Patents

Literature

57results about How to "Improve greenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic method of 4A molecular sieve

InactiveCN104211082ALow activation energy consumptionReduce pollutionAluminosilicate zeolite type-AMolecular sieveActivation method

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

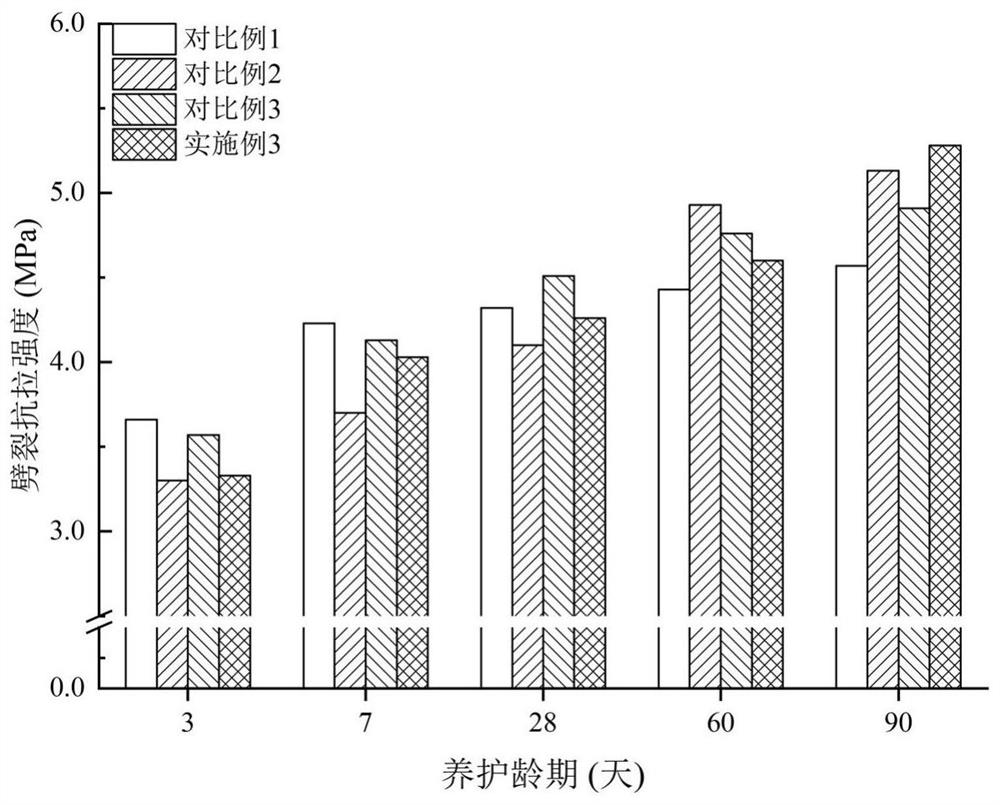

High-strength recycled concrete as well as preparation method and application thereof

InactiveCN112851250AReduce manufacturing costImprove greennessSolid waste managementAggregate (composite)Slag

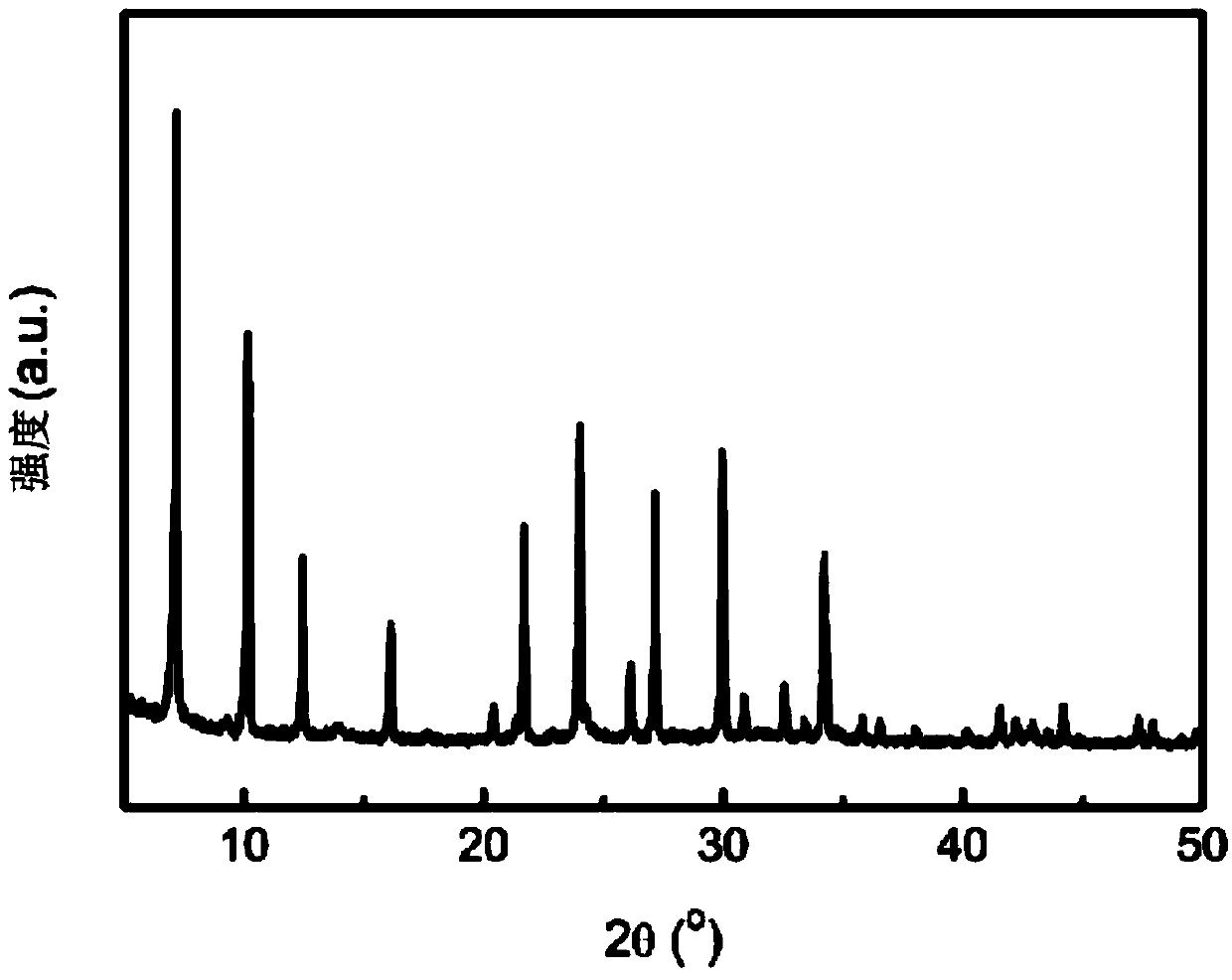

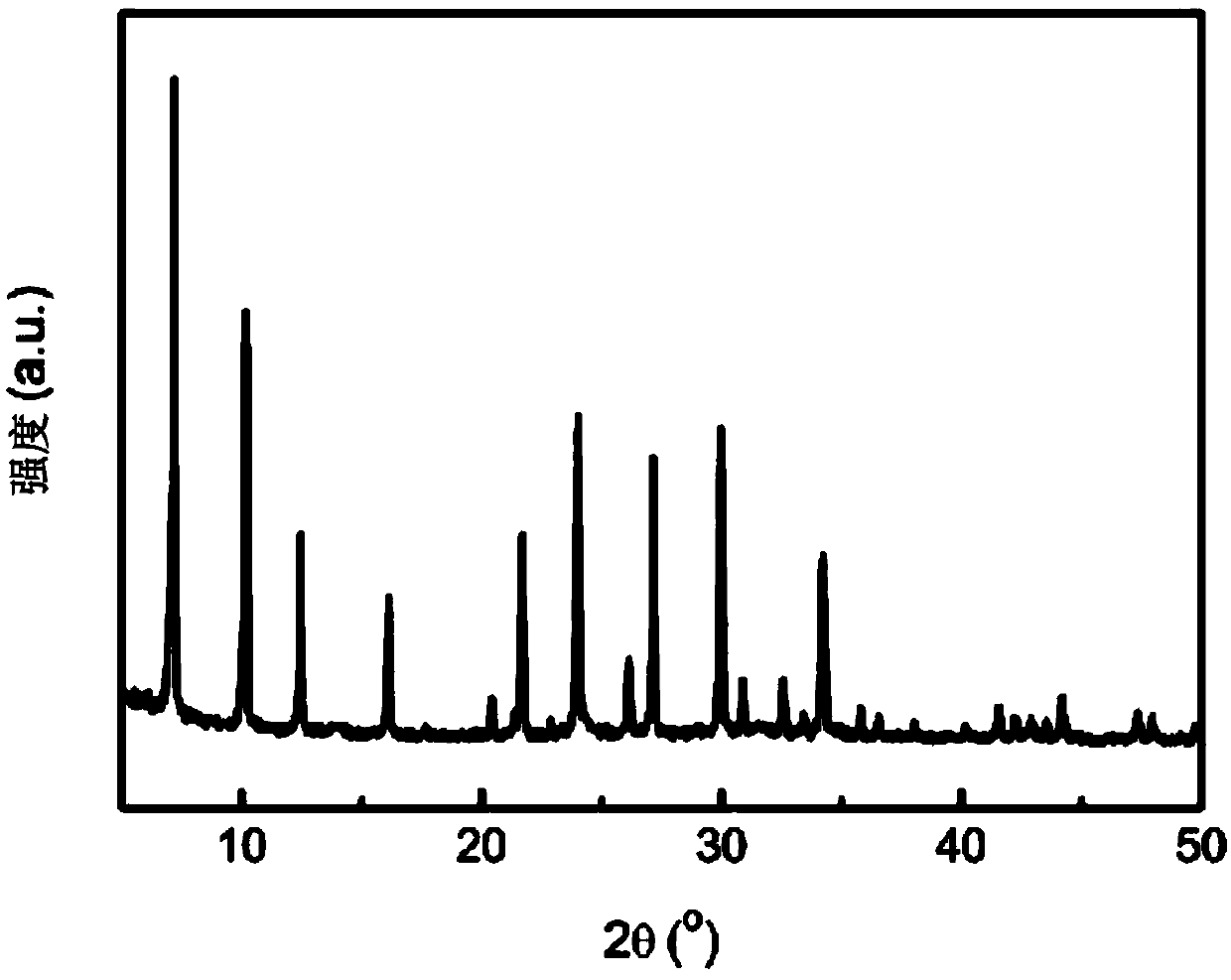

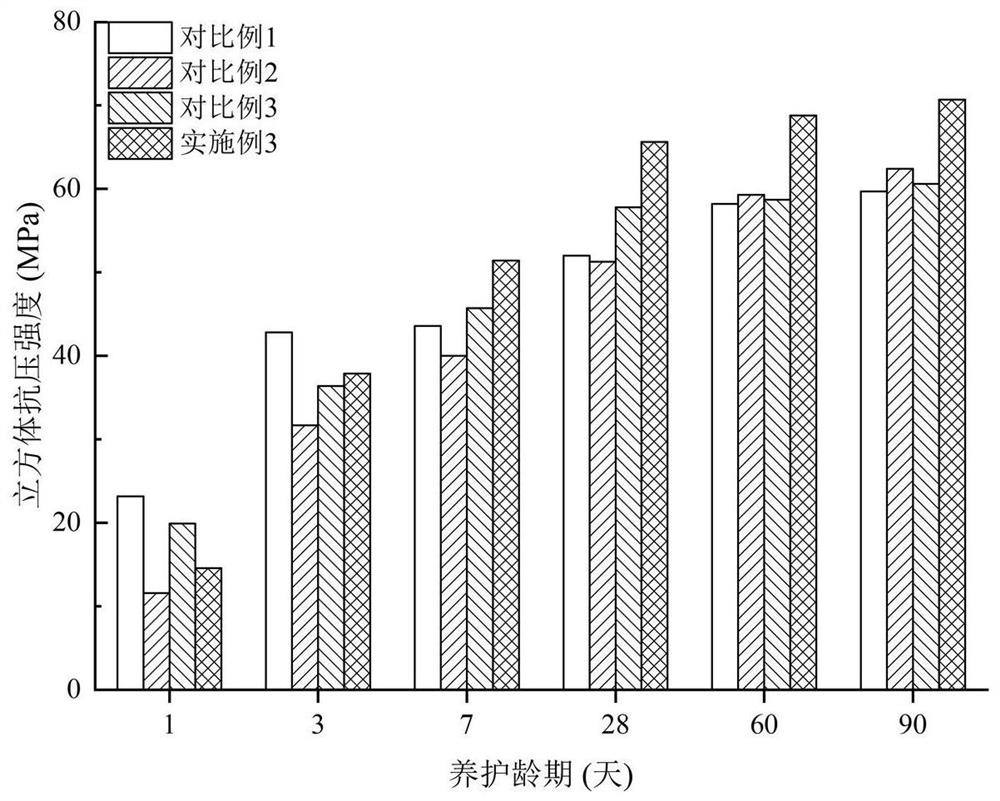

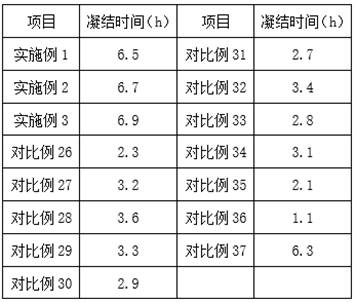

The invention relates to the technical field of building materials, in particular to high-strength recycled concrete and a preparation method and application thereof, and the high-strength recycled concrete is prepared from the following raw materials in parts by weight: 290 to 443 parts of cement; 20 to 70 parts of fly ash; 20 to 70 parts of slag; 20 to 70 parts of silica fume; 20 to 70 parts of metakaolin; 650 to 750 parts of fine aggregate; 550 to 600 parts of natural coarse aggregate; 450 to 510 parts of recycled coarse aggregate; 4.0 to 7.0 parts of a water reducing agent; and 140 to 160 parts of water. The high-strength recycled concrete is designed and prepared on the basis of the service environment and load-bearing requirements of a recycled concrete structure, and mineral admixtures comprise coal ash, slag, silica fume and metakaolin. According to the preparation method, a pre-wetting-double slurry wrapping method is adopted, the recycled aggregate is subjected to pre-wetting, slurry wrapping and repeated stirring treatment, the internal microstructure of the concrete is enhanced, and the mechanical property of the recycled concrete and the durability of the recycled concrete in a composite salt erosion environment are improved.

Owner:XIAN TECHNOLOGICAL UNIV

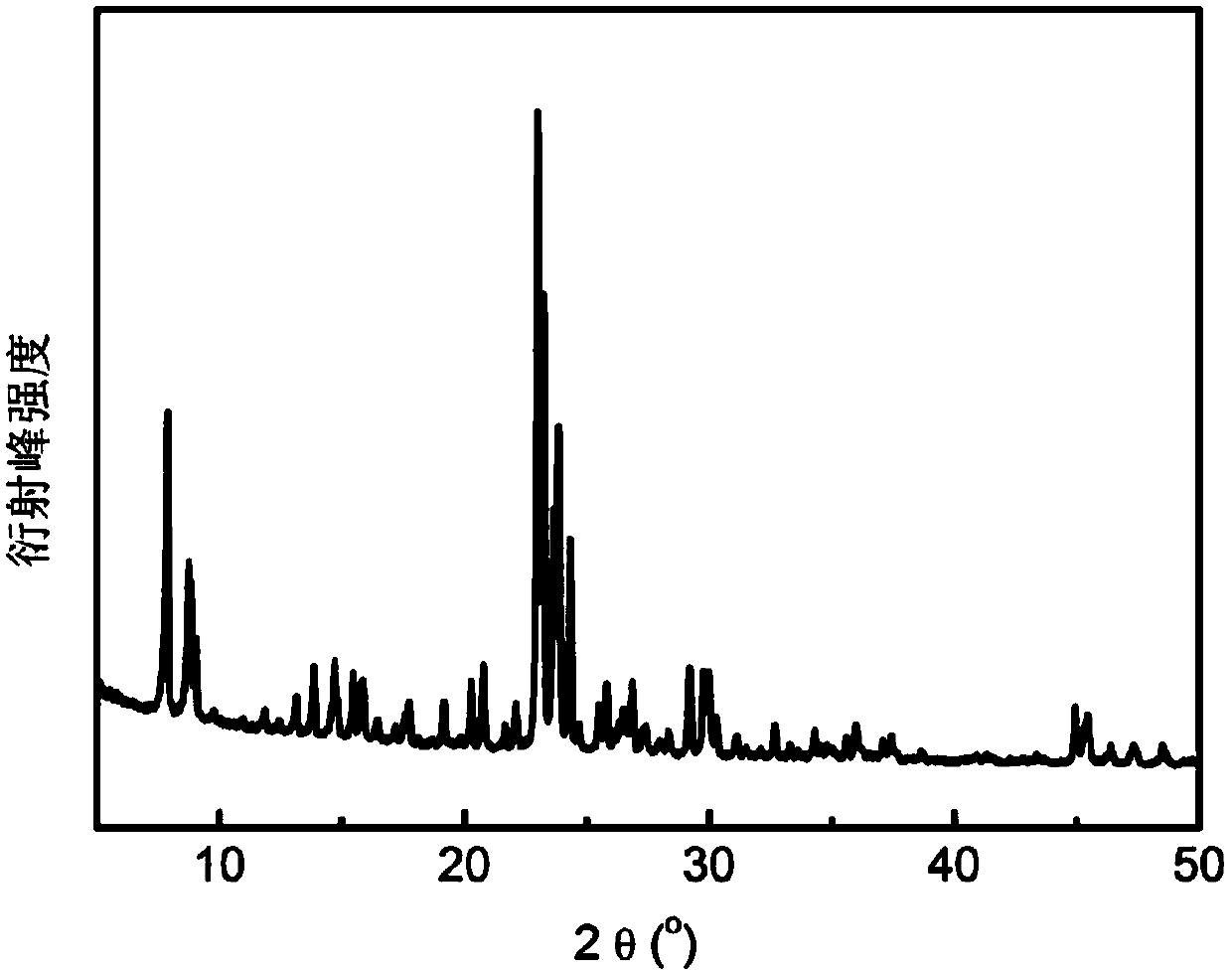

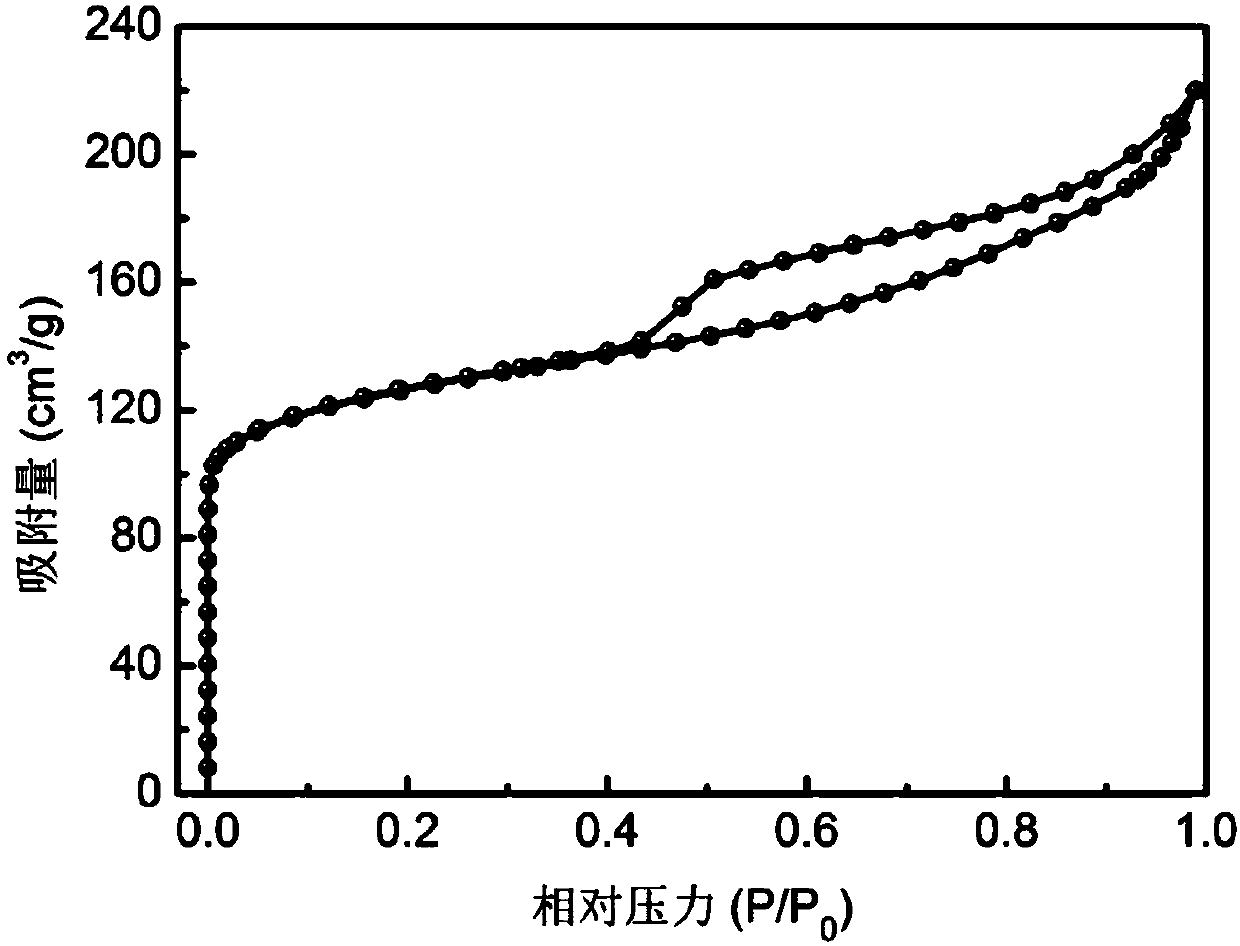

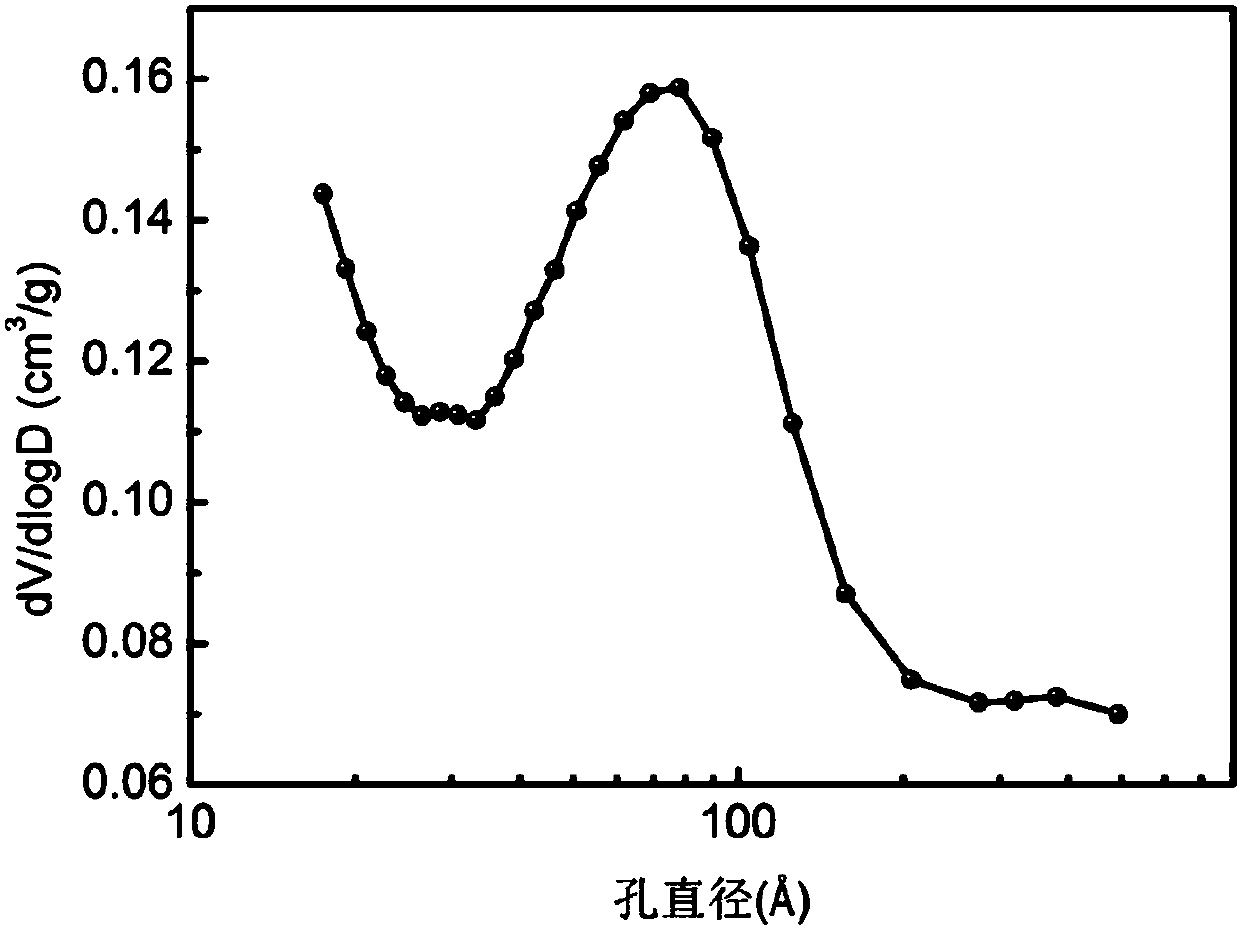

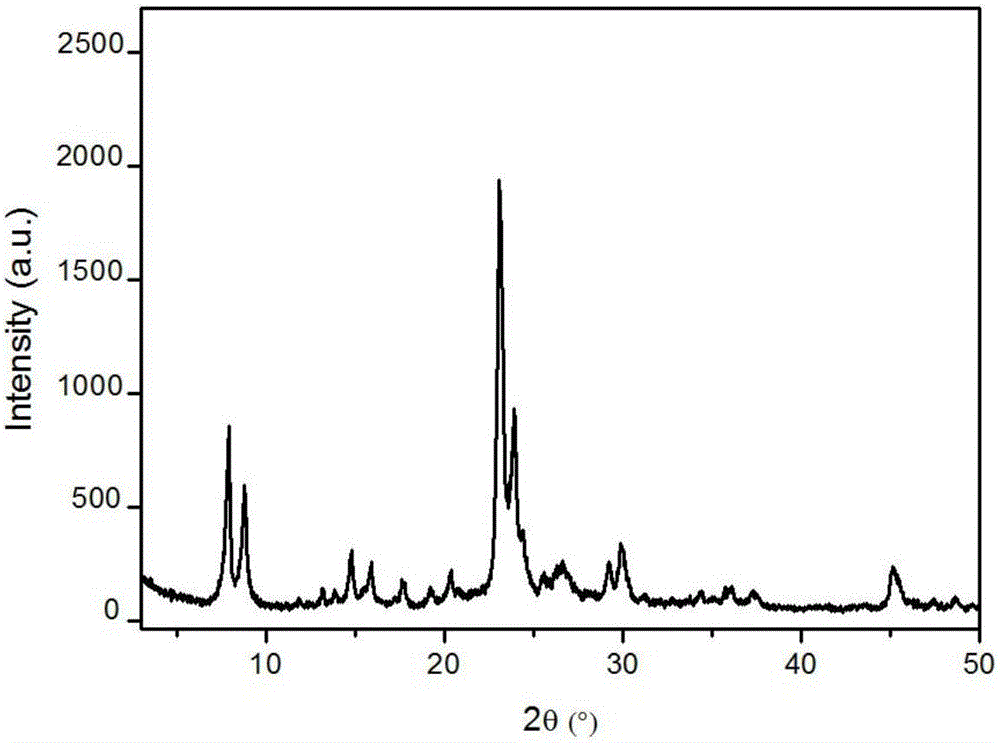

Gradient pore HZSM-5 (hydrogen zeolite socony mobile-5) molecular sieve and preparation method thereof

ActiveCN107777700AReduce manufacturing costImprove greennessNanotechnologyPentasil aluminosilicate zeoliteMolecular sieveChemistry

The invention provides a gradient pore HZSM-5 molecular sieve and a preparation method thereof. The preparation method takes natural clay minerals as raw materials to synthesize a microporous NaZSM-5molecular sieve without application of template agent, performs alkali treatment on the microporous NaZSM-5 molecular sieve through crystallized mother liquid to prepare a gradient pore NaZSM-5 molecular sieve, and performs acid exchange on the gradient pore NaZSM-5 molecular sieve through acid liquor to obtain the gradient pore HZSM-5 molecular sieve. The invention also provides the gradient poreHZSM-5 molecular sieve prepared through the method. The preparation method of the gradient pore HZSM-5 molecular sieve does not require any template agent as well as additional alkali source during alkali treatment and has no discharge of acid liquor or alkali liquor during the whole process, thereby greatly reducing the production cost of molecular sieves and improving the environmental properties of the preparation process; the prepared gradient pore HZSM-5 molecular sieve is rich in micro-mesoporous composite gradient pore structures.

Owner:PETROCHINA CO LTD +1

Method for preparing cold-soluble green tea powder and product

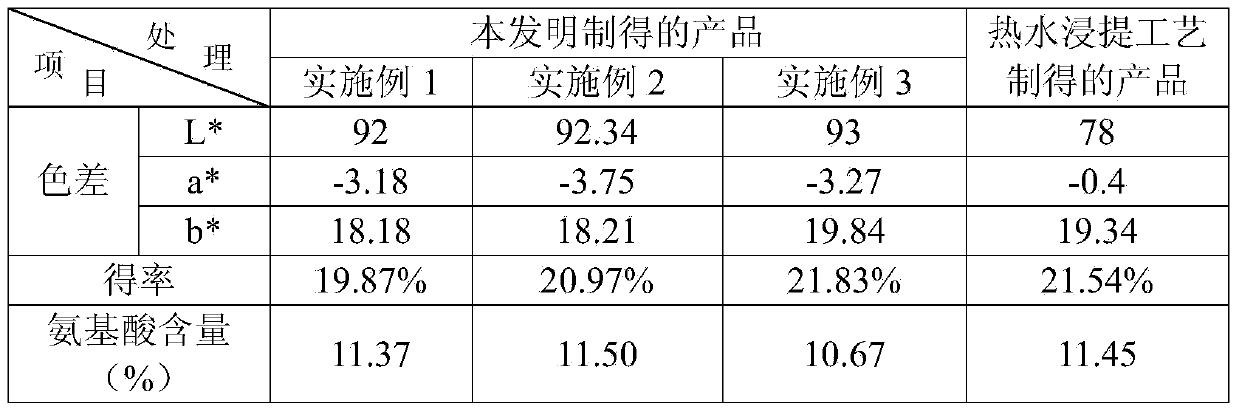

The invention discloses a method for preparing cold-soluble green tea powder. The method includes the following steps that after green tea is pulverized, the pulverized green tea is filtered through a 40-80 mesh screen, deionized water is added according to the feed liquid mass ratio of 1:10-1:30, extraction is performed on the mixture for 10-30 minutes at the pressure value of 100-400MPa after the mixture is sealed, then, extract liquid is filtered with a piece of 150-300 mesh filter cloth, filtrate is collected and centrifuged for 10-40 minutes at the rotating speed of 3000r / min-5500r / min, supernatant is collected and concentrated to the state that the soluble solid accounts for 16-22%, and concentrated liquor is acquired; finally, the concentrated liquor is frozen and dried in a vacuum freezing mode at -40 - -70 DEG C for 24-48 hours, and the cold-soluble tea powder is acquired. The cold-soluble tea powder prepared with the method is good in cold-dissolving effect and capable of dissolving fast at 3-8 DEG C, the tea powder and tea soup are greener than that acquired through hot water extraction, taste mellow and sweet slightly and thus are well liked by consumers.

Owner:SOUTHWEST UNIV

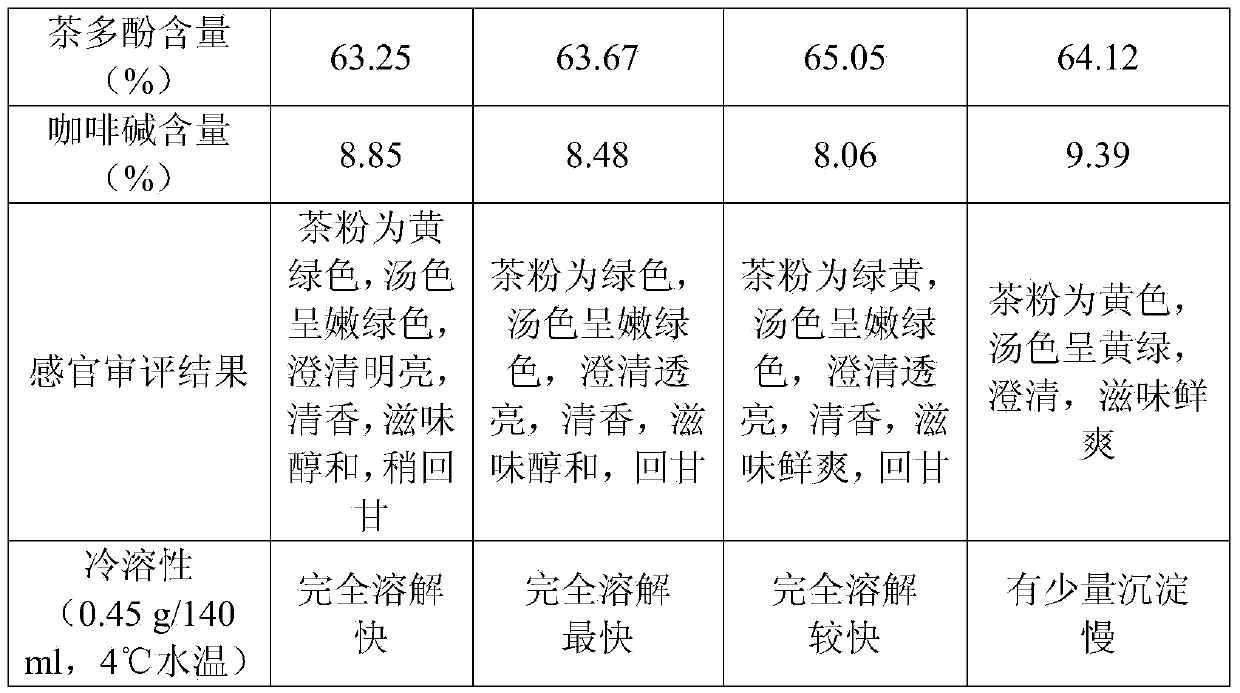

Carbohydrate modified lithium conductive polymer/inorganic hybrid electrolyte and application thereof

InactiveCN107069082ARich sourcesLower Electrolyte CostsSolid electrolytesFuel and secondary cellsConductive polymerLithium–air battery

The invention discloses a carbohydrate modified lithium conductive polymer / inorganic hybrid electrolyte and application thereof. The electrolyte comprises a carbohydrate modified lithium conductive polymer and a lithium salt, wherein the carbohydrate modified lithium conductive polymer is obtained by crosslinking reaction or direct mixing of a carbohydrate compound and a lithium conductive polymer and / or a lithium conductive micromolecule compound. The electrolyte is compatible with high conductivity of an inorganic material and flexibility of a polymer material, has high lithium ion conductivity and good processability, and is suitably used for preparing a lithium ion battery, a lithium-sulfur or lithium-air battery and the like with large capacity and good cycle property; and the electrolyte is low in cost and is simple to prepare, and the selection range and the application field of a lithium battery material are expanded.

Owner:CENT SOUTH UNIV

Method for preparing 5-alkoxy methyl furfural from carbohydrate

PendingCN109942519ALess side effectsImprove conversion efficiencyOrganic chemistrySolid acidLiquid fuel

The invention belongs to the field of organic solid waste resourceful utilization, and discloses a method for preparing 5-alkoxy methyl furfural from carbohydrate. The method is characterized by including the following steps of establishing a two-phase system as the reaction medium by using ionic liquid with bromide ions or a deep-eutectic solvent with bromide ions as the reaction phase and usingan organic solvent as the extraction phase, adding a solid acid catalyst with strong Lewis acidity, a carbohydrate raw material, an alcohol raw material and the reaction medium to a reactor, and continuously converting the carbohydrate raw material into 5-alkoxy methyl furfural under the heating and stirring conditions. By means of the method, the Bronsted acid catalysis side reaction can be reduced, the reaction efficiency and selectivity are greatly improved, the conversion efficiency, green property and economy of fuel additives for converting the carbohydrate into 5-alkoxy methyl furfuralare improved, the subsequent separation and purification process can be reduced with liquid fuel and the like as the extraction phase, and products are directly integrated in liquid fuel products.

Owner:NANKAI UNIV +1

Class C40 slag-doped recycled aggregate self-compacting concrete and production method thereof

InactiveCN107200526AReduce production processEasy dischargeSolid waste managementResource depletionSlag

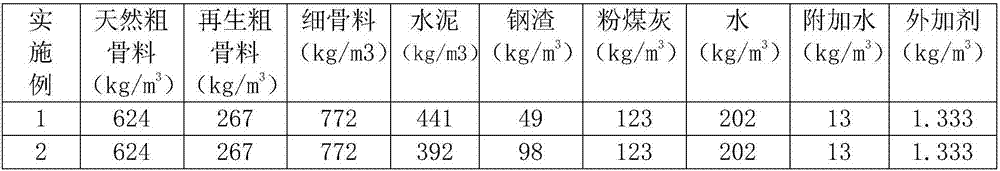

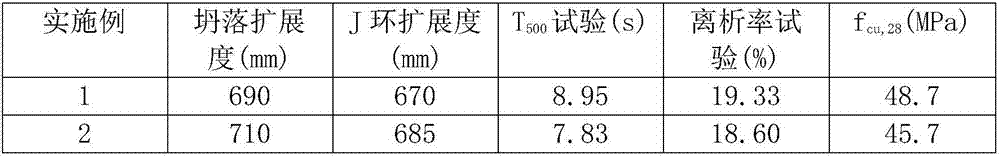

The invention discloses class C40 slag-doped recycled aggregate self-compacting concrete and a production method thereof; the Class C40 slag-doped recycled aggregate self-compacting concrete comprises 1 part of water, 3.089 parts of natural coarse aggregate, 1.322 parts of recycled coarse aggregate, 3.822 parts of fine aggregate, 1.941-2.183 parts of cement, 0.2426-0.4851 part of slag, 0.609 part of fly ash, 0.064 part of added water, and 0.00495-0.0124 part of an admixture. The class C40 slag-doped recycled aggregate self-compacting concrete has good mobility, filling performance and segregation resistance, both gradual loss and strength of the concrete meet the related requirements of buildings, the production method is simple, the production cost of self-compacting concrete under same ratio and strength is lowered, the slag and building waste treatment problem is solved, the burden of resource exhaustion is relieved, and the concrete and the production method thereof are green and suitable for industrial production.

Owner:JIANGSU UNIV OF SCI & TECH

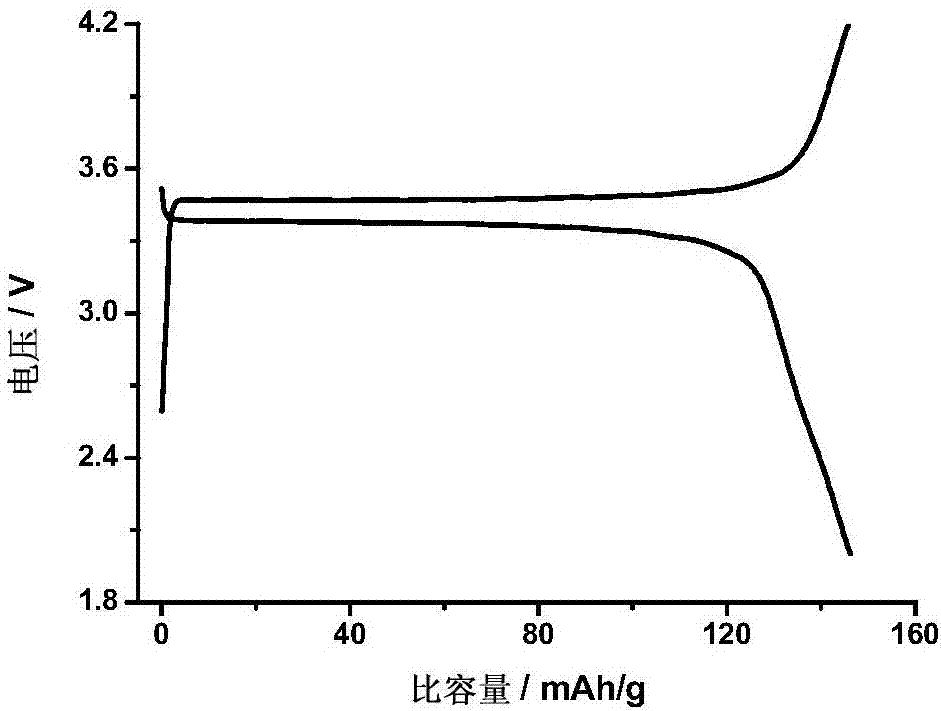

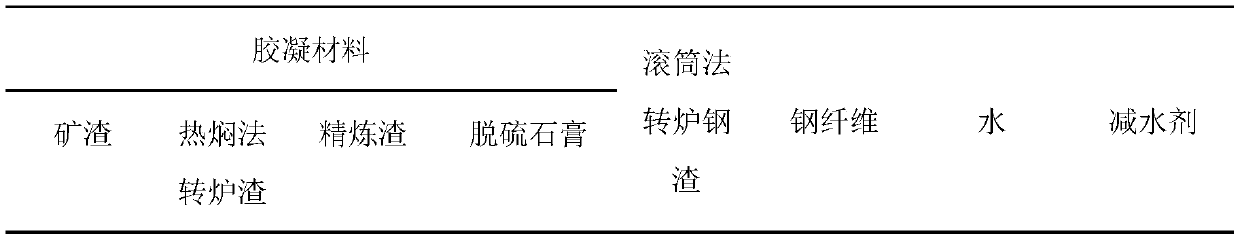

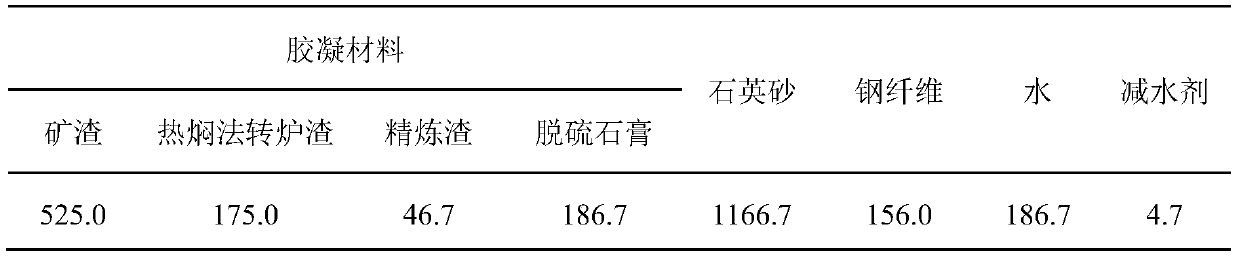

Steel fiber reinforced ultra-high-performance concrete synergistically prepared by multiple solid waste and preparation method of steel fiber reinforced ultra-high performance concrete

The invention provides a steel fiber reinforced ultra-high-performance concrete synergistically prepared by multiple solid waste and a preparation method of the steel fiber reinforced ultra-high performance concrete, and belongs to the technical field of solid waste resource utilization. The steel fiber reinforced ultra-high-performance concrete is prepared from the components in percentage by weight: 35%-50% of a binding material, 35%-50% of an aggregate, 0%-3% of a water reducing agent, 5%-8% of a steel fiber and 7%-9% of water, during preparation, firstly slag, heat stewing converter slag,refining slag and industrial by-product gypsum are separately ground or ground in a mixed mode, and the binding material is prepared through even mixing; and then after the binding material, the skeletal material, the water reducing agent, the steel fiber and the water are stirred evenly in percentage by mass, casting molding is conducted and maintenance is conducted, and the steel fiber reinforced ultra-high-performance concrete synergistically prepared by the multi-solid waste is obtained. According to the steel fiber reinforced ultra-high-performance concrete and the preparation method, theultra-high-performance concrete with compressive strength of 100 MPa to 160 MPa and flexural strength of 35 MPa to 45 MPa in 28 days under the standard curing condition is prepared, the utilization rate of the solid waste in the ultra-high-performance concrete is increased significantly, the cost is lowered, and obvious environmental and economic benefits are achieved.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

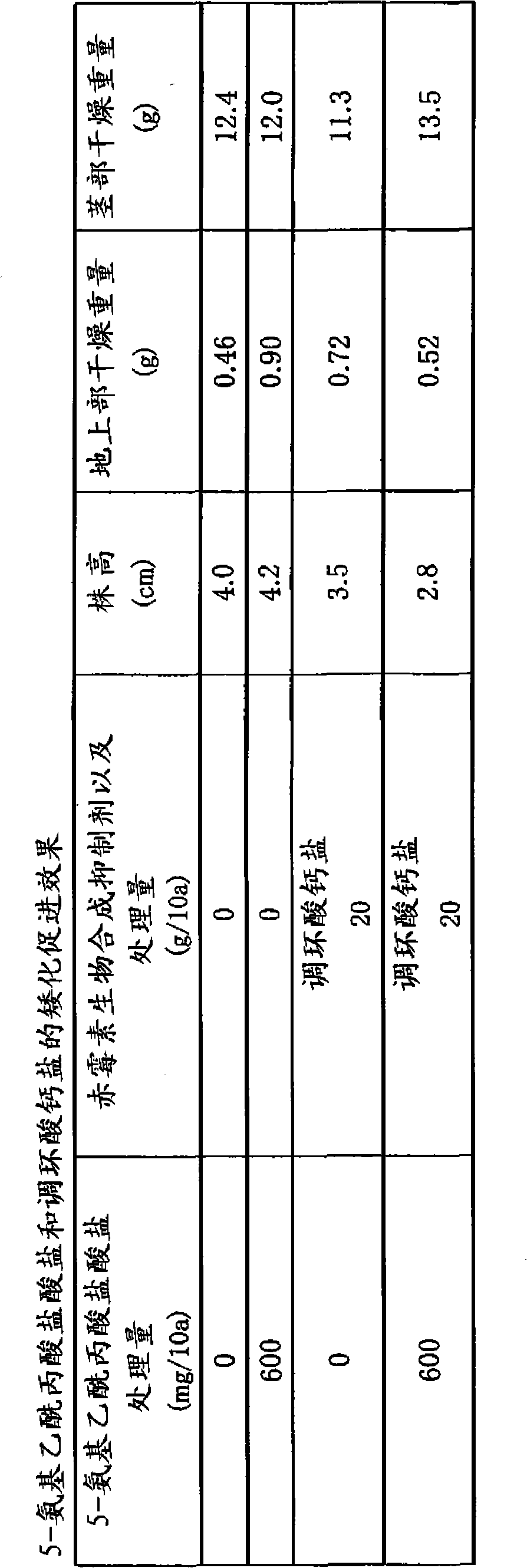

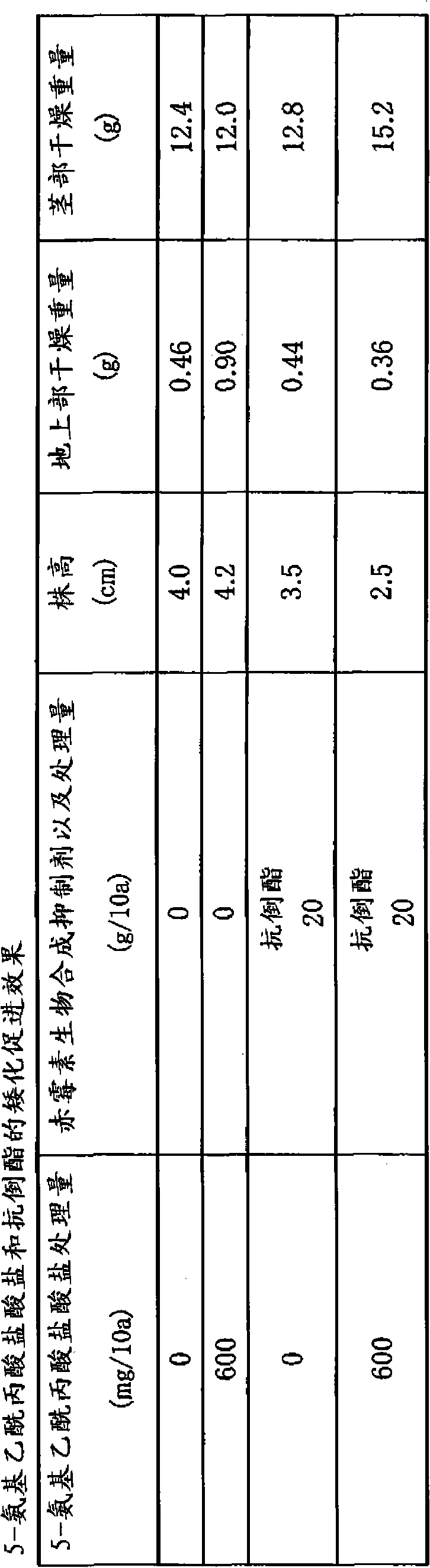

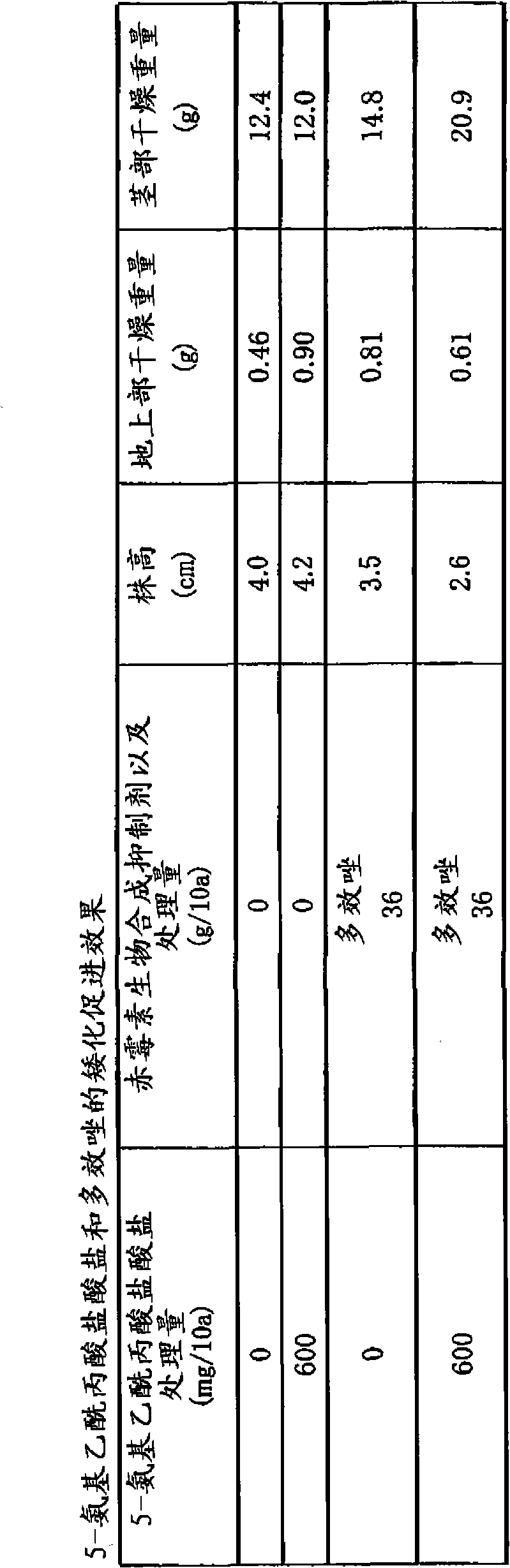

Agent for improving lawn grass qualities

InactiveCN102123587APromote dwarfingImprove greennessBiocidePlant growth regulatorsGibberellic acid biosynthesisBULK ACTIVE INGREDIENT

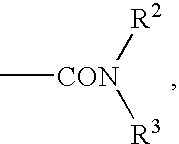

Provided is an agent for improving lawn grass qualities which has excellent effects of promoting dwarfing, fattening stem, increasing leaf count and improving green color. An agent for improving lawn grass qualities which comprises as the active ingredients 5-aminolevulinic acid or a derivative or salt thereof represented by general formula (1) and a gibberellin biosynthesis inhibitor: general formula (1) R2R1NCH2COCH2CH2COR3 (1) wherein R1 and R2 each independently represents a hydrogen atom, an alkyl group, an acyl group, an alkoxycarbonyl group, an aryl group or an aralkyl group; and R3 represents a hydroxy group, an alkoxy group, an acyloxy group, an alkoxycarbonyloxy group, an aryloxy group, an aralkyloxy group or an amino group.

Owner:COSMO TRADE & SERVICE CO LTD

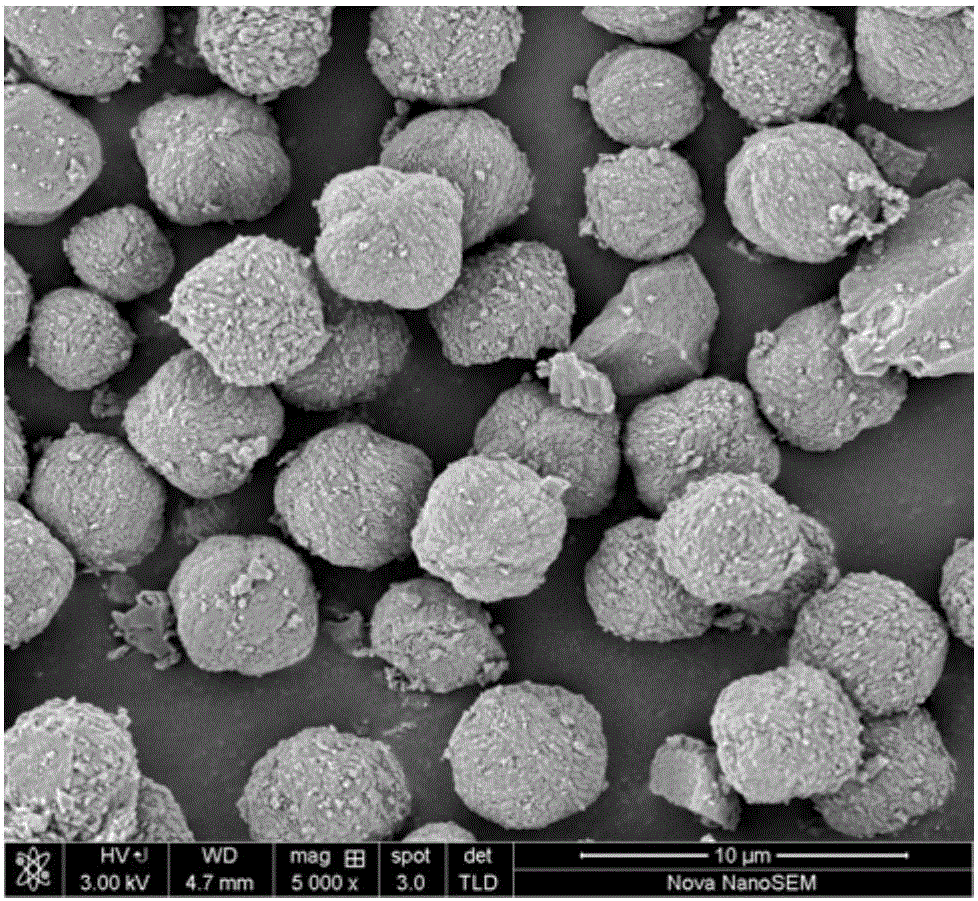

Synthesis method for ZSM-11 molecular sieve with nano multi-stage pores

ActiveCN106430234AHigh crystallinitySmall grainNanotechnologyPentasil aluminosilicate zeoliteMolecular sieveAlcohol

The invention discloses a synthesis method for a ZSM-11 molecular sieve with nano multi-stage pores. The synthesis method comprises the following steps of (1) carrying out acid treatment on calcined kaolin to obtain modified kaolin; (2) mixing the modified kaolin with an additional silicon source, an organic template agent, inorganic base, alcohol and water and stirring uniformly; (3) drying slurry prepared in the step (2) to form xerogel; and (4) crystallizing the xerogel under the assistance of water vapor, calcining crystallization products obtained at high temperature to obtain the ZSM-11 molecular sieve. The synthesis method disclosed by the invention has the advantages that the ZSM-11 molecular sieve with the nano multi-stage pores is high in degree of crystallinity, small in grain and good in hydrothermal stability, and has large specific surface area and rich microporous and mesoporous channels; simultaneously, the synthesis cost of the ZSM-11 molecular sieve is greatly reduced, and a product does not need to be filtered, so that the environment-friendly effect in the synthesis process is obviously improved.

Owner:PETROCHINA CO LTD +1

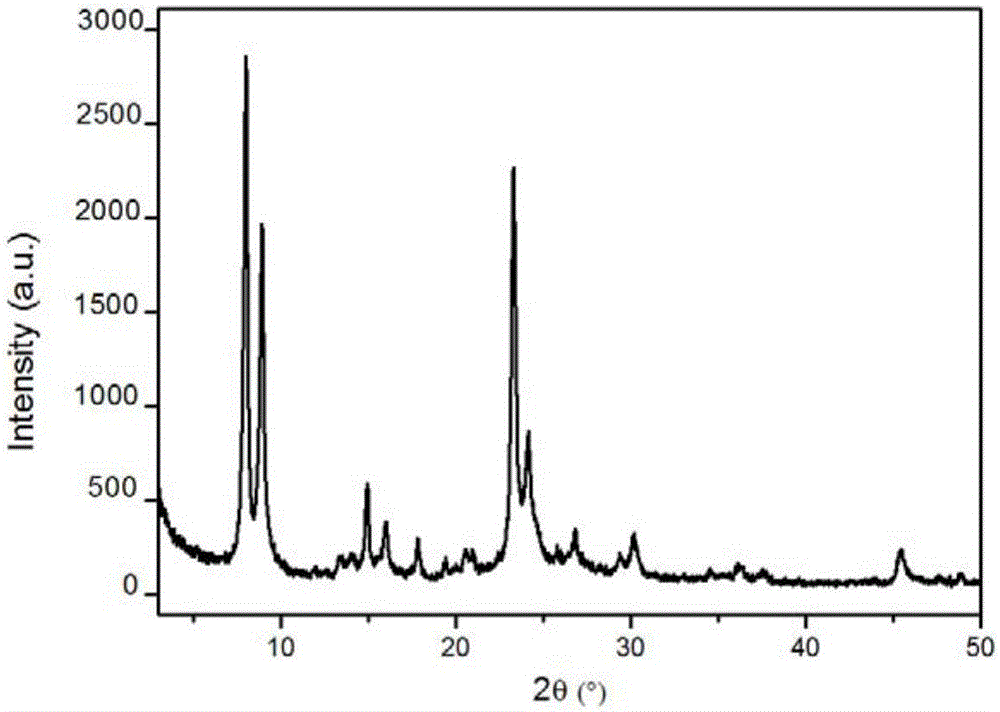

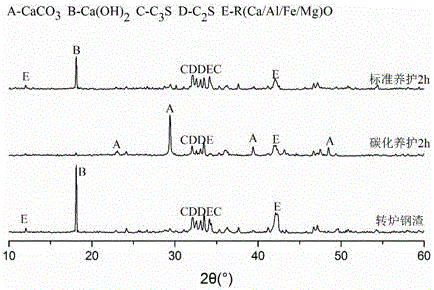

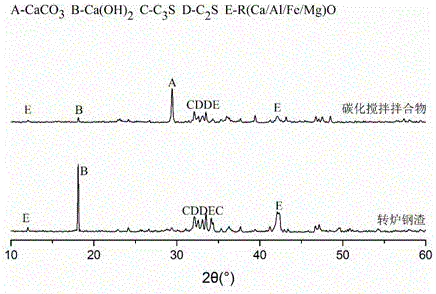

Method for preparing building material product by clinker-free steel slag gel material and multiple CO2 absorbing techniques

InactiveCN106431158AEnhanced absorption of CO

<sub>2</sub>

amountHigh strengthSolid carbonCompression molding

The invention discloses a method for preparing a building material product by a clinker-free steel slag gel material and multiple CO2 absorbing techniques. The method comprises the following steps of using ground steel slag as the clinker-free gel material, and mixing with a proper amount of water; performing two steps of carbonizing mixing and conventional mixing, and compressing and forming a mixture; performing carbonizing curing and standard curing, so as to obtain a green building material product. The method has the advantages that by adopting the techniques, the steel slag is completely used as the gel material; compared with the single carbonizing, the content of solid carbon in a curing sample by the multiple carbonizing is increased by 18 to 20 percent; by performing multiple carbonizing and standard curing, the strength of the sample is greatly improved.

Owner:WUHAN UNIV

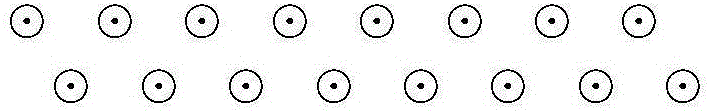

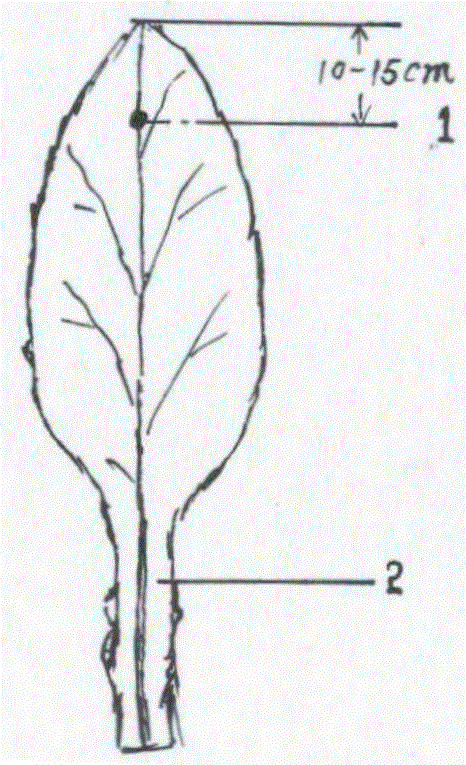

Method for increasing green degree of ball-flower bud branches of loose-flower cauliflower

The invention relates to a method for increasing green degree of ball-flower bud branches of loose-flower cauliflower. The method increases green degree of ball-flower bud branches through changing cultivation patterns and methods. The method comprises measures of planting density changing, water management, fertilization management, leaf binding and flower protection. The planting density changing is realized by increasing row and line spacings of plants, and row spacing is 50cm to 60 cm, line spacing is 60 cm to 70 cm. A hole V-shaped mode is used, and the plants are planted in a staggered manner. Through increasing planting density, and water management, fertilization management, and leaf binding and flower protection and other comprehensive measures, an objective of increasing the green degree of ball-flower bud branches of loose-flower cauliflower is realized, and various produced cauliflowers are high in quality and good in commodity value.

Owner:江苏翰雅有机农场有限公司

Processing method capable of improving fragrant tea quality

InactiveCN106417694AImprove greennessImprove production ratePre-extraction tea treatmentChemistryProcess engineering

The invention relates to a fragrant tea processing method, and in particular relates to a processing method capable of improving fragrant tea quality. The fragrant tea processing method mainly comprises the steps of carrying out electromagnetic heavy fixation on spread tea leaves and carrying out technical processing of working procedures, namely secondary drying, typing by virtue of a Quhao machine and complete fire drying. Fragrant tea produced by adopting the fragrant tea processing method provided by the invention is curly, tight and thin in appearance strips, verdant in color and luster, high and lasting in incense, strong and refreshing in taste and clear in liquor color and has the characteristic of high quality. Compared with the traditional fragrant tea processing method, the fragrant tea processing method is uniform in fixation and high in efficiency, the original color and luster of the tea leaves can be maintained to the utmost extent, and the product is verdant in color and luster. The technical processing of the working procedures, namely the secondary drying, typing by virtue of the Quhao machine and complete fire drying, is adopted for replacing a cyclic drum roasting working procedure of the traditional fixation machine, the verdant degree and crimping tight degree of the fragrant tea are obviously improved, the breaking rate is reduced, and the yield of the fragrant tea is improved. The fragrant tea processing method provided by the invention avoids the phenomena that the traditional fragrant tea is not verdant enough in color and luster, not tight and thin enough in strips and relatively high in breaking rate.

Owner:LISHUI AGRI SCI

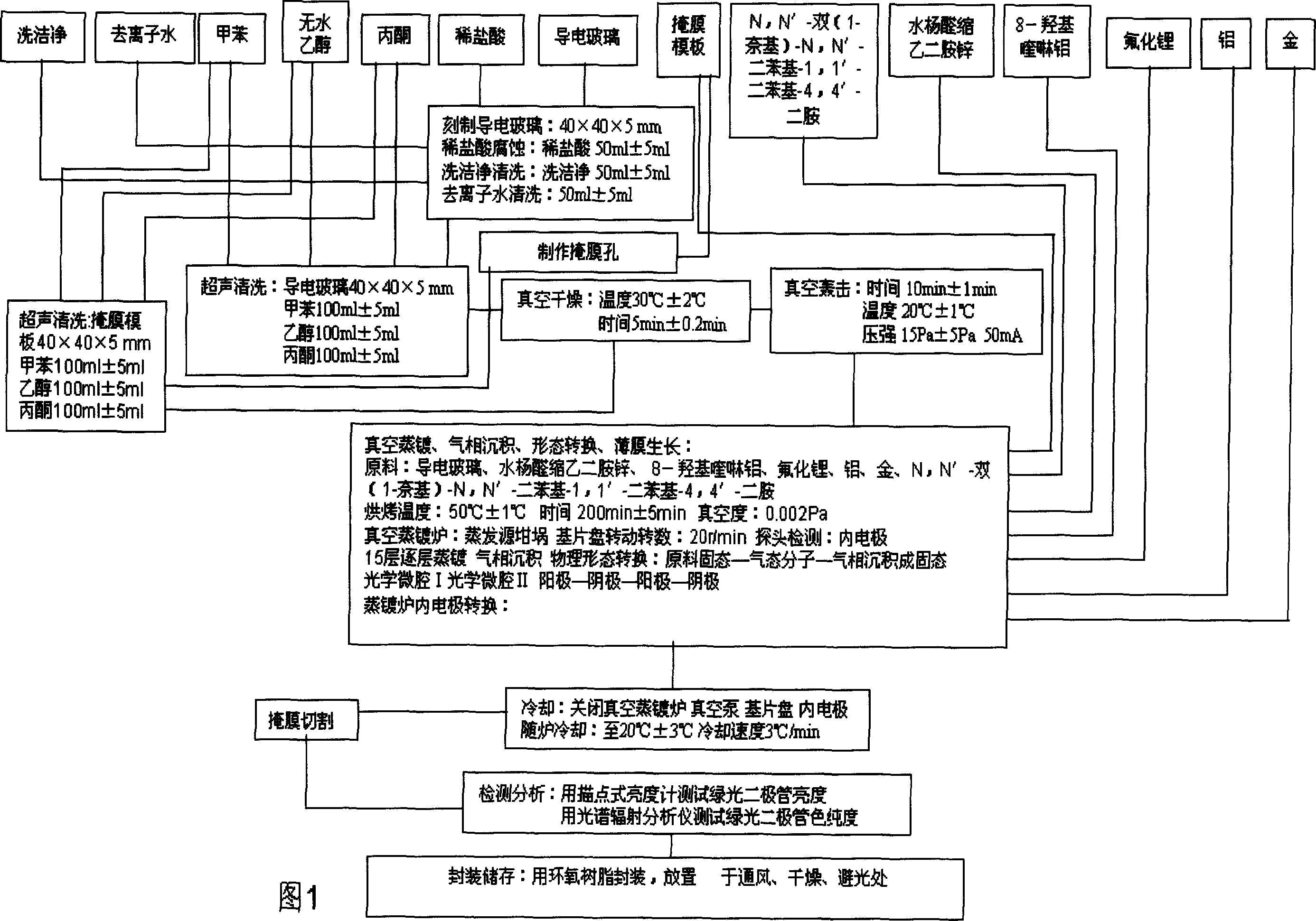

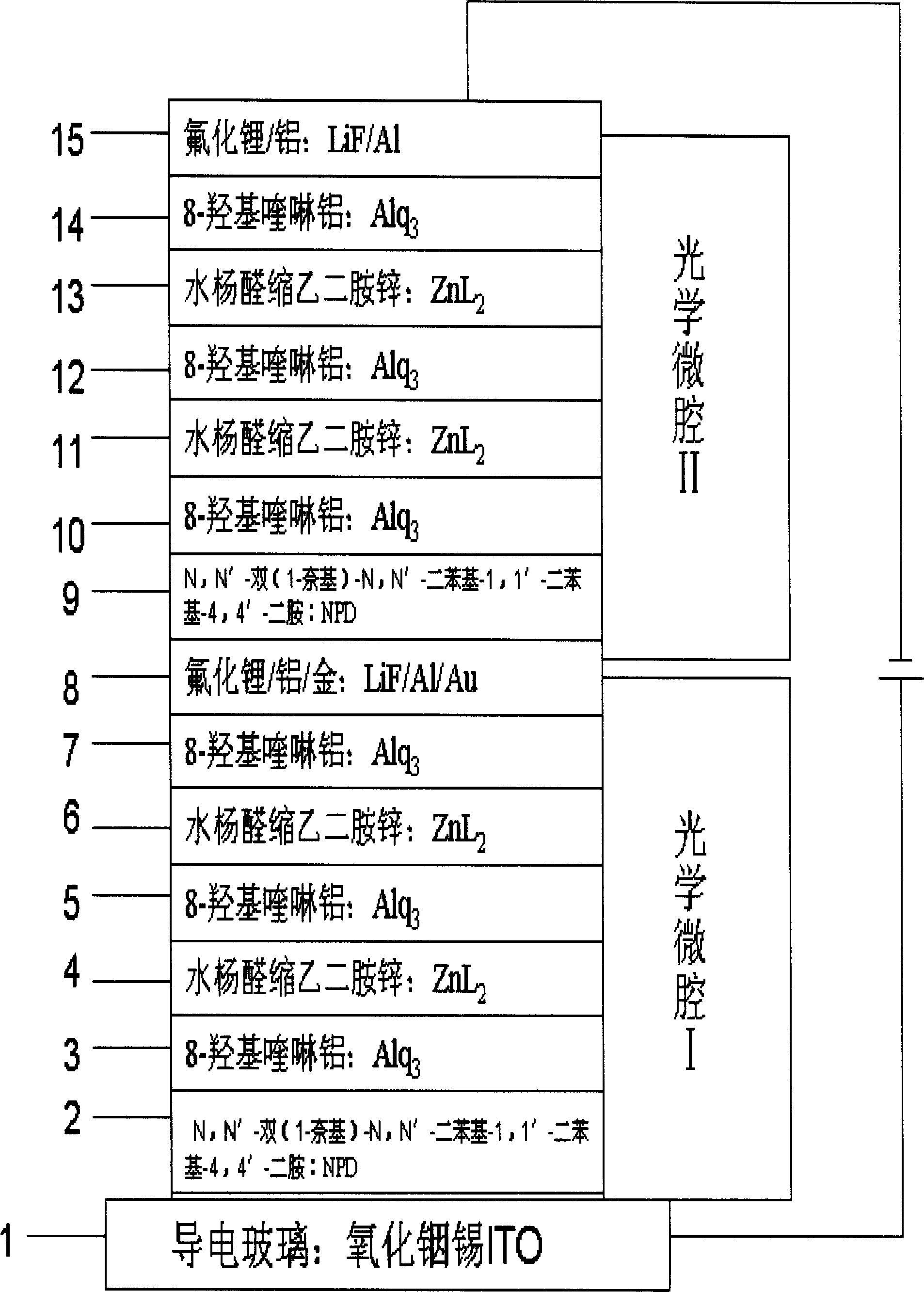

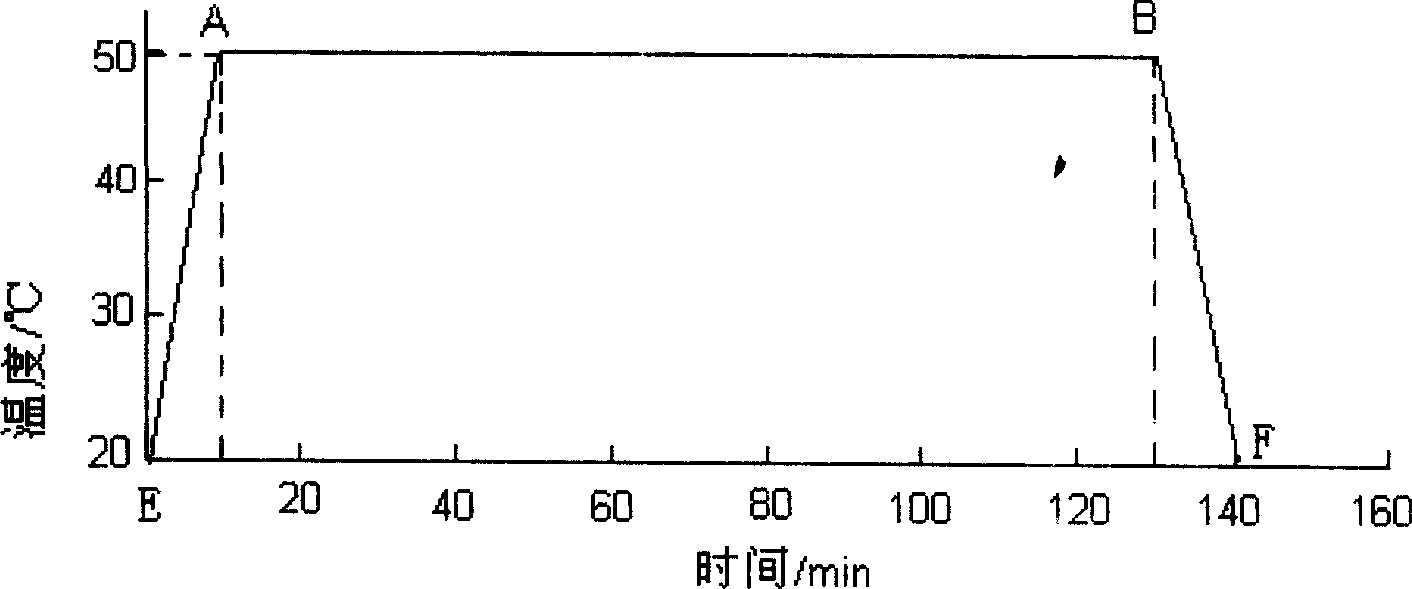

Green diode with optical microcavity structure and production thereof

InactiveCN1819305AIncrease brightnessImprove luminous efficiencyVacuum evaporation coatingSolid-state devicesEthylenediaminePotential well

The preparation method takes 8-hydroxyquinoline, N, N'-bis(1-napgthel)-N, N'-diphenyl-1, 1'-dipheny-4, 4'-diamine (NPD), lithium fluoride, aluminum and gold as raw materials, and takes Salicylidenc-Ethylenediamine Zinc as a materials for luminescing green light. The conducting glass tin indium oxide is taken as the substrate of light emitting device. The absolute ethyl alcohol, toluene, acetone, and cleaning agent is taken as detergent. The diluted hydrochloric acid is taken as etching agent. The optical micro-cavity structure of two light-emitting units is adopted, namely 15 layers structure. Through etching conductive glass, cleaning with detergent by ultrasound, drying in vacuum, finely selecting chemical materials, finally the green light emitting diode is acquired. Both thicknesses of potential barrier and potential well in the optical micro-cavity are 3nm+ / -0.5nm. The lithium fluoride / aluminum / gold are used to make intermediate layer with a thickness of 8nm+ / -0.5nm between cathode and anode. The voltages in each layer are evenly and consistent. The green light emitting diode thereof has high luminous efficiency and better green color purity, and the color coordinate is x=0.3246, y=0.5386.

Owner:TAIYUAN UNIV OF TECH

Foamed wall material and preparation method thereof

The invention discloses a foamed wall material and a preparation method thereof. In the prior art, the method for recycling light construction waste does not exist. A purpose of the invention is to solve the disadvantage in the prior art. The invention provides a foamed wall material, which comprises the following raw materials by weight: 40-60 parts of light construction waste, 15-30 parts of cement, 5-20 parts of an admixture, 0.5-5 parts of a composite foaming agent, 0.2-0.4 part of fiber, 0.2-0.7 part of a water reducing agent, 0.08-0.15 part of a foam stabilizer and 45-65 parts of water.According to the invention, the foamed wall material is prepared by using the light construction waste as the raw material, the characteristics of the light construction waste are fully considered, and the light construction waste does not need to be further grinded after being grinded, so that the procedures and the energy are saved, the high-temperature and high-pressure maintenance with the boiler is not required, the energy consumption is reduced, and the utilization rate of the construction waste is increased.

Owner:深圳市鹏城建筑集团有限公司

Lawn grass fertilizer used in warm seasons

InactiveCN1669994ANutrient content fullReasonable ratio of nutrientsFertilizer mixturesFertilizerChemistry

The invention discloses a lawn grass fertilizer used in warm seasons wherein the effective constituents in the fertilizer include (by weight ratio), nitrogen 48.7-40.3, phosphorus pentoxide 20.5-15.1, potassium oxide 34.6-28.4, magnesium 5.2-2.8, zinc 2.0-1.0, boron 0.7-0.4, molybdenum 0.2-0.1. Compared with the prior art, the beneficial effects of the invention include full nutrient content, reasonable nourishing proportion, and higher utilization efficiency of fertilizer.

Owner:JIANGHAN UNIVERSITY

Maintenance method for garden landscape lawn

InactiveCN108812088AAchieve growth controlWide variety of sourcesBiocidePlant growth regulatorsUniconazoleWeed

The invention provides a maintenance method for a garden landscape lawn. The maintenance method comprises the following steps: (1) laying plant ash onto the surface layer of soil when a lawn is established, then using salicylic acid to prepare a salicylic acid aqueous solution with a concentration of 0.5 to 1 mg / L, spraying the salicylic acid aqueous solution onto the plant ash, and sowing grass seeds in 5 to 7 days after the salicylic acid aqueous solution is sprayed; (2) uniformly mixing salicylic acid, citric acid, polyacrylamide, ferrous sulfate and magnesium sulfate with water so as to obtain a mixed solution which is used right after prepared, and respectively spraying the mixed solution once to the lawn before the lawn turns green in spring and before the lawn is withered and turnsyellow in autumn; and (3) uniformly mixing uniconazole, naphthaleneacetic acid, abscisic acid, ferrous sulfate and potassium dihydrogen phosphate with water so as to obtain a mixed solution which is used right after prepared, spraying the mixed solution once to a vigorously-growing cold-season lawn in spring, and spraying the mixed solution once to a vigorously-growing warm-season lawn in midsummer. The maintenance method provided by the invention has the advantages of preventing weeds from surviving, significantly increasing the content of chlorophyll and greatly reducing the number of timesof lawn trimming.

Owner:ZHEJIANG NORMAL UNIVERSITY

Plant-activating agent

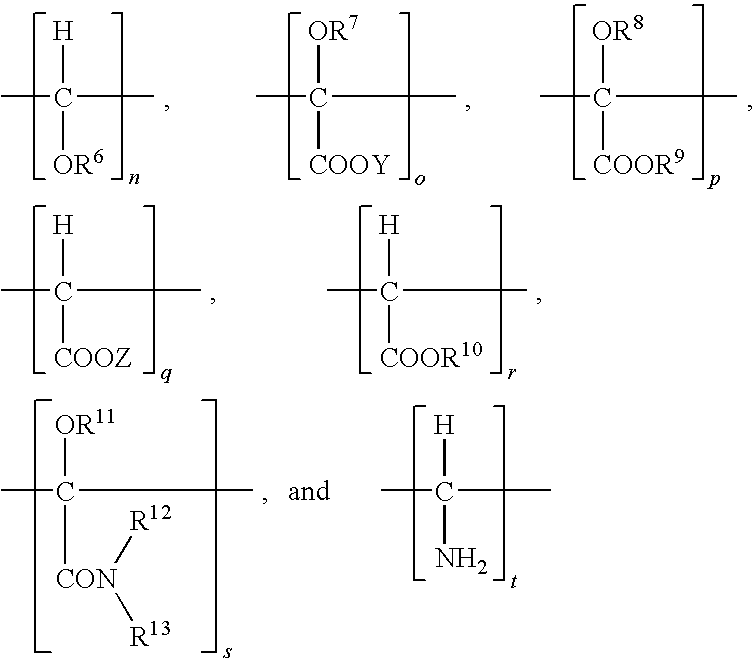

InactiveUS7829500B2PromoteImprove efficiencyBiocideDead animal preservationGlycerol DerivativesOrganic acid

Owner:KAO CORP

Lawn grass fertilizer used in warm seasons

InactiveCN100336783CIn line with the law of absorptionPromote growthFertilizer mixturesWarm seasonNitrogen

The invention discloses a lawn grass fertilizer used in warm seasons wherein the effective constituents in the fertilizer include (by weight ratio), nitrogen 48.7-40.3, phosphorus pentoxide 20.5-15.1, potassium oxide 34.6-28.4, magnesium 5.2-2.8, zinc 2.0-1.0, boron 0.7-0.4, molybdenum 0.2-0.1. Compared with the prior art, the beneficial effects of the invention include full nutrient content, reasonable nourishing proportion, and higher utilization efficiency of fertilizer.

Owner:JIANGHAN UNIVERSITY

Folding guardrail convenient for rapid highway construction

InactiveCN109518632AReasonable usePlay the role of fasteningWith built-in powerEnergy efficient lightingSelf lockingEngineering

Owner:青岛龙运君业贸易有限公司

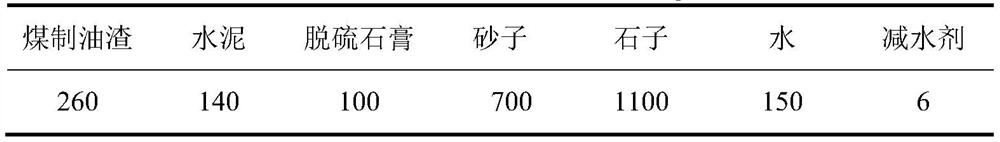

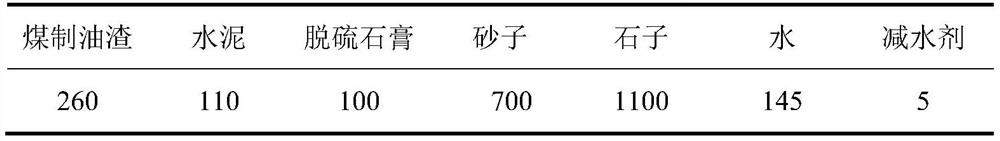

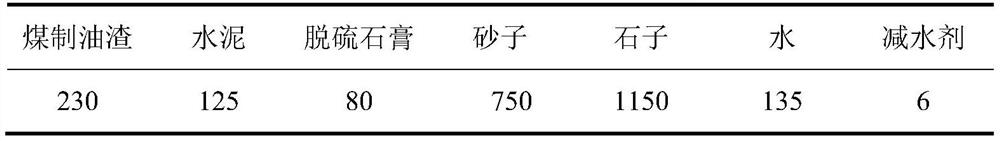

Premixed pump concrete prepared from coal oil residues and preparation method thereof

ActiveCN114477907ASolve the problem of high calcium-silicon ratio and high carbon emissionsHigh strengthSolid waste managementProcess engineeringWater reducer

The invention discloses premixed pump concrete prepared from coal oil residues and a preparation method of the premixed pump concrete, and belongs to the technical field of solid waste resource comprehensive utilization and building materials. The premixed pumped concrete is prepared from the following raw materials in parts by weight: 200-260 parts of coal oil residues, 110-140 parts of cement, 70-100 parts of gypsum, 700-750 parts of fine aggregate, 1100-1200 parts of coarse aggregate, 4-6 parts of a water reducing agent and 125-150 parts of water, and the cement, the coal oil residues and the gypsum in parts by weight are mixed and ground to prepare a cementing material; and uniformly stirring and mixing the cementing material with the fine aggregate, the coarse aggregate, the water reducing agent and the water to obtain the premixed pumped concrete prepared from the coal oil residues. According to the invention, two industrial solid wastes, namely the coal oil residue and the desulfurized gypsum, are co-processed, so that waste is turned into wealth, and the prepared premixed pump concrete is high in early hydration rate, relatively high in early strength and excellent in performance.

Owner:SHEXIAN QINGZHANG CEMENT MFG CO LTD +2

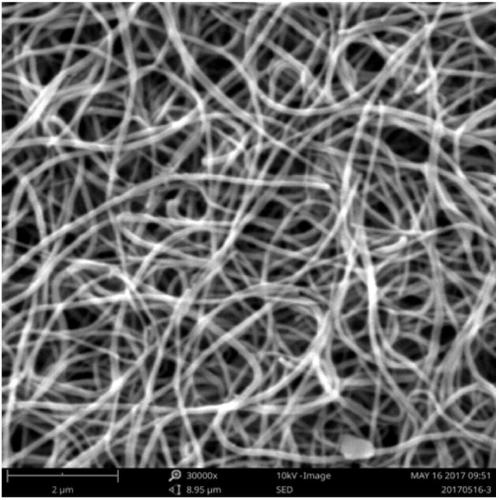

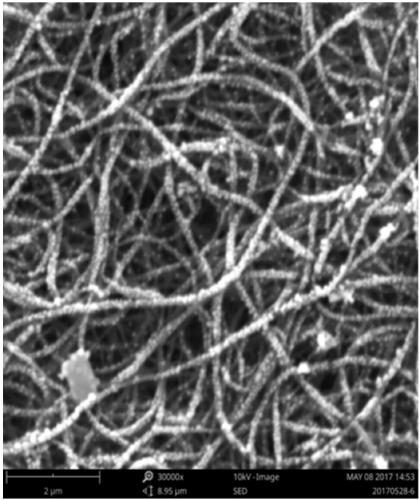

Preparation method of core-shell silver nanowire based on conductive polymer

ActiveCN109663905AImprove controllabilityImprove greennessMaterial nanotechnologyTransportation and packagingFlexible electronicsBody fluid

The invention relates to the technical field of flexible electronic materials, the invention specifically discloses a preparation method of core-shell silver nanowires based on a conductive polymer. The method comprises the following steps of preparing a conductive polymer nanowire and depositing a nano silver shell layer on the surface of the conductive polymer nanowire; the preparation method comprises the following steps that firstly, a conductive polymer nanowire precursor body fluid and a nano-silver precursor body fluid are prepared, and an electrochemical polymerization method is adopted to induce the reaction of monomers in the conductive polymer nanowire precursor body fluid to be converted into conductive polymer nanowires; in the nano-silver precursor body fluid, nano-silver isdeposited on the conductive polymer nanowires through an electrochemical reduction method, finally, the core-shell silver nanowires are formed. According to the method, due to the fact that the cost of the conductive polymer is very low, the silver quantity required by the core-shell silver nanowires is much lower than that of traditional silver nanowires, and a low-cost flexible transparent electrode can be obtained.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

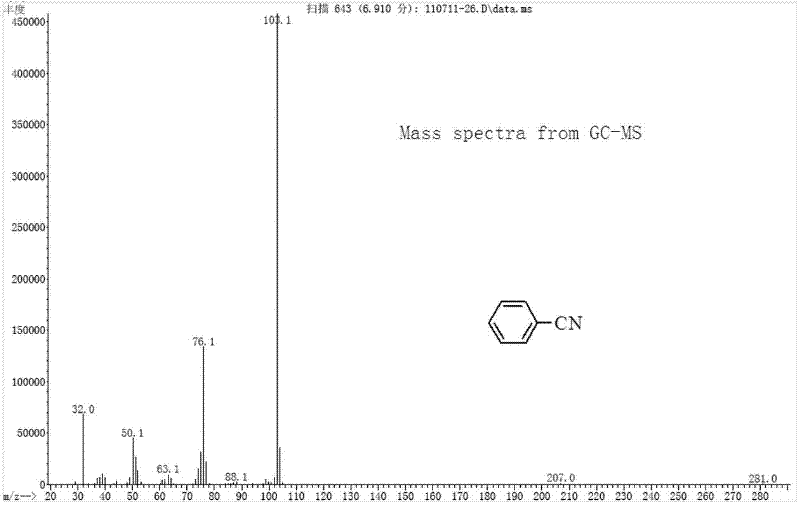

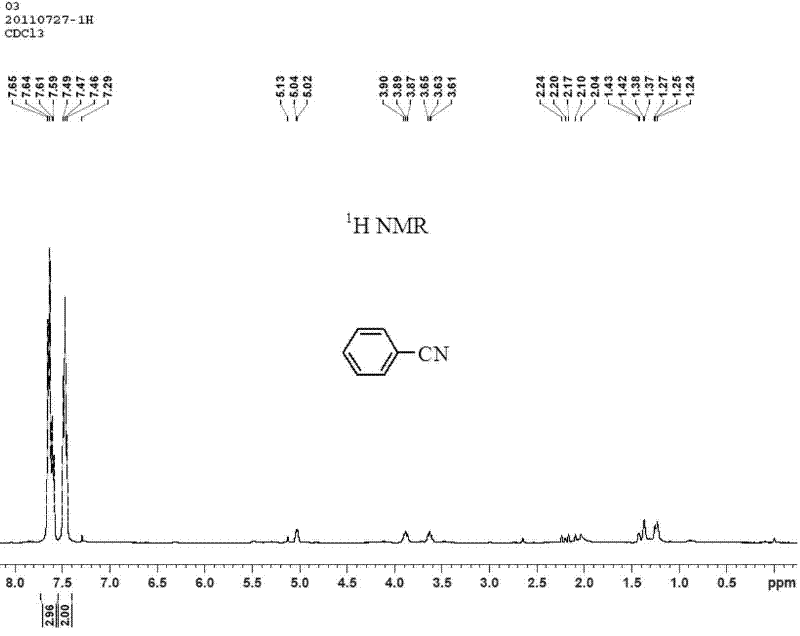

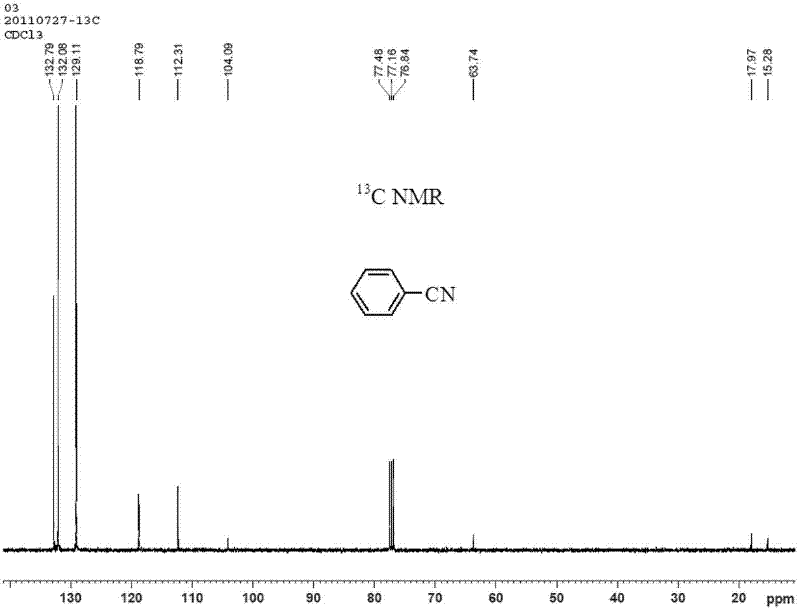

Method for synthesizing aromatic nitrile with arylboronic acid

InactiveCN102358715ALow toxicityImprove greennessCarboxylic acid nitrile preparationOrganic compound preparationArylCyanide

The invention belongs to the technical field of synthesis of an aromatic nitrile compound, in particular relates to a method for synthesizing aromatic nitrile with arylboronic acid. In the presence of catalysts, alkali and iodine, the aromatic nitrile is obtained through a reaction of the arylboronic acid and a cyanide reagent in organic solvent. The cyanide reagent is K4 [Fe (CN) 6] or K4 [Fe (CN) 6]*3H2O which is small in toxicity and cheaper. The method for synthesizing the aromatic nitrile compound is low in production cost and free of highly toxic materials.

Owner:HENAN UNIV OF SCI & TECH

Planting management method for improving selenium content of white tea

InactiveCN108967009AImprove absorption rateIncreased selenium contentSuperphosphatesOther chemical processesFertilizerCarbon dioxide

The invention relates to the technical field of white tea planting, in particular to a planting management method for improving the selenium content of white tea. The planting management method includes an arable land selenium increasing method and a water fertilizer selenium increasing method and / or gas selenium increasing method. According to the method, pH (potential of hydrogen) of planting soil is adjusted to range from 7.1 to 7.5 before the white tea is planted, selenium elements in the soil is greatly absorbed by white tea trees in weakly alkaline environments, the content of selenium elements in the tea is effectively improved, barium chloride is added into fertilizers, so that sulfate in the soil rapidly precipitate under the combined action of barium ions, storage amount of sulfate radicals in the soil or the tea trees is decreased, so that the selenium elements are absorbed by the tea trees, the content of carbon dioxide in tea garden air is increased in continuous several days of five days after selenium-rich farm manure is applied once, so that photosynthesis of the tea trees is improved, and selenate and selenite of the farm manure are efficiently absorbed by the teatrees.

Owner:GUIZHOU QIANREN TEA ECOLOGICAL AGRI TOURISM DEV

Green circulation method for producing ethyl maltol

ActiveCN111547749ATake advantage ofReduce manufacturing costOrganic chemistryElectrolysis componentsActivated carbonOrganic solvent

The invention requests to protect a green circulation method for producing ethyl maltol. The method is characterized in that the method comprises the following steps: adding water into the basic magnesium chloride-containing solid waste and uniformly stirring; then distilling under reduced pressure to remove the organic solvent, adding acid, then further decolorizing through a tubular filter provided with activated carbon, then dropwise adding a sodium hydroxide solution with the molar concentration of 2.5-4mol / L; and after the reaction is completed, centrifuging, drying, crushing, grading, inspecting and packaging. The method is short in technological process and mild in production condition, waste in maltol production can be fully utilized, high economic returns can be obtained, finally,the production cost of maltol is reduced, and pollution is reduced. The utilization efficiency of resources is effectively improved, and the greenness and sustainability of a maltol production process are improved.

Owner:广东省肇庆华格生物科技有限公司

Heat-insulation foamed cement board based on foam concrete wastes

ActiveCN108395170AGood economic and environmental benefitsRich varietySolid waste managementCeramicwareScrapCement board

The invention discloses a heat-insulation foamed cement board based on foam concrete wastes. The heat-insulation foamed cement board comprises, by weight, 70-80 parts of ordinary Portland cement, 20-30 parts of fly ash, 0.5-1 part of a foaming agent, 6-24 parts of foam concrete, 55-60 parts of water and 1-1.5 parts of a water reducer. The foam concrete wastes are crushed, sieved and classified toform artificial light aggregates with different particle sizes, and then are added into a foam concrete body to produce the self-heat insulation board. The solid wastes are adopted, so the heat-insulation foamed cement board has low cost; the wastes are changed into effective resources and recycled, so the heat-insulation foamed cement board has the advantages of energy-saving and environmentally-friendly production process, good economic and environmental benefits, increase of the types of energy-saving and heat-insulation wall materials, and improvement of the greenness of an inorganic lightweight material. The heat-insulation foamed cement board produced in the invention has a heat insulation coefficient of 0.06-0.10 w / m.k, a compressive strength of 1 Mpa or more, a bulk density of 490-640 kg / m<3> and a volume water absorption rate of 15-20%.

Owner:JIAXING UNIV

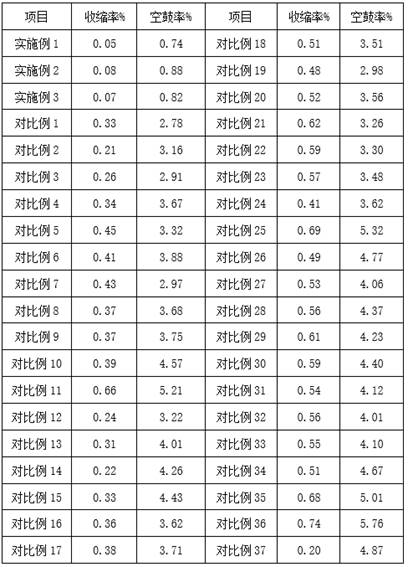

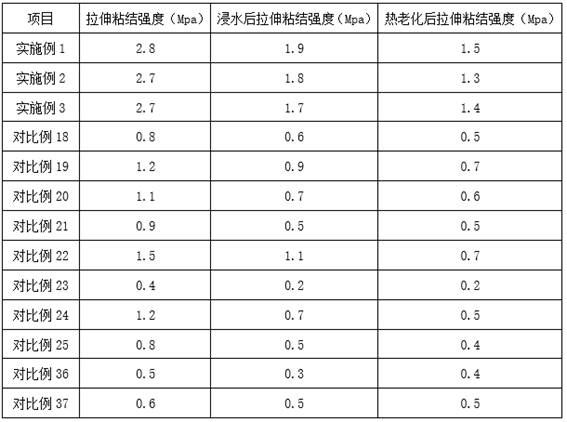

Dry-mixed ceramic tile adhesive mortar

The invention provides ceramic tile pasting mortar and a preparation method thereof. Waste tires are used for preparing machine-made sand, the existence of black garbage is effectively reduced, and meanwhile, the modified waste tire particles have very high ductility and excellent energy absorption performance, and can effectively prevent the dry shrinkage phenomenon of the mortar in the solidification process. A binding agent is added, the binding force of the mortar to the ceramic tile is increased, meanwhile, the binding agent is alkaline, the interface on the back face of the ceramic tile can be slightly reacted, the roughness of the interface is increased, and the binding agent can adhere and cure the mortar interface more easily. A modified retarder is added, so that the coagulation speed of the mortar is slowed down, the mortar does not react with groups outside modified waste tire particles and a binder, meanwhile, the modified retarder has the effect of a plastic stabilizer, the anti-sagging property of the mortar is improved, the micro-reaction inside the mortar is stabilized, and the bonding capacity of the mortar and a matrix interface is improved.

Owner:龙南县彩艺装饰材料厂

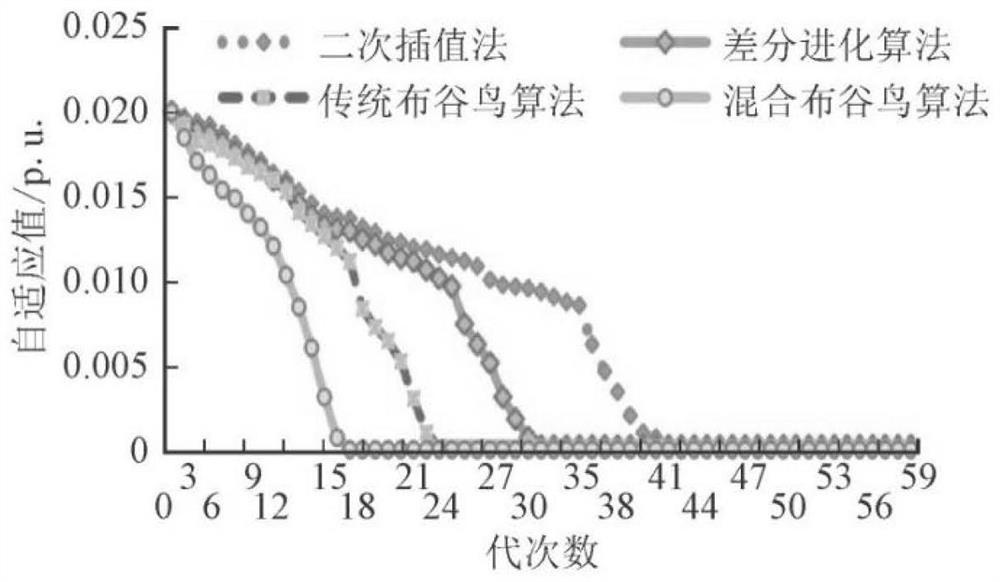

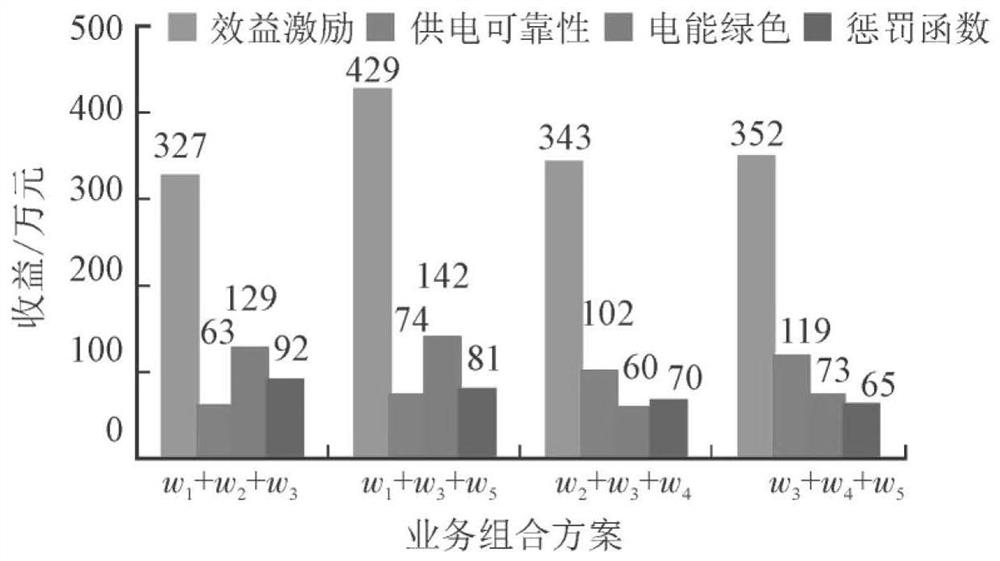

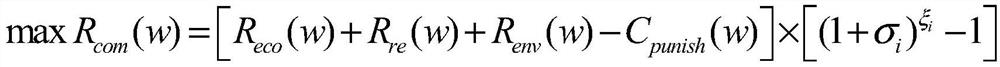

Multi-service combinatorial investment optimization method for 5G and power grid basic resource sharing

PendingCN113971476AGuaranteed profitGuaranteed reliabilityFinanceForecastingSocial benefitsBusiness enterprise

The invention discloses a multi-service combinatorial investment optimization method for 5G and power grid basic resource sharing. The method comprises the following steps: S1, carrying out the permutation and combination of a plurality of pre-investment services of an investor, and forming a plurality of multi-service combinatorial investment schemes; S2, constructing a multi-service portfolio investment scheme benefit measurement and calculation model; and S3, respectively substituting each multi-service portfolio investment scheme in the S1 into the benefit measurement and calculation model constructed in the S2 for solving, taking the scheme with the highest comprehensive benefit as the optimal multi-service portfolio investment scheme, and adjusting investment services of investors according to the optimal multi-service portfolio investment scheme to optimize a multi-service combined investment mode of 5G base station and power grid basic resource sharing. According to the invention, economic benefits, environmental benefits and social benefits can be considered when a power grid company invests a plurality of 5G base stations and power grid basic resource sharing services; the reliability of power grid power supply is ensured and the greenness of electric energy supply is improved; and the market competitiveness of companies is improved, and sustainable development of power grid enterprises is promoted.

Owner:国网山西省电力公司经济技术研究院

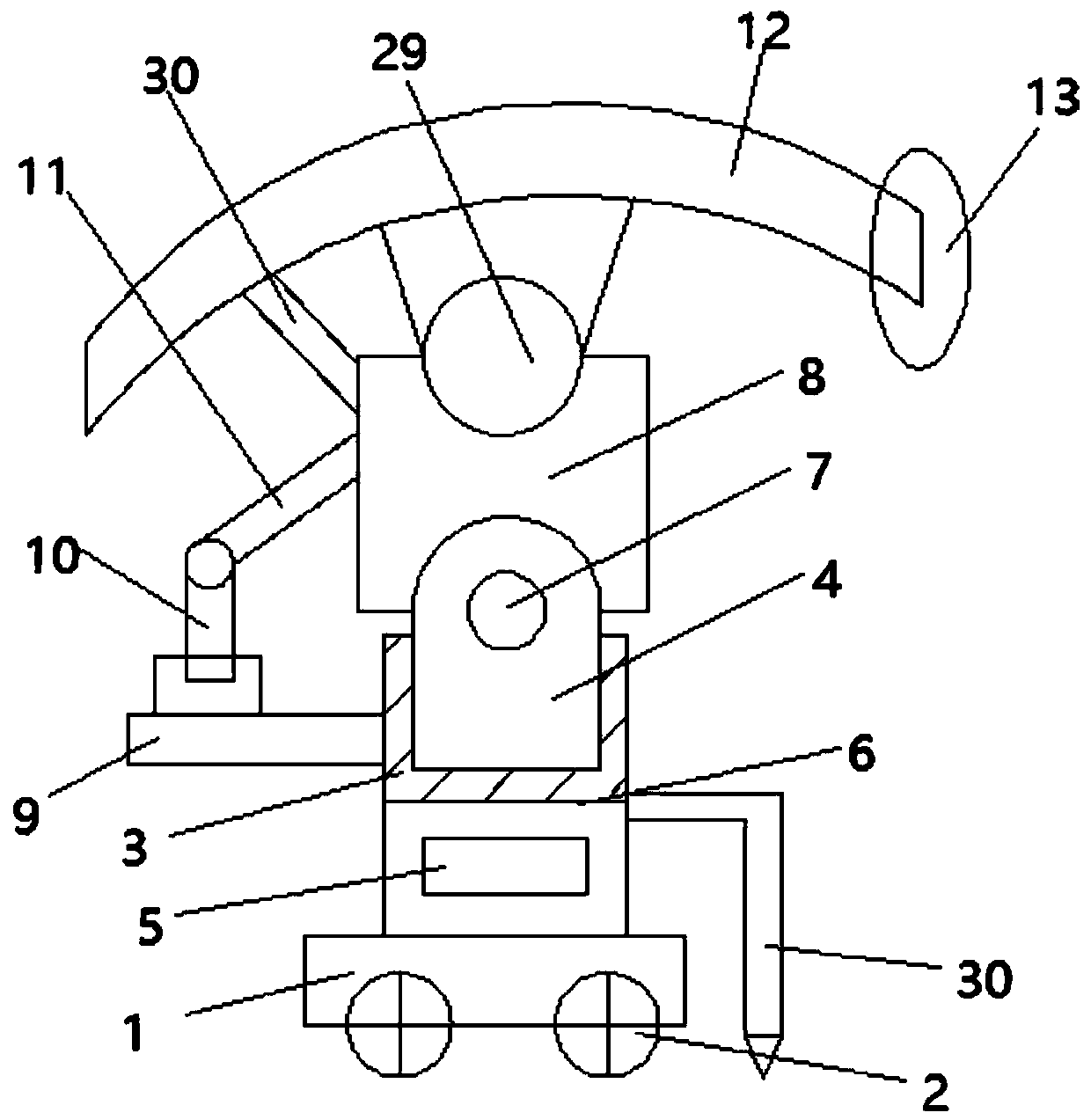

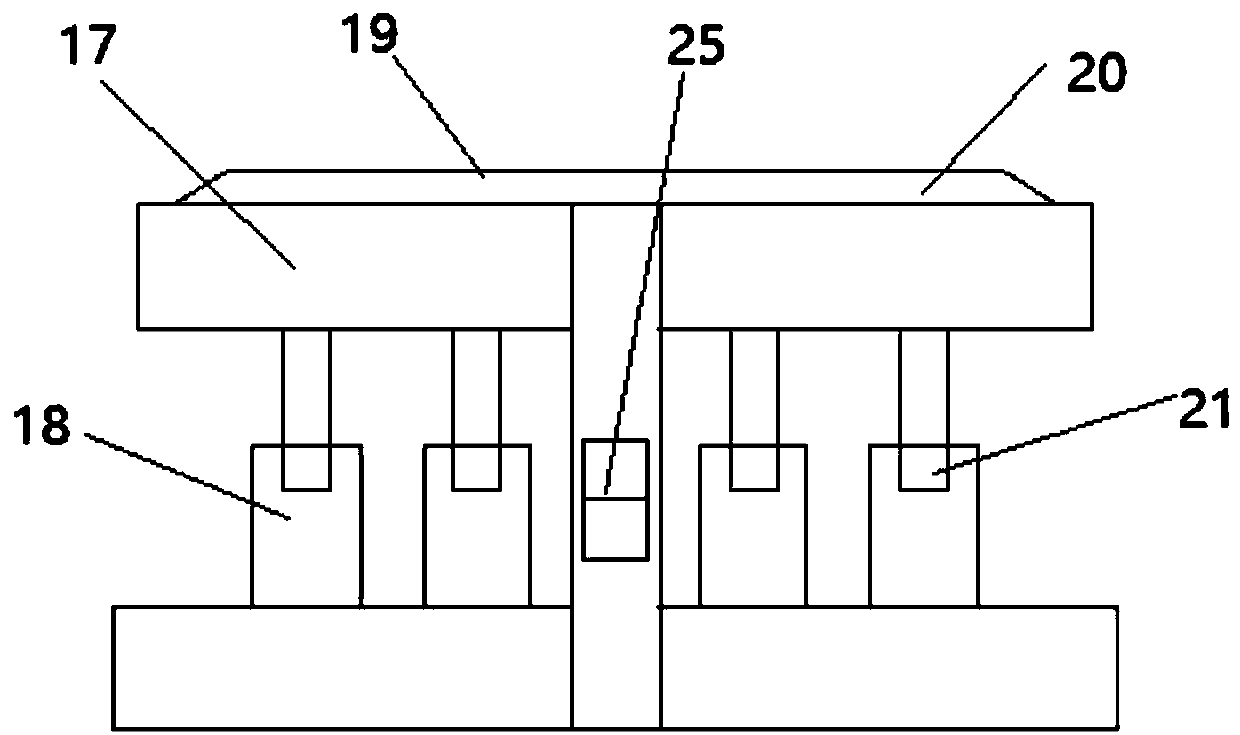

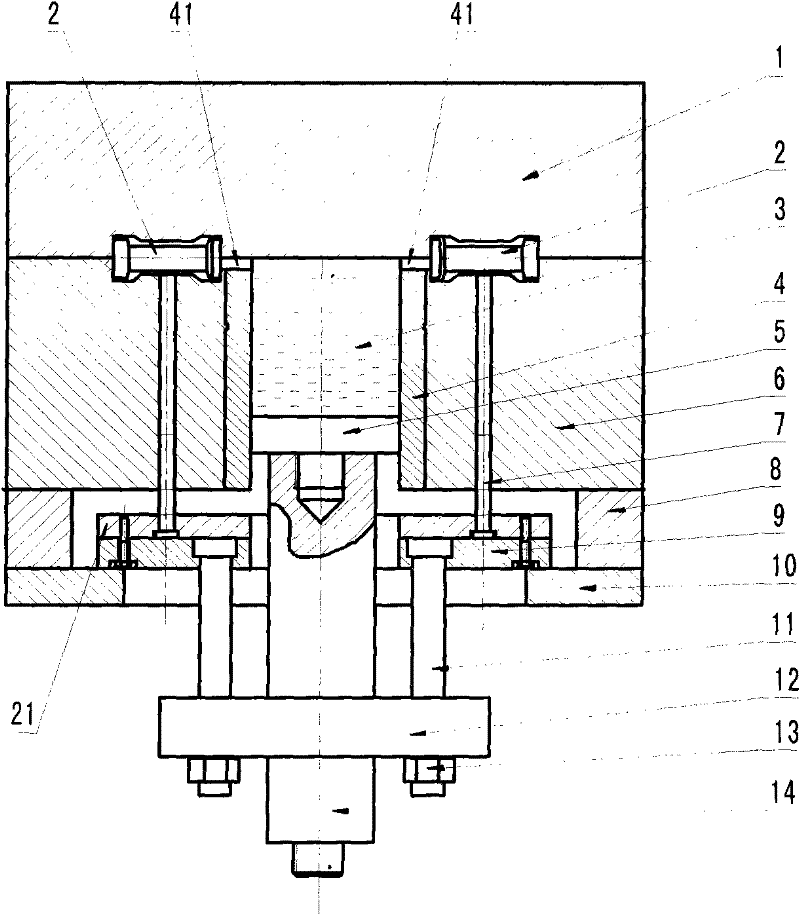

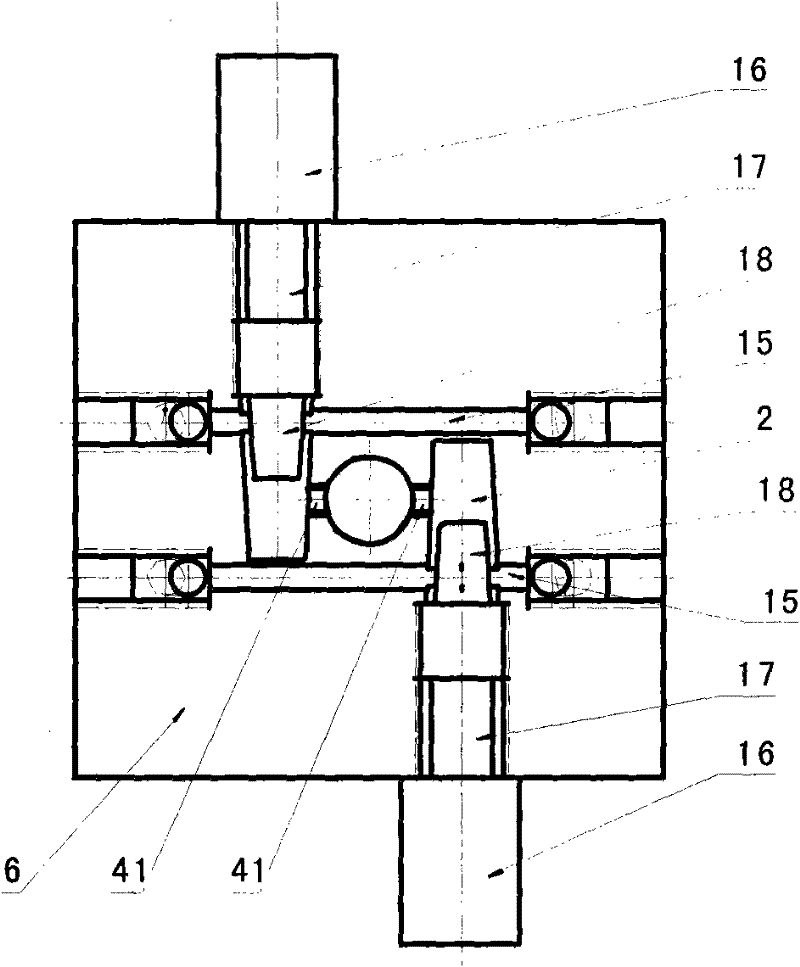

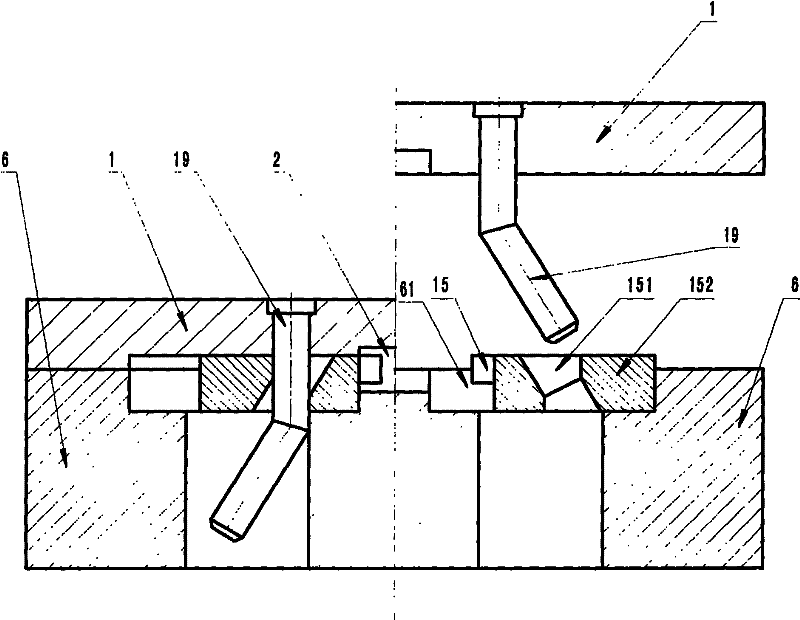

Manufacturing method of bucket tooth and applied mould thereof

The invention provides a manufacturing method of bucket tooth and an applied mould thereof. Liquid bucket tool material is poured into a material storage cavity, a core puller is utilized to push a tooth cavity core and a pin hole core into a bucket tooth mould cavity; an upper mould and a lower mould are closed, and pressure is maintained to be 3000-15000kN; the lower cylinder of a hydraulic cylinder drives a pressure head to push the liquid bucket tooth material in the material storage cavity to be filled with the bucket tooth mould cavity at the linear speed of 10-100m / s, pressure is increased to be 500-5000KN, and pressure is maintained until the material is completely solidified. The core puller is utilized to pull out the tooth cavity core and the pin hole core; the lower cylinder drives a material tray to push an ejector rod to eject the bucket tooth and residue material, heat treatment is carried out, thus obtaining the bucket tooth of the invention; the lower cylinder returns, the material tray pulls the ejector rod and the pressure head to be descended and reset, and next operating cycle is executed. Material utilization is 85-95%, strength is improved by 20-30% compared with a sand-cast bucket tooth, impact toughness is improved by 15-25%, energy consumption is reduced by 20-30%, cost is reduced by 15-30%, and hour output can reach 150 pieces. Qualified bucket tooth can be manufactured without a dead head or sand mould.

Owner:BEIJING JIAOTONG UNIV +1

Cracking-resisting compacting agent for concrete

InactiveCN102010147AGood compatibilityGood slump performanceSolid waste managementUltimate tensile strengthWater reducer

The invention discloses a cracking-resisting compacting agent for concrete. The cracking-resisting compacting agent comprises siliceous dust, triethanolamine and an air entraining agent, wherein the doping ratio of the siliceous dust to the triethanolamine to the air entraining agent is 1.5 percent: (0.015-0.045 percent): (0.015-0.030 percent). The cracking-resisting compacting agent is well compatible with other additives (such as a water reducing agent); good collapse protecting effect on freshly mixed concrete can be achieved by adding the cracking-resisting compacting agent; the using of the cracking-resisting compacting agent does not influence the strength of the concrete but increases the early strength of the concrete; and the content of internally-doped cracking-resisting compacting agent is low, so that the increase of engineering cost is small. The cracking-resisting compacting agent does not prolong the condensing time of the concrete; and the concrete does not newly produce calcium-containing matters in the early period of hydration when the cracking-resisting compacting agent is doped into the concrete, so that the low carbon development requirement of the concrete is met. The defects in the aspects of durability, energy consumption and environmental friendliness of C3S, C3A and the like are reduced, and the green degree of gelled materials is improved.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com