Folding guardrail convenient for rapid highway construction

A technology for expressways and guardrails, applied to roads, roads, road safety devices, etc., can solve the problems of not being able to play a good role in reminding and warning, the warning effect of guardrails is not strong, and the cost of transportation and storage has increased. Achieve the effect of improving green performance, improving stability and safety, and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

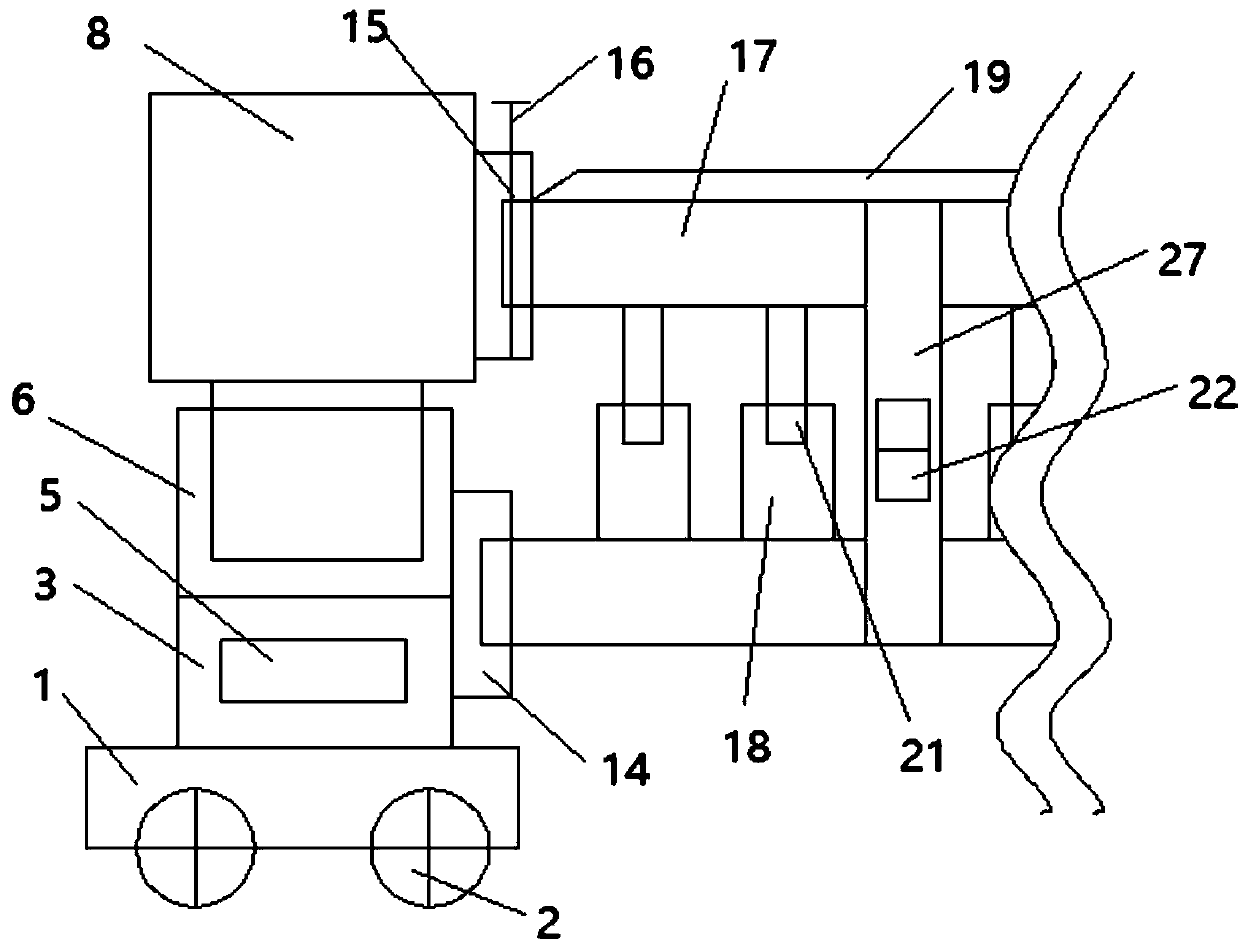

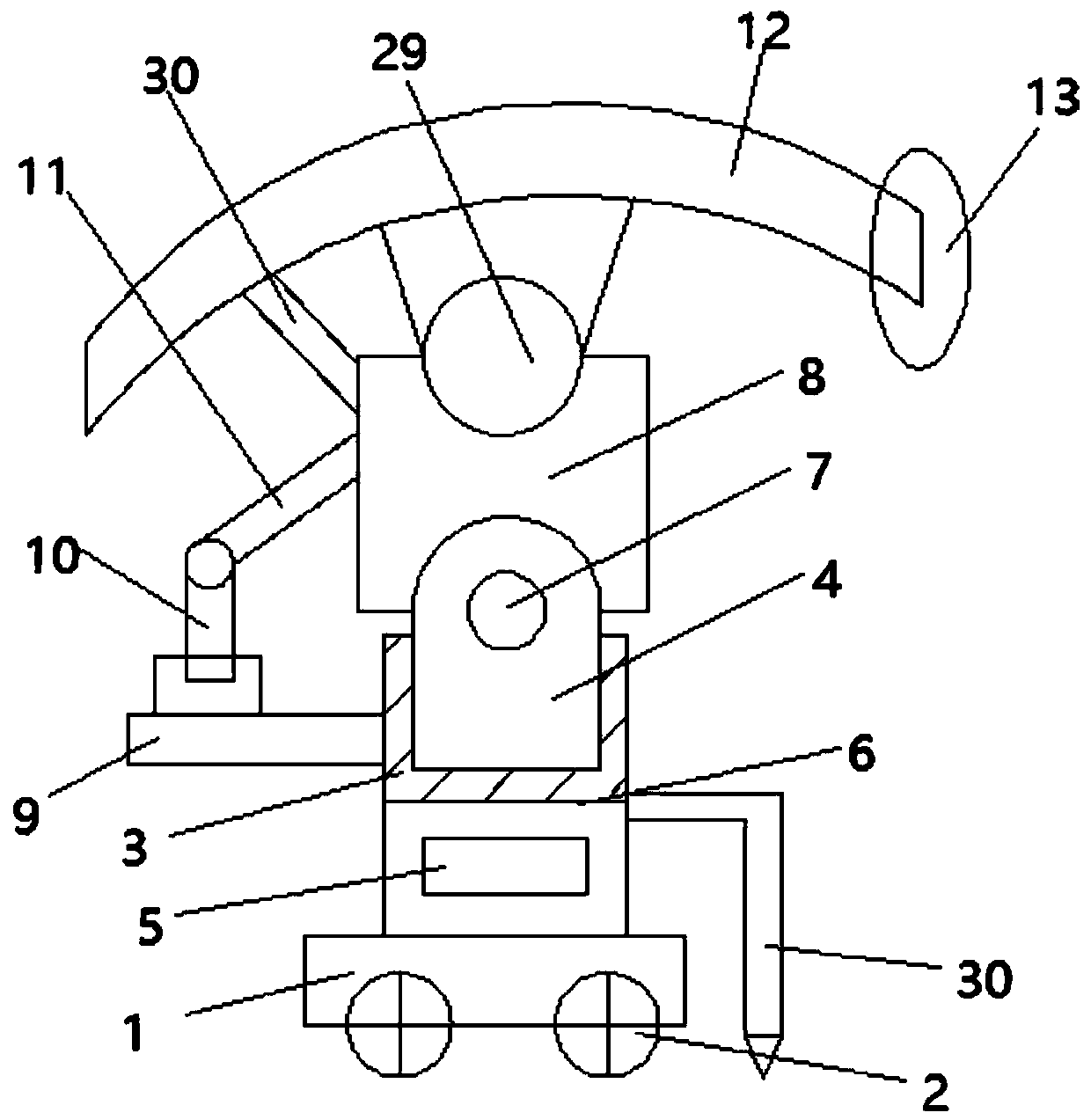

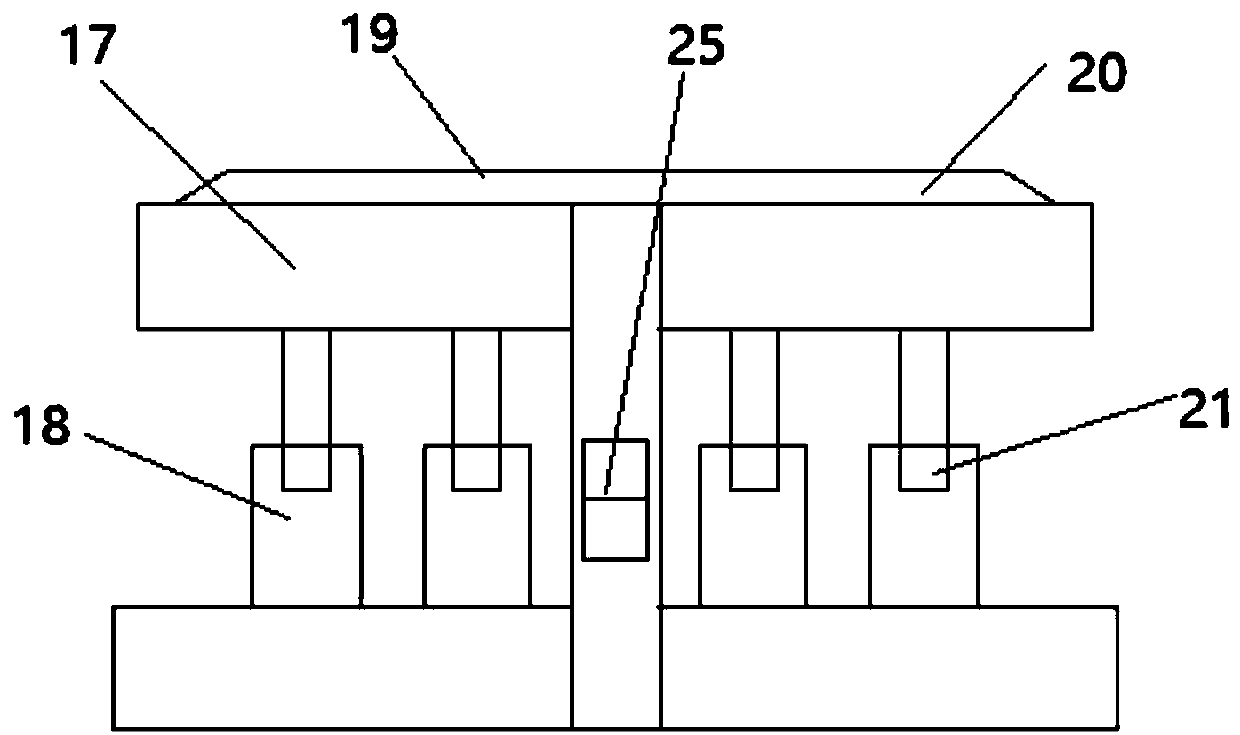

[0032] according to Figure 1-5 As shown, the present invention provides a foldable guardrail that is convenient for expressway construction. The technical solution is as follows: It includes a bottom support 1, which is a rectangular parallelepiped frame structure, and a self-locking pulley 2 is installed on the lower surface of the bottom support 1. A first guardrail 3 is installed on the upper surface of the bottom support 1, a jack 4 is arranged above the inside of the first guardrail 3, and an electric control box 5 is arranged on the outer surface of the first guardrail 3, the electric control box 5 is connected to the upper side of the horizontal connecting rod 6, the upper end of the jack 4 is provided with a first hinge pin 7, the upper side of the first hinge pin 7 is connected with a second guardrail 8, and the first guardrail 3 has a mounting base installed on one side surface 9.

[0033] The electromagnetic hydraulic cylinder 10 is arranged on the upper surface of t...

no. 2 approach

[0046] Second embodiment: a folding guardrail convenient for expressway construction, including: a bottom support 1 which is a rectangular parallelepiped frame structure, a self-locking pulley 2 is installed on the lower surface of the bottom support 1, and the bottom support 1 The upper surface is rotatably supported and installed with a first guardrail 3, a jack 4 is arranged above the inside of the first guardrail 3, an electric control box 5 is arranged on the outer surface of the first guardrail 3, and the electric control box 5 is connected with The horizontal connecting rod 6 is provided with a first hinge pin 7 at the upper end of the jack 4, a second guardrail 8 is connected above the first hinge pin 7, and a mounting base 9 is installed on one side surface of the first guardrail 3.

[0047] The electromagnetic hydraulic cylinder 10 is arranged on the upper surface of the mounting base 9. A first intermediate support rod 11 connected to the second guardrail 8 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com