Rebar materials convenient to connect

A technology of ribs and connecting blocks, applied to structural elements, building components, building reinforcements, etc., can solve problems such as wasting time and inconvenient welding, and achieve the effects of stable connection, improved work efficiency, and resource and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

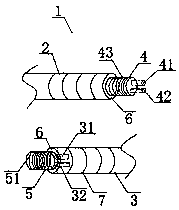

[0016] Embodiment one, combined with the attached figure 1 , a bar for easy connection, including a bar body 1, the bar body 1 includes a first bar 2 and a second bar 3, and a cylindrical connecting block is arranged on the first bar 2 4. A first thread 43 is provided on the connecting block 4, and the connecting block 4 is solid, and a cylindrical sleeve 5 is provided on the second rib 3, and the connecting block 4 and the sleeve The diameters of 5 correspond to each other; the inside of the socket pipe 5 is hollow, and a second thread 51 is provided on the inside of the socket pipe 5, and the first thread 43 on the connecting block 4 is connected with the inside of the socket pipe 5. Correspondingly, the second thread 51 is set correspondingly, and threaded lines 7 are provided on the reinforcement body 1, passing through the connection block 4 and the socket pipe 5 on the surfaces of the first reinforcement 2 and the second reinforcement 3 respectively. A washer 6 is provi...

Embodiment 2

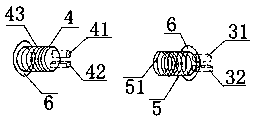

[0018] Embodiment two, combined with figure 2 , the connecting block 4 is provided with a clamping device, and the clamping device is respectively a first cylindrical clamping block 41 and a first square column clamping block 42; One side of the socket pipe 5 is provided with a second cylindrical clamping block 31 and a second square column clamping block 32 corresponding to the clamping device, and the second cylindrical clamping block 31 and the second square column clamp Block 32 is all hollow settings.

[0019] The setting of the clamping device, that is, the setting of the solid first cylindrical clamping block 41 and the first square column clamping block 42 on the connecting block 4 and the hollow second cylindrical clamping block on the second rib 3 31 and the second square columnar clamping block 32, when the connecting block 4 is inserted into the socket pipe 5, the first cylindrical clamping block 41 on the connecting block 4 and the corresponding sleeve of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com