Patents

Literature

48results about How to "Play a role in compressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

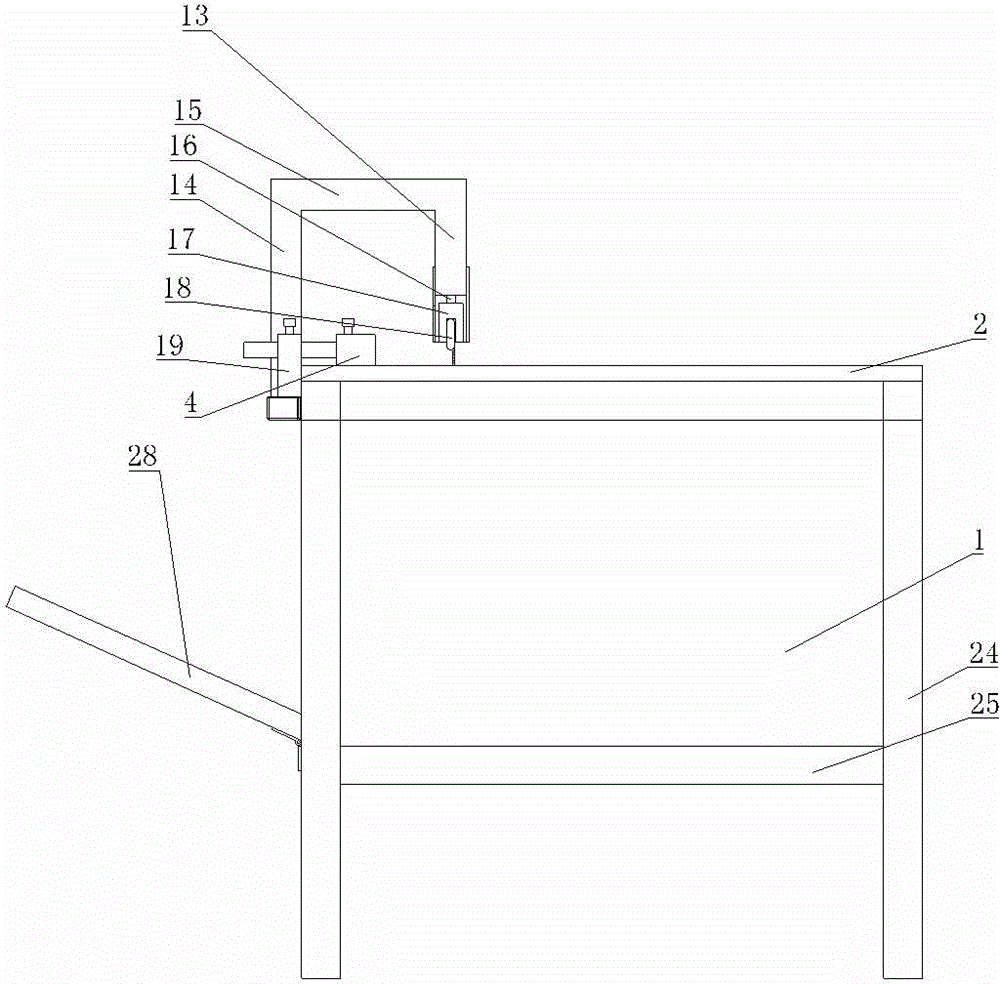

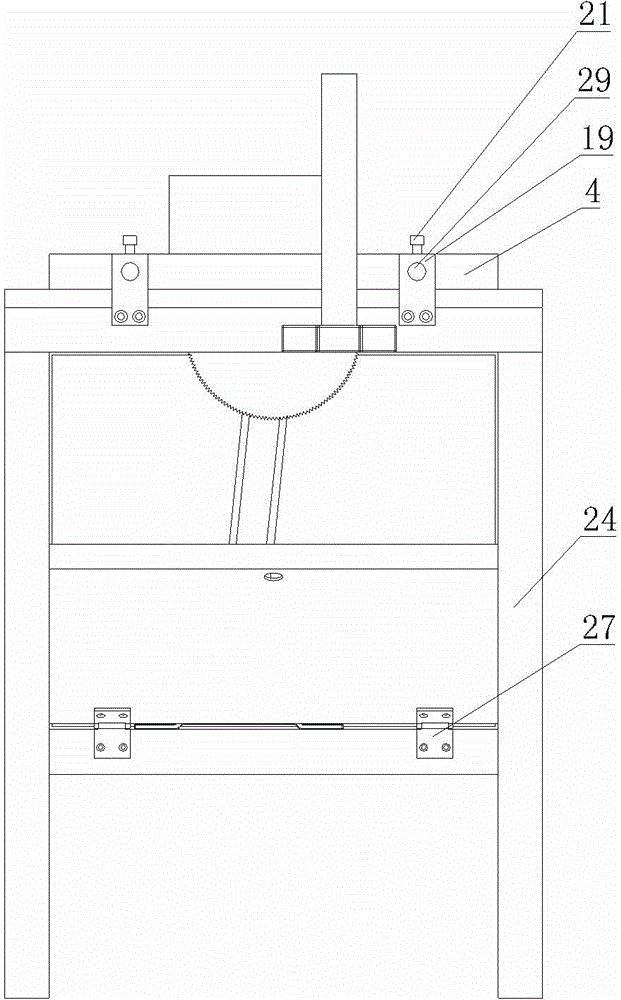

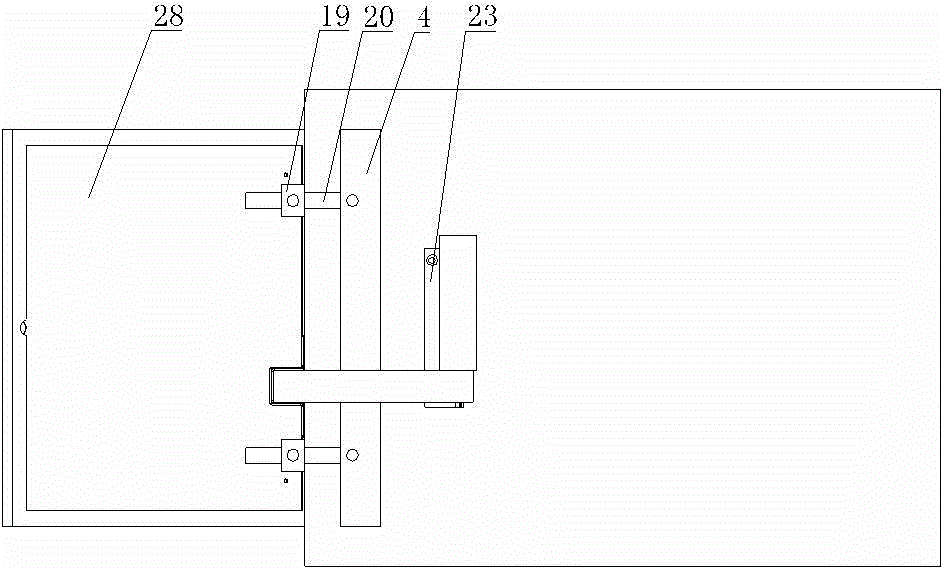

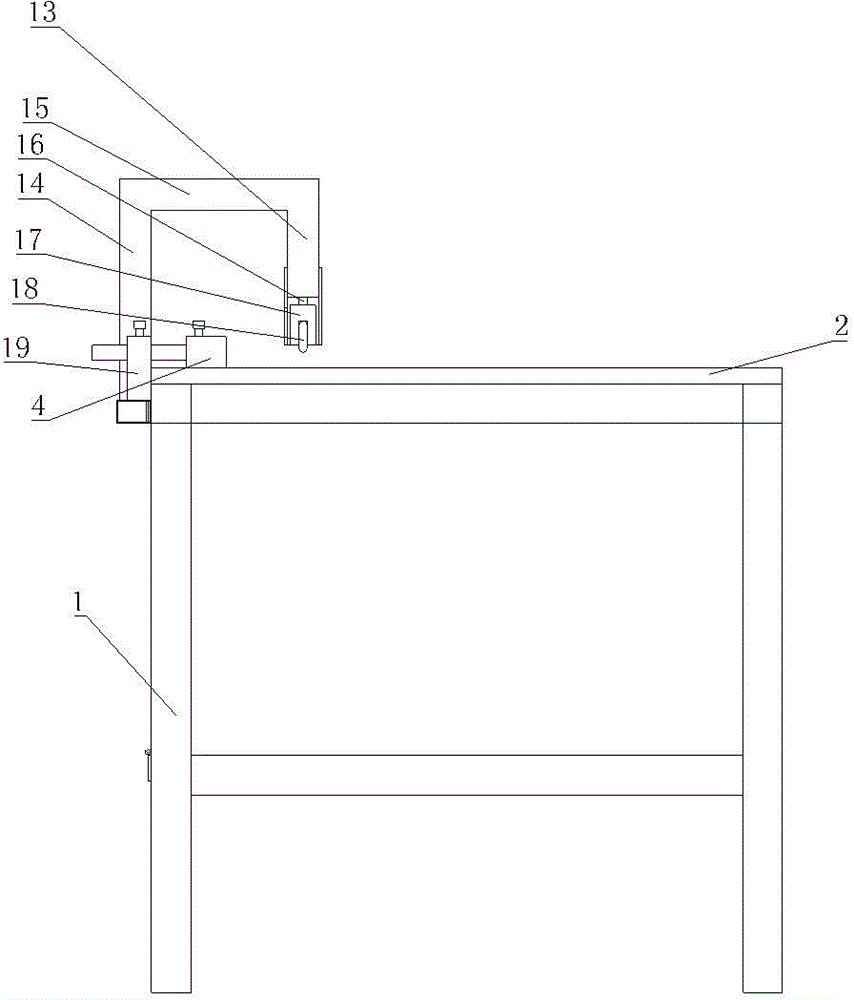

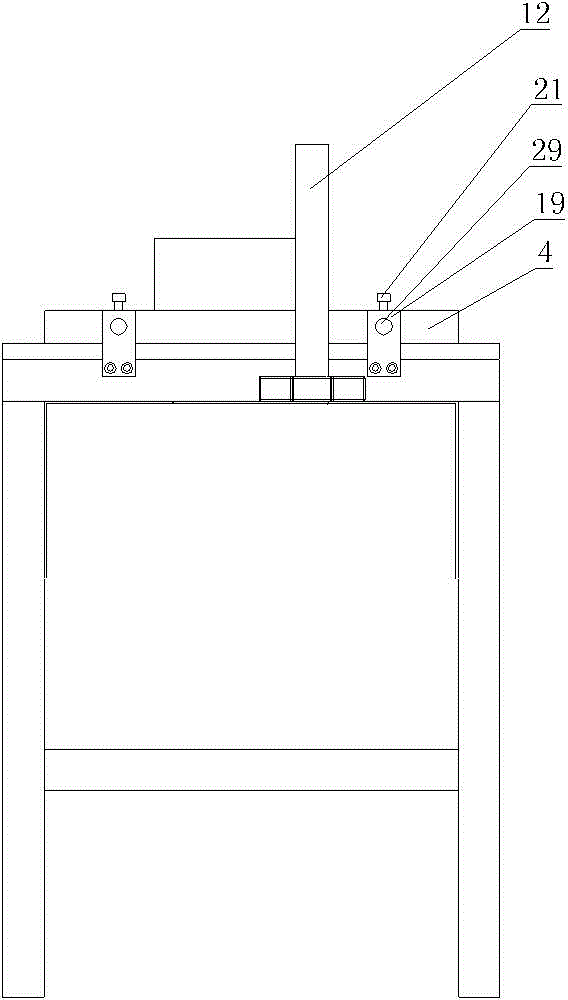

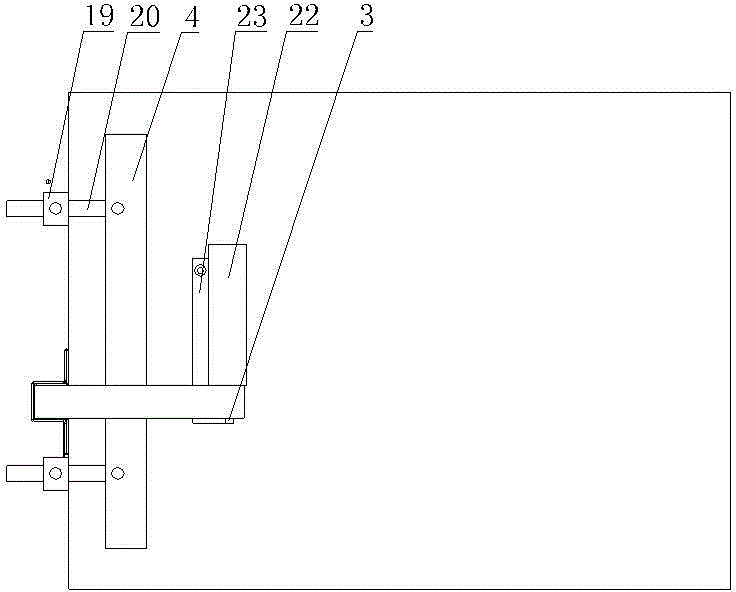

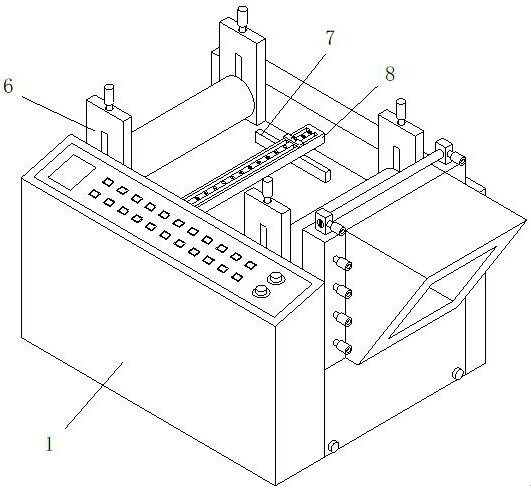

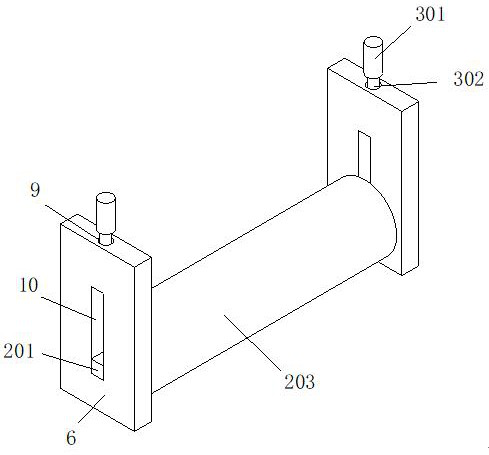

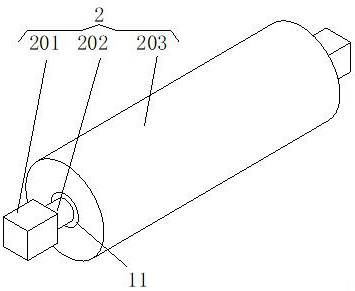

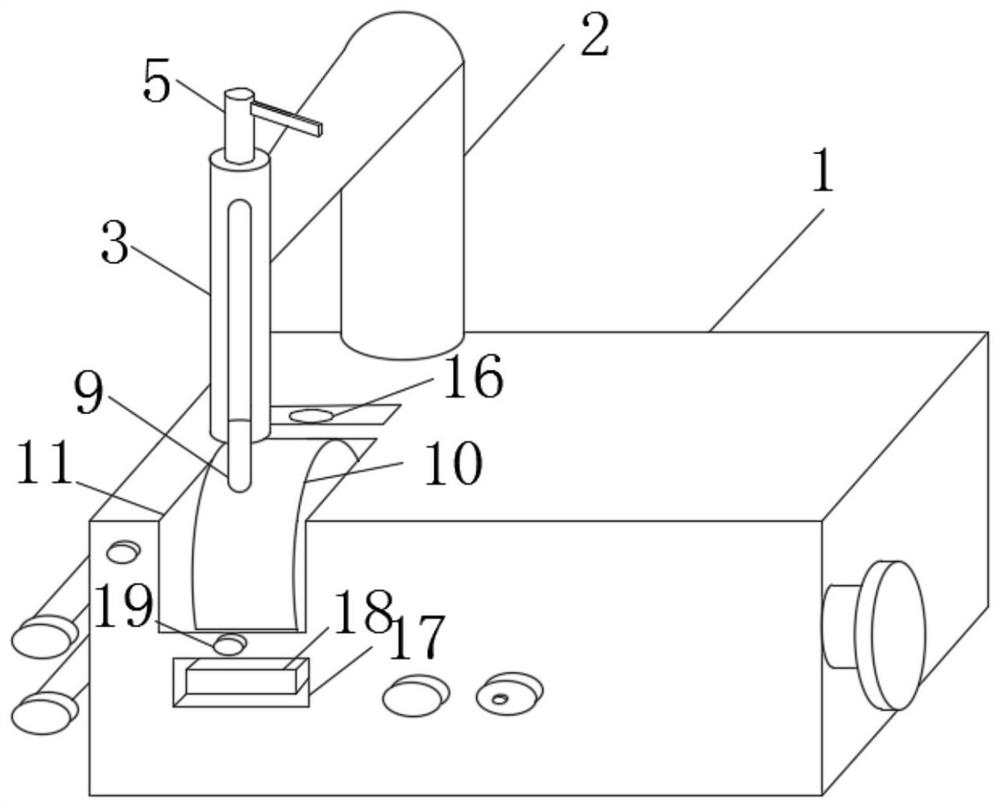

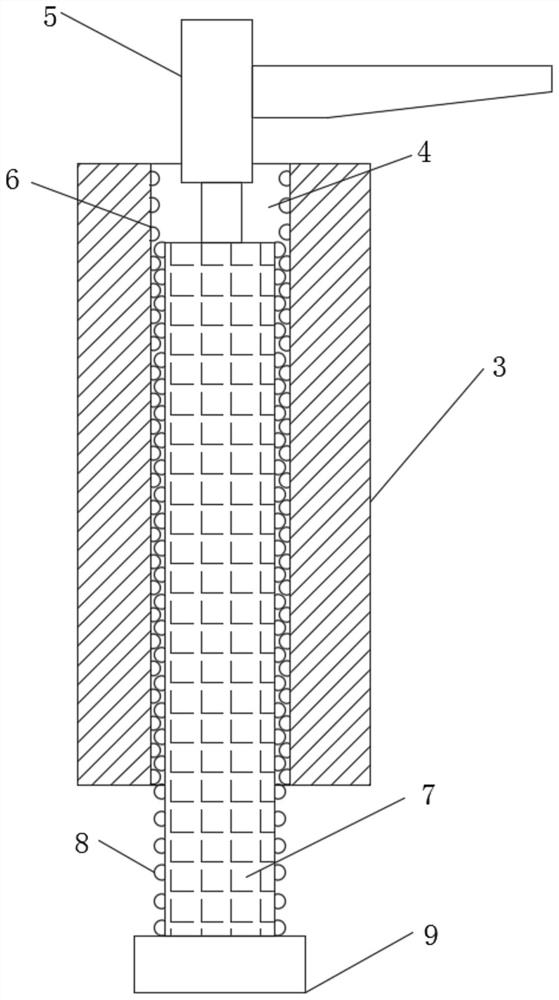

Intelligent numerically-controlled hydraulic sheet shearing machine

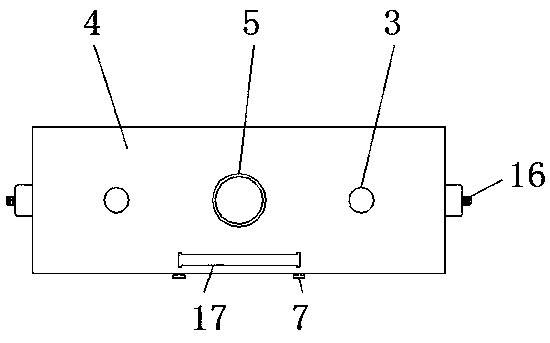

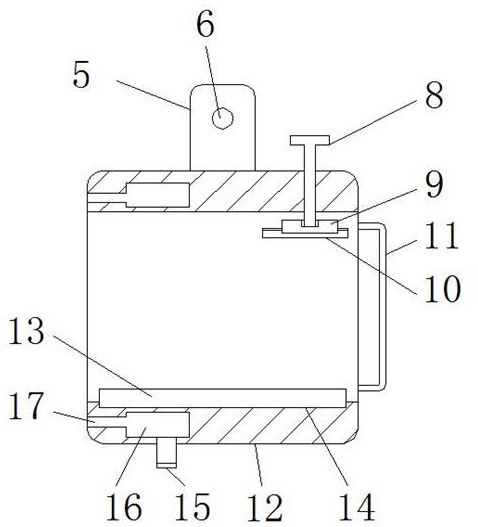

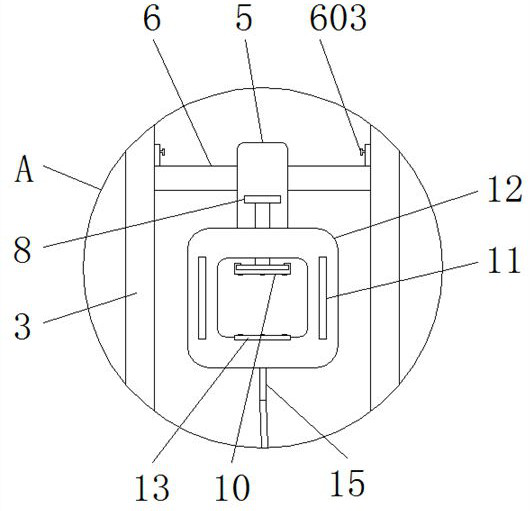

PendingCN111774634APlay a role in compressingEasy to move to the leftShearing machinesShearing machine accessoriesStructural engineeringMachine

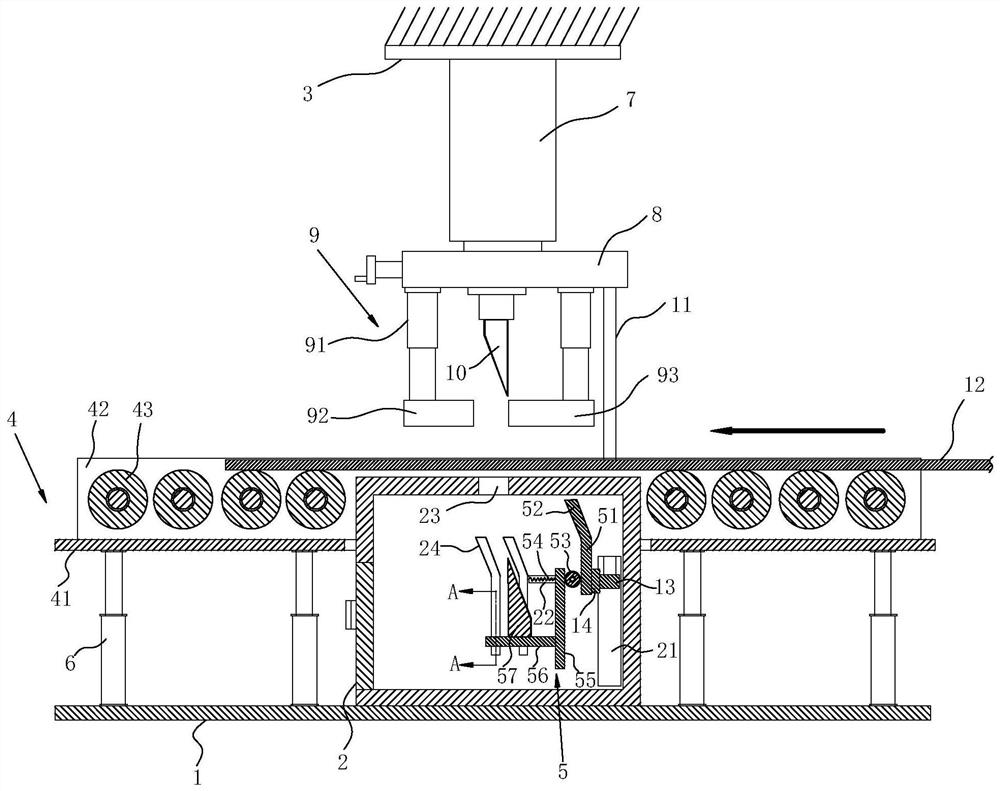

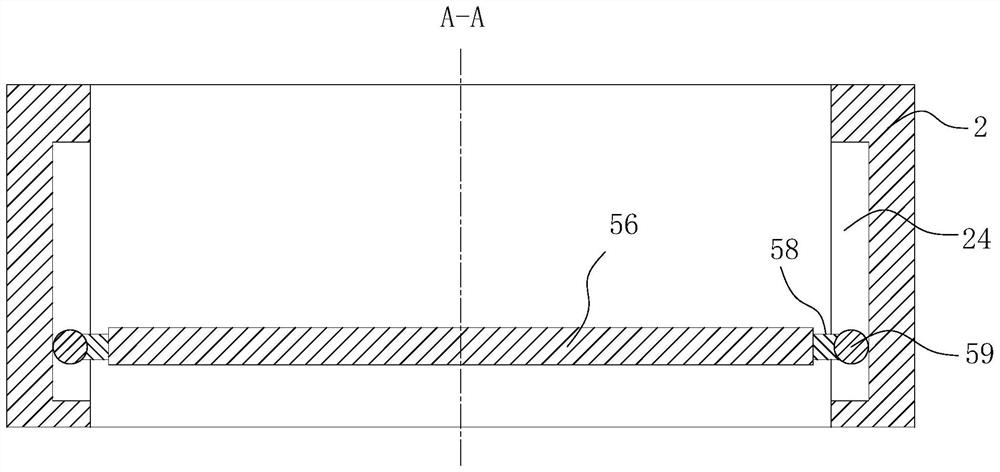

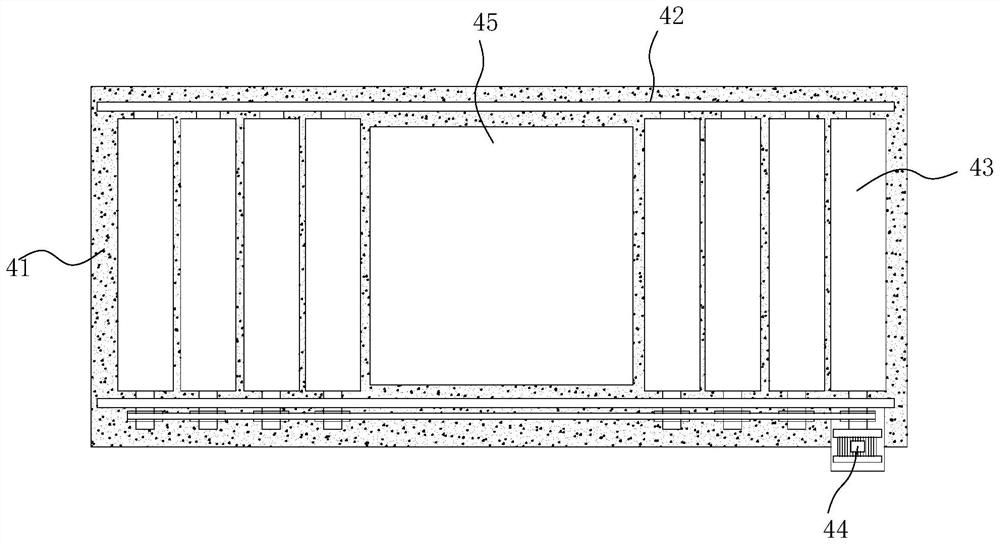

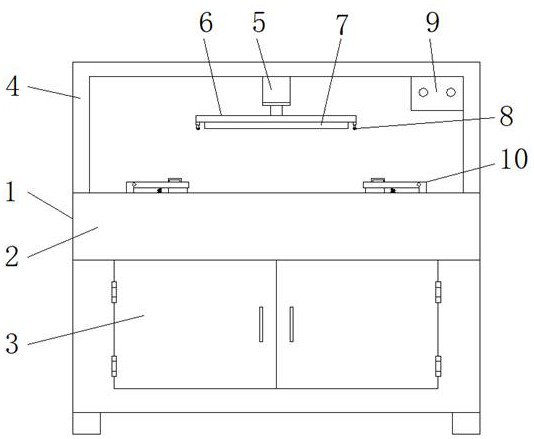

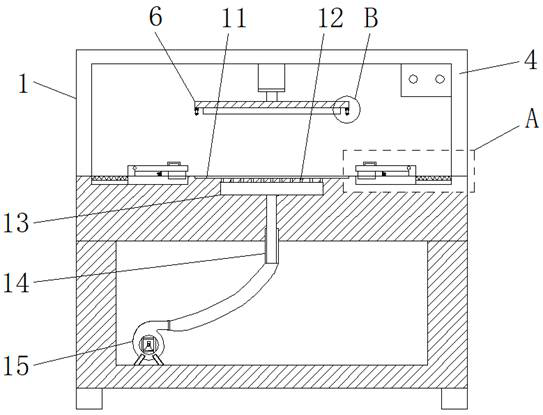

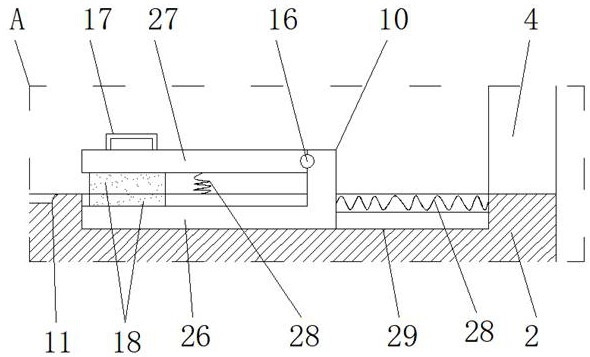

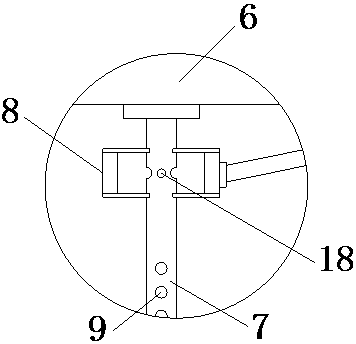

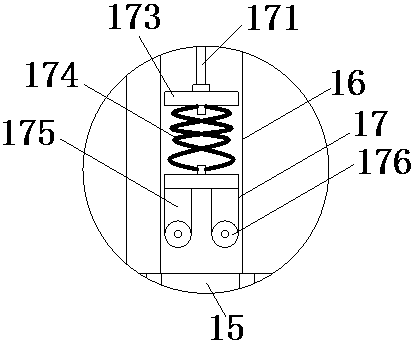

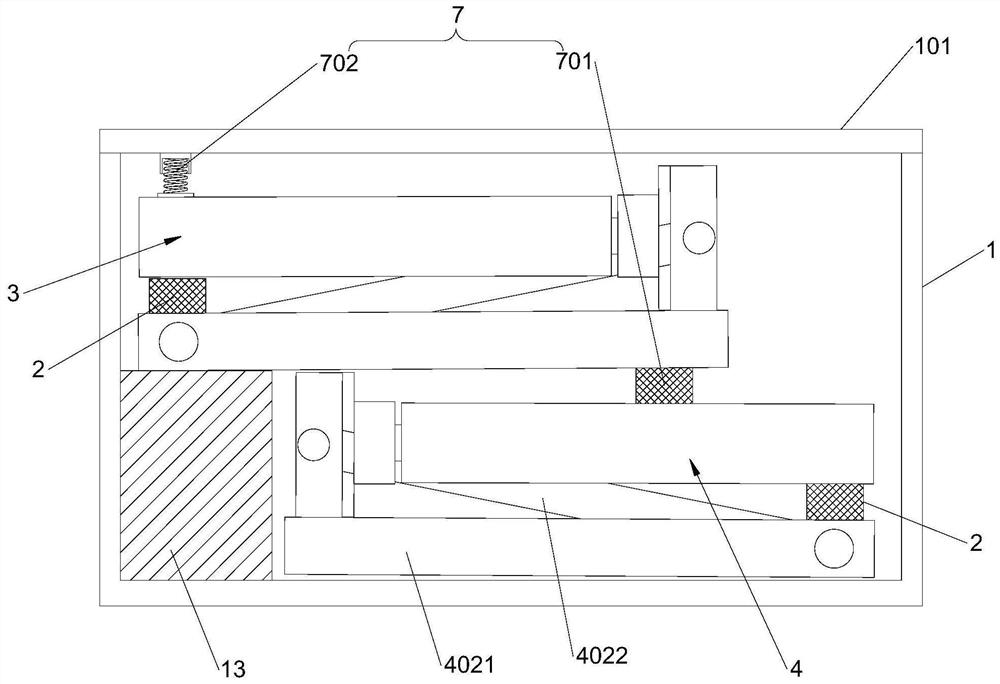

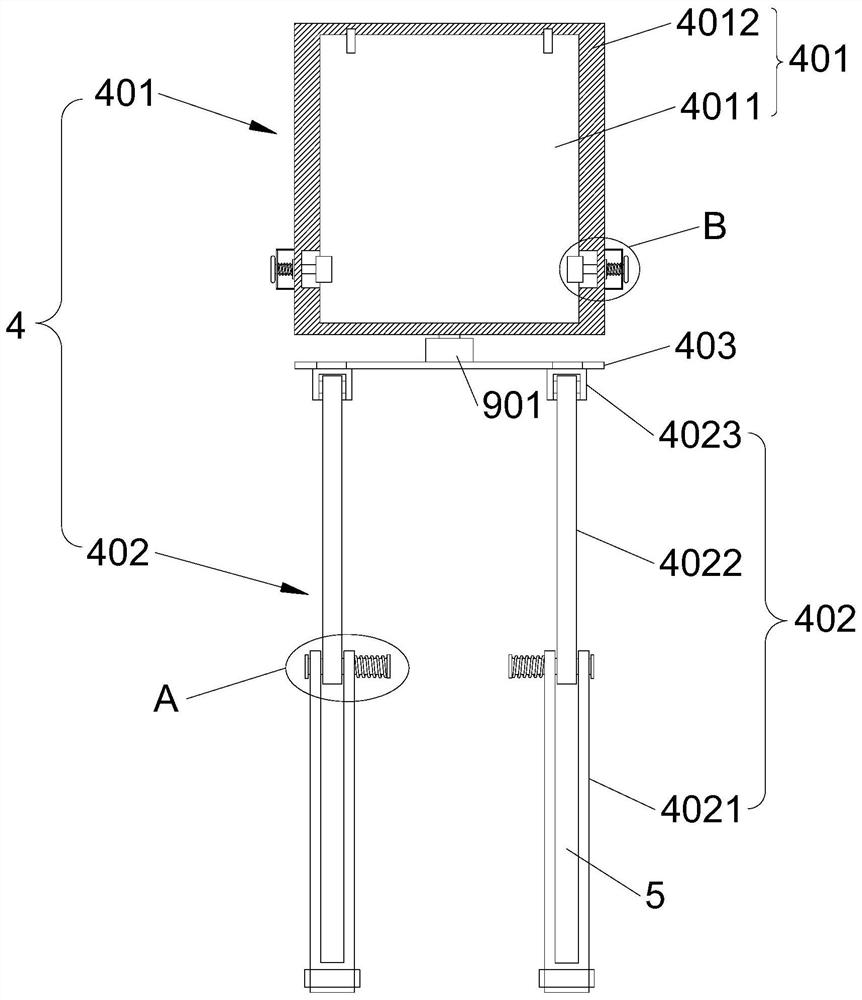

The invention discloses an intelligent numerically-controlled hydraulic sheet shearing machine, and belongs to the technical field of sheet shearing machines. The machine comprises a base, spring telescopic columns, a conveying mechanism, a fixing frame, a pressing mechanism, a workbench and an extruding mechanism; the base is transversely arranged on a bottom surface; the multiple spring telescopic columns are vertically fixed to the top of the base; the pressing mechanism comprises pressing rods symmetrically arranged on the two sides of a sheet shearing cutter; the workbench is fixed to themiddle of the base, the interior of the workbench is of a hollow structure, the top of the workbench is provided with a sheet shearing opening part, and the rear inner wall of the workbench is provided with a transverse sliding groove; and the extruding mechanism comprises a sliding block arranged in the sliding groove. According to the machine, the inventive concept is ingenious and the practicability is high; when a mounting base moves downwards, the sheet shearing cutter can be driven to move downwards so as to shear a steel sheet, the folded edge of the cut steel sheet can be extruded tobe flat, and burrs at the cut position can be polished; and the application range is wide, and the machine is suitable for application and popularization.

Owner:苏强

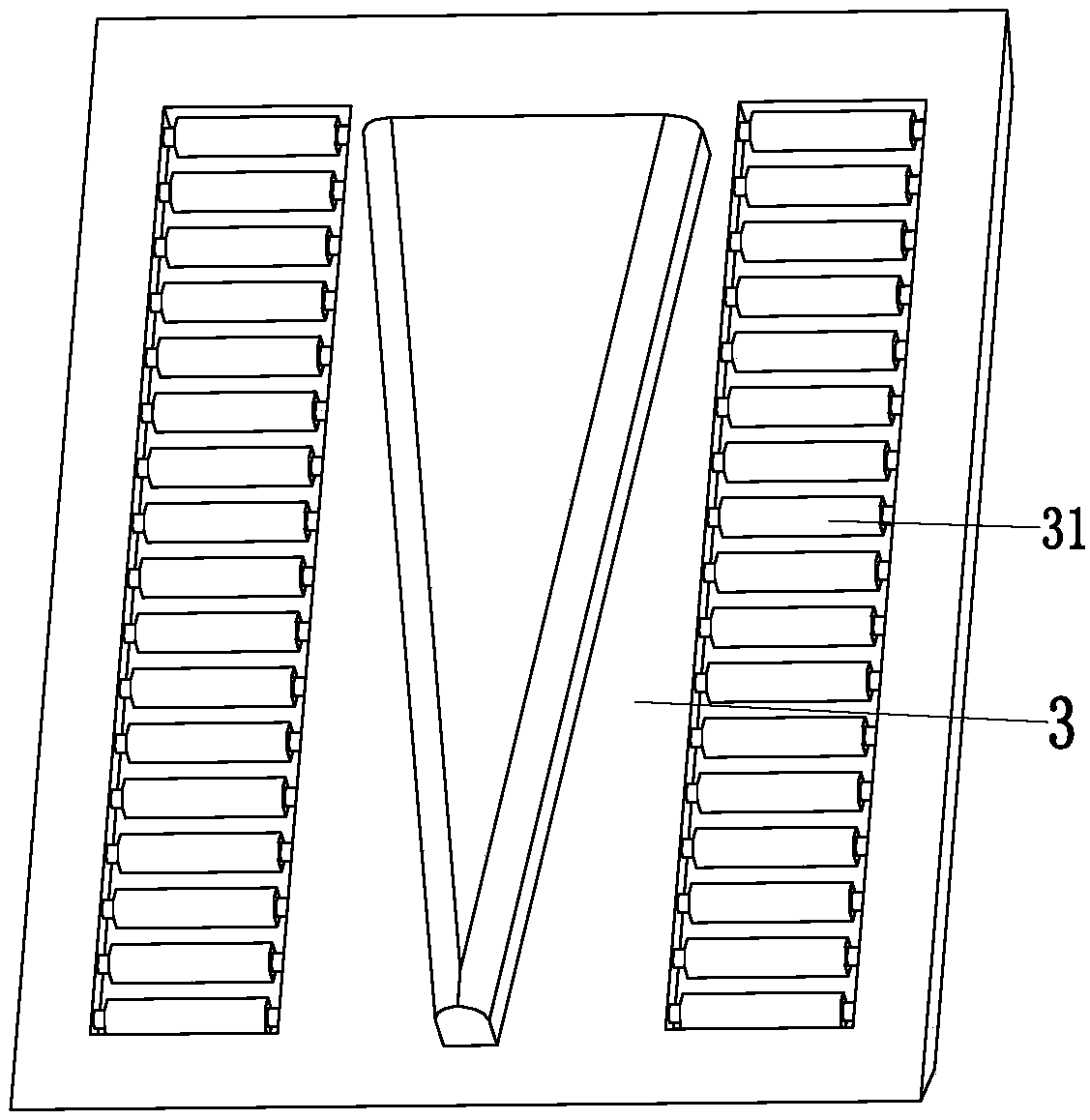

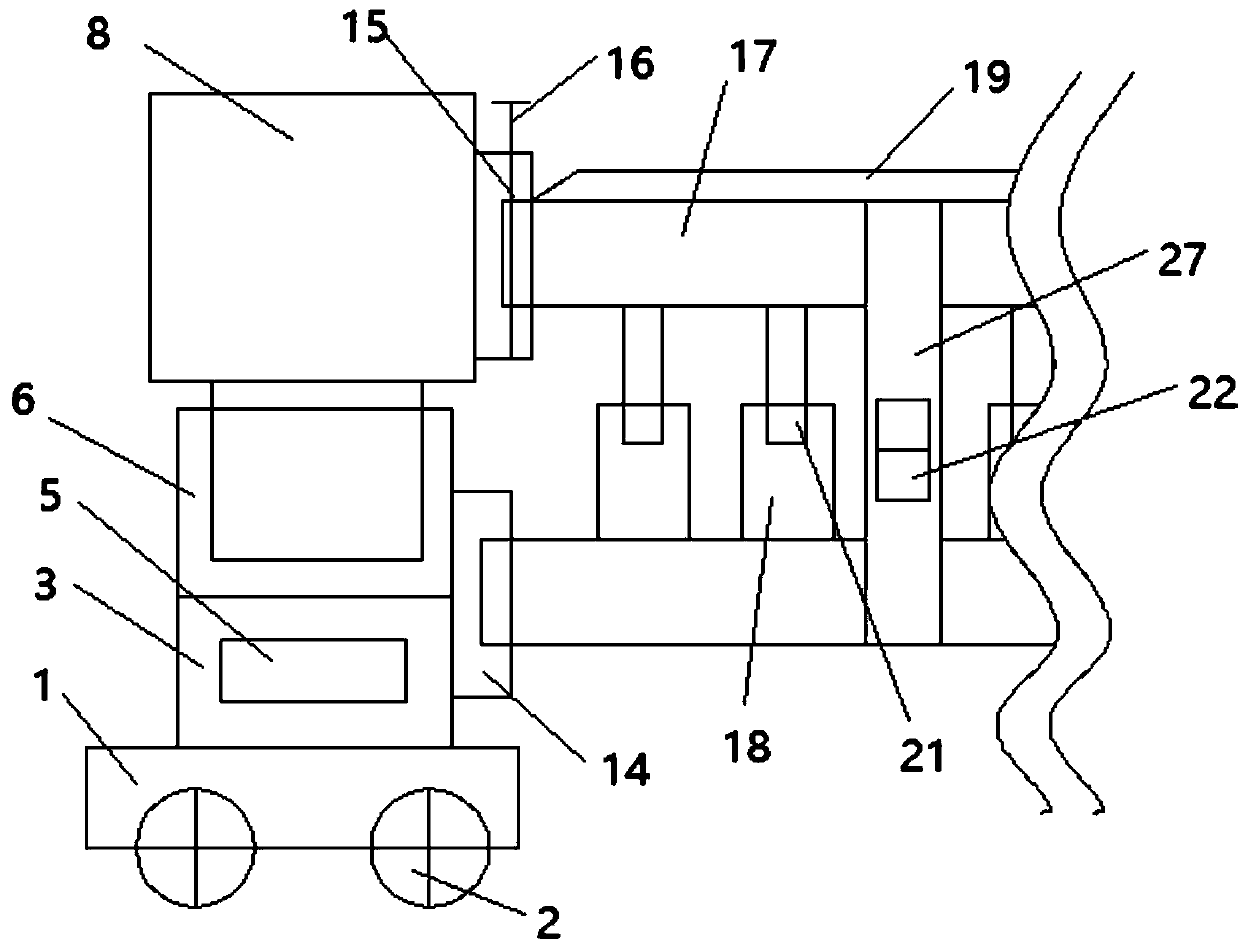

Live pig hanging automatic processing system

ActiveCN109452341APlay a role in the separationAvoid incomplete cuttingSplitting instrumentsSlaughterhouse arrangementsThoracic structureEngineering

The present invention relates to a live pig hanging automatic processing system. The live pig hanging automatic processing system comprises a supporting bottom plate, a cutting plate, a guiding plateand a stablizing device, the cutting plate is arranged on a top part of a right end of the supporting bottom plate, the fixing device is arranged on a top part of the cutting plate, a left end of thecutting plate is connected with a right end of the guiding plate, and a left end of the guiding plate is arranged on a top part of a left end of the supporting bottom plate; and the stablizing devicecomprises a stabilizing bracket, a positioning telescopic body, a positioning spring, positioning push rods, a positioning connecting plate, positioning wheels, an external support mechanism, an extrusion mechanism and a separation guide block. The live pig hanging automatic processing system can solve problems that during live pig half cutting, many people are needed to assist cutting of the livepigs, the live pig half cutting has risks, the live pig half cutting is uneven, the live pig half cutting cuts thoracic cavity of the live pigs and causes waste, the live pig cutting is incomplete, and can achieve functions of positioning conveying and pressing cutting of the live pigs.

Owner:XIAMEN YINXIANG GROUP

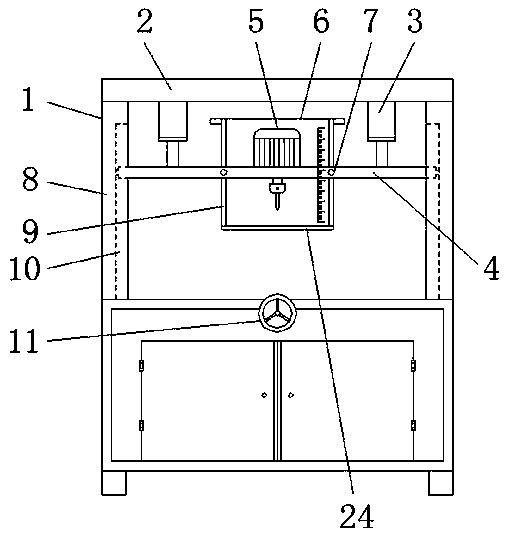

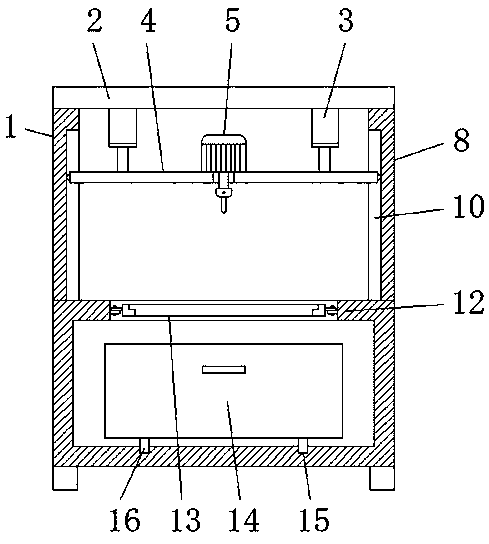

Machining drilling device with protective function

ActiveCN109550997AWith protective functionEasy to slidePositioning apparatusBoring/drilling componentsHydraulic cylinderMachining

The invention discloses a machining drilling device with a protective function. The machining drilling device comprises a drilling device body, a supporting frame, a hydraulic cylinder, a motor, a tightening nut, a supporting rod, a handwheel, a machining table, a chip collecting bucket and a moving wheel; and the supporting frame is arranged at the top of the drilling device body, the lower end of the supporting frame is connected with a lifting plate through the hydraulic cylinder, an anti-collision bar is arranged at the lower end of a protective plate, the supporting rod is welded to the lower end of the supporting frame, the machining table is arranged below the lifting plate, a moving groove is formed in the inner side of a fixing plate and is in bolt connection with a fixing bar, the chip collecting bucket is arranged under the fixing plate, the handwheel is arranged at the outer end of a rotating rod, the rotating rod is in bearing connection with the machining table, and a limiting block is arranged on the rear side inside the machining table. According to the machining drilling device with the protective function, waste chips generated during drilling can be isolated froman operator, and the operator conveniently rotates the fixing plate.

Owner:盐城市景睿模具科技有限公司

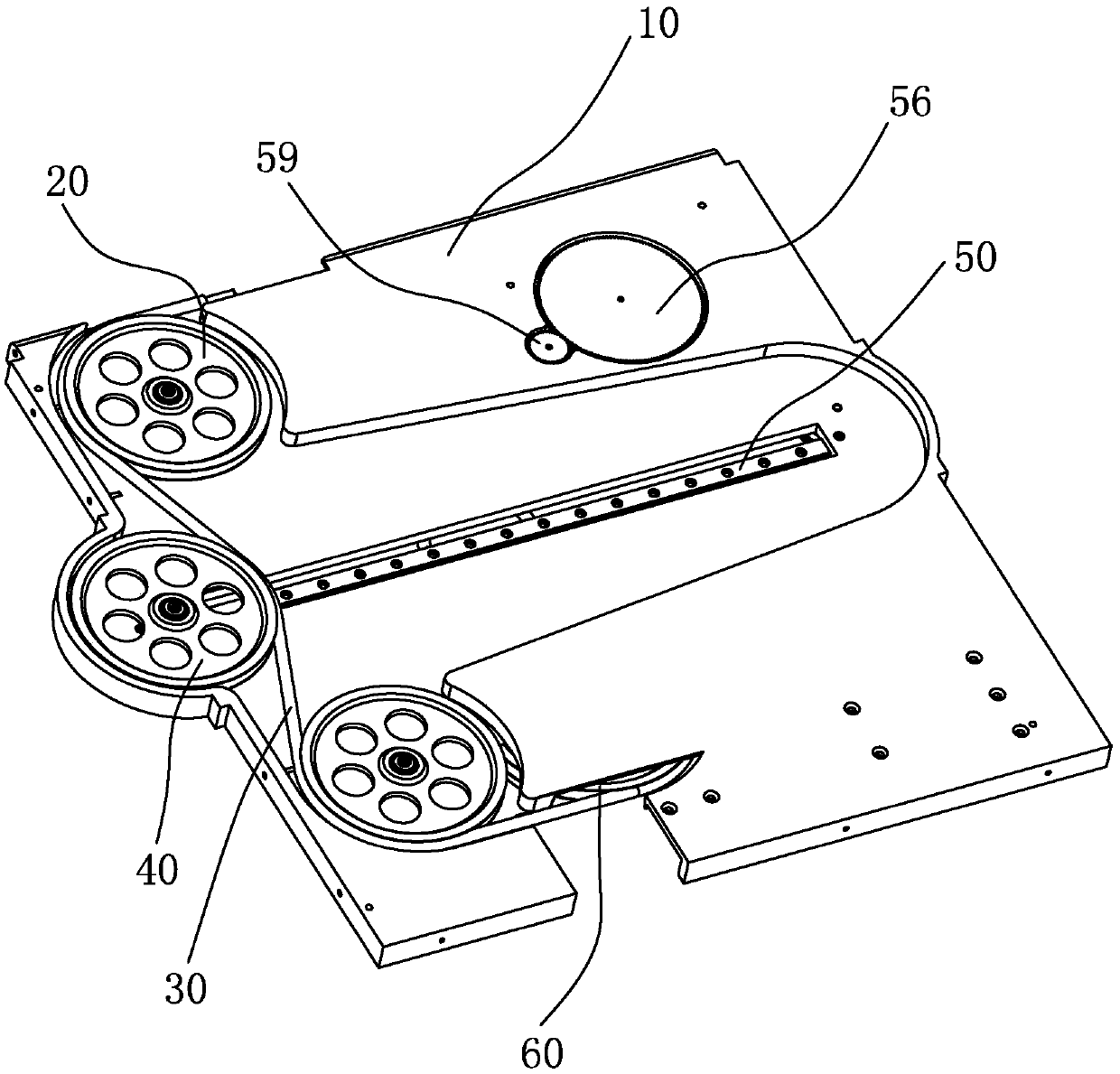

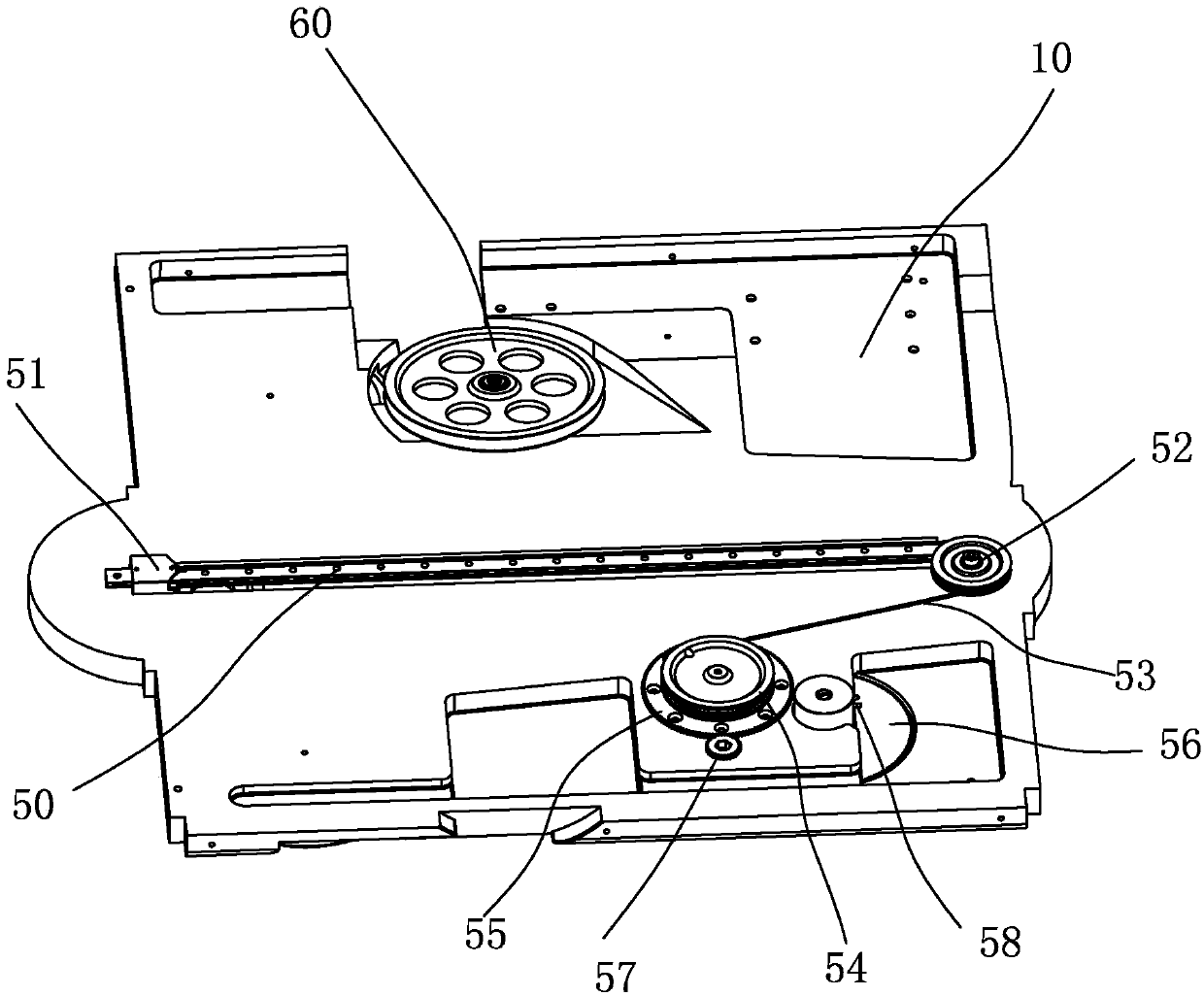

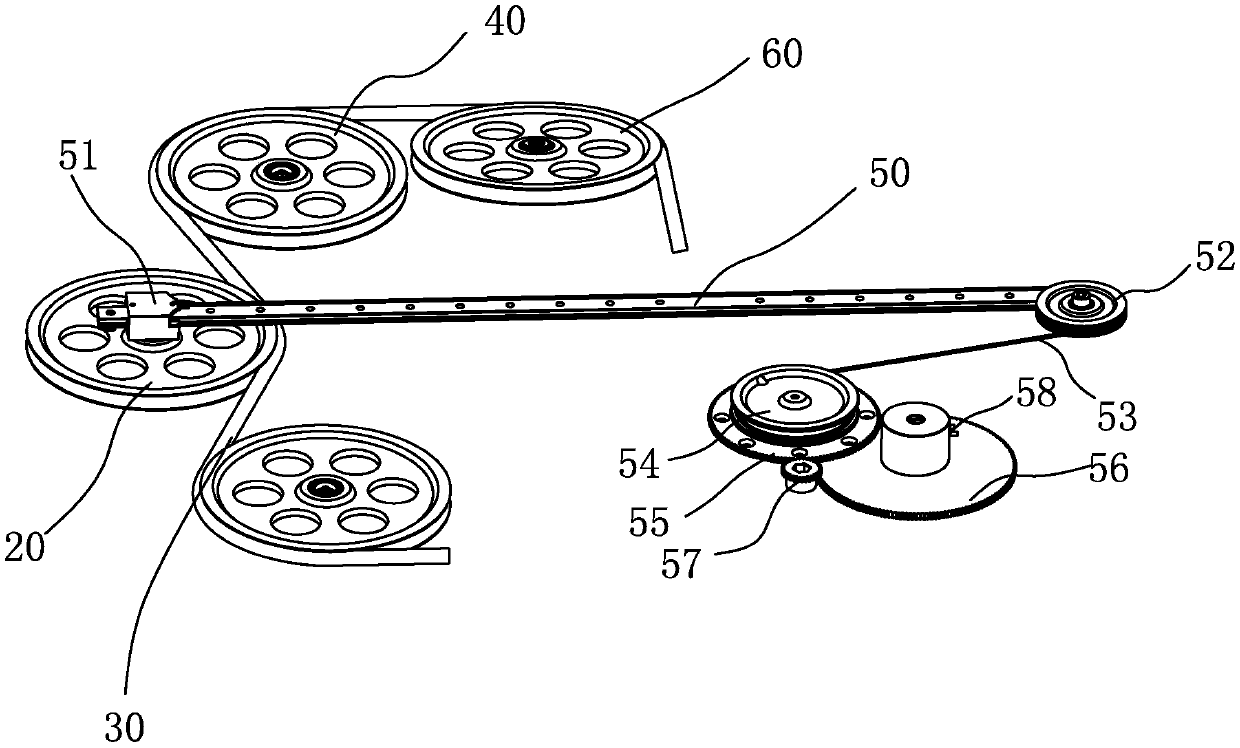

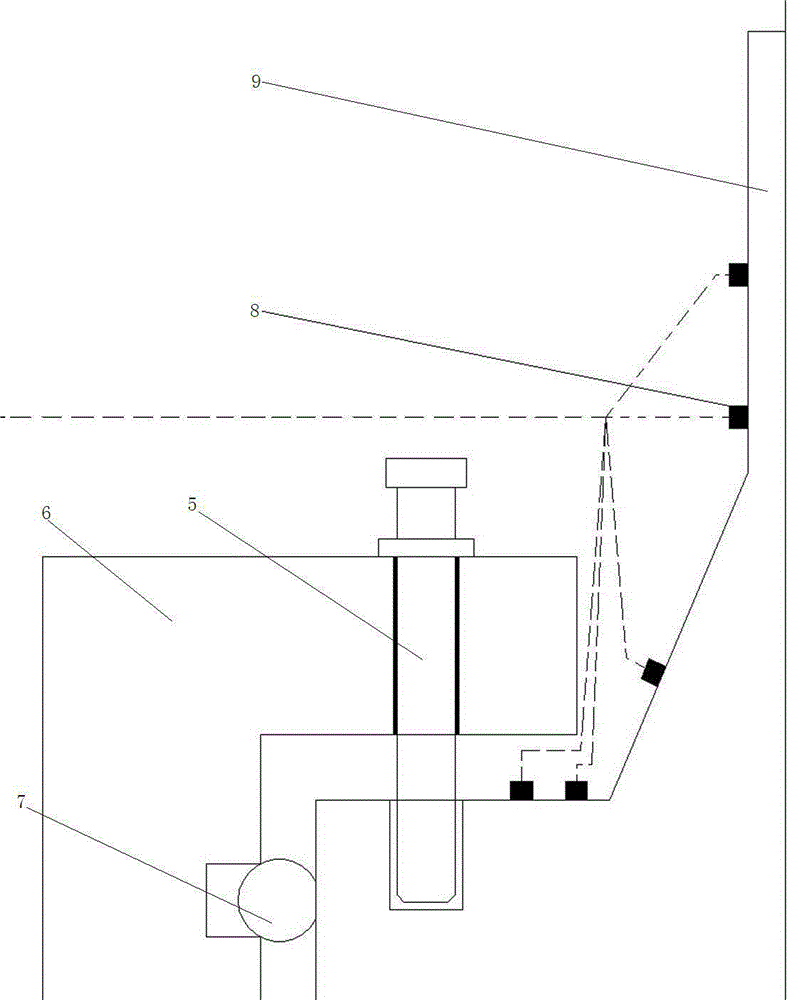

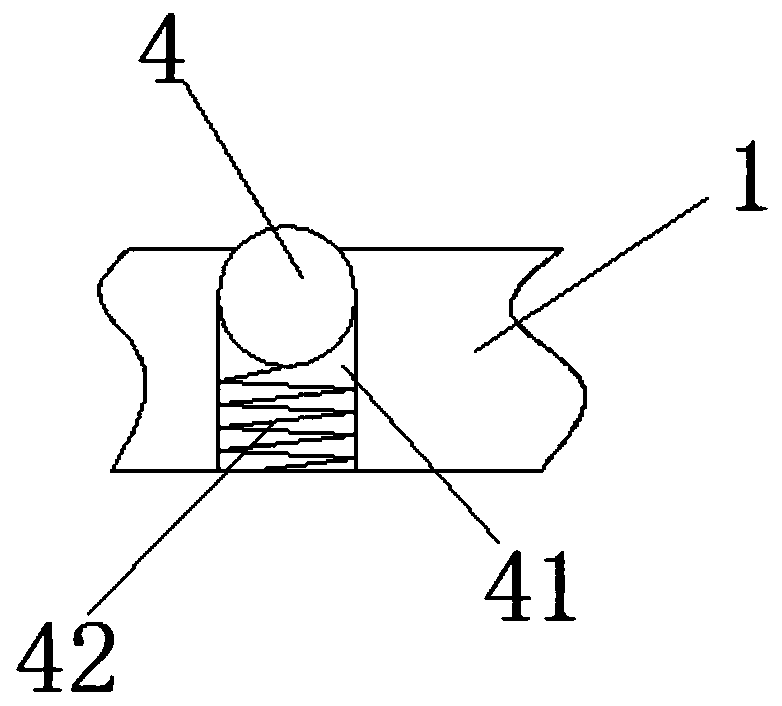

Take-up and pay-off buffering structure for mooring unmanned aerial vehicle and working method thereof

The invention relates to a take-up and pay-off buffering structure for a mooring unmanned aerial vehicle and a working method thereof. The structure comprises a take-up and pay-off wheel, a bufferingassembly and an adjusting assembly. The buffering assembly comprises a buffering wheel, a sliding rail, a sliding block and an adjusting assembly. A distance for a cable to pass through is formed between the take-up and pay-off wheel and the buffering wheel. The adjusting assembly comprises a position adjusting structure, a winding control mechanism used for controlling the take-up and pay-off speed of a winding cylinder, and a sensor used for detecting the position of the buffering wheel. The sliding block is connected with the buffering wheel and located on the sliding rail. The position adjusting structure is connected with the sliding block. The sensor and the position adjusting structure are connected with the winding control structure. The sensor detects the position of the bufferingwheel, a detection signal is transmitted to the winding control structure, and the winding control structure controls the winding cylinder to take up and pay off wires and controls the take-up and pay-off speed of the winding cylinder. According to the structure, in the ascending pay-off process or the descending take-up process, the phenomenon of winding or knotting is avoided, and winding displacement of the whole winding cylinder is uniform.

Owner:SHENZHEN SUNWIN INTELLIGENT CO LTD

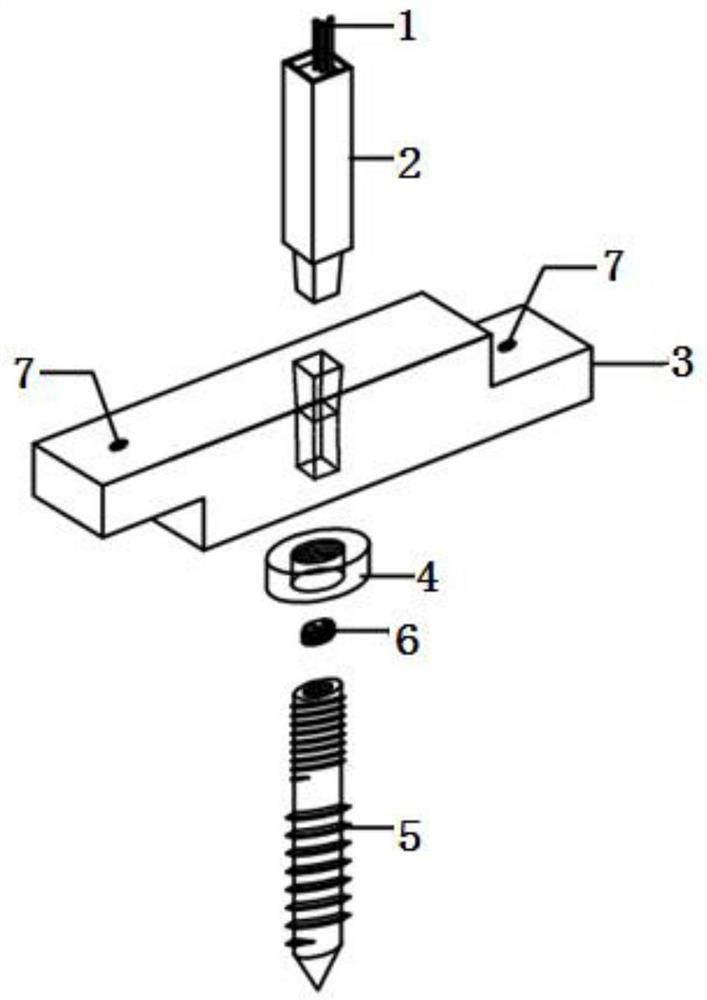

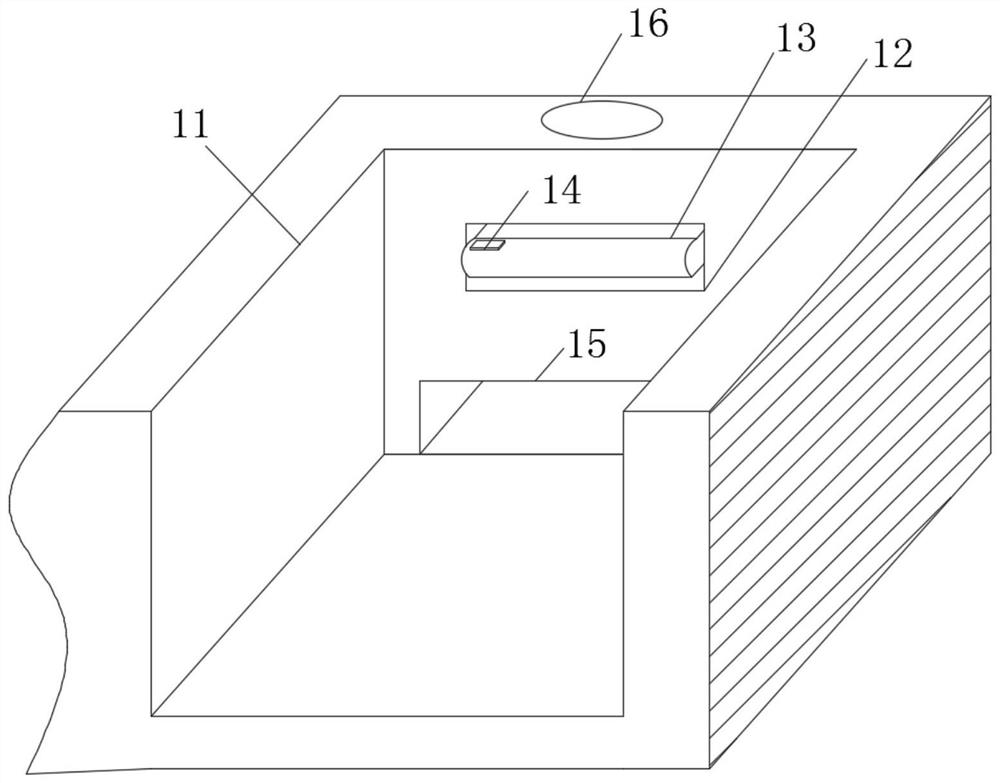

Clamp and method for single surface electroplating of substrates

InactiveCN105350059AThe substrate is fixed and stableUniform platingElectrolysis componentsBiomedical engineeringElectroplating

The invention provides a clamp for single surface electroplating of substrates. The clamp comprises a supporting plate, two probe electrodes and electrode leads connected with the probe electrodes. The supporting plate is provided with a groove matched with the substrates. One ends of the probe electrodes are fixed to the supporting plate through studs, and probes of the probe electrodes are placed into accommodation holes in the supporting plate. In electroplating, the substrates are placed into the groove, and the probes of the probe electrodes rotate to the substrates. According to the clamp, the back surfaces of the substrates are stably attached to the groove of the supporting plate through the tension of water, the probe electrodes have the electrode electroplating effect and can press the substrates, and therefore the back surfaces of the substrates can be completely isolated from electroplating liquid, and single surface electroplating of the substrates can be successfully realized. The clamp has the advantages of being simple in structure, easy and convenient to use, free of pollution, low in cost and high in efficiency.

Owner:SHIJIAZHUANG HAIKE ELECTRONICS TECH CO LTD

Leakage detecting device of high-temperature flange connecting system

InactiveCN105423018APlay a role in compressingThe test result is accurateFlanged jointsMass spectrum analysisElectrical and Electronics engineering

The invention relates to a leakage detecting device of a high-temperature flange connecting system. The leakage detecting device comprises a sealed cavity formed by two leakage detecting pipes, a first flange, a second flange and a gasket. A heating mechanism is arranged in the sealed cavity, and a pressurizing mechanism delivers gas into the sealed cavity. The outer side of the first flange and the outer side of the second flange are sleeved with an annular rigid piece, two annular grooves are formed in the inner side of the rigid piece and internally provided with sealing rings respectively, and the two sealing rings are in close contact with the lateral side of the first flange and the lateral side of the second flange respectively. A plurality of pairs of threaded through holes evenly distributed around the leakage detecting pipes are formed in the rigid piece, each pair of threaded through holes are symmetrical with respect to the gasket, a bolt is arranged in each threaded through hole, and the first flange and the second flange are matched and jacked through the pairs of bolts. The sealed leakage detecting cavity is defined by the gasket, the first flange, the second flange, the sealing rings and the rigid piece and connected with a mass spectrum detector through a pipe. According to the leakage detecting device, normal stressing of the gasket can not be influenced by the leakage detecting cavity, and the testing result is truer.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

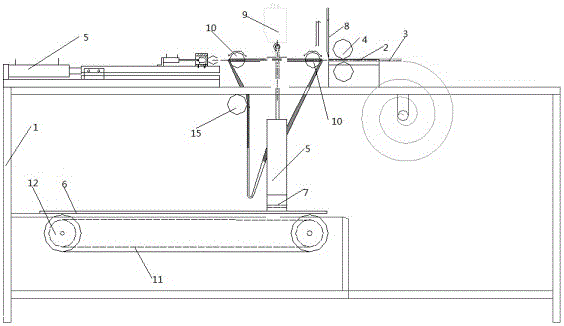

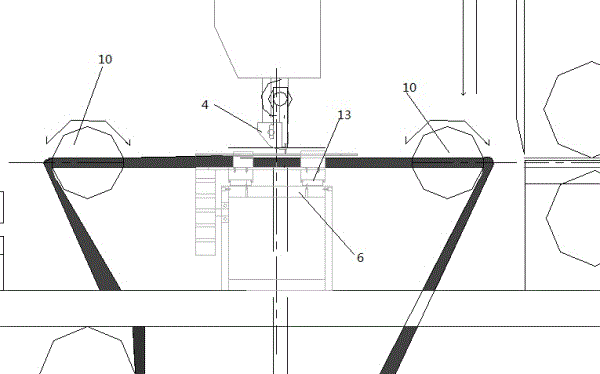

Fully-automatic flexible production equipment and production process of annular lifting belt

InactiveCN105780317AGuidePlay a role in compressingWorkpiece carriersWork-feeding meansEngineeringFully automatic

The invention discloses fully-automatic flexible production equipment and production process of an annular lifting belt.The equipment comprises a base, a flat belt cutting system and a flat belt sewing system, the base is provided with a rotating shaft, the rotating shaft is provided with a rolled flat belt, belt pressing wheels are arranged on the flat belt, the belt pressing wheels press the flat belt tightly, a linear air cylinder is fixedly arranged on the base, the base is provided with a guide rail, the guide rail is provided with a slide block, the slide block can perform linear reciprocating motion relative to the guide rail fixed to the base, a small air cylinder is fixedly arranged on the slide block, and the slide bock drives a gripper at the tail end to be opened and closed through reciprocating linear motion; the flat belt cutting system is composed of a cutter, a horizontal stretching mechanism and a vertical stretching mechanism, the cutter is arranged above the base, and the horizontal stretching mechanism and the vertical stretching mechanism can guarantee sufficient space in the sewing process.

Owner:曾庆鹏

Plastic plate cutting machine

InactiveCN105619482ANot easy to damageSimple structureMetal working apparatusParallel plateElectric machinery

The invention provides a plastic plate cutting machine which is simple in structure, convenient to operate, capable of conveniently cutting plastic, good in cutting effect, capable of ensuring flush cut edges, high in safety coefficient and capable of protecting operators and a saw blade against injuries and damage. The plastic plate cutting machine comprises a machine frame, a top plate which is horizontally arranged is fixed to the upper end of the machine frame, and a saw groove parallel to the cutting direction is formed in the top plate. The plastic plate cutting machine is characterized in that a parallel plate parallel to the saw groove is arranged at one side of the saw groove, and a pressing mechanism is further arranged on one side of the top plate; a motor mounting seat is arranged on the lower portion of the machine frame, and a spindle box is fixed to the lower side corresponding to the top plate through bolts; a motor is mounted on the motor mounting seat, and an output shaft of the motor is connected with a driving belt pulley; the spindle box comprises a spindle, a driven belt pulley is mounted at one end of the spindle, and the driving belt pulley and the driven belt pulley are fixedly connected through a belt; the saw blade is connected to the other corresponding end of the spindle, and the upper end of the saw blade can stretch out of the saw groove.

Owner:WUXI FORMEN TECHN

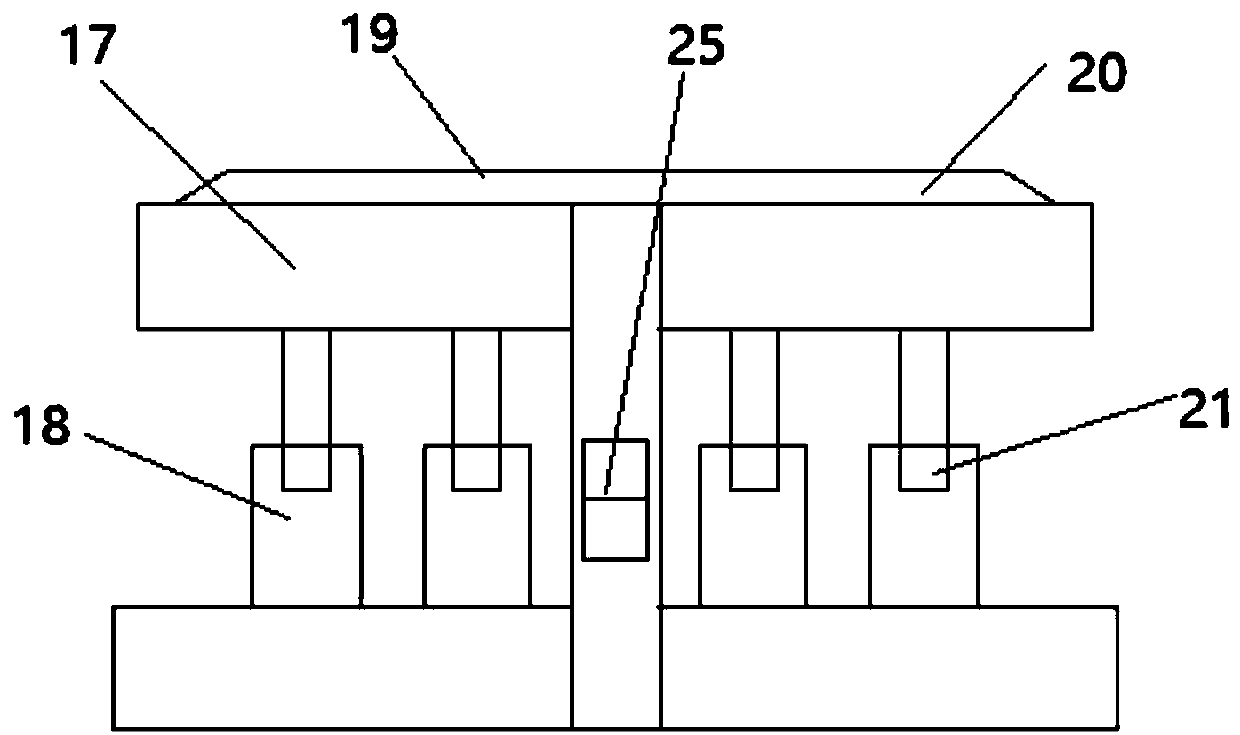

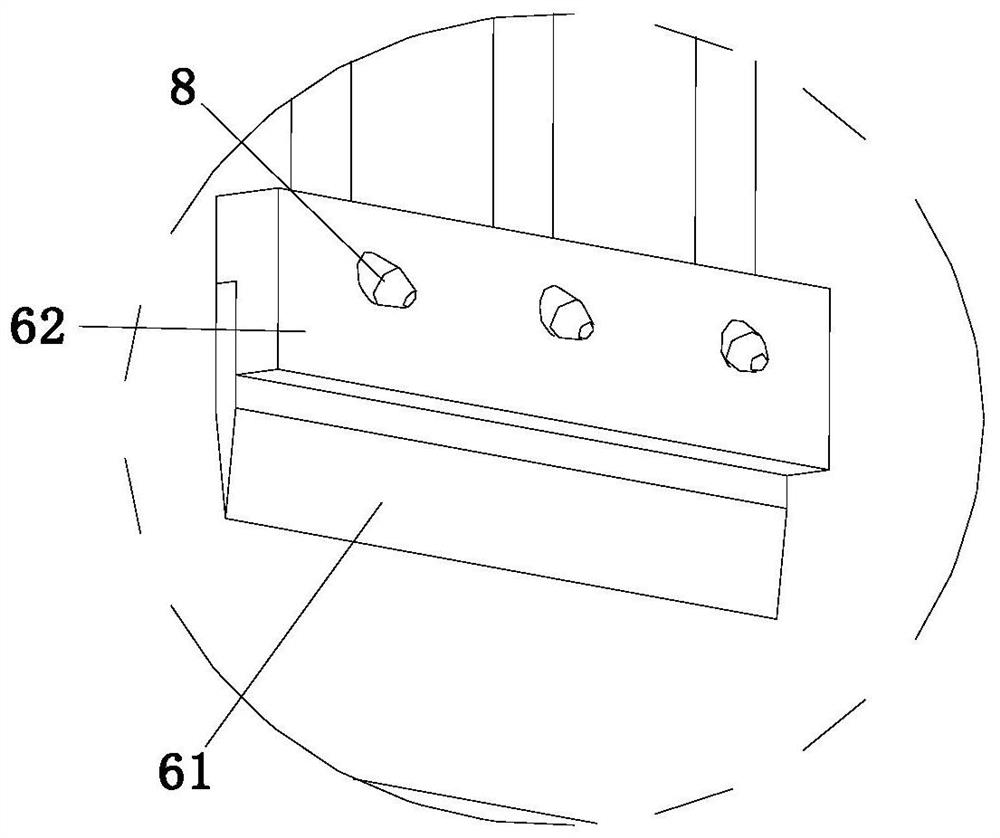

Base plate fixing device of heater rod bending forming machine

PendingCN110116174APlay a role in compressingSolve the relatively simple problem of only fixing a single-thickness bottom plateMetal-working feeding devicesPositioning devicesHeater RodEngineering

The invention discloses a base plate fixing device of a heater rod bending forming machine. The device comprises a base; pressing frames are fixedly mounted at four angles of the upper end surface ofthe base; pressing blocks are mounted in grooves at the tops of the inner sides of the pressing frames; thread rods are fixedly mounted at the tops of the pressing blocks; the thread rods penetrate through the tops of the pressing frames; a first baffle plate is fixedly mounted at one end of the base; two sides of the first baffle plate are fixed on the outer sides of the pressing frames; a secondbaffle plate is rotationally mounted on the other side of the base; mounting frames are fixedly mounted at four angles of the lower end of the base; support plates are fixedly mounted on the lower end surface of the base on the inner sides of the mounting frames; and slide plates capable of vertically sliding are slidingly mounted at the lower ends of the mounting frames. In the device, the pressing frames can achieve a pressing effect on machined base plates mounted on the base; and thread rods can be used for adjusting the heights of the pressing blocks to meet the base plates with different thicknesses and sizes, so that the problems of simpler fixed plates and capability of fixing the base plates with one thickness in the prior art are solved.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

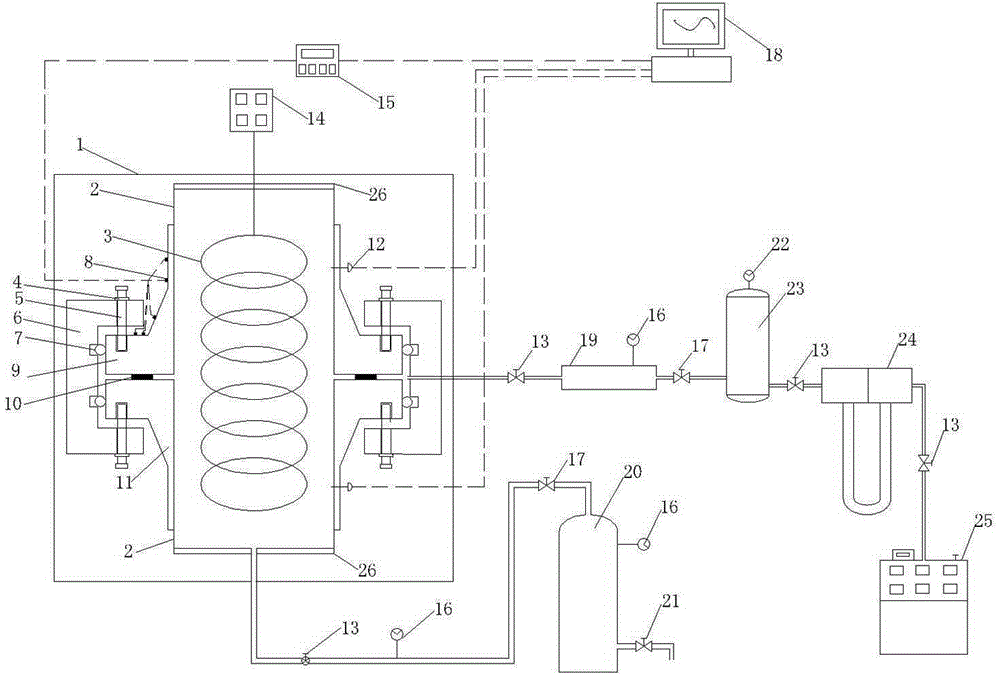

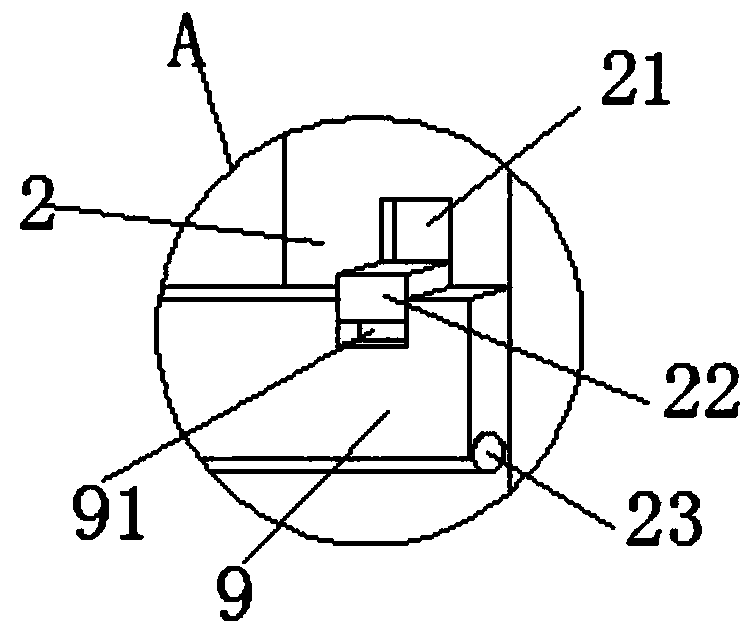

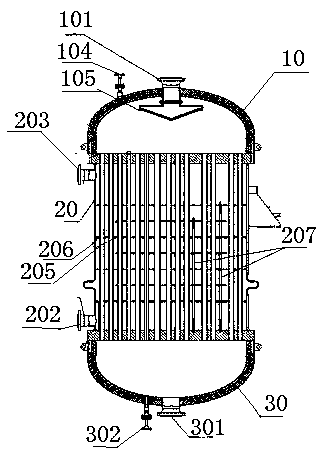

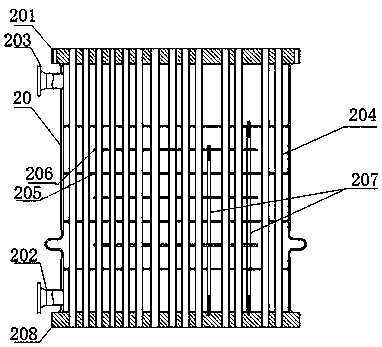

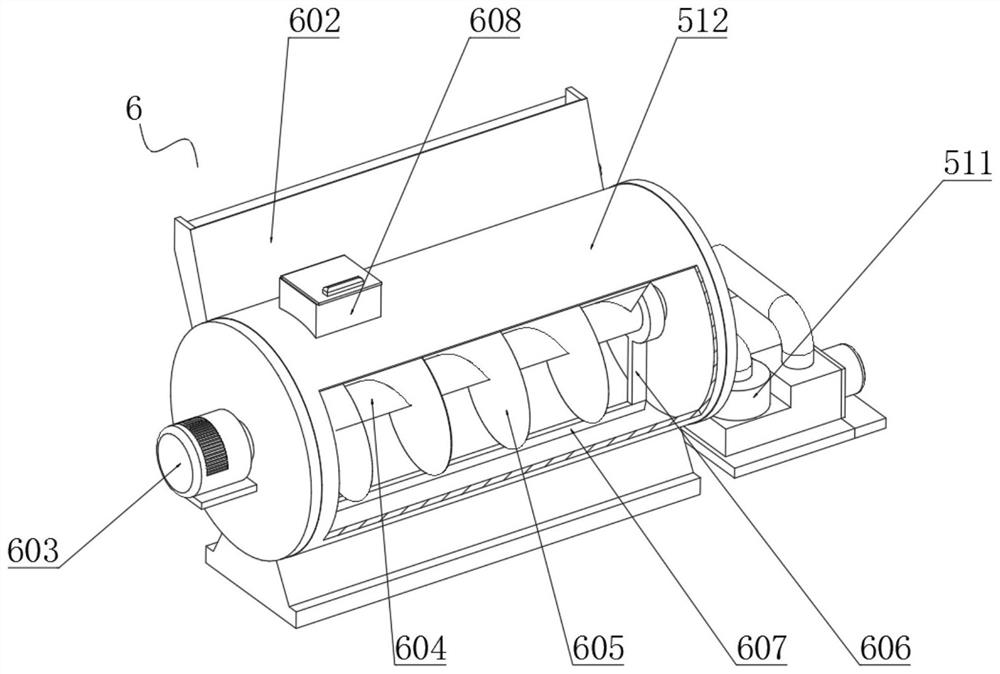

Methane hydrochlorination reactor

InactiveCN110947354AImprove liquidityImprove uniformityChemical/physical/physico-chemical stationary reactorsThermodynamicsWater chlorination

The invention discloses a methane hydrochlorination reactor. The methane hydrochlorination reactor comprises an upper sealing head, a shell and a lower sealing head which are fixedly connected in sequence from top to bottom, a feeding pipe is arranged at the upper part of the upper sealing head, and a discharging pipe is arranged at the bottom of the lower sealing head. The methane hydrochlorination reactor further comprises: an upper sealing plate which is fixedly connected to the upper end of the shell; a lower sealing plate fixedly connected to the lower end of the shell; a liquid inlet pipe fixedly connected to the lower part of the shell and positioned above the lower sealing plate; and a liquid outlet pipe fixedly connected to the upper part of the shell and positioned below the upper sealing plate; and heat exchange tubes, wherein the two ends of the heat exchange tubes are respectively fixedly connected with the upper sealing plate and the lower sealing plate to communicate with inner cavities of the upper sealing head and the lower sealing head.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

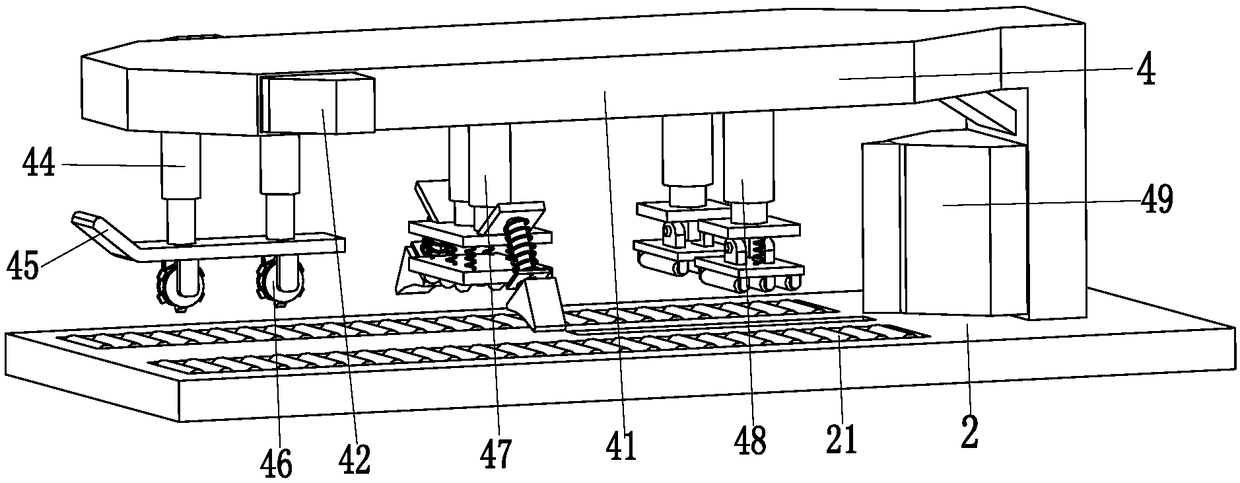

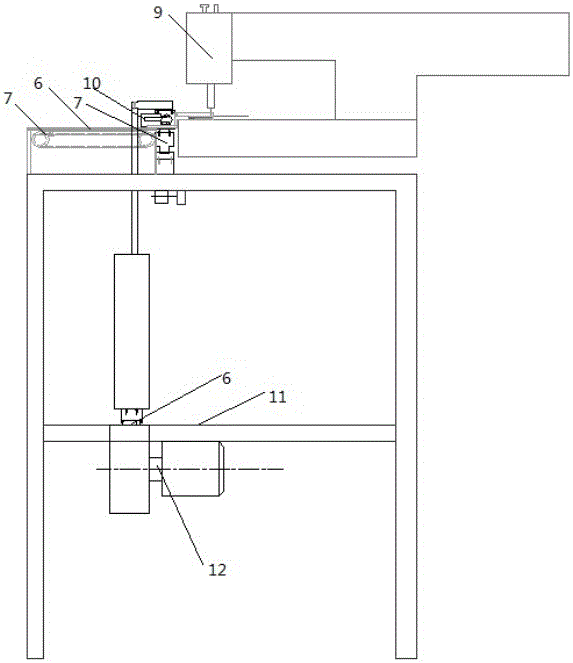

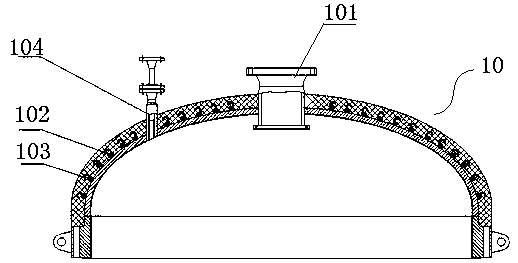

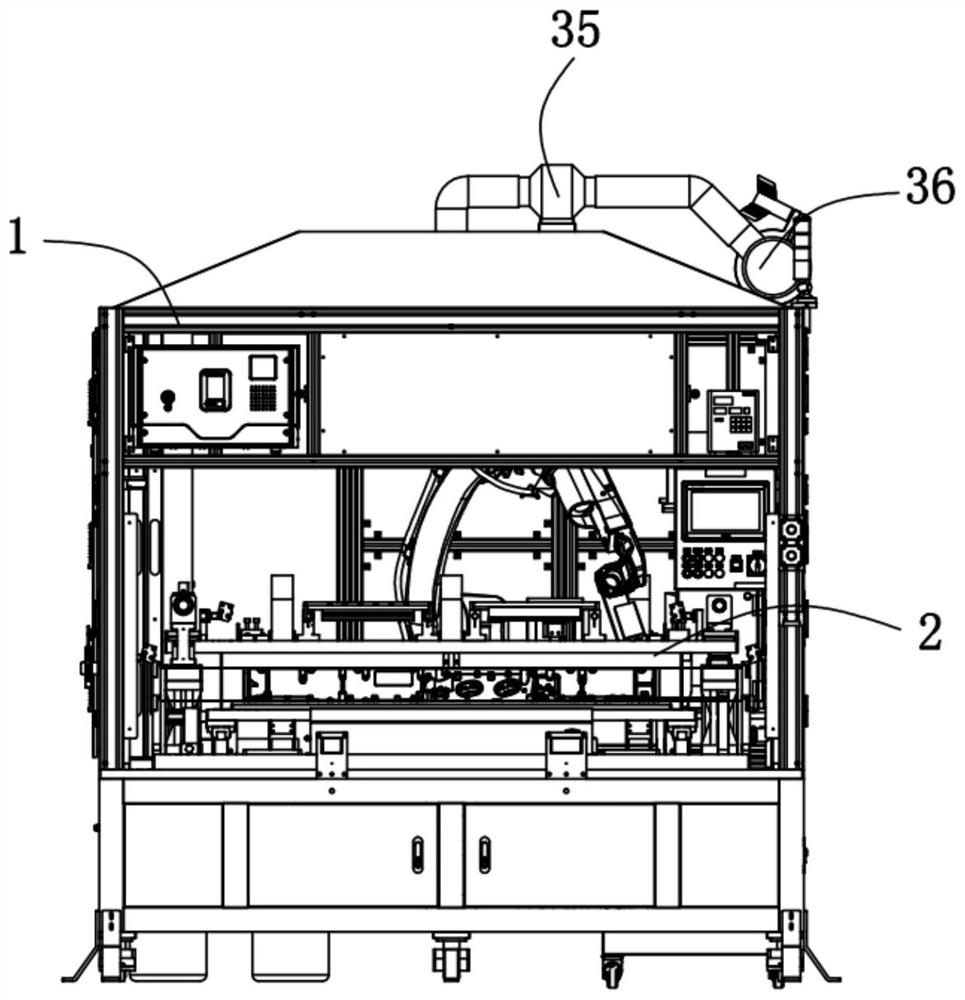

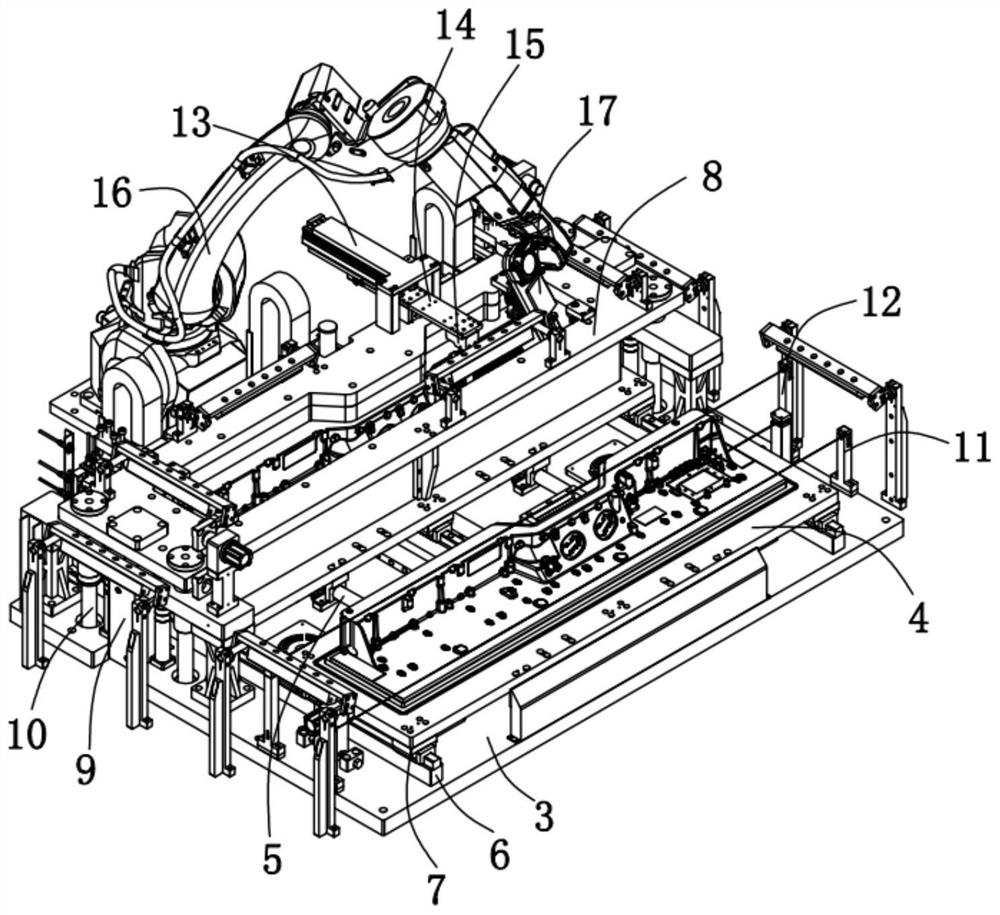

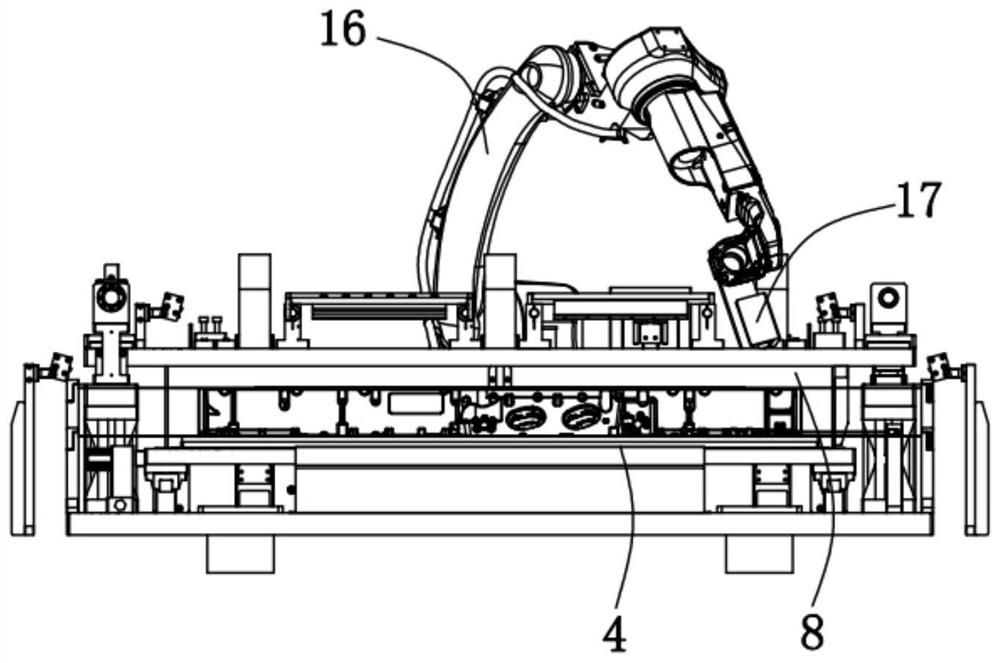

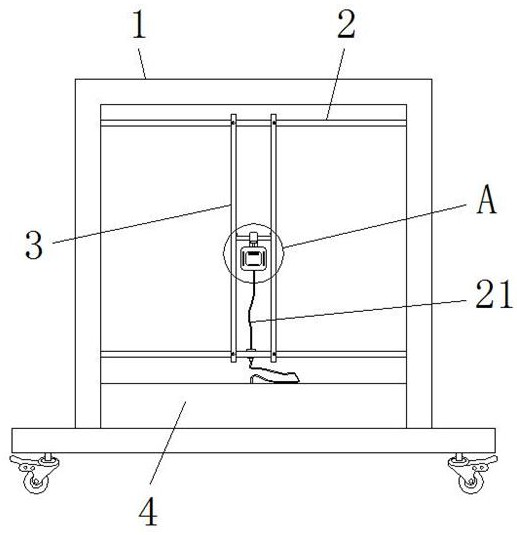

Helium detector for automobile storage battery box

PendingCN112033612AEasy to moveAchieve sealingDetection of fluid at leakage pointEngineeringMechanical engineering

The invention discloses a helium detector for an automobile storage battery box. The detector comprises a table frame, a working part is arranged on the table frame, the working part comprises a mounting plate, the mounting plate is fixedly mounted on the table frame, and a front-back transplanting device, a vacuum box and a leakage detection device are arranged at the top of the mounting plate. The front-back transplanting device is used for installing and moving a storage battery box, the vacuum box is used for fixing and blocking the storage battery box, and the leakage detection device isused for detecting whether the storage battery box leaks air or not. Through arrangement of the front-back transplanting devices, the vacuum box and the leakage detection device, movement, sealing, vacuumizing, helium filling, helium leakage detection and the like of the storage battery box can be realized, so that the airtightness detection of the battery box is realized; meanwhile, helium is used as detection gas, so that the detection is more sensitive and accurate.

Owner:NANTONG GUANGYE AUTOMATION SYST ENG

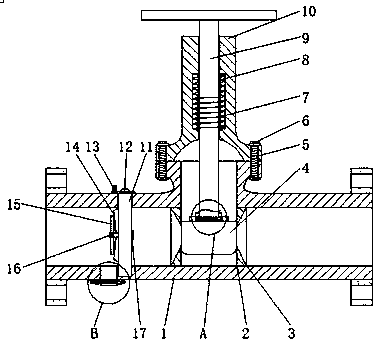

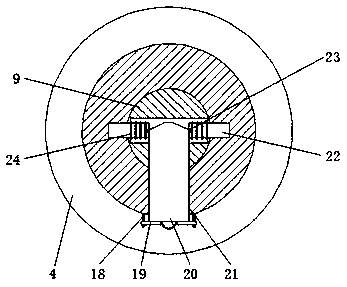

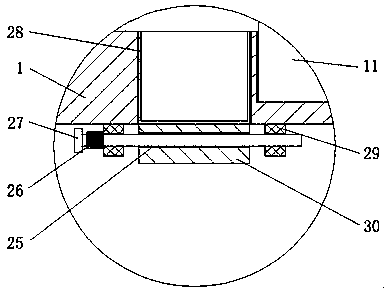

Valve with valve clack convenient to replace and replacing method

InactiveCN110985696AEasy to replaceSmooth rotationSlide valveFiltration separationStructural engineeringVALVE PORT

The invention discloses a valve with a valve clack convenient to replace and a replacing method. The valve comprises a lower valve body, wherein a valve seat is fixedly connected to the center of an inner cavity of the lower valve body, a sealing ring is fixedly connected to the inner wall of the valve seat, an upper valve body is arranged at the top of the lower valve body, fastening screw holesare formed in the two sides of the bottom of the upper valve body and the two sides of the top of the lower valve body correspondingly, fastening bolts are arranged in inner cavities of the fasteningscrew holes in a penetrating mode correspondingly, a valve rod is arranged at the top of the upper valve body, and the bottom of the valve rod sequentially penetrates through the upper valve body andthe lower valve body from bottom to top and extends to the top of the inner cavity of the lower valve body. Through cooperative use of the valve clack, the fastening screw holes, the fastening bolts,the valve rod, the upper valve body, a first screw, a first baffle, a sliding clamping block, a first sliding groove, a limiting clamping block, a stable sliding block, a first spring, a stable sliding groove and a limiting clamping groove which are arranged, the problem that the valve clack of an existing valve is inconvenient to replace, the replacement time is greatly increased, and the convenience of the valve is reduced is solved.

Owner:陈美姻

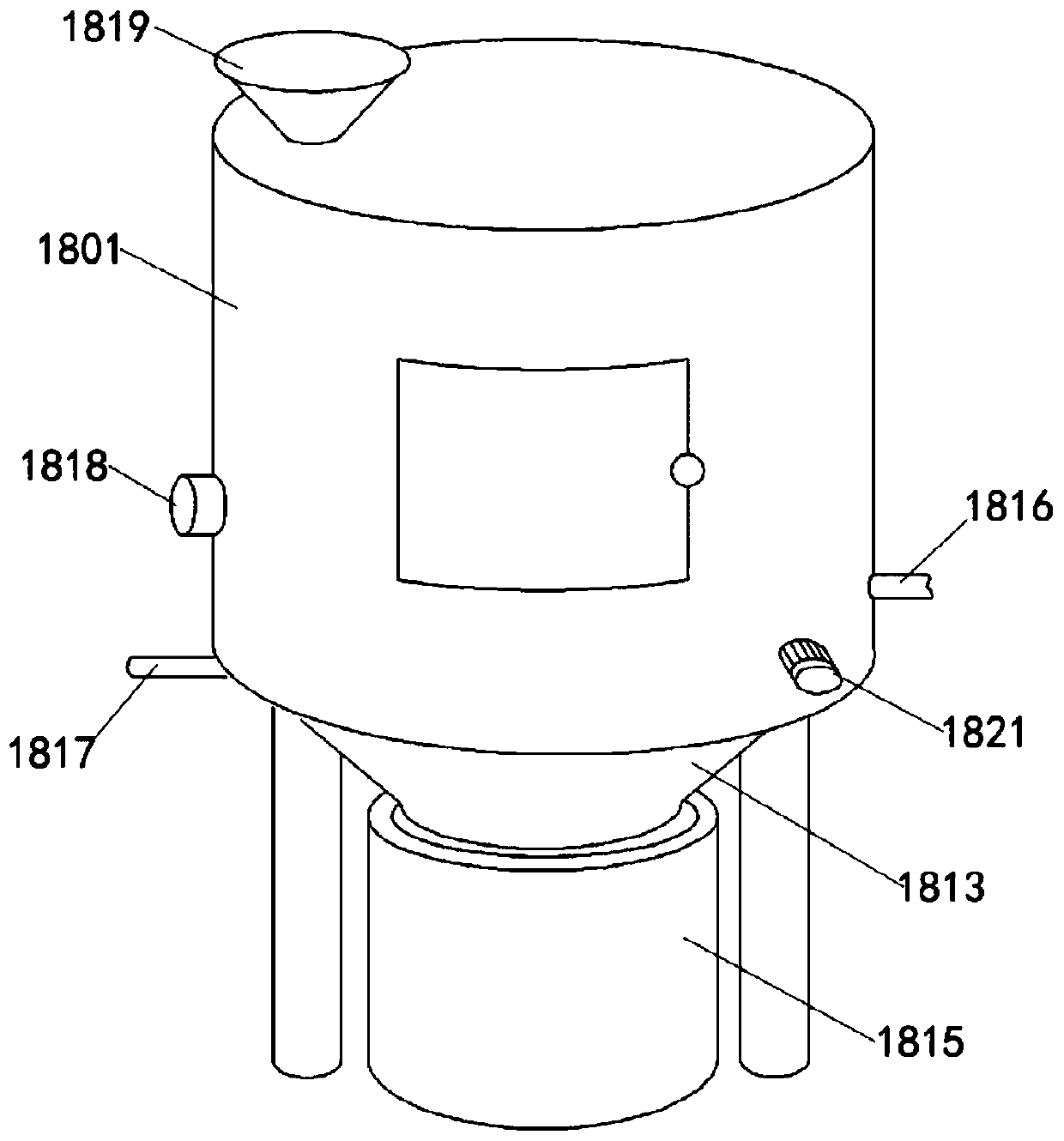

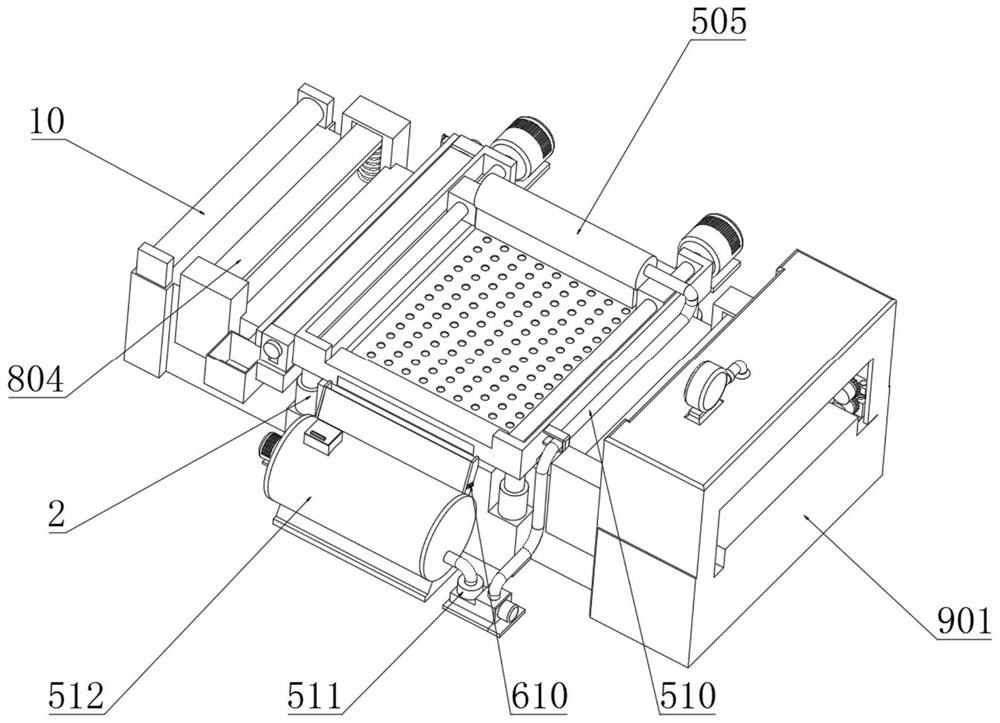

Plastic film blowing system with reheating function

InactiveCN111497058AImprove energy utilizationImprove drying efficiencyFlat articlesActivated carbonElectric machine

The invention discloses a plastic film blowing system with a reheating function. The plastic film blowing system involves a raw material drying device and a film blowing device, wherein plastic raw material dried by the raw material drying device is manually fed into a storage hopper of the film blowing device; the raw material drying device comprises a drying housing, wherein the bottom wall of the drying housing is fixedly connected with a reheating cylinder, a stirring motor is fixedly connected to the upper end of the reheating cylinder, and an output shaft of the stirring motor is fixedlyconnected with a stirring block through a folding rod; an electric material falling door is formed in the bottom wall of the drying housing, an electric heater is fixedly connected in the reheating cylinder, the upper end of the electric heater is in communication with an outlet of a suction fan through an air inlet pipe of the heater, an inlet of the suction fan is in communication with an outlet of an activated carbon box, multiple layers of honeycomb activated carbon layers are arranged in the activated carbon box, an inlet air pipe of the activated carbon box is provided with an opening located at the surface of the reheating cylinder, and an outlet pipe of the electric heater is in communication with a plurality of branched spray pipes; and a material falling housing is arranged below the drying housing, a gate plate door is arranged at the bottom of the material falling housing, and a material collecting barrel with an opening in the upper end is placed below the gate plate door.

Owner:明柏森

Guiding and limiting mechanism of plastic plate cutting machine

InactiveCN105619501APlay a role in compressingMake sure it is flushMetal working apparatusParallel plateEngineering

The invention provides a guiding and limiting mechanism of a plastic plate cutting machine. The guiding and limiting mechanism is simple in structure, convenient to operate, good in cutting effect, capable of guaranteeing that cut edges are flush and high in safety factor, facilitates cutting of plastics and protects operators and saw blades against injuries and damage. The guiding and limiting mechanism comprises a machine frame. A horizontally-arranged top plate is fixed to the upper end of the machine frame; and the top plate is provided with a sawing channel parallel to the cutting direction. A parallel plate parallel to the sawing channel is arranged on one side of the sawing channel. One side of the top plate is further provided with a pressing mechanism. The pressing mechanism comprises a pressing supporting frame fixed to one side of the machine frame. The pressing supporting frame comprises a front rod, a rear rod and a horizontal cross rod which is connected with the front rod and the rear rod. The rear rod is arranged perpendicular to the top plate. The upper end of the rear rod is connected with the rear end of the horizontal cross rod. The front end of the horizontal cross rod is fixedly connected with the upper end of the front rod to enable the front rod to be correspondingly arranged above the sawing channel. The lower end of the front rod is fixedly connected with an elastic connecting rack. The lower end of the elastic connecting rack is connected with a rolling wheel bracket. A rolling wheel is mounted on the rolling wheel bracket.

Owner:WUXI FORMEN TECHN

Coil support forming device and coil support forming method

InactiveCN108927943AIncrease productivityShorten molding timeShaping toolsDomestic articlesMetal forming processInjection molding process

The invention provides a coil support forming device. The coil support forming device is used for forming of a coil support and comprises pins and a plastic body, wherein the pins are partially wrapped in the plastic body. The coil support forming device also comprises a stamping mechanism, a cutting mechanism and an injection molding mechanism integrally arranged therein, wherein the stamping mechanism is used for stamping of the pins so as to form limiting parts; the cutting mechanism is used for cutting the pins having undergone press forming to required length; and the injection molding mechanism is used for injection molding of the plastic body on the cut limiting parts of the pins. The invention also provides a coil support forming method. The coil support forming device and the coilsupport forming method provided by the invention have the advantages that a metal forming process and an injection molding process are integratedly designed, so the coil support can be continuously produced without interruption; production efficiency is effectively improved; and the finished coil support has the advantage of good quality.

Owner:深圳市三多乐智能传动有限公司

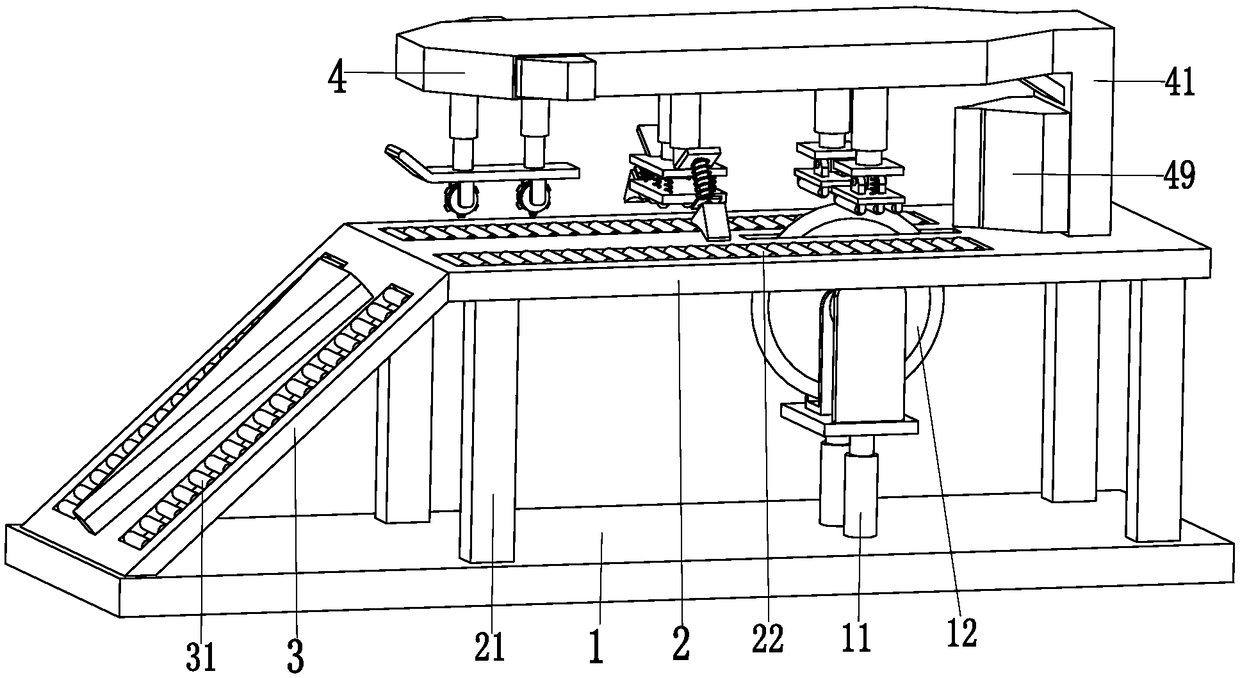

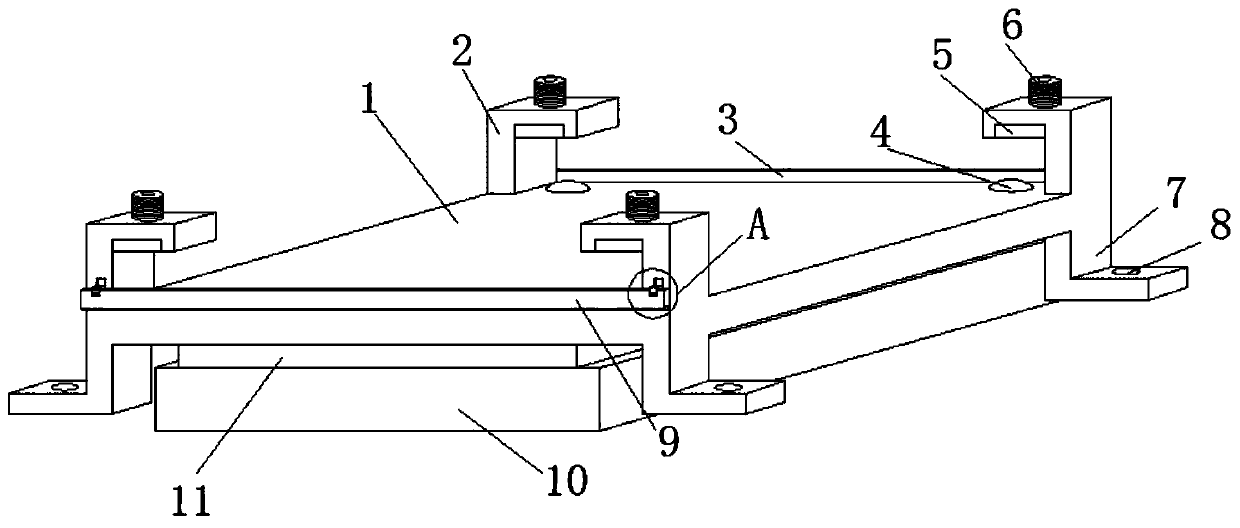

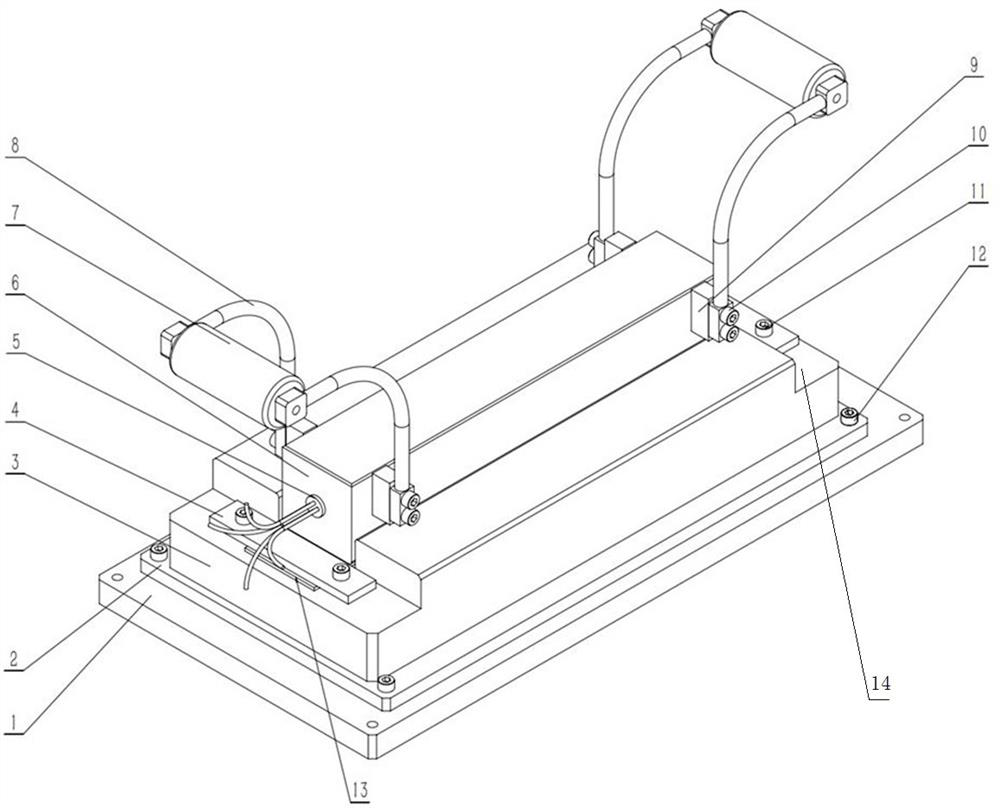

Thermoplastic carbon fiber prepreg tape laminated plate sample preparation device

The invention relates to a thermoplastic carbon fiber prepreg tape laminated plate sample preparation device, and belongs to the field of composite material forming processing. The thermoplastic carbon fiber prepreg tape laminated plate sample preparation device comprises a mounting base, a sample preparation mold, a hot pressing block, a pressing assembly and a pressing sheet, a sample preparation groove which is as wide as a to-be-processed carbon fiber prepreg tape laminated layer and is used for positioning the to-be-processed carbon fiber prepreg tape laminated layer is formed in the sample preparation mold, and the pressing sheet is detachably connected with the sample preparation mold through a pressing bolt so as to press the carbon fiber prepreg tape laminated layer extending out of the sample preparation groove; the hot-pressing block conducts heat and is internally provided with a heating piece for heating the hot-pressing block, the heating piece is connected with the temperature control assembly, and the hot-pressing block is used for being placed in the sample preparation groove to melt resin on the carbon fiber prepreg tape; and the pressing assembly is fixed on the hot pressing block and is used for carrying out hot pressing operation under the manual action and taking the hot pressing block out of the sample preparation groove under the manual action. According to the sample preparation device, the consistency of the fiber direction and tension of the thermoplastic carbon fiber prepreg tape laminated plate can be ensured, and the operation safety is improved.

Owner:大工碳鼎科技洛阳有限公司

Folding guardrail convenient for rapid highway construction

InactiveCN109518632AReasonable usePlay the role of fasteningWith built-in powerEnergy efficient lightingSelf lockingEngineering

Owner:青岛龙运君业贸易有限公司

Cutting device with good pressing effect for lithium battery aluminum foil machining

InactiveCN112356127AGood compression effectEasy to compressElectrode carriers/collectorsLi-accumulatorsEngineeringAluminum foil

The invention relates to the technical field of lithium battery aluminum foil machining, in particular to a cutting device with a good pressing effect for lithium battery aluminum foil machining. Thecutting device comprises a device body, wherein fixing plates are fixedly connected to the two sides of the inner wall of the device body, a pressing assembly is movably connected between the oppositesides of every two corresponding fixing plates, pulling assemblies are fixedly connected to the tops of the pressing assemblies, the tops of the pulling assemblies penetrate to the tops of the fixingplates, a connecting plate is fixedly connected to the inner wall of the device body, and the two sides of the interior of the connecting plate are each movably connected with two movable blocks. Thecutting device with the good pressing effect for lithium battery aluminum foil machining has the advantages that the pressing effect on aluminum foil is good, and the aluminum foil is prevented fromwrinkling in the machining process; and besides, limiting structures are arranged and used in cooperation with pressing devices to prevent the position of the lithium battery aluminum foil from deviating in the cutting process, so that the accuracy of the cutting size is guaranteed, the generation of waste is reduced, and use convenience is brought to a user.

Owner:衡阳市瑞启新能源有限公司

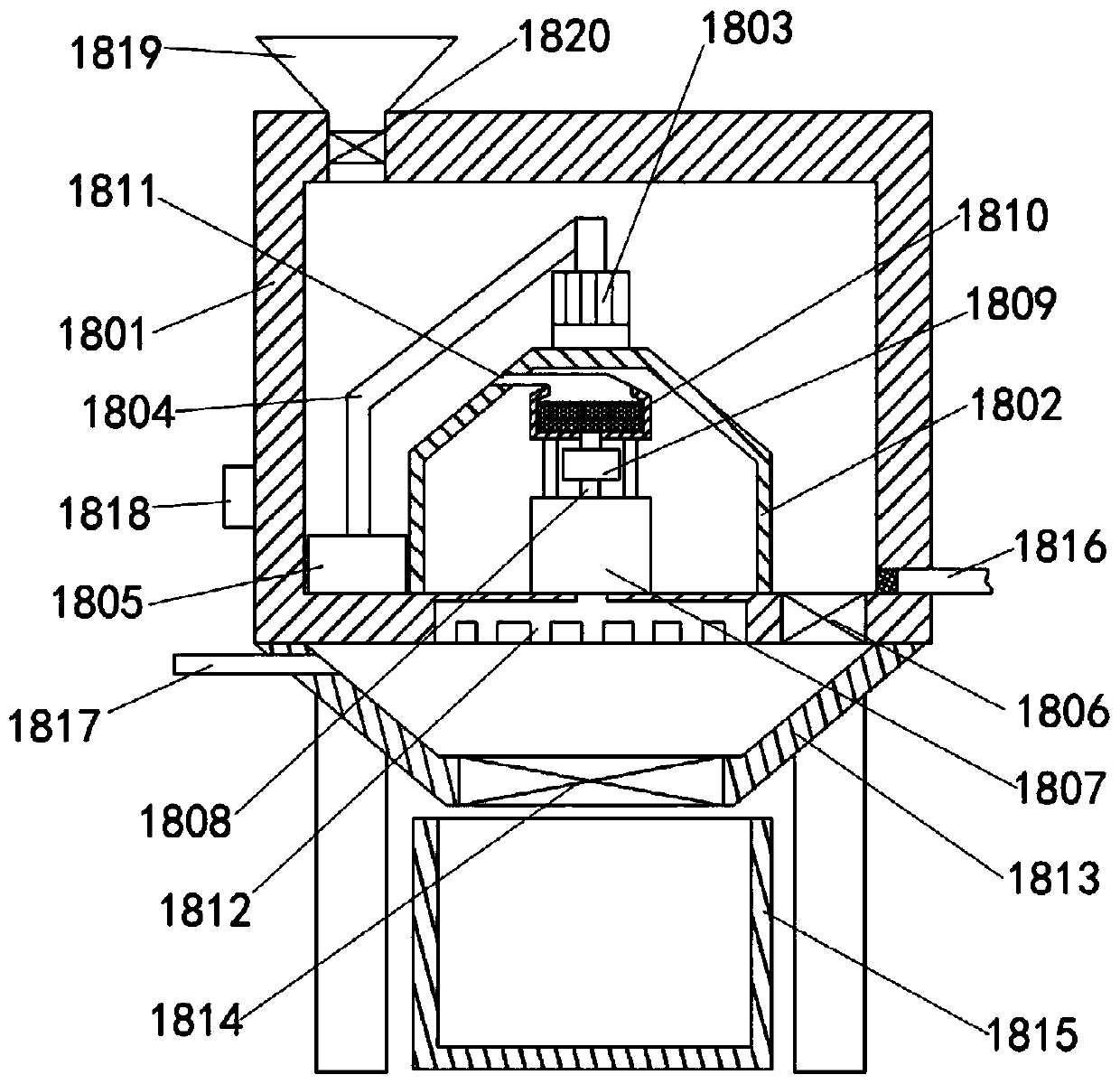

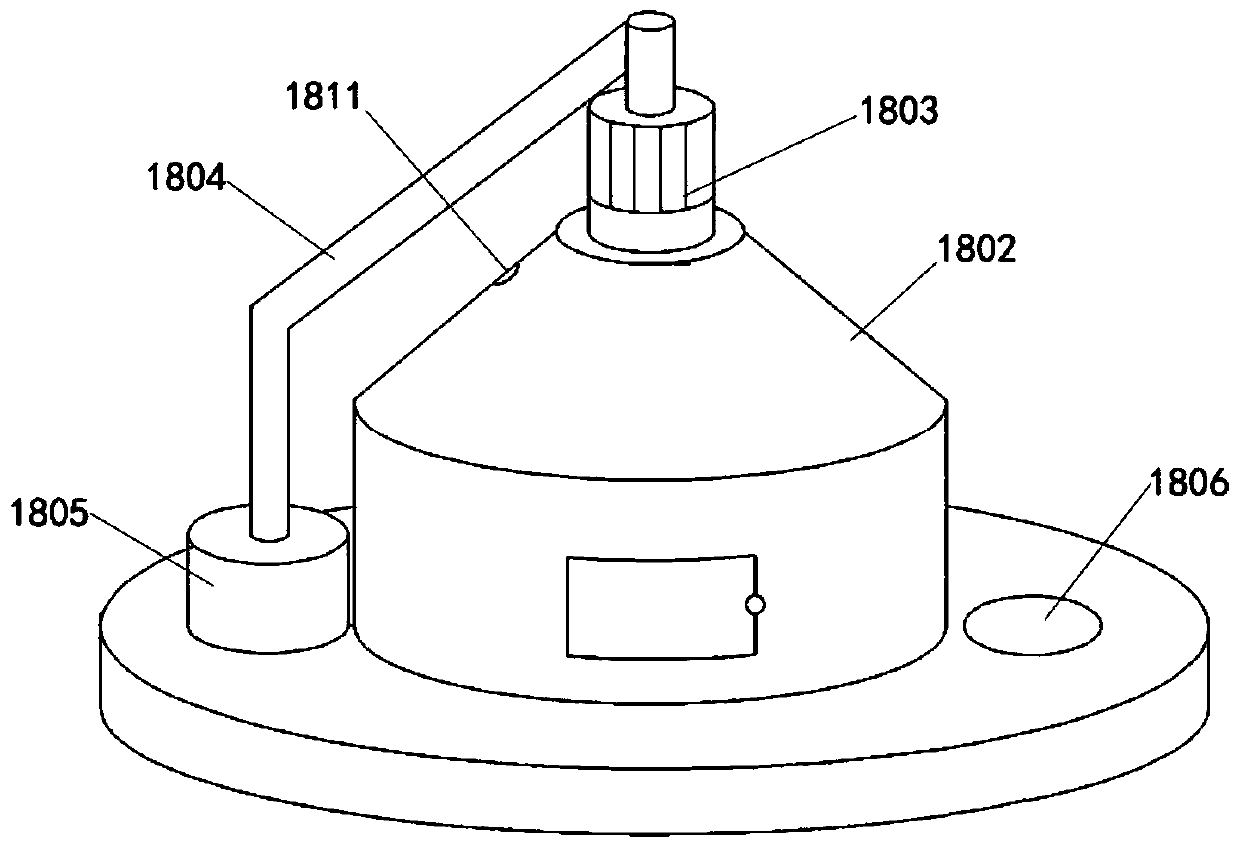

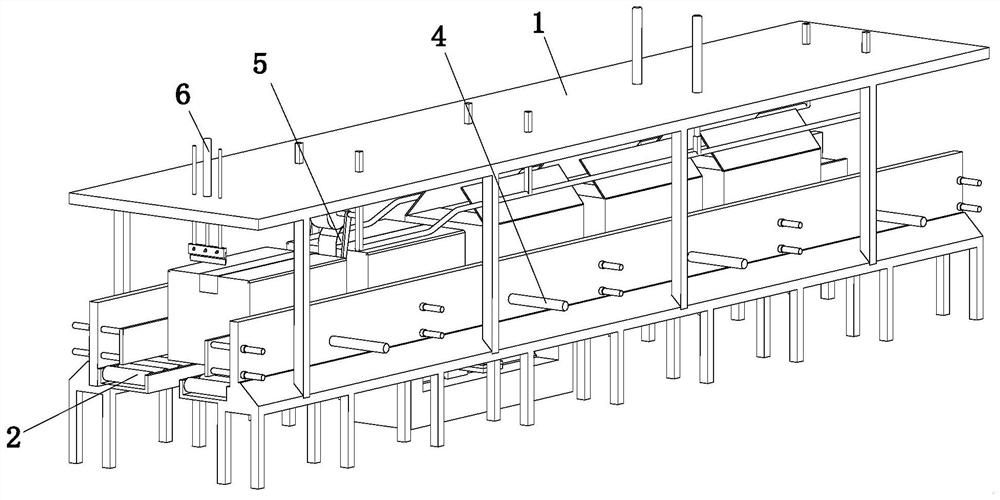

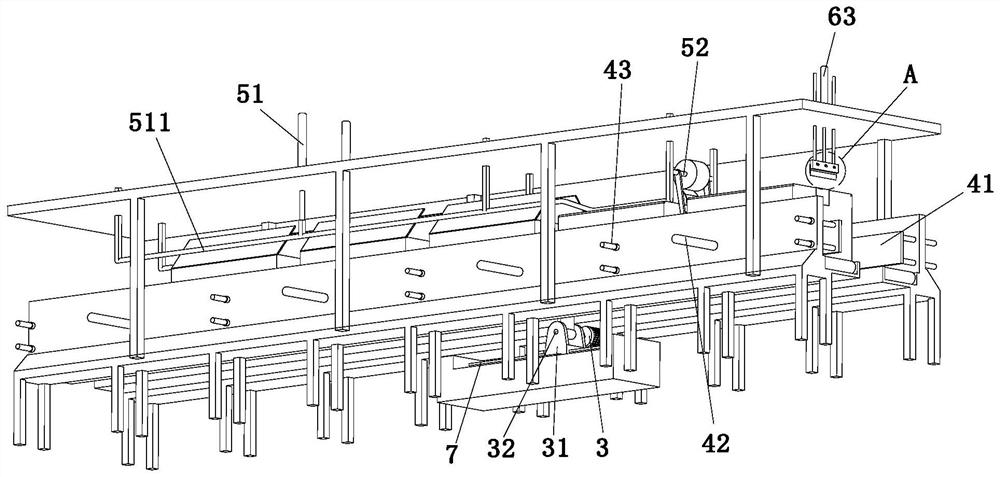

Sintering furnace used on solar battery production line

InactiveCN108518957AReduce distractionsPlace stableFinal product manufactureCharge treatment typeEngine displacementAirflow

The invention discloses a sintering furnace used on a solar battery production line. The sintering furnace comprises a rack and a conveyor belt, wherein a drying room is arranged on the left side of the top end of the rack; a sintering room is arranged on the right side of the drying room; the upper conveyor belt surface of the conveyor belt penetrates through the drying room and the sintering room; first material inlets / outlets corresponding to the conveyor belt are formed in the left and right end side walls of the drying room; second material inlets / outlets corresponding to the conveyor belt are formed in the left and right end side walls of the sintering room; and a plurality of uniformly arranged drying devices are arranged in the drying room, the drying devices are arranged at the bottom ends of the upper conveyor belt surface of the conveyor belt, a plurality of symmetrically distributed exhaust ports are formed in the top end of the drying room, and an exhaust fan is arranged in each exhaust port. The sintering furnace disclosed by the invention reduces the influence of an air flow on a silicon wafer, prevents drifting collision of the silicon wafer as a result of blowing of the air flow, improves the product quality, can adjust the gas displacement flexibly and conveniently, and saves energy.

Owner:ZHANGJIAGANG GUOLONG SOLAR TECH CO LTD

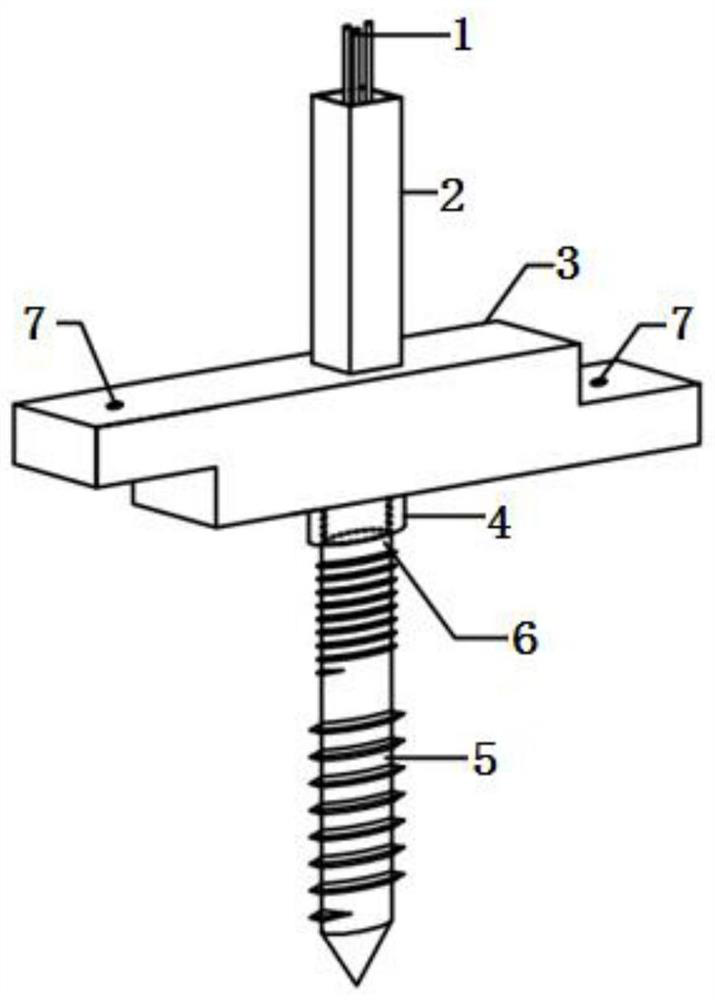

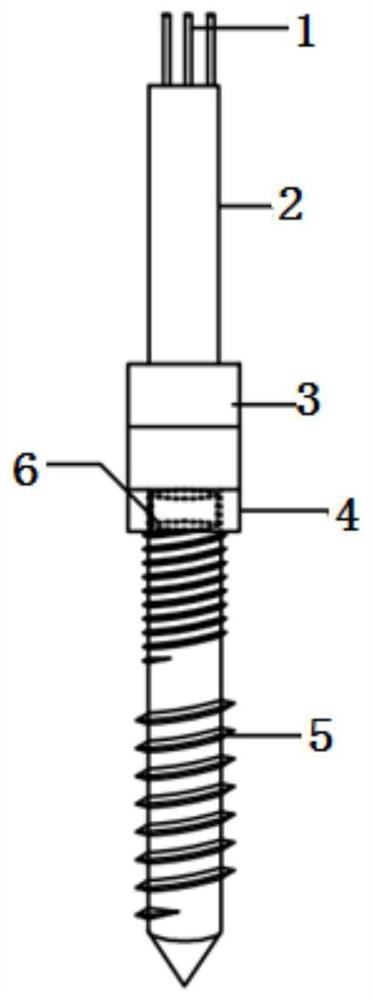

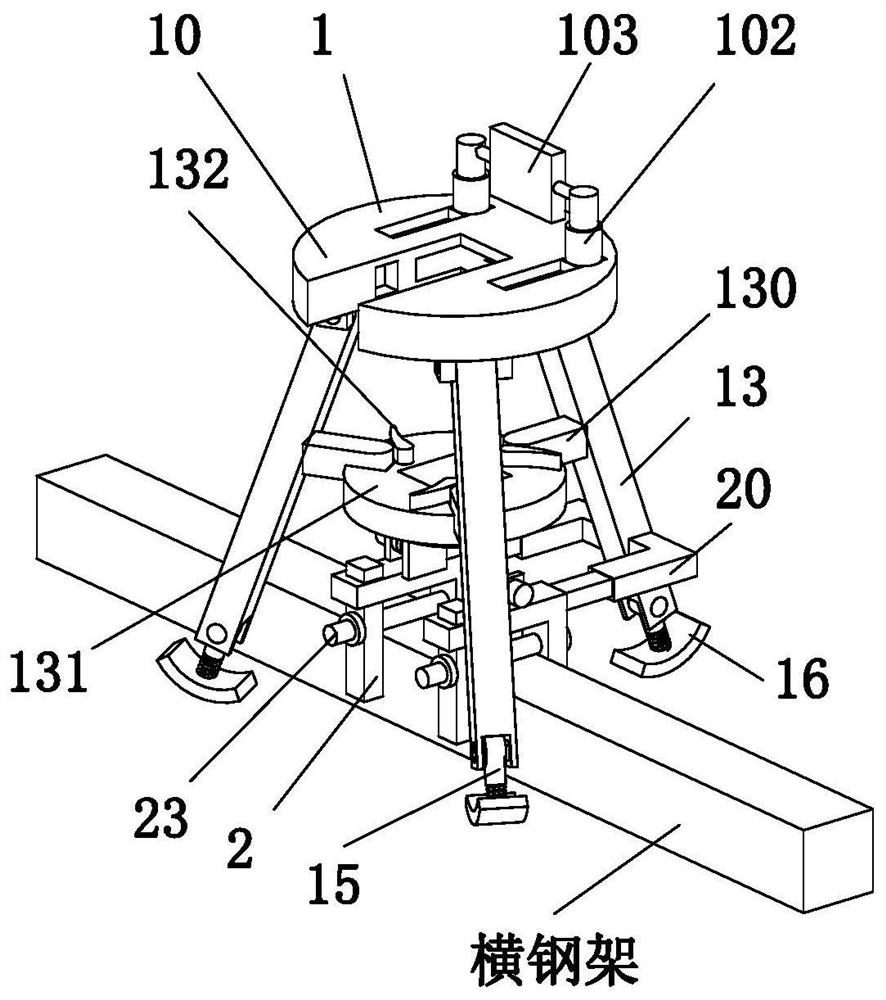

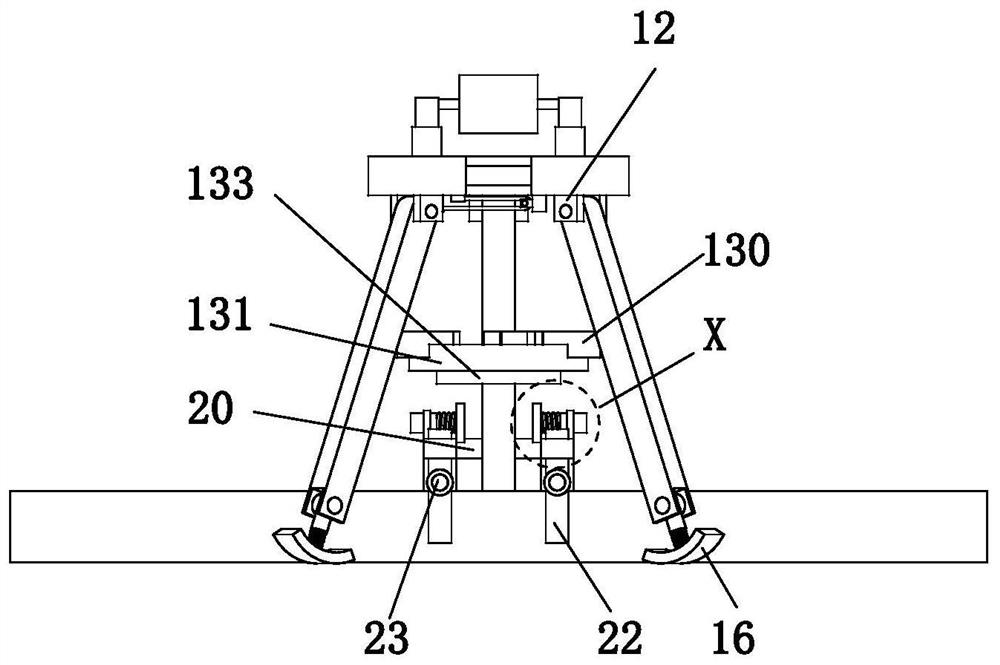

Unbonded prefabricated assembly type frame building foundation joint and connecting method thereof

ActiveCN112982473AImprove assembly efficiencyReduce construction costsBulkheads/pilesEnvironmentally friendlyArchitectural engineering

The invention relates to an unbonded prefabricated assembly type frame building foundation joint and a connecting method thereof. The unbonded prefabricated assembly type frame building foundation joint comprises a prefabricated bearing column, a prefabricated ground beam, an underground pile, an anchorage device, an inhaul cable and a prefabricated ground beam tray, wherein the prefabricated bearing column is of a solid columnar structure, a plurality of column holes penetrating through the axial direction of the prefabricated bearing column are formed in the prefabricated bearing column, a through hole penetrating through the axial direction of the prefabricated ground beam is formed in the prefabricated ground beam, the through hole is configured to allow the lower end of the prefabricated bearing column to be inserted therein, the underground pile is of a hollow columnar structure, the anchorage device is of a solid columnar structure, a plurality of anchorage device holes penetrating through the axial direction of the anchorage device are formed in the anchorage device, the anchorage device is detachably installed in a cavity of the underground pile, the inhaul cable is arranged in the column holes of the prefabricated force bearing column and the anchorage device holes of the anchorage device in a penetrating mode, and the prefabricated ground beam tray is of a hollow columnar structure and is arranged at the upper end of the ground pile in a sleeving manner. According to the unbonded prefabricated assembly type frame building foundation joint, the prefabricated assembly type is really achieved, the construction period is greatly shortened, the bearing capacity is high, the overall performance is good, and the joint can be repeatedly used, is green and environmentally friendly and has quite high economic benefits.

Owner:BEIJING UNIV OF TECH

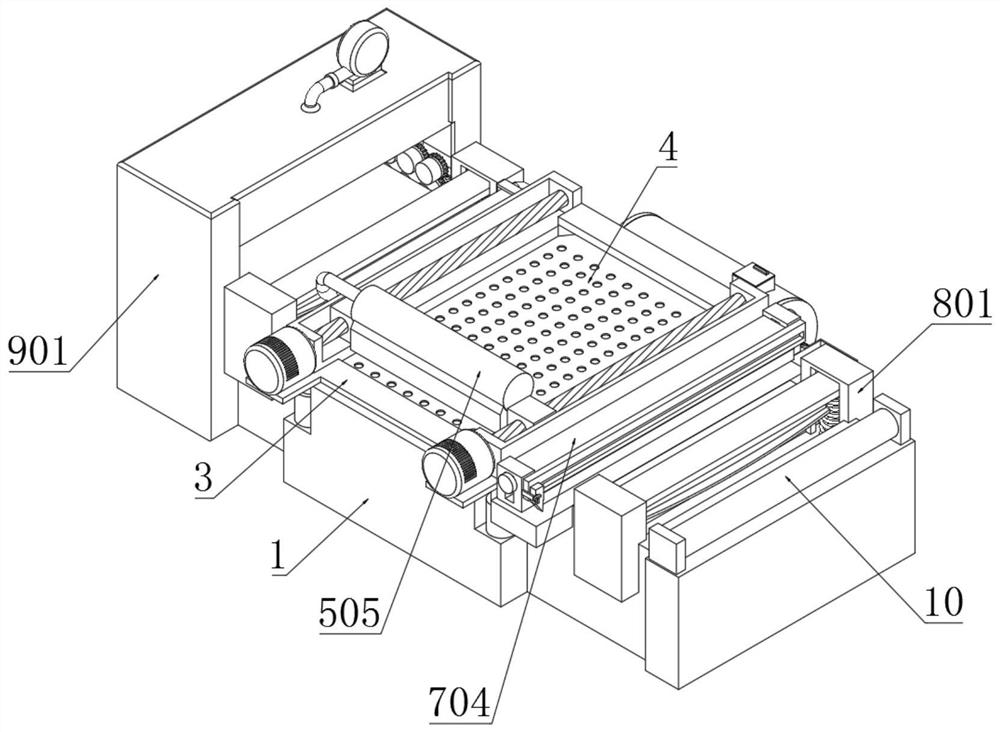

A printing and dyeing treatment device capable of improving the printing and dyeing quality of printed and dyed cloth

ActiveCN111591009BScientific and reasonable structureEasy to useMechanical cleaningInking apparatusStructural engineeringMechanical engineering

The invention discloses a printing and dyeing treatment device capable of improving the printing and dyeing quality of printed and dyed cloth. The two ends of the top of the base are symmetrically fixed with fixed seats, and the middle part of the fixed seat is provided with a rectangular groove, and an extrusion spring is fixedly installed inside the rectangular groove. The top of the extrusion spring is fixedly connected with a connecting plate, the middle part of the bottom end of the connecting plate is fixedly connected with an adjusting plate, one end of the bottom of the adjusting plate is fixedly connected with a leveling plate, and the two side walls inside the fixing seat are symmetrically provided with chute. The invention has a scientific structure. Reasonable, safe and convenient to use, through the combined use of the adjusting plate and the extrusion spring, the tension of the cloth during the running process can be dynamically adjusted to avoid the deformation of the cloth caused by excessive pulling when the cloth is running, and the pattern of printing and dyeing of the cloth will occur after the deformation of the cloth Change, through the use of the leveling plate, it has a leveling effect on the cloth, preventing the cloth from being wrinkled during the traveling process and causing the cloth to be unable to be printed, dyed, processed and rolled normally.

Owner:普宁市鸿骏实业有限公司

Negative pressure type embossing device capable of rapidly unfolding clothes

InactiveCN112680920AAvoid wrinklesGood for normal embossing operationsPattern makingEngineeringPleat

The invention discloses a negative pressure type embossing device capable of rapidly unfolding clothes. The embossing device comprises an embossing device body, an operation table, a protective door, a support frame, a telescopic mechanism, a support plate, an embossing plate, a control box, a connecting pipe, an exhaust fan, a reset rotating shaft and a fixing screw, wherein the operation table is arranged on the embossing device body; the protective door is arranged on the front side of the operation table; a sliding part is arranged at the lower end of a tensioning structure; the sliding part is connected with a sliding groove in the upper end face of the operation table; meanwhile, a pulling frame is welded to the upper end of a pressing part; and pressing blocks are glued to the inner sides of the front ends of the sliding part and the pressing part. According to the negative pressure type embossing device capable of rapidly unfolding the clothes, by improving an operation table and an embossing plate mounting structure of an existing embossing device, when the clothes are embossed, the area, needing to be embossed, of the clothes can be spread flatly, so that wrinkles of the clothes are avoided, normal embossing operation of the clothes is facilitated, and the embossing quality of the clothes is improved.

Owner:马鞍山鸿儒工业设计有限公司

A kind of reinforcement treatment method of steel structure bridge

ActiveCN111691318BReduced Relative Offset PhenomenaImprove stabilityBridge erection/assemblyBridge strengtheningClassical mechanicsEngineering

Owner:浙江东冶建设有限公司

Packaging device for packaging boxes

PendingCN112607122AImplement encapsulationImprove packaging efficiencyWrapper twisting/gatheringAdhesive beltEngineering

The invention discloses a packaging device for packaging boxes, and relates to the technical field of packaging equipment. The packaging device for the packaging boxes comprises an installation frame, a conveying device, an adjusting device, limiting devices, a glue sealing device and a cutting device, wherein the conveying device is arranged at the middle part of the installation frame, the adjusting device is arranged at the lower end of the conveying device, and two limiting devices are arranged; the two limiting devices are symmetrically installed at the two sides of the conveying device, the glue sealing device comprises a gland assembly and a glue sealing assembly, the gland assembly and the glue sealing assembly are both arranged on the upper part of the installation frame, and the glue sealing assembly is located at one end of the gland assembly; and the cutting device is installed on the installation frame and located beside the glue sealing assembly. The packaging device for the packaging boxes can be suitable for packaging the packaging boxes of different sizes, so that the application range of the packaging device for the packaging boxes is widened; and in addition, the packaging boxes do not need to be packaged by tearing adhesive tape one by one, so that the packaging process is more continuous, and the working efficiency is increased.

Owner:温州雅光印务有限公司

A round blade leather machine for making flat sneakers

ActiveCN110305991BEasy to control the amount of adjustmentPlay a role in compressingLeather manufacturingStructural engineeringKnife blades

The invention discloses a round blade leather machine for making flat sneakers, which comprises a leather machine body and a support rod, the support rod is fixedly connected to the upper end of the leather machine body, one end of the support rod is fixedly connected with an upper blade groove column, an upper blade There is an inner groove cavity in the middle of the groove column; when the device adjusts the adjustment column, it is convenient to control the adjustment amount, and after adjustment, the two sides play a role of compression; by setting on the side wall of the circular blade groove When the round blade is working, the sharpening block plays a grinding role on the surface of the round blade, making the surface of the grinding blade smoother, greatly reducing the burrs caused by the round blade on the leather; through grinding The brush connected to the knife block is directly oiled on the circular blade peeling machine, and the brush contacts the surface of the circular blade to perform lubrication operation when the circular blade is working. The device has a simple structure and saves time and effort.

Owner:鹤山市新易高鞋业有限公司

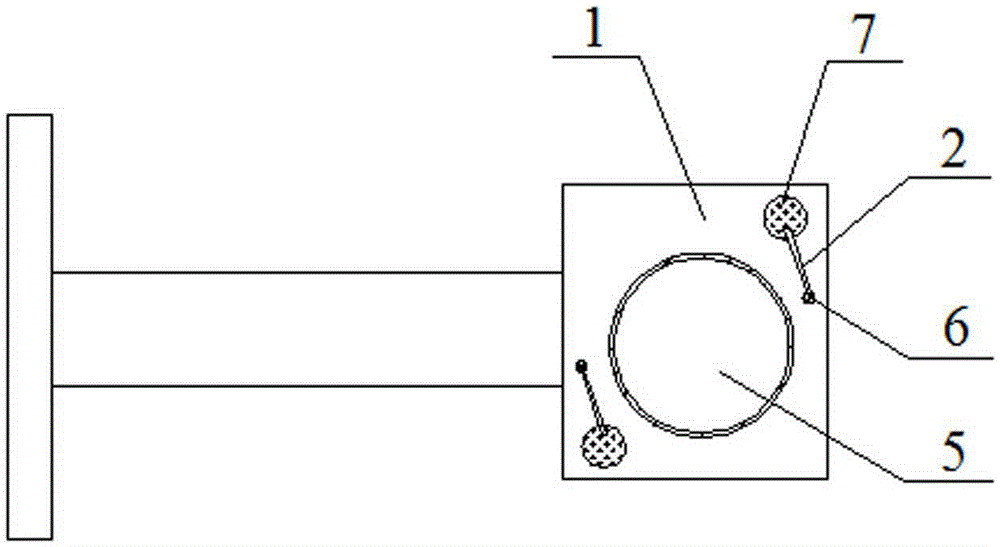

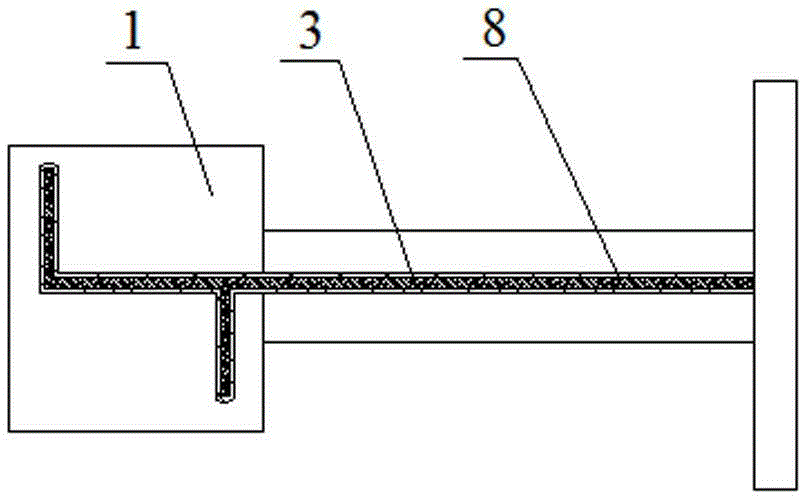

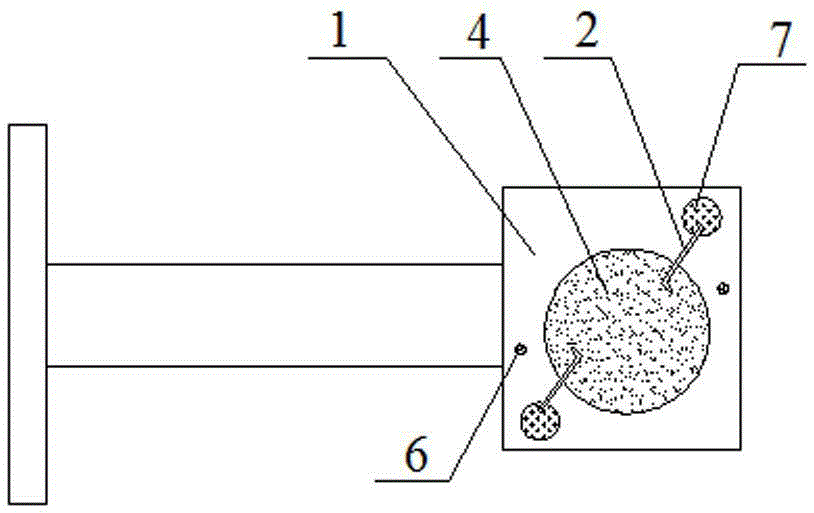

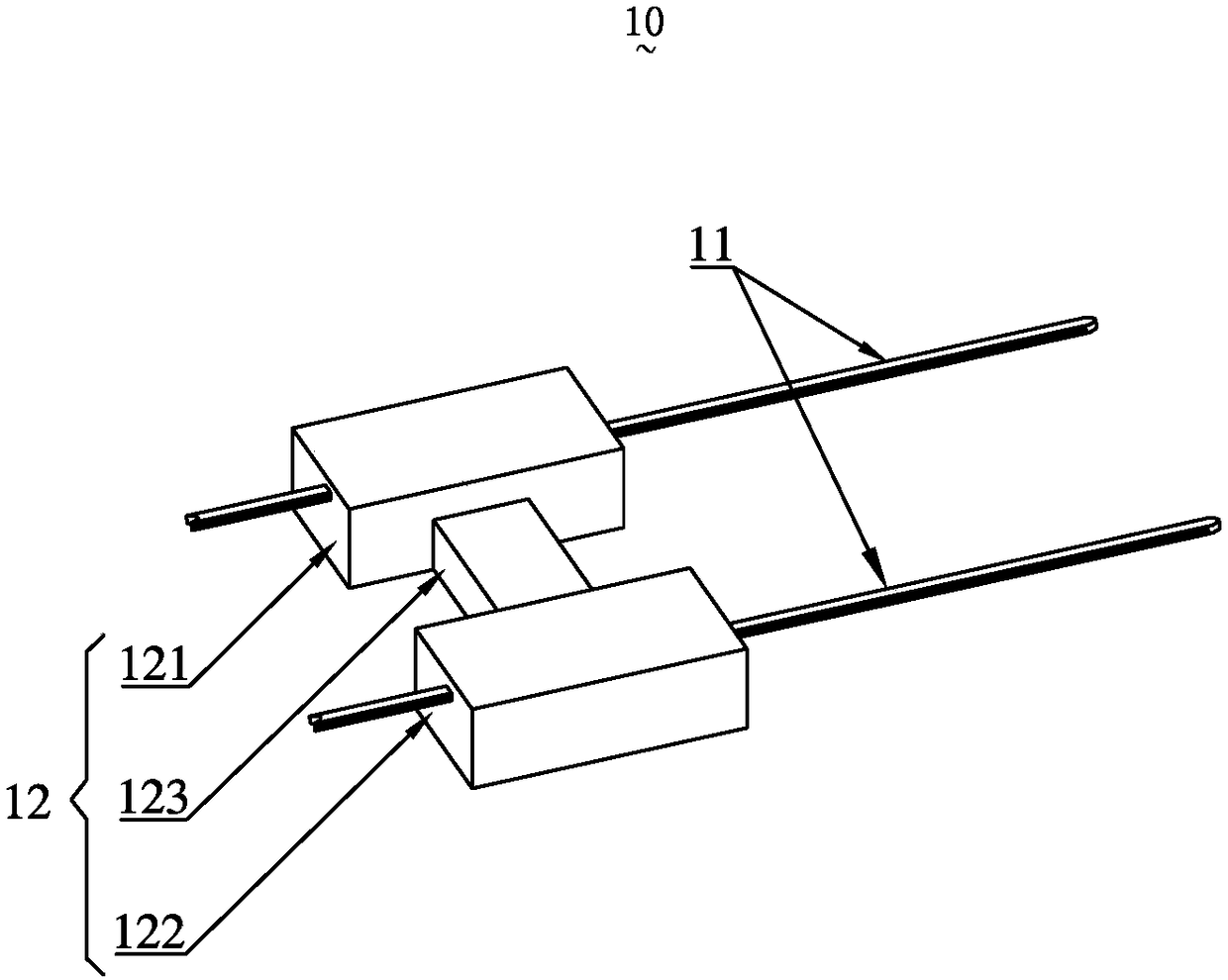

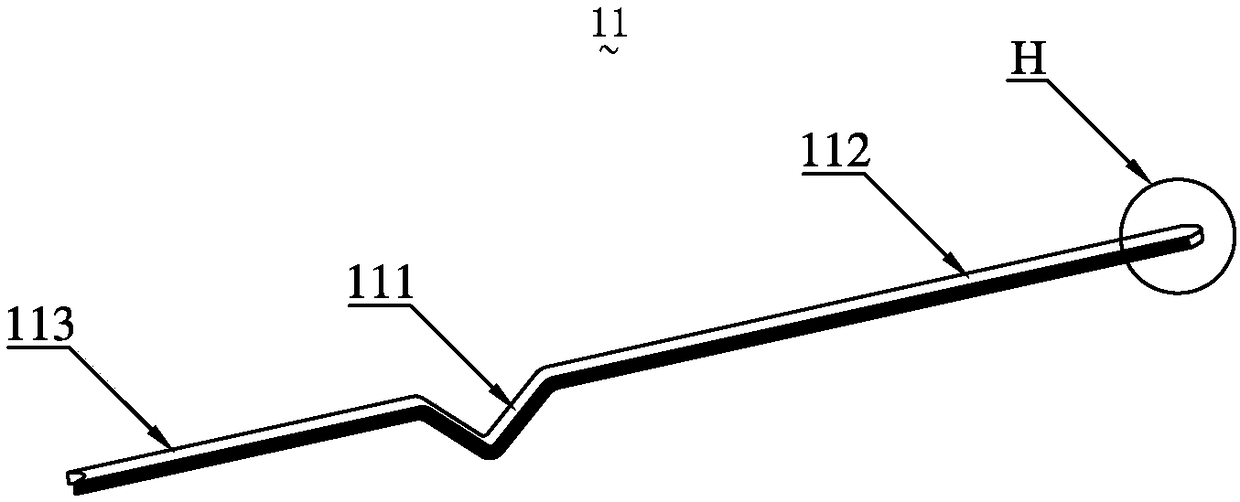

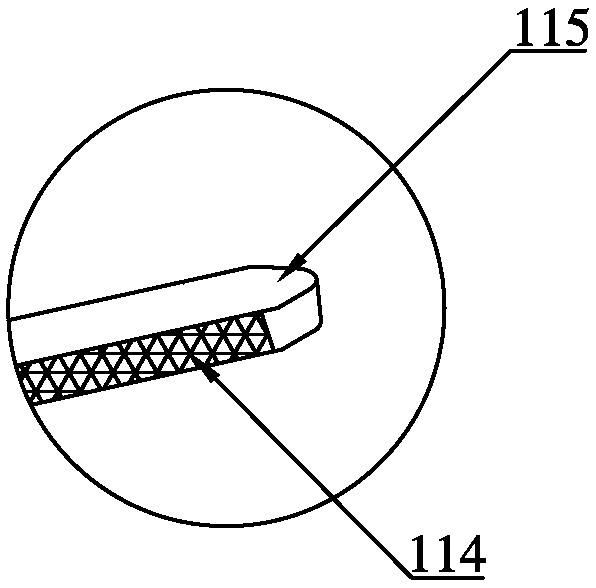

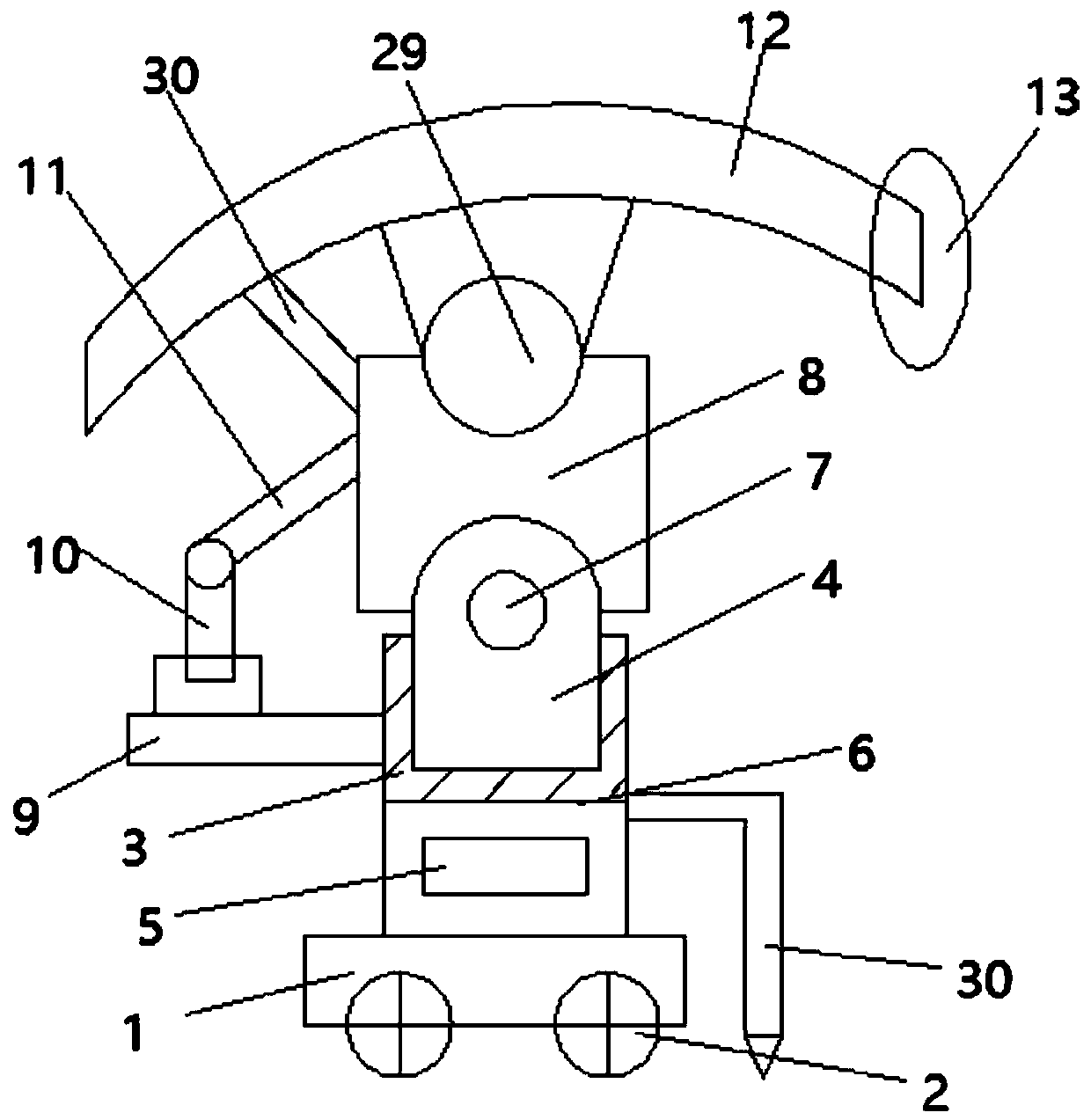

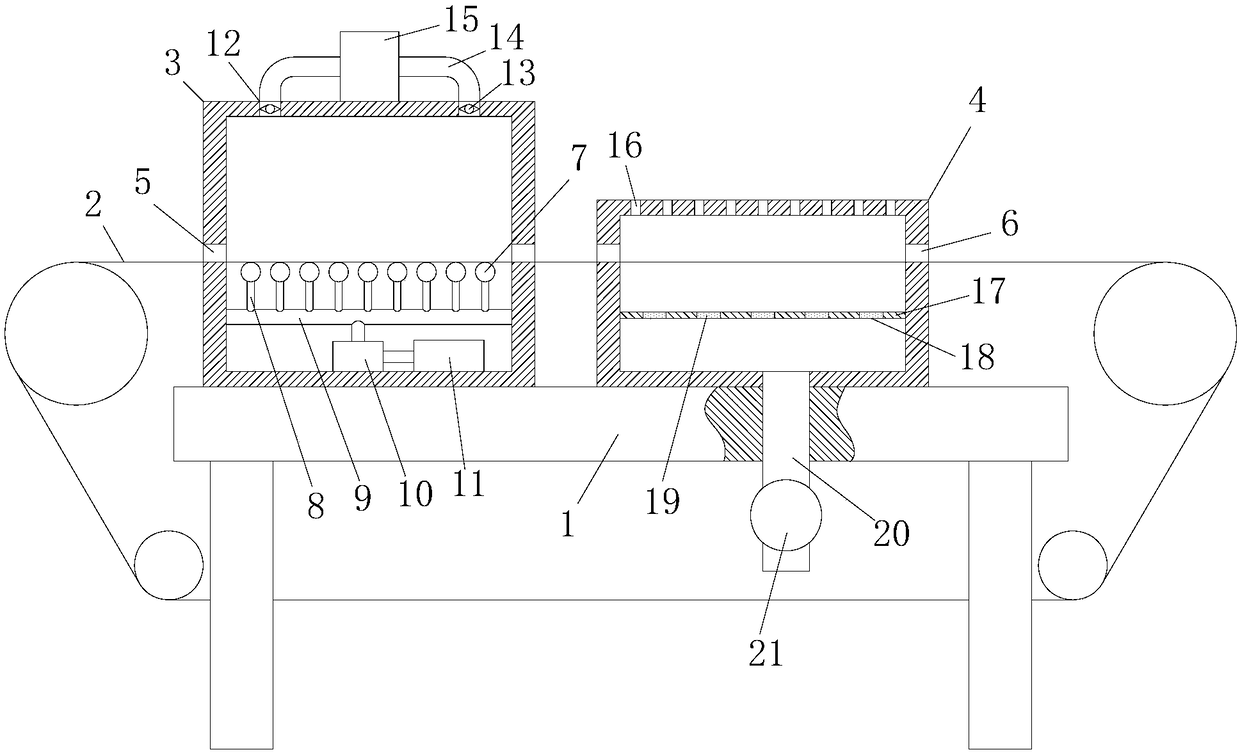

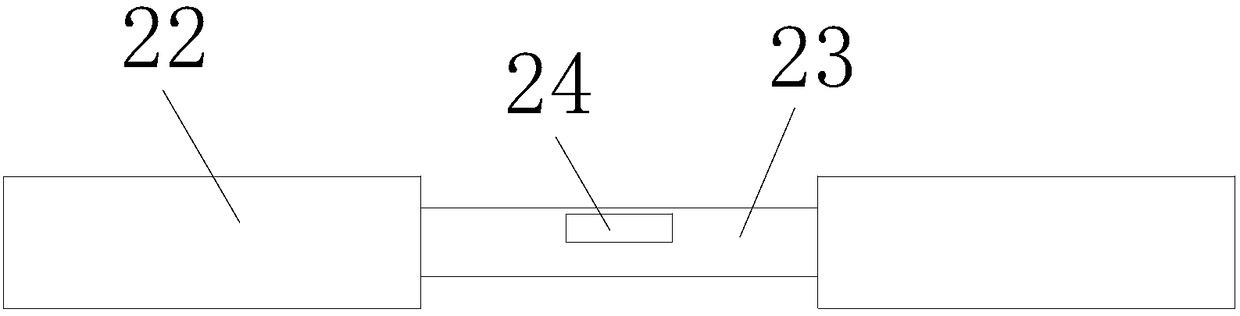

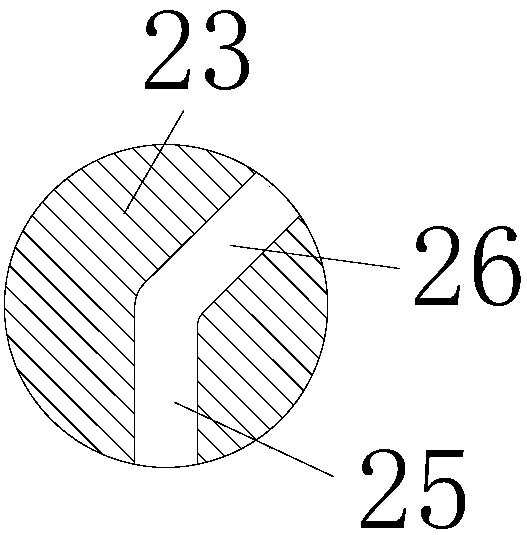

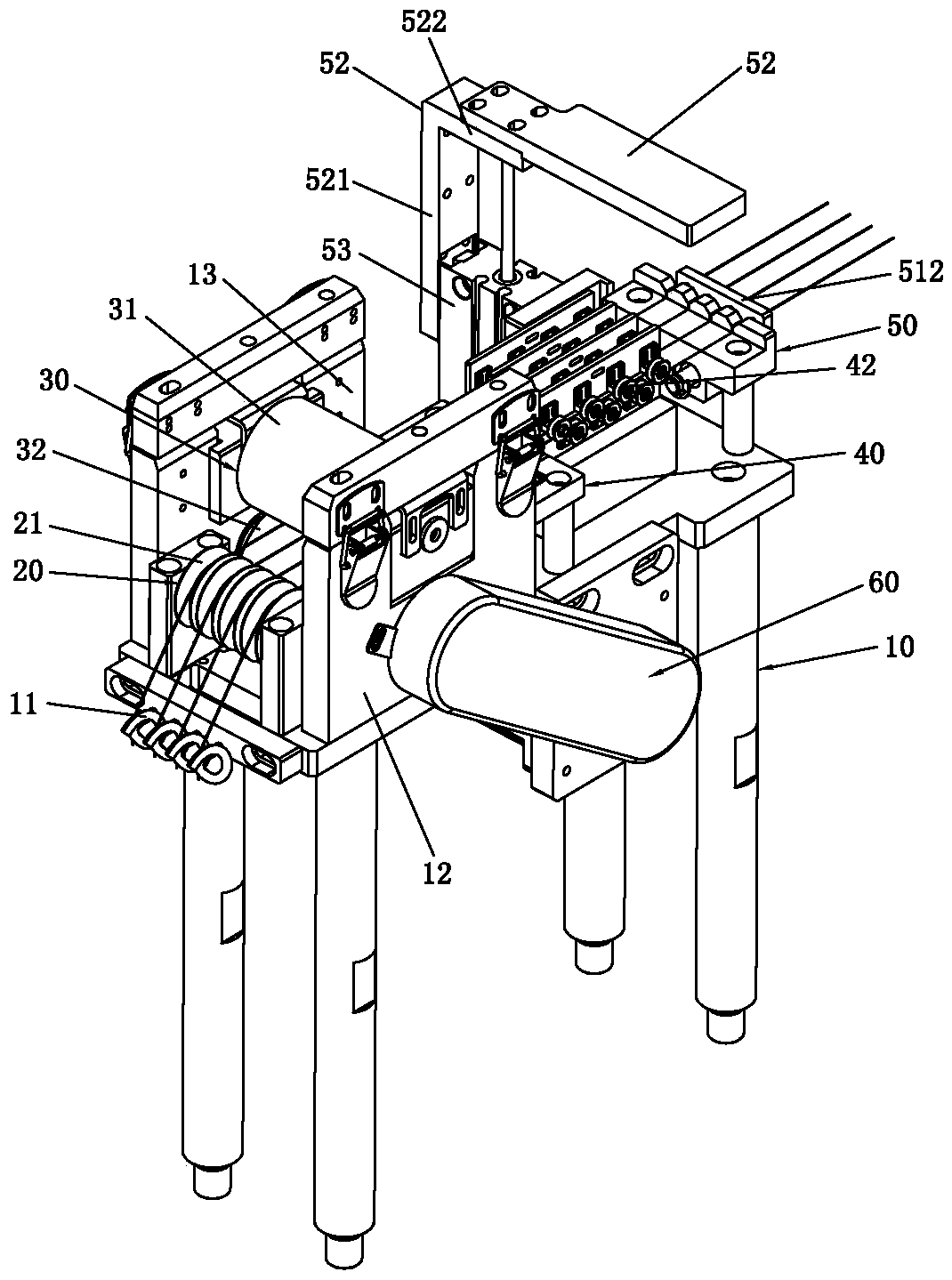

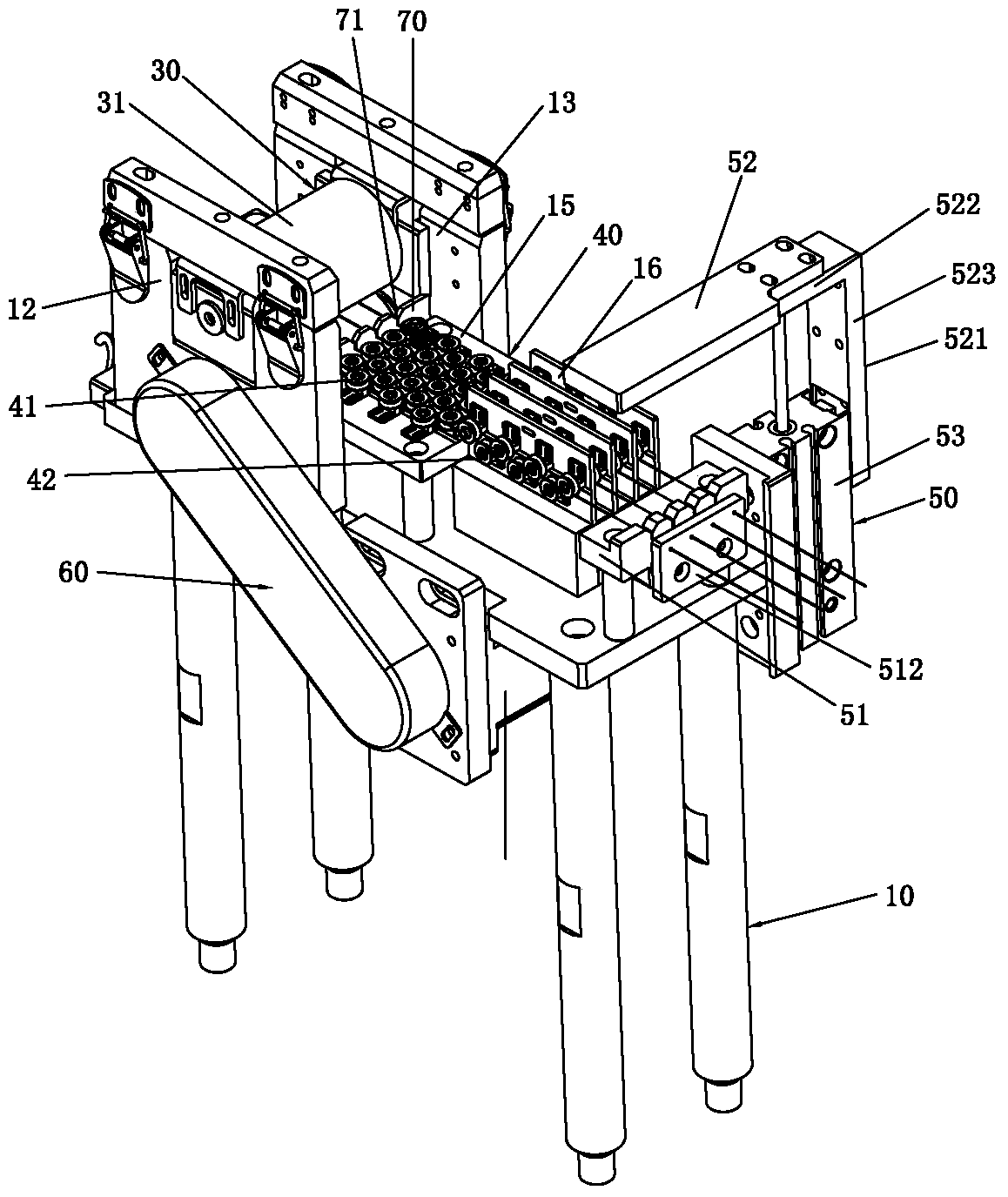

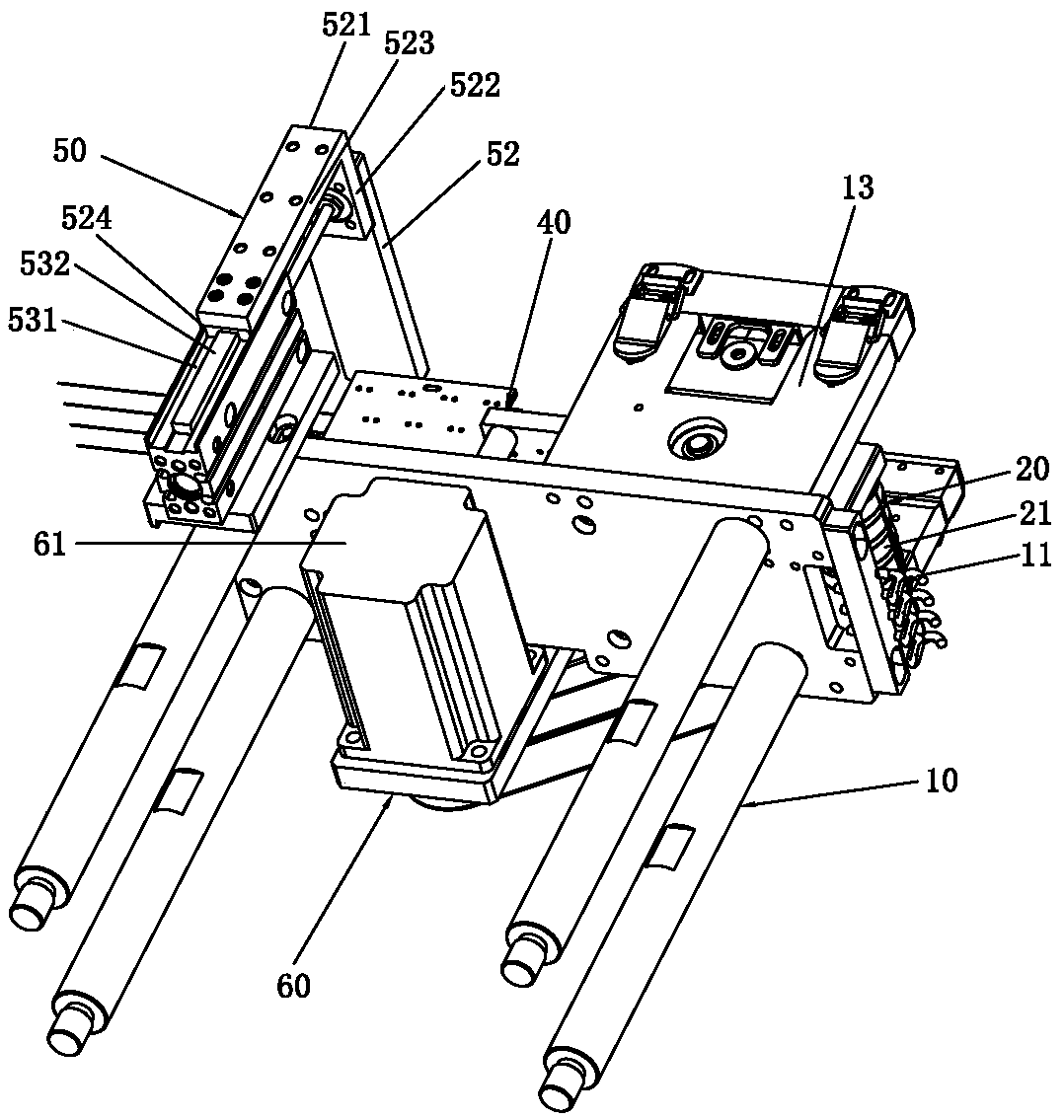

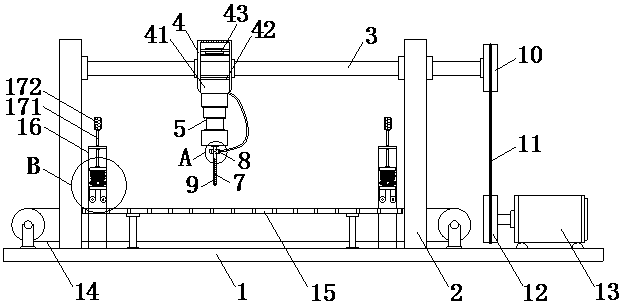

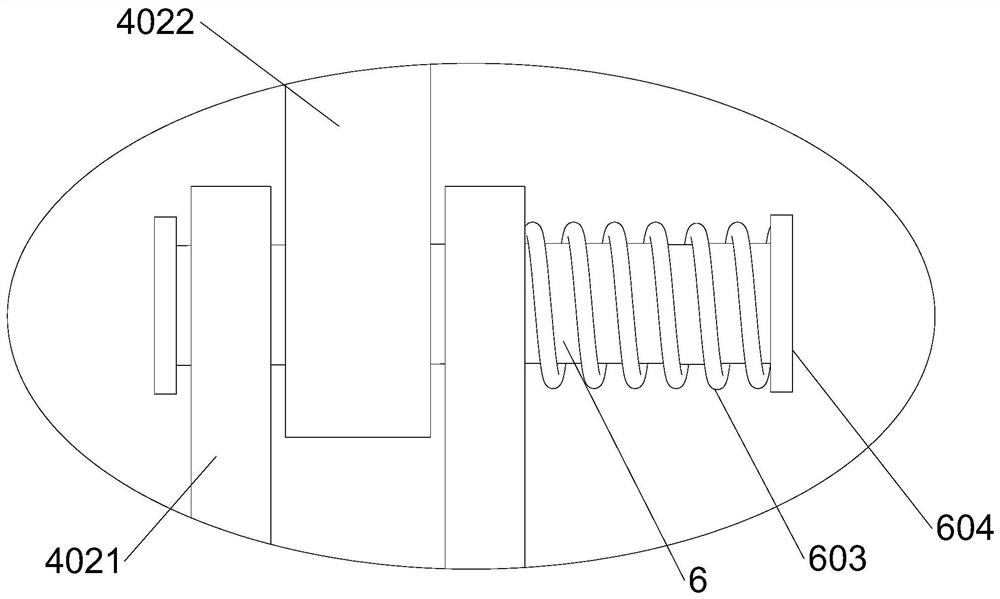

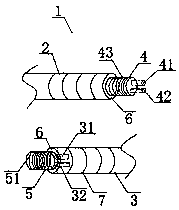

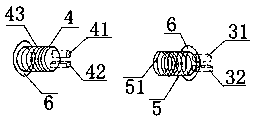

Cable straightening facility and cable straightening technology

The invention discloses a cable straightening facility and a cable straightening technology. The cable straightening facility comprises a machine body, a guide mechanism, a press mechanism, a straightening mechanism and a clamping mechanism. The guide mechanism is used for guiding the cable incoming direction of cables, the press mechanism is used for tightly pressing and locating the cables, thestraightening mechanism is used for straightening the cables, and the clamping mechanism is used for preventing the straightened cables from deforming. The guide mechanism, the press mechanism, the straightening mechanism and the clamping mechanism are arranged on the machine body in sequence. The straightening mechanism comprises straightening press wheel sets. In this way, by means of the designof the guide mechanism, the press mechanism, the straightening mechanism and the clamping mechanism, the automatic straightening operation of the cables is achieved, the structural design is simple,exquisite and reasonable, the straightening efficiency is high, and the straightening quality of the cables is consistent. Due to the arrangement of the press mechanism of the cable straightening facility, the situation that the cables jump up and down when the straightening work is conducted is avoided. Meanwhile, the straightening mechanism straightens the cables through the straightening presswheel sets, and therefore the problems that the straightening effect is poor when cable grooves are too wide, and the cables can be damaged when the cable grooves are too narrow are solved.

Owner:皓星智能装备(东莞)有限公司

A steel pipe punching machine

ActiveCN106041166BAvoid affecting manufacturing processesPrevent from compromising accuracyFeeding apparatusPositioning apparatusPunchingEngineering

The invention discloses a steel pipe perforating machine which comprises a base. Supporting frames are fixedly mounted at the two ends of the upper surface of the base. A moving lead screw is mounted on the supporting frames in a sleeved manner. A scrap collection mechanism is mounted on the moving lead screw in a sleeving manner. The bottom end of the scrap collection mechanism is fixedly connected with an electric telescopic rod. The end, far away from the scrap collection mechanism, of the electric telescopic rod is fixedly connected with a perforating motor. A drill bit is fixedly mounted on an output shaft of the perforating motor. A scrap guide hole communicating with the scrap collection mechanism through a hose is formed in the top of the drill bit. A sealing piece is arranged on the outer portion of the scrap guide hole, wherein the drill bit is sleeved with the sealing piece. Scrap collection holes communicating with the scrap guide hole are formed in the bottom end of the drill bit at equal distance. One end of the moving lead screw penetrates and extends out of one supporting frame to be fixedly connected with the axis of a driven disc. According to the steel pipe perforating machine, the scrap collection holes are formed in the drill bit and cooperate with the scrap collection mechanism, negative pressure is generated through a draught fan, and therefore scraps generated by machining can be collected, and the situation that the scraps are accumulated, and consequently next machining is influenced is avoided.

Owner:无锡市汇鼎金属制管有限公司

Radiology department image diagnosis film reading device

The invention discloses a radiology department image diagnosis film reading device, and relates to the technical field of diagnosis image film reading devices. The film reading device comprises a boxbody, a cover plate is hinged to the box body, a first film reading unit and a second film reading unit which can be stored in the box body are arranged on the two sides of the interior of the box body respectively, and a positioning assembly used for elastically supporting the first film reading unit and the second film reading unit is arranged in the box body; the first film reading unit and thesecond film reading unit each comprise a film reading assembly and a foldable folding supporting assembly, each film reading assembly comprises a light-transmitting plate and a frame, the light-transmitting plates are installed in the frames, supporting plates are arranged at the upper ends of the folding supporting assemblies, and rotating connecting assemblies are arranged between the supporting plates and the frames; and each film reading assembly is also provided with a pressing assembly for elastically pressing the film. The film reading device can be stored and carried, occupies a smallspace, and is convenient for doctors to read films when going out for treatment or academic communication and the like; and the two films can be conveniently compared and observed at the same time.

Owner:山西白求恩医院

Rebar materials convenient to connect

InactiveCN108756079AGuaranteed firmnessPlay a role in compressingBuilding reinforcementsEngineeringRebar

The invention discloses rebar materials convenient to connect. The rebar materials convenient to connect comprise rebar material bodies, wherein the rebar material bodies comprises first rebar materials and second rebar materials, cylindrical connecting blocks are arranged on the first rebar materials, first screw threads are arranged on the connecting blocks, and the connecting blocks are arranged in a solid core shape. Cylindrical socketed pipes are arranged on the second rebar materials, and the socketed pipes are hollow inside. Second screw threads are arranged on the inner sides of the socketed pipes, gaskets penetrating through the connecting blocks and the socketed pipes are correspondingly arranged on the surfaces of the first rebar materials and the second rebar materials. The rebar materials convenient to connect have the beneficial effects that through the arrangement of the connecting blocks, the socketed pipes and clamping devices, the rebar material bodies can be connected with each other without welding, and the connection is stable, the resources and time are saved, and the work efficiency is improved.

Owner:江苏海川新材料科技有限公司

A slotting device for building decoration that can improve slotting precision

ActiveCN110253767BHigh precisionEasy to useWorking accessoriesStone-like material working toolsBuilding renovationIndustrial engineering

The invention discloses a slotting device for building decoration which can improve the slotting precision, which comprises a support frame, a dust collection box, a bearing, a handle, a connecting pipe, a connecting channel, a dust suction port and a hose. The inside of the support frame A sliding rod is provided, and a supporting plate is arranged on the sliding rod, and a dust collection box is arranged under the supporting plate, a lifting groove is opened on the inner side of the supporting plate, and the inside of the lifting groove is connected with the supporting rod, and the supporting rod The middle part of the connecting block is connected with the connecting block, the second sliding block is arranged under the first sliding block, and the second sliding block is connected with the bottom end inside the fixed shell through the sliding groove, and the handle bolt is connected to the fixed shell The outer side of the support plate is provided with knobs on the upper and lower sides of the front side. The slotting device for building decoration which can improve the slotting precision can improve the slotting precision of the wall surface, and the slotting machine can be installed and removed from the fixed casing according to the slotting requirements, which is convenient for users to use.

Owner:上海美凯龙装饰工程集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com