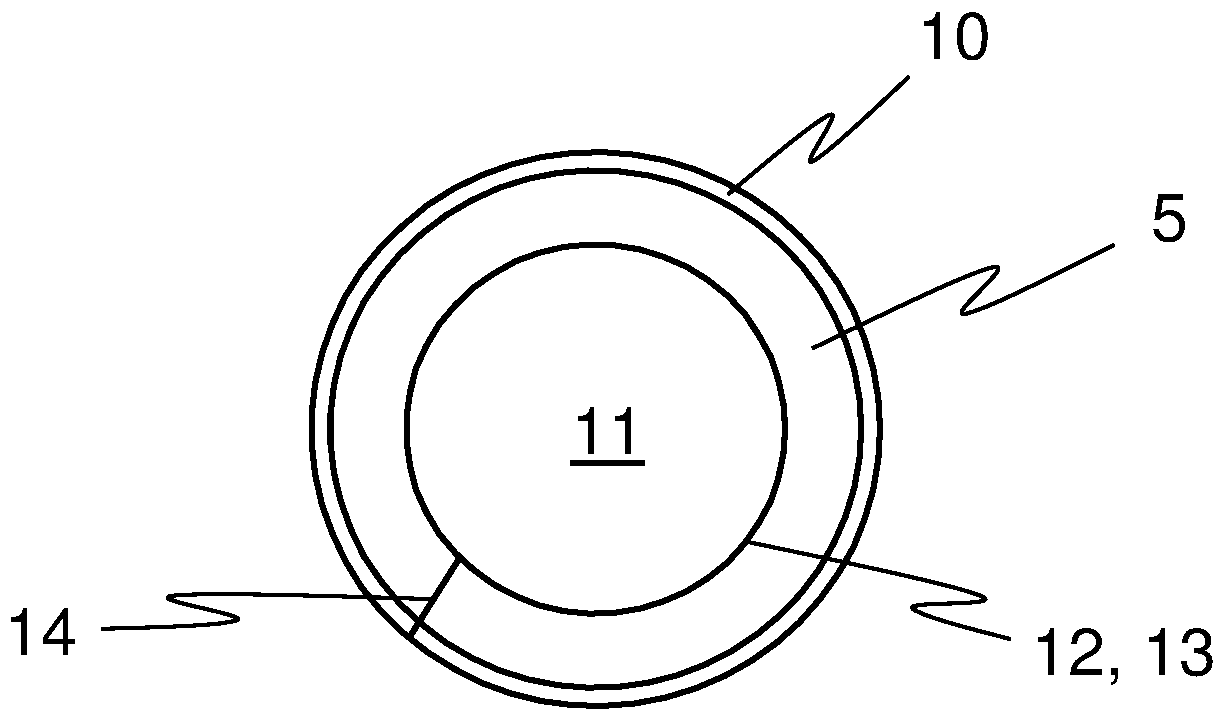

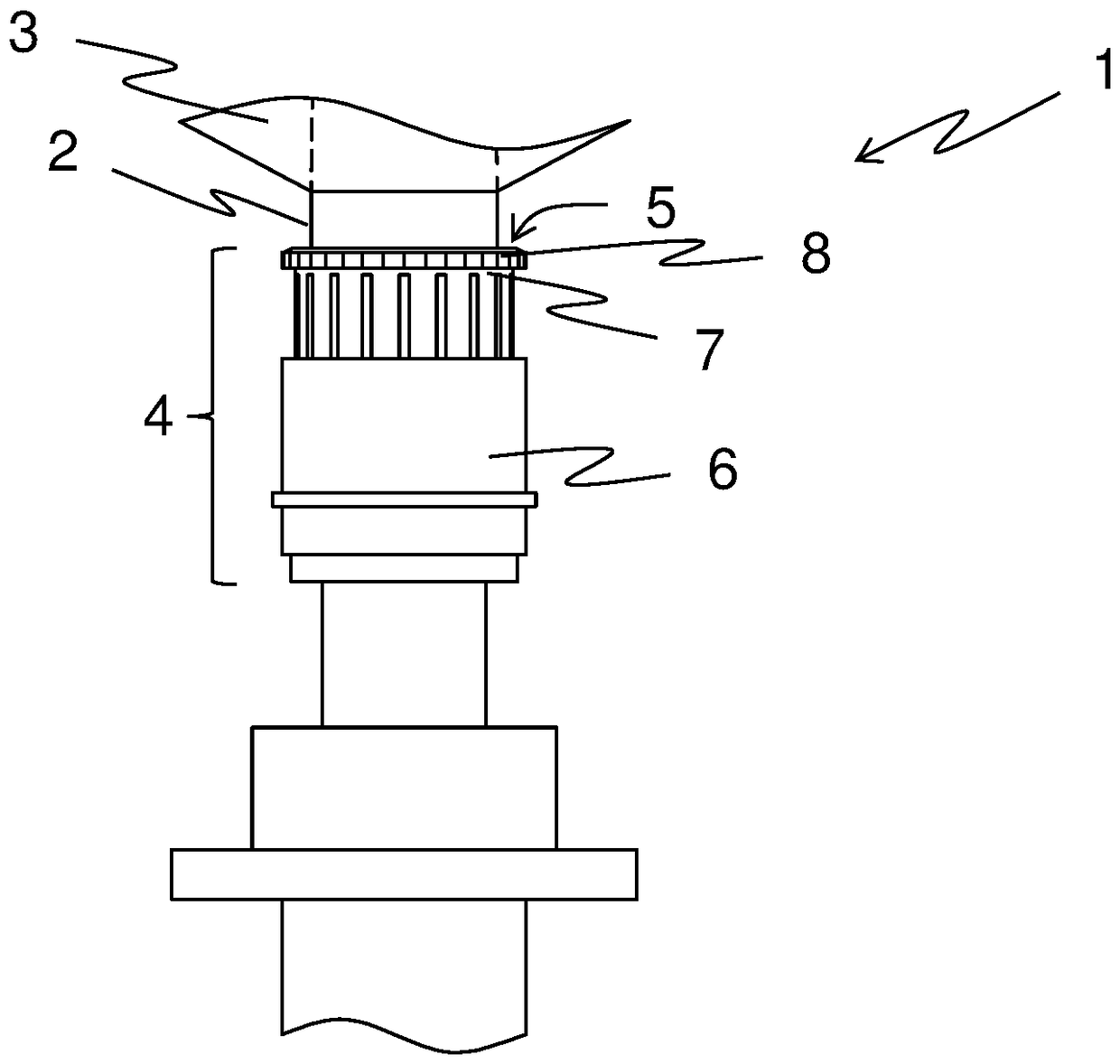

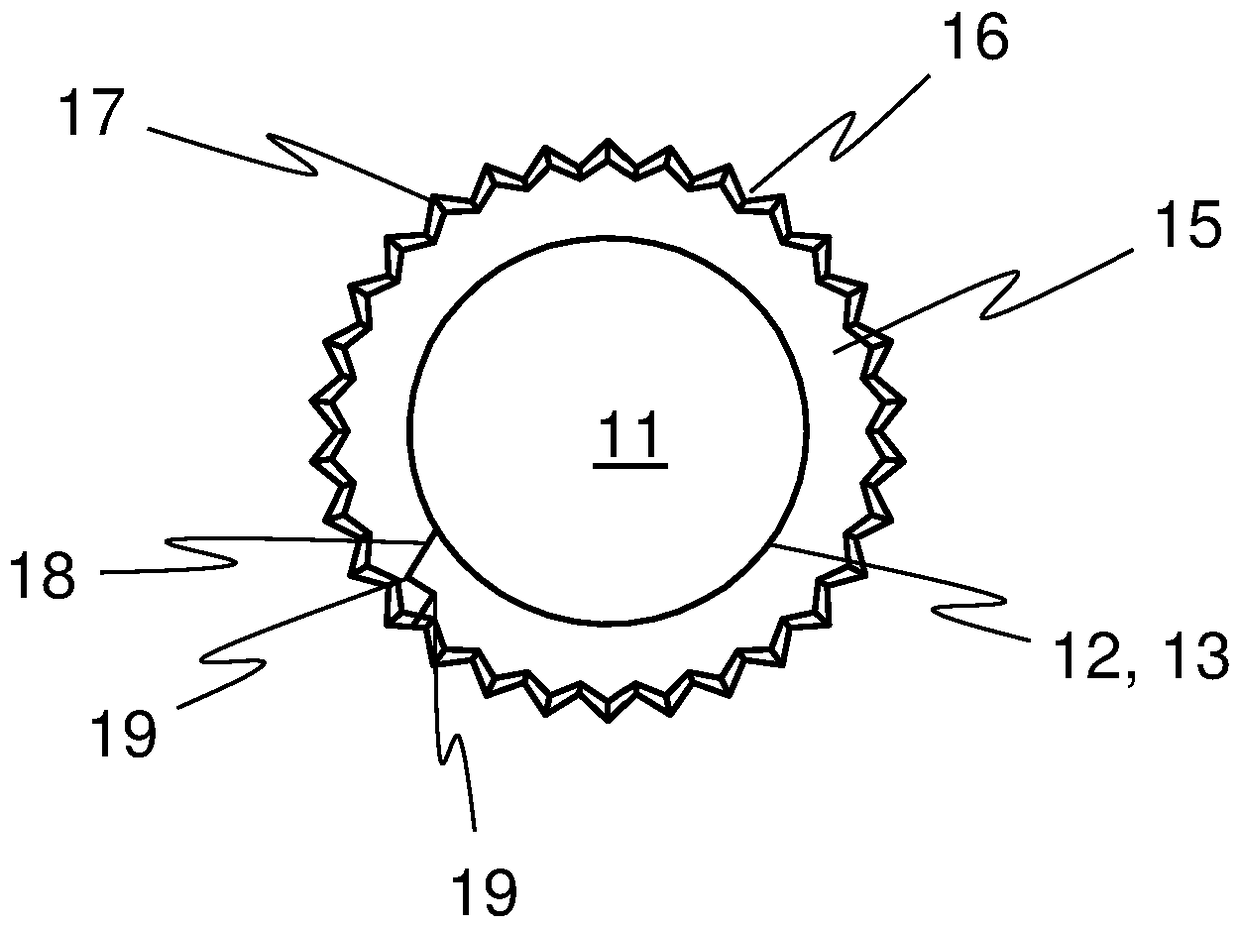

Cutting device

The present invention relates to a spindle (1) for a workstation of a textile machine, in particular of a ring spinning machine, having a shank (2) for receiving a tube which becomes a cop (3) as theresult of a thread being wound up, and a cutting device (5, 15, 20) for cutting the thread when the cop (3) is taken off the spindle (1), wherein the cutting device (5, 15, 20) has a cutout (11) for enclosing the shank (2), an inner region (12, 24) adjoining the cutout (11), and a cutting region (10, 16, 21). According to the invention, the inner region (12, 24) of the cutting device (5, 15, 20) has at least one clamping region (13, 25) for clamping the cutting device (5, 15, 20) to the shank (2). Furthermore, the invention relates to a cutting device (5, 15, 20) for cutting a thread when a cop (3) is taken off a spindle (1).

Owner:MASCHINENFABRIK RIETER AG

An automatic film extension device

The invention relates to a device for achieving continuous supply of films automatically. The device is simple in structure, high in working efficiency and capable of achieving automation film connection. The device comprises a machine frame, more than two unreeling rollers arranged on the machine frame in a rotary mode, a fusing device arranged in front of the unreeling rollers and used for cutting off the packaging films, a hot melting jointing device arranged in front of the fusing device and used for connecting two packaging films, and an electrical control system, wherein the fusing device comprises a support arranged on the machine frame, a fusing base arranged on the support, and a fusing driving device arranged on the support, two press-fit bases are arranged on the support and located above and below the fusing base respectively, the two press-fit bases can get away from or approach the fusing base under the driving of the fusing driving device, fusing wires communicated with an external power supply are arranged on the upper side and the lower side of the fusing base respectively, and the unreeling rollers, the hot melting jointing device, the fusing wires and the fusing driving device are all connected with the electrical control system.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

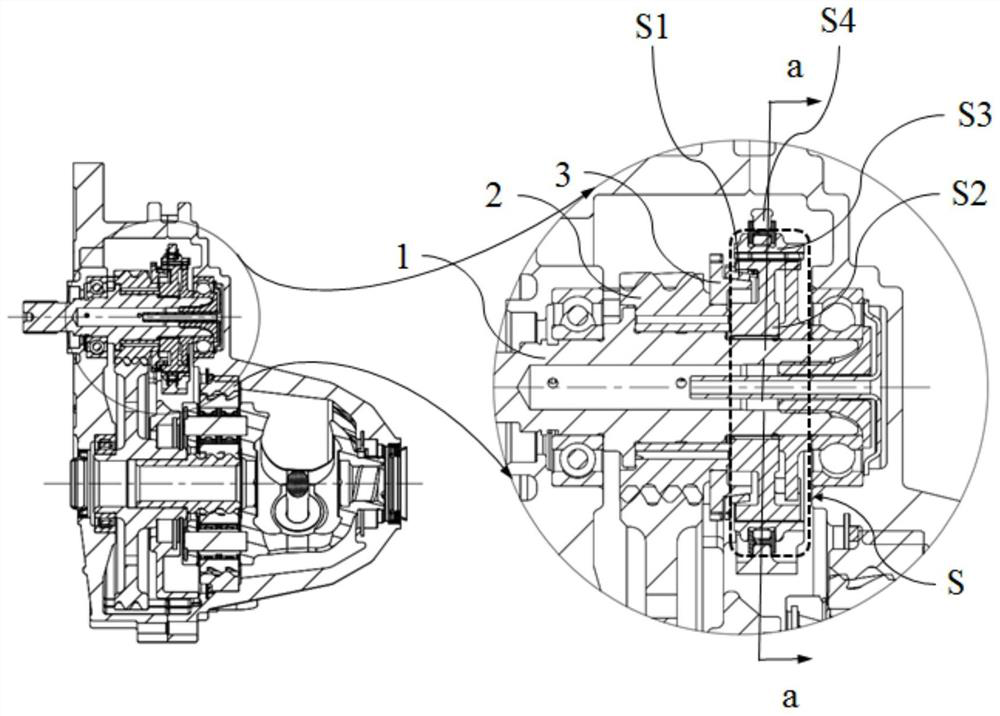

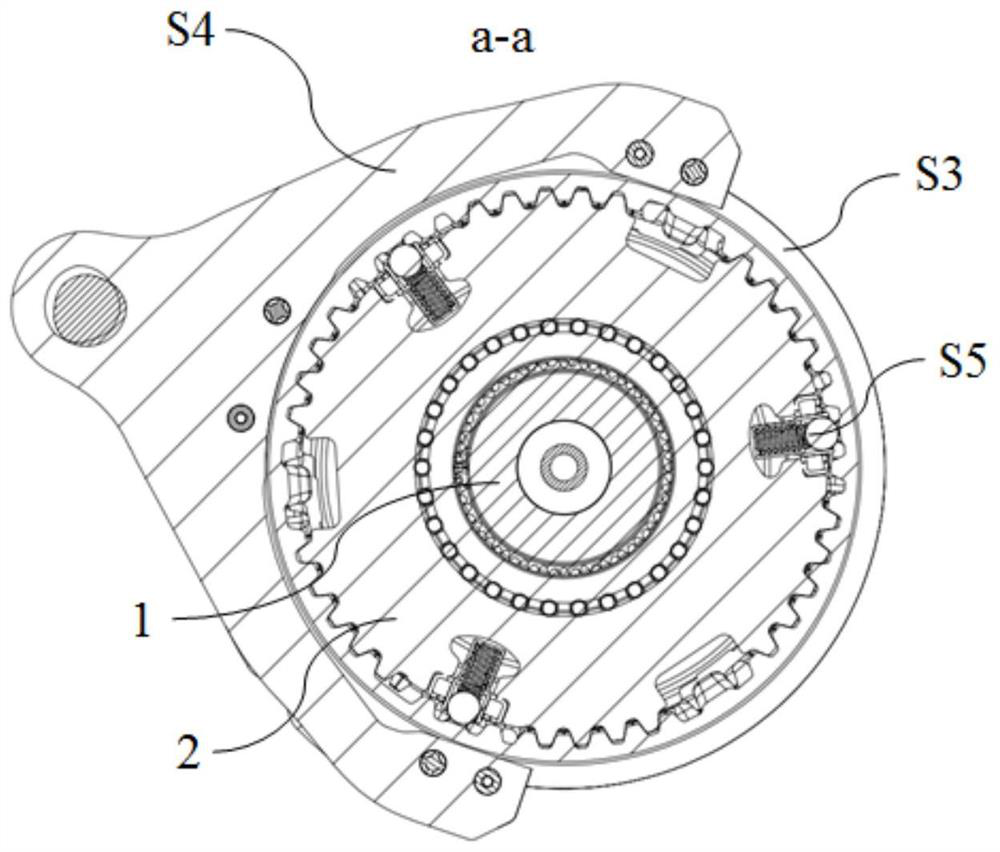

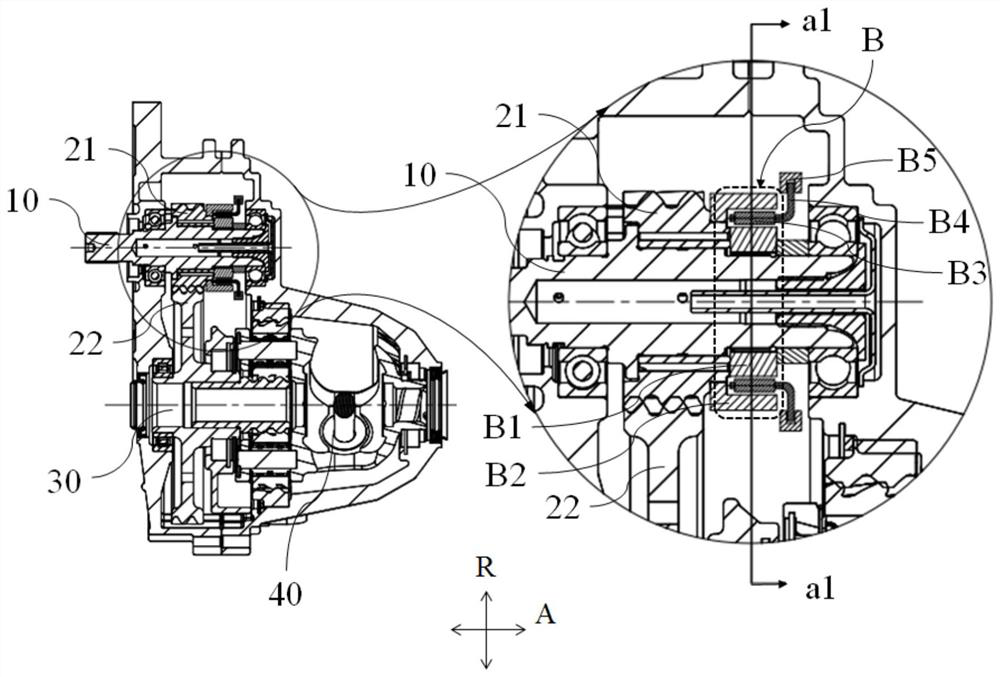

Synchronous bearing and electric shaft driving system of vehicle

PendingCN112413060ASimple structureEasy to operateMechanical actuated clutchesToothed gearingsClassical mechanicsTorque transmission

The invention provides a synchronous bearing and an electric shaft driving system of a vehicle. The synchronous bearing (B) comprises an inner ring (B1), an outer ring (B2), rolling bodies (B3) and aretainer (B4), the outer circumferential surface of the inner ring (B1) is sunken towards the radial inner side to define a plurality of grooves (G), the rolling bodies (B3) are accommodated in the grooves (G), the grooves (G) are provided with deep parts (G1) and shallow parts (G2, G3) with different radial depths, the retainer (B4) can abut against the inner ring (B1) to move in the axial direction and the circumferential direction at the same time, the rolling bodies (B3) move between the deep portion (G1) and the shallow portions (G2, G3), and therefore the rolling bodies (B3) can roll freely or be locked by the inner ring (B1) and the outer ring (B2). According to the synchronous bearing, the structure is simple, operation is convenient, and the torque transmission or cut-off processof an input shaft and an output shaft can be stably conducted.

Owner:SCHAEFFLER TECH AG & CO KG

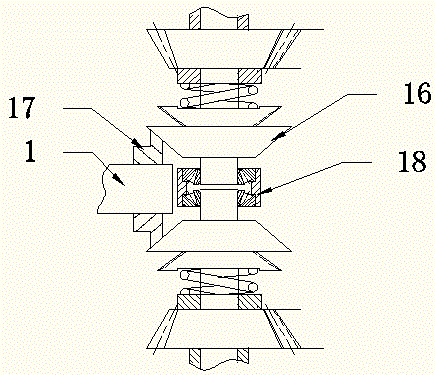

A ring-cloth double-cone friction type stepless automatic transmission device

ActiveCN105840755BEnsure stabilityWith self-adjusting functionGearingAutomatic transmissionDrive shaft

Owner:SHAOYANG UNIV

Safe film interrupting mechanism and film interrupting method thereof

The invention relates to the field of automatic film winding, in particular to a safe film interrupting mechanism. The safe film interrupting mechanism is rotatably arranged on a winding machine and comprises a support, a mounting base arranged on the support, a first guide roller mechanism arranged in the middle of the mounting base, an ironing mechanism arranged on the mounting base and located on one side of the first guide roller mechanism, and a cutting mechanism arranged on the side, away from the ironing mechanism, of the mounting base. The cutting mechanism comprises a cutting knife and a cutting driving device which is arranged on the mounting base and is used for driving the cutting knife to move up and down. The ironing mechanism comprises an ironing cylinder arranged on the mounting base, a supporting plate arranged on a piston rod of the ironing cylinder and an ironing plate arranged on the supporting plate. The technical problem that when an existing winding film machine adopts an electric heating component to achieve winding film breaking, fire potential safety hazards are prone to being generated is solved. The invention also provides a film interrupting method.

Owner:FUJIAN HENGAN HLDG CO LTD +2

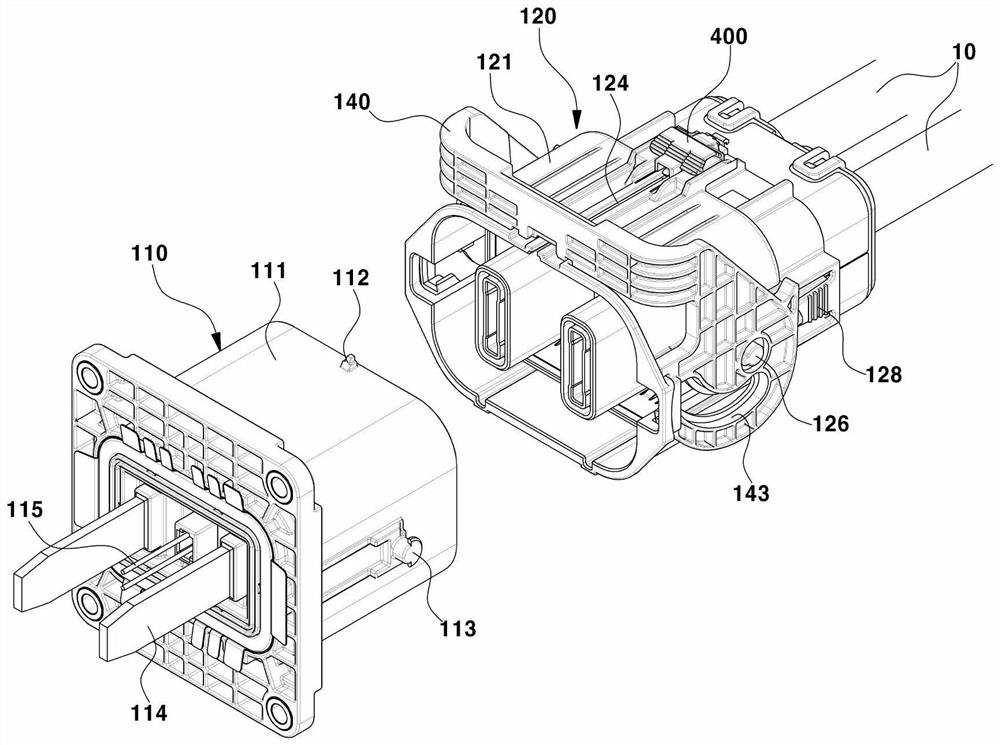

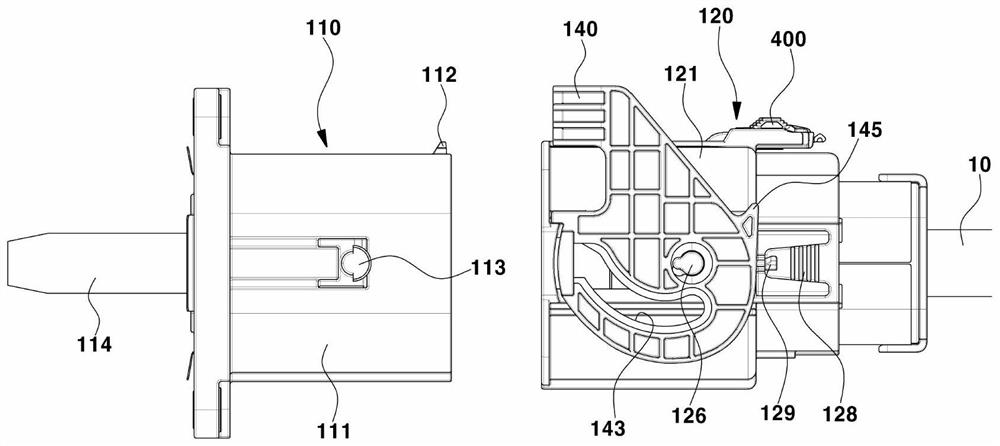

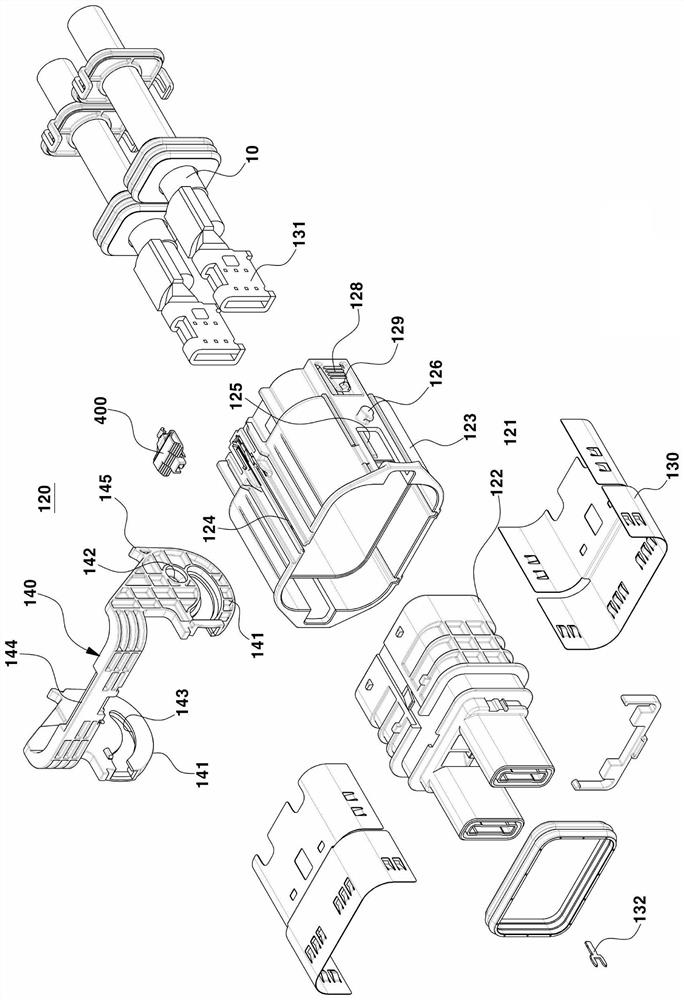

Connector assembly

PendingCN114696166ACut off stabilitySafe separationVehicle connectorsCoupling contact membersStructural engineeringMechanical engineering

Disclosed is a connector assembly which enables electrically safe disconnection and disconnection because it is possible to ensure a time interval between a disconnection time point of an interlock terminal and a disconnection time point of a power supply terminal when a connector is disconnected. To disconnect and separate the female connector and the male connector, the connector assembly may include an intermediate locking mechanism that restricts a lever for disconnecting the connectors in a state in which the interlock terminals of the two connectors are separated from each other and the power terminals of the two connectors are in contact with each other, in this way, a two-step disconnection can be achieved in which the power supply is switched off after the lever is limited in the intermediate locked state and then the connector is completely disconnected by the additional operating lever.

Owner:HYUNDAI MOTOR CO LTD +2

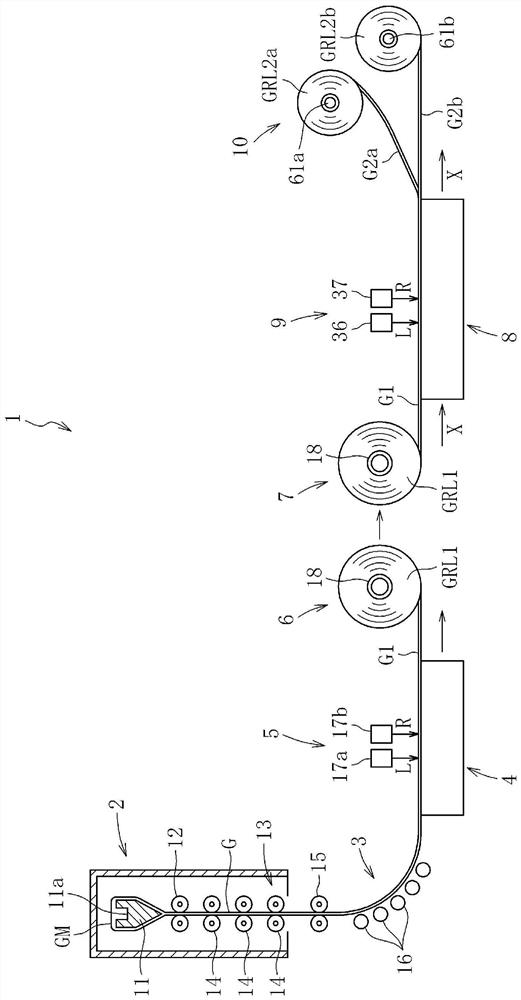

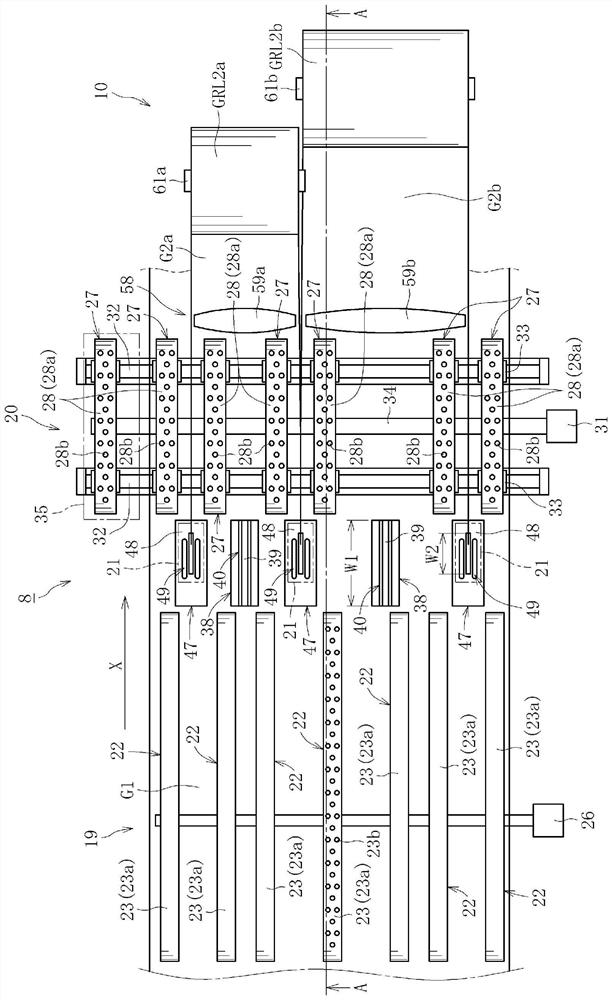

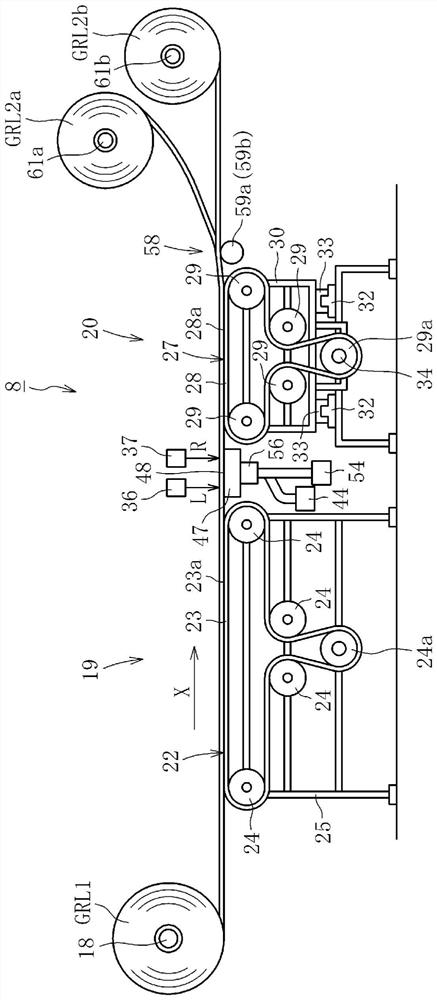

Glass film manufacturing method, glass roll manufacturing method, and glass film manufacturing device

PendingCN114761364ACut off stabilityImprove qualityConveyorsGlass transportation apparatusCutting glassLaser light

A method for producing a glass film (G1), the method including at least a cutting step (S5) for cutting a band-shaped glass film (G1) while conveying the band-shaped glass film (G1) in a predetermined direction by a conveyance device (8), and in the cutting step (S5), the glass film (G1) is cut in a predetermined cutting region (21) by irradiating the glass film (G1) with laser light (L). The support conveyance surfaces (23a, 28a) of the glass film (G1) of the conveyance device (8) are broken in the cutting region (21) of the glass film (G1). In addition, a first platform (38) that can contact and support the glass films (G2a, G2b) is disposed at a position that is located in the width direction of the glass film (G1) with respect to the cutting region (21) and corresponds to the center side in the width direction of the cut glass films (G2a, G2b).

Owner:NIPPON ELECTRIC GLASS CO LTD

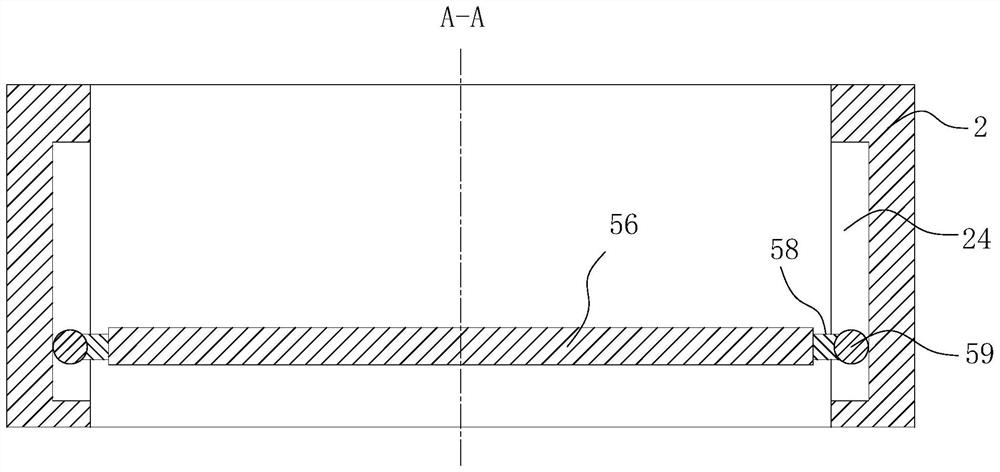

Semiconductor device

InactiveCN100442446CCut off stabilityWon't breakDecorative surface effectsSemiconductor/solid-state device manufacturingForeign matterEngineering

A semiconductor device, wherein a substrate (51) is formed in a rectangular shape with four sides along dicing lines, and a jetty part (56) is formed to surround all the peripheries of an actuator element (50) and electrode pads (54) and (55) for input / output. The jetty part (56) is formed in a rectangular shape with four sides, and each side thereof is continuously extended parallel with each side of the substrate (51). Since the adhesion of a protective tape (9) can be increased by the jetty part (56), foreign matters (104) produced in dicing can be prevented from adhering to the actuator element (50) and the electrode pads (54) and (55).

Owner:TOKYO ELECTRON LTD

Cutting mechanism of spring coiling machine

The invention discloses a cutting mechanism of a spring coiling machine, and relates to the technical field of spring coiling machines. The cutting mechanism comprises a machine cabinet, a long main plate is arranged on one side of the machine cabinet through lifting, and an adjusting assembly is arranged between the machine cabinet and the long main plate; a core bar is inserted into the middle of the long main plate, main connecting bases are movably arranged at the two ends of the long main plate, cutter bases are arranged at the ends, away from the long main plate, of the main connecting bases, cutters are inserted into the cutter bases, and adjusting assemblies are arranged between the main connecting bases and the long main plate. The long main plate can drive the cutters and the core bar to wholly move, lifting is carried out according to changes of external diameters of the springs accordingly, and steel wires are not conceded in the cutting process of the cutters, and are morestably cut off; the two cutters are independently controlled respectively, processing modes of a left-rotating spring and a right-rotating spring can be switched at random, and adjustment is free andconvenient and fast; travels of the cutters are shortened, cutting space is reduced, cutting points of the cutters are more stable and accurate, completeness of cut surfaces of the steel wires is guaranteed, and the quality of formed springs is higher.

Owner:湖北江一特智能科技有限公司

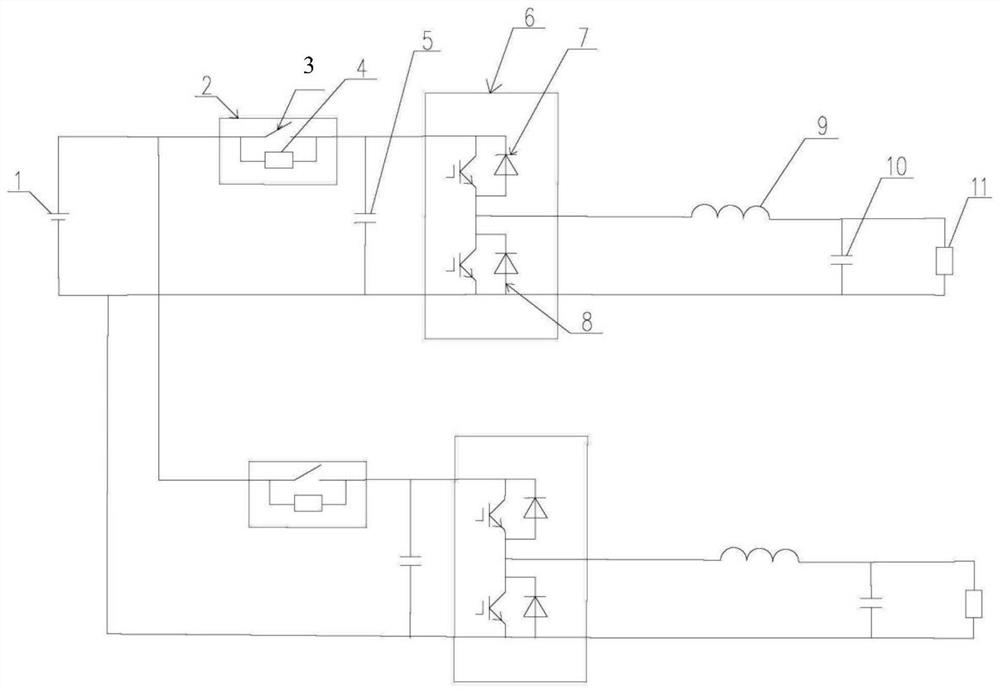

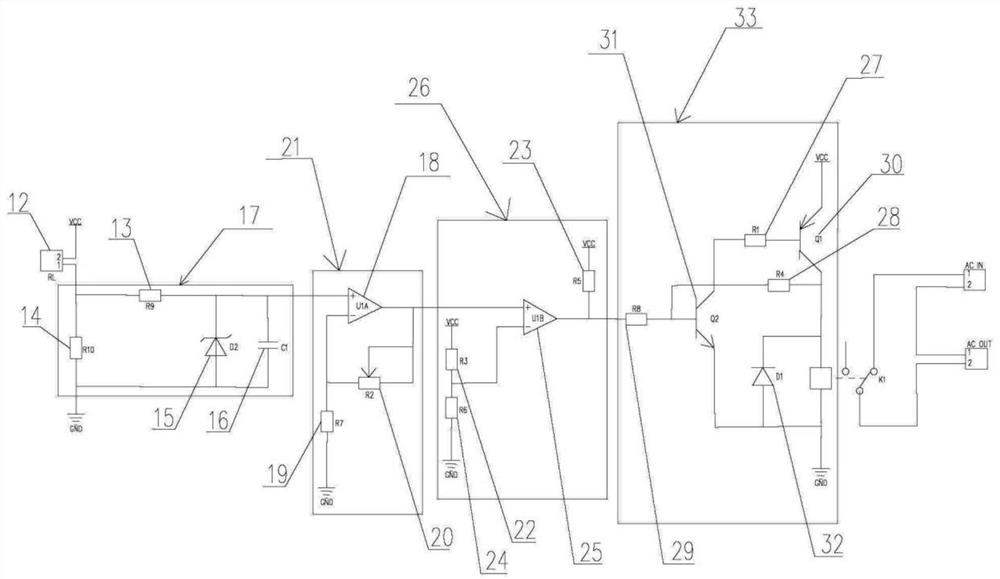

DC-DC converter and overcurrent protection circuit thereof

PendingCN113036723ASafety cut offCut off stabilityEmergency protective circuit arrangementsDc-dc conversionHemt circuitsControl theory

The invention relates to a DC-DC converter and an overcurrent protection circuit thereof, which belong to the technical field of low-voltage power distribution networks and power electronics. The overcurrent protection circuit can accurately detect the change condition of the load current, the first triode is controlled to be switched on under the condition of overcurrent of the load current, after the first triode is switched on, the collector of the first triode is changed into low level to enable the second triode to be switched on, VCC is loaded to the base of the first triode through the collector of the second triode, self-locking is formed, and the power supply of the DC-DC converter can be safely and stably cut off during overcurrent. Overcurrent protection is achieved through the driving and self-locking circuit composed of the two triodes, the cost is low, and the anti-interference capacity is high.

Owner:国网河北省电力有限公司雄安新区供电公司 +2

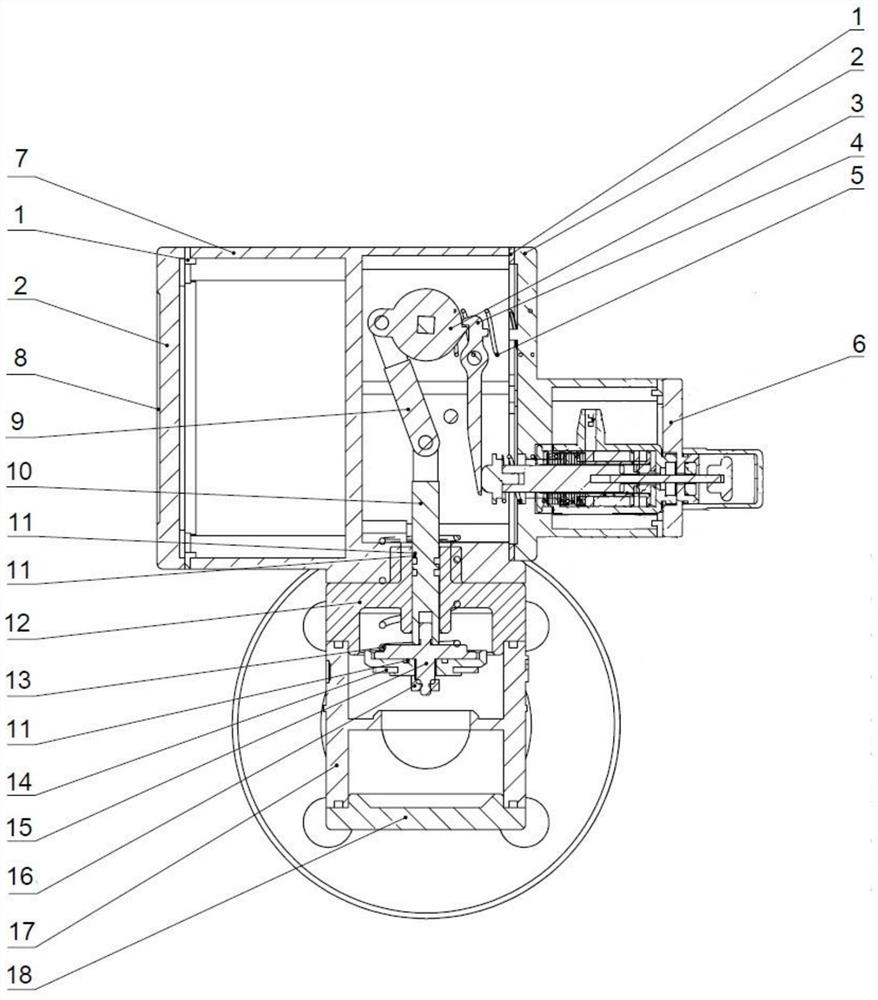

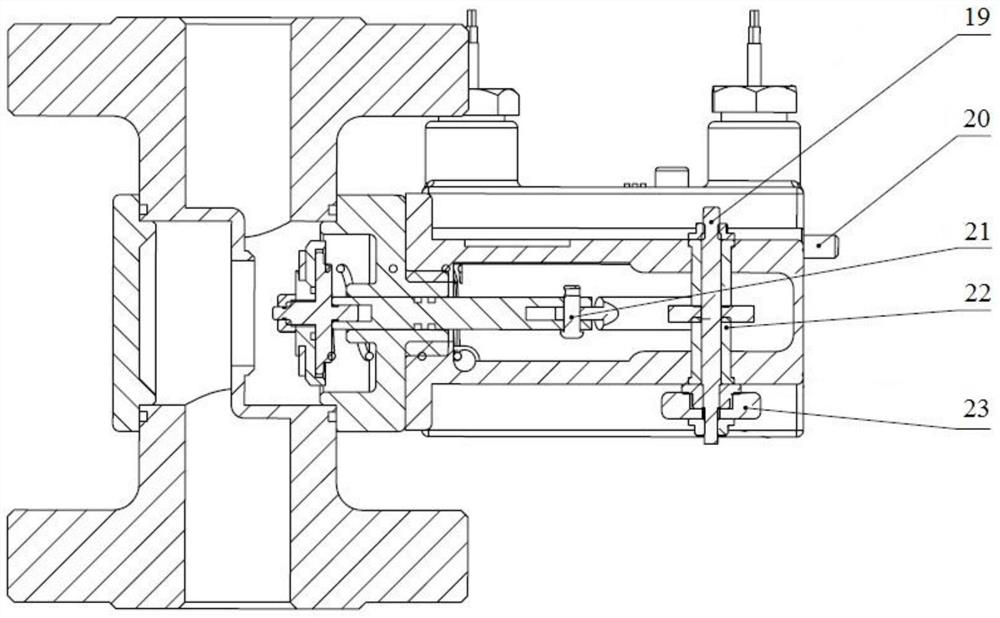

A mechanical electromagnetic gas emergency cut-off valve

ActiveCN106122575BSolve problems such as errorsGuaranteed closing and opening efficiencyOperating means/releasing devices for valvesEngineeringCam

The invention discloses a mechanical electromagnetic type fuel gas emergency shut-off valve which comprises a valve body, a shell, a valve deck, a valve element, a valve clack, reset springs and an actuating mechanism, wherein the valve element comprises a mandrel, a connecting rod, a cam and a pothook; the lower part of the mandrel is connected with the valve clack; the middle of the mandrel is mounted on the valve body in a sliding and sealing manner; the upper part of the mandrel stretches into the shell to be hinged to the lower end of the connecting rod; the cam and the pothook are rotatably mounted on the shell; one end of the cam is hinged to the upper end of the connecting rod, and a lug matched with the pothook is arranged at the other end of the cam; the lower part of the pothook abuts against the actuating mechanism, and the upper end of the pothook is hooked on the lug of the cam through the reset spring II. The mechanical electromagnetic type fuel gas emergency shut-off valve can be rapidly started under any circumstance, can resist against complex pipeline pressure, and is simple in structure, safe and reliable, unlikely to damage, long in service life, and applicable to popularization and application.

Owner:HEBEI QINHAN ELECTRONICS TECH CO LTD

A sheet metal stamping die based on flat demoulding

Owner:佛山市普瑞生数控钣金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com