Synthesis method for ZSM-11 molecular sieve with nano multi-stage pores

A technology for ZSM-11 and synthesis methods, applied in the direction of molecular sieves and base exchange compounds, nanotechnology, chemical instruments and methods, etc., can solve the problems of increasing the synthesis cost of ZSM-11 molecular sieves, increasing synthesis costs, unfavorable industrial applications, etc., to achieve Enrich micropores and mesoporous channels, reduce waste liquid discharge, and have good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

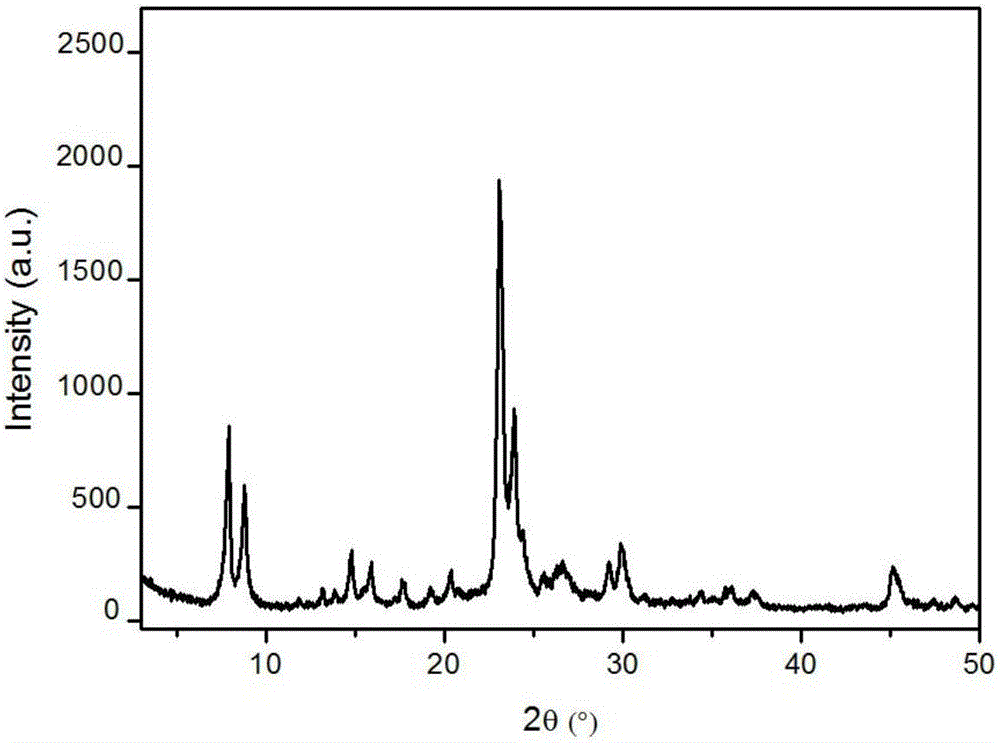

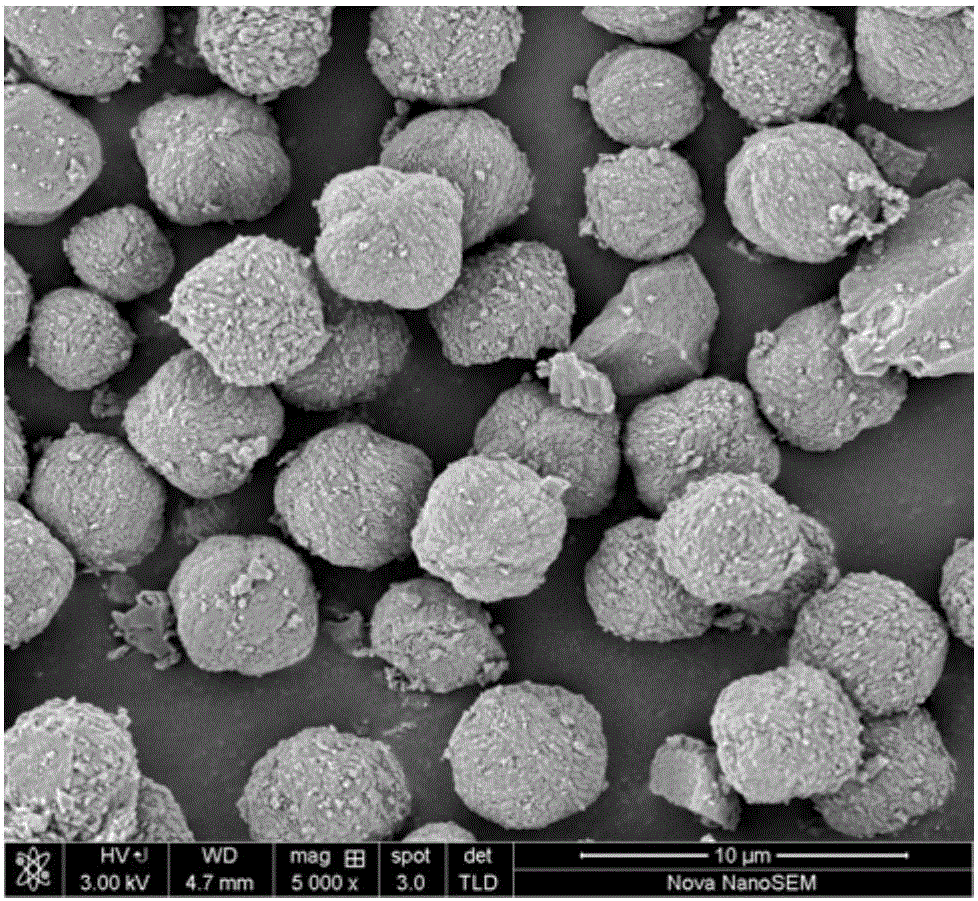

[0058] The synthesis of embodiment 1 ZSM-11 molecular sieve

[0059] (1) Roast 40 g of kaolin at 850° C. for 1 h to obtain roasted kaolin, mix the roasted kaolin with 200 mL of hydrochloric acid solution with a concentration of 6 mol / L (liquid-solid ratio is 5 mL / g), then heat and stir at 90° C. for 6 h, Afterwards, filter cake was obtained by filtration, and the filter cake was dried at 100° C. for 6 hours to obtain modified kaolin. The active silica content in the modified kaolin was determined to be 96.37%, and the active alumina content was 2.28%.

[0060] (2) Add 12.68g of white carbon black, 18.88g of tetrabutylammonium hydroxide (TBAOH) solution (40%, mass concentration), 66.86g of deionized water, 0.89g of sodium hydroxide, 34.23g of ethanol and 10.00g of g modified kaolin, the molar ratio of each raw material in the slurry after mixing is as follows: 1SiO 2 :0.006Al 2 o 3 :0.03Na 2 O:0.1TBAOH:10H 2 O:2EtOH. It is calculated that the active silicon oxide in the ...

Embodiment 2

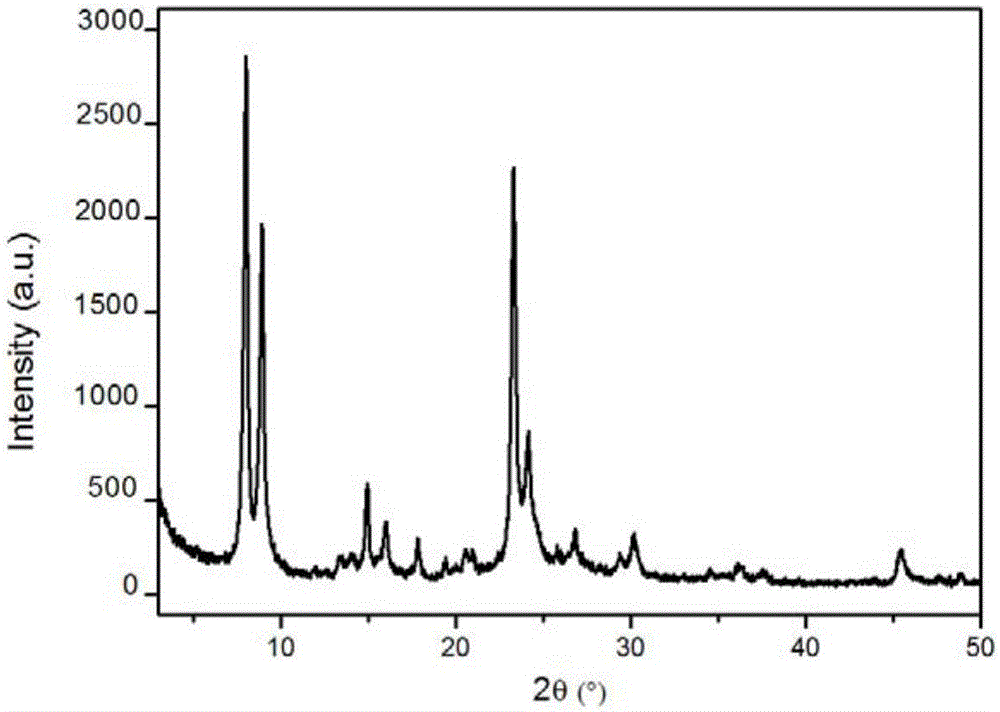

[0064] The synthesis of embodiment 2 ZSM-11 molecular sieves

[0065] (1) Roast 60 g of kaolin at 750° C. for 3 h to obtain roasted kaolin, mix the roasted kaolin with 480 mL of nitric acid solution with a concentration of 6 mol / L (liquid-solid ratio is 8 mL / g), then heat and stir at 80° C. for 3 h, Afterwards, filter cake was obtained by filtration, and the filter cake was dried at 120° C. for 12 hours to obtain modified kaolin. The active silica content in the modified kaolin was determined to be 95.26%, and the active alumina content was 3.66%.

[0066] (2) Add 13.47g ethyl orthosilicate, 29.78g tetrabutylphosphorus hydroxide (TBPOH) solution (40%, mass concentration), 193.83g deionized water, 0.86g sodium hydroxide and 30.00g modified kaolin, the molar ratio of each raw material in the slurry after mixing evenly is as follows: 1SiO 2 :0.02Al 2 o 3 :0.02Na 2 O:0.08TBPOH:20H 2 O. It is calculated that the active silicon oxide in the above-mentioned modified kaolin acc...

Embodiment 3

[0070] The synthesis of embodiment 3 ZSM-11 molecular sieves

[0071] (1) Roast 30 g of kaolin at 900° C. for 4 h to obtain roasted kaolin, mix the roasted kaolin with 180 ml of hydrochloric acid solution with a concentration of 8 mol / L (liquid-solid ratio is 6 mL / g), then heat and stir at 90° C. for 2 h, Afterwards, filter cake was obtained by filtration, and the filter cake was dried at 120° C. for 24 hours to obtain modified kaolin. The active silica content in the modified kaolin was determined to be 90.31%, and the active alumina content was 6.13%.

[0072] (2) 30.57g of tetrabutylammonium hydroxide (TBAOH) solution (40%, mass concentration), 54.11g of deionized water, 55.40g of ethanol and 20.00g of modified kaolin were added successively under stirring, and each raw material in the slurry was mixed uniformly The molar ratio is as follows: 1SiO 2 :0.04Al 2 o 3 :0.2TBAOH:10H 2 O:4EtOH. It is calculated that the active silicon oxide in the above-mentioned modified ka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com