Fabric cleaning device for mechanical processing of textiles

A textile machinery and cleaning device technology, which is applied in the direction of processing textile material equipment configuration, mechanical cleaning, and processing textile material carriers, etc., can solve the problems of the production impact of finished fabrics, achieve good compaction effect, prevent slipping, and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

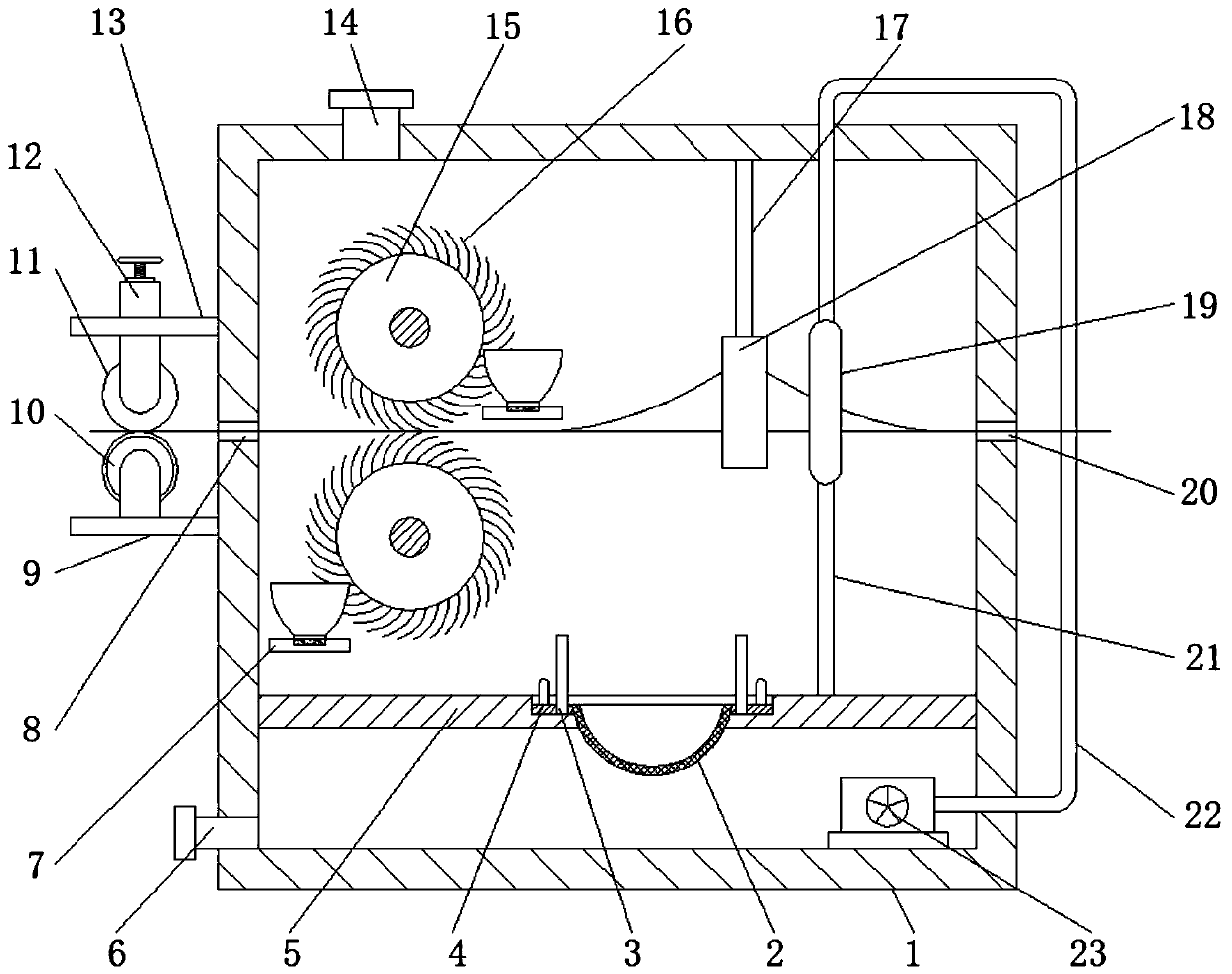

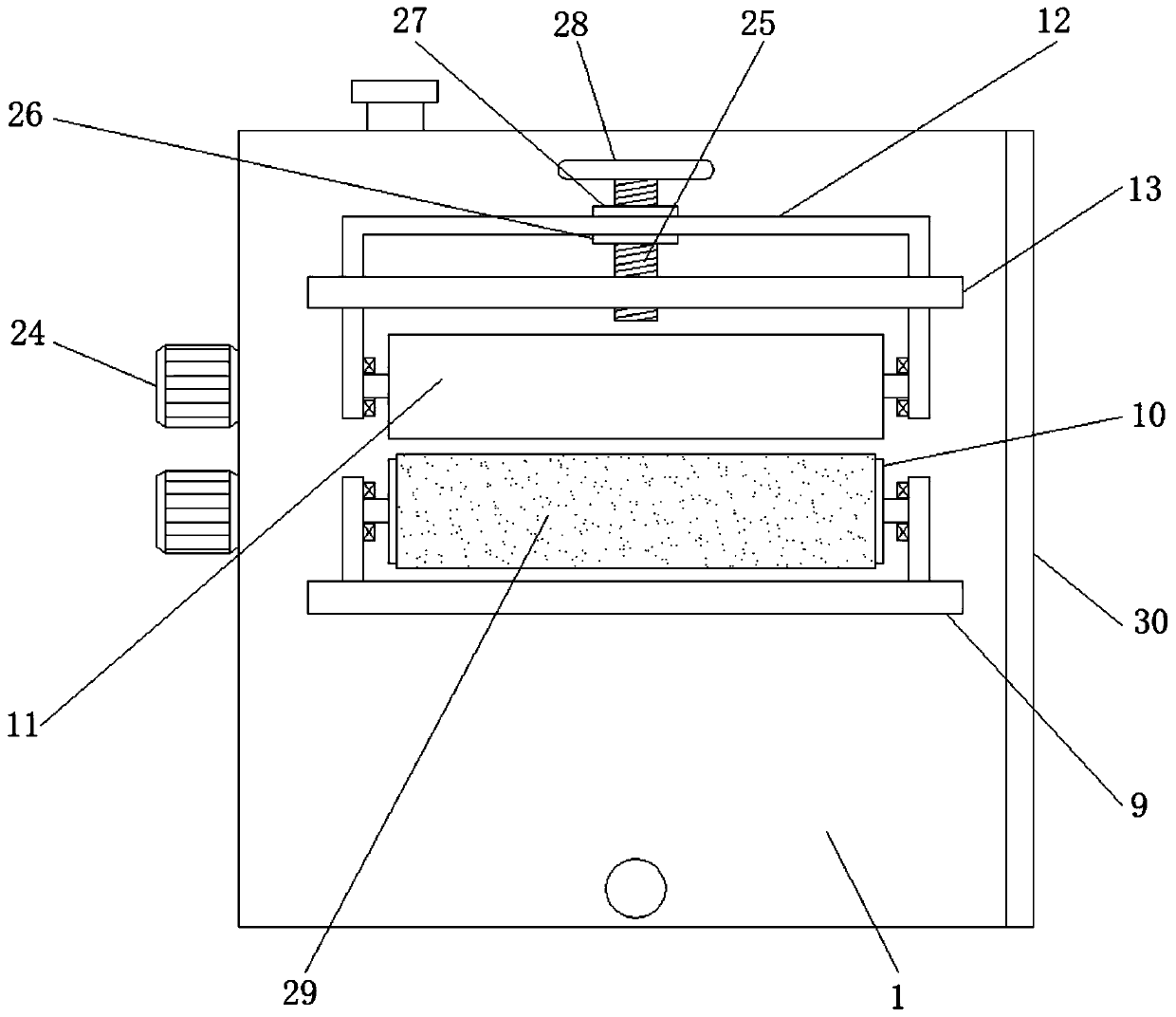

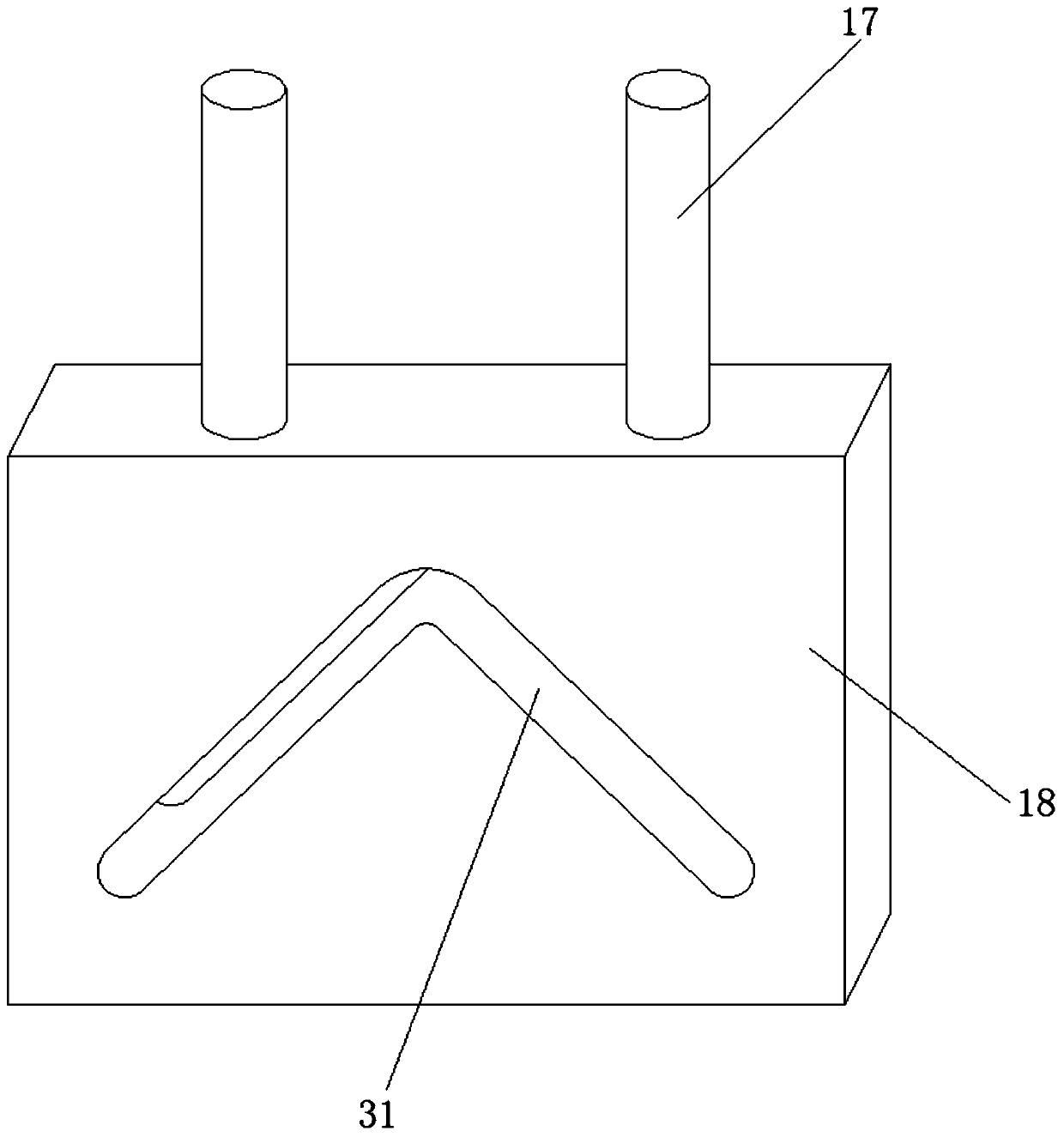

[0032] refer to Figure 1-6, a fabric cleaning device for textile machinery processing, comprising a cleaning box 1, the inner wall of the cleaning box 1 is welded with a partition 4, and the top outer wall of the partition 4 is provided with a groove, and the bottom inner wall of the groove is welded with a limit rod 3, The outer wall of the limit rod 3 is slidably connected with a filter plate 4, and handles are welded near the two sides of the top outer wall of the filter plate 4. The outer wall of the bottom of the filter plate 4 has a fixed opening, and the inner wall of the fixed opening is connected by bolts. Filter screen 2, one side outer wall of cleaning box 1 is connected with motor 24 by bolt, and the quantity of motor 24 is two, and the output shaft outer wall of motor 24 is provided with cleaning roller 15, and the outer wall of cleaning roller 15 is bonded with equidistant The brushes 16 distributed in a ring, the top outer wall of the partition 5 are welded wit...

Embodiment 2

[0036] refer to Figure 7 , a fabric cleaning device for textile machinery processing. Compared with Embodiment 1, this embodiment also includes an observation port on one side of the outer wall of the cleaning box 1, and an observation window 37 is connected to the inner wall of the observation port by fastening bolts.

[0037] Working principle: when in use, the observation window 37 on the cleaning tank 1 is convenient for observing the use status of the cleaning water. When the cleaning water is too turbid, the cleaning water can be replaced through the water changing pipe 6 and the water inlet pipe 14, which is more convenient to use .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com