Methane hydrochlorination reactor

A hydrochlorination and reactor technology, which is applied in the field of methane hydrochlorination reactors, can solve problems such as uneven temperature distribution, poor distributor performance, and small number of pipes, so as to reduce equipment maintenance costs, improve uniformity, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

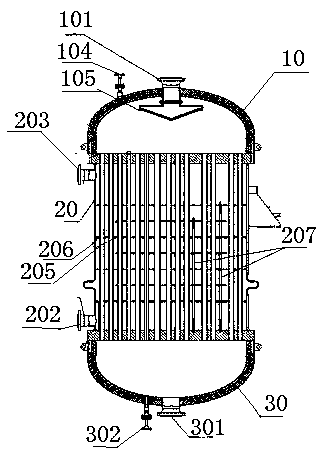

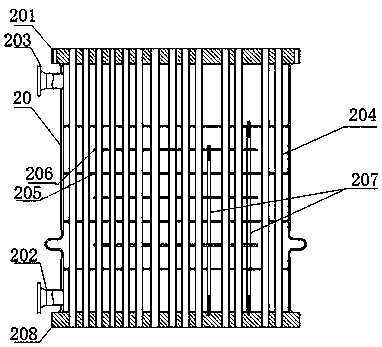

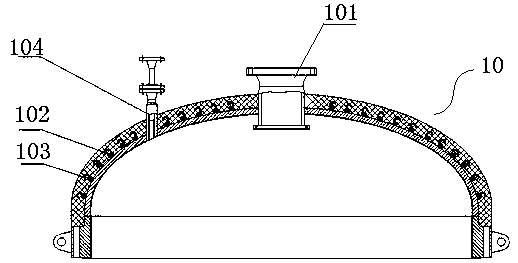

[0046] like Figure 1~4 Shown, a kind of methane hydrochlorination reactor, comprises from top to top the upper seal head 10, shell 20, lower seal head 30 that are fixedly connected successively, and described upper seal head 10 top is provided with feed pipe 101, and lower seal head 10 top is provided with feed pipe 101, and lower seal The bottom of the head 30 is provided with a discharge pipe 301, which also includes an upper sealing plate 201 welded and fixedly connected to the upper end of the housing 20; a welded lower sealing plate 208 fixedly connected to the lower end of the housing 20; a liquid inlet pipe 202, Welding is fixedly connected to the lower part of the housing 20 and is located above the lower sealing plate 208; the liquid outlet pipe 203 is welded and fixedly connected to the upper part of the housing 20 and is located below the upper sealing plate 201; a plurality of heat exchange tubes 204 are respectively welded and fixedly connected at both ends The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com