Cutting device with good pressing effect for lithium battery aluminum foil machining

A technology of cutting device and lithium battery, applied in the direction of lithium battery, metal processing, battery electrode, etc., can solve the problems of the scale affecting cutting, the poor pressing effect of lithium battery aluminum foil, and the inconvenience for users to use, and achieve the pressing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

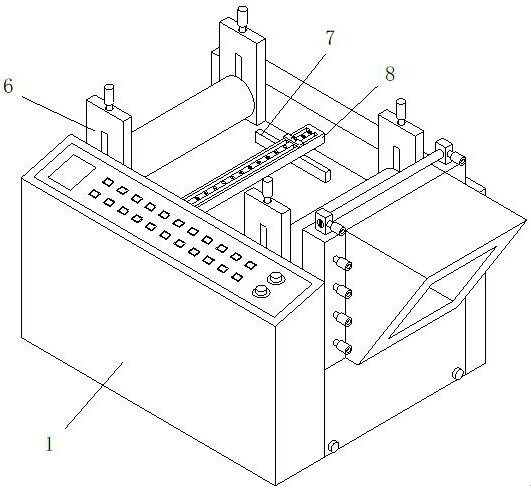

[0030] see Figure 1-8 , a cutting device for lithium battery aluminum foil processing with good compression effect, comprising a device body 1, fixed plates 6 are fixedly connected to both sides of the inner wall of the device body 1, and the opposite sides of the two fixed plates 6 are flexibly connected to press The top of the pressing component 2 is fixedly connected with the pulling component 3, the top of the pulling component 3 penetrates to the top of the fixed plate 6, the inner wall of the device body 1 is fixedly connected with the connecting plate 8, and both sides of the connecting plate 8 are Two movable blocks 14 are movably connected, the limit plate 7 is fixedly connected between the bottoms of the two movable blocks 14, the transmission assembly 5 is fixedly connected inside the movable block 14, and the buckle assembly is fixedly connected between the tops of the transmission assembly 5 4. The top of the connection plate 8 is provided with a slot 12 for use ...

Embodiment 2

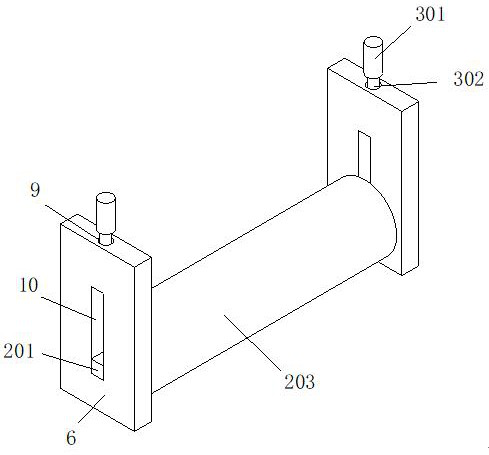

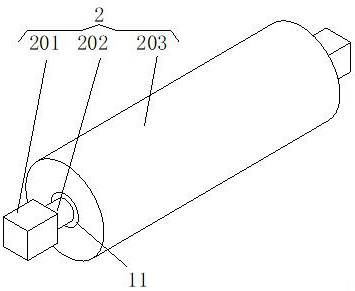

[0034] refer to Figure 2-4A cutting device for lithium battery aluminum foil processing with good pressing effect also includes a pressing assembly 2, wherein the pressing assembly 2 includes a pressing roller 203, and both sides of the pressing roller 203 are movably connected with a rotating rod 202, and the rotating rod The side of 202 away from the pinch roller 203 is fixedly connected with a transmission block 201, the surface of the transmission block 201 is movably connected with the fixed plate 6, and the top of the transmission block 201 is fixedly connected with the pulling assembly 3. Through the pinch roller 203, lithium The aluminum foil of the battery performs the function of pressing and limiting, which prevents the aluminum foil of the lithium battery from wrinkling when moving, thereby reducing the generation of waste. The pulling assembly 3 includes a connecting rod 302, and the bottom of the connecting rod 302 is fixedly connected to the top of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com