Synthetic method of 4A molecular sieve

A synthesis method and molecular sieve technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems that do not conform to the development trend of modern green chemical industry, affect the utilization rate of silicon-aluminum species, and seriously pollute the environment , to achieve excellent physical and chemical properties, less pollution, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Commercially available kaolin is dried and pulverized into powder (the present invention has no specific requirements on the degree of pulverization, usually pulverized until passing through a 20-mesh sieve). Weigh 10.00g of kaolin powder, mix evenly with 84.00g of sodium hydroxide solution, dry at 200°C, and set aside. Wherein the sodium hydroxide solution is prepared by dissolving 14.00 g of sodium hydroxide solid in 70.00 g of deionized water.

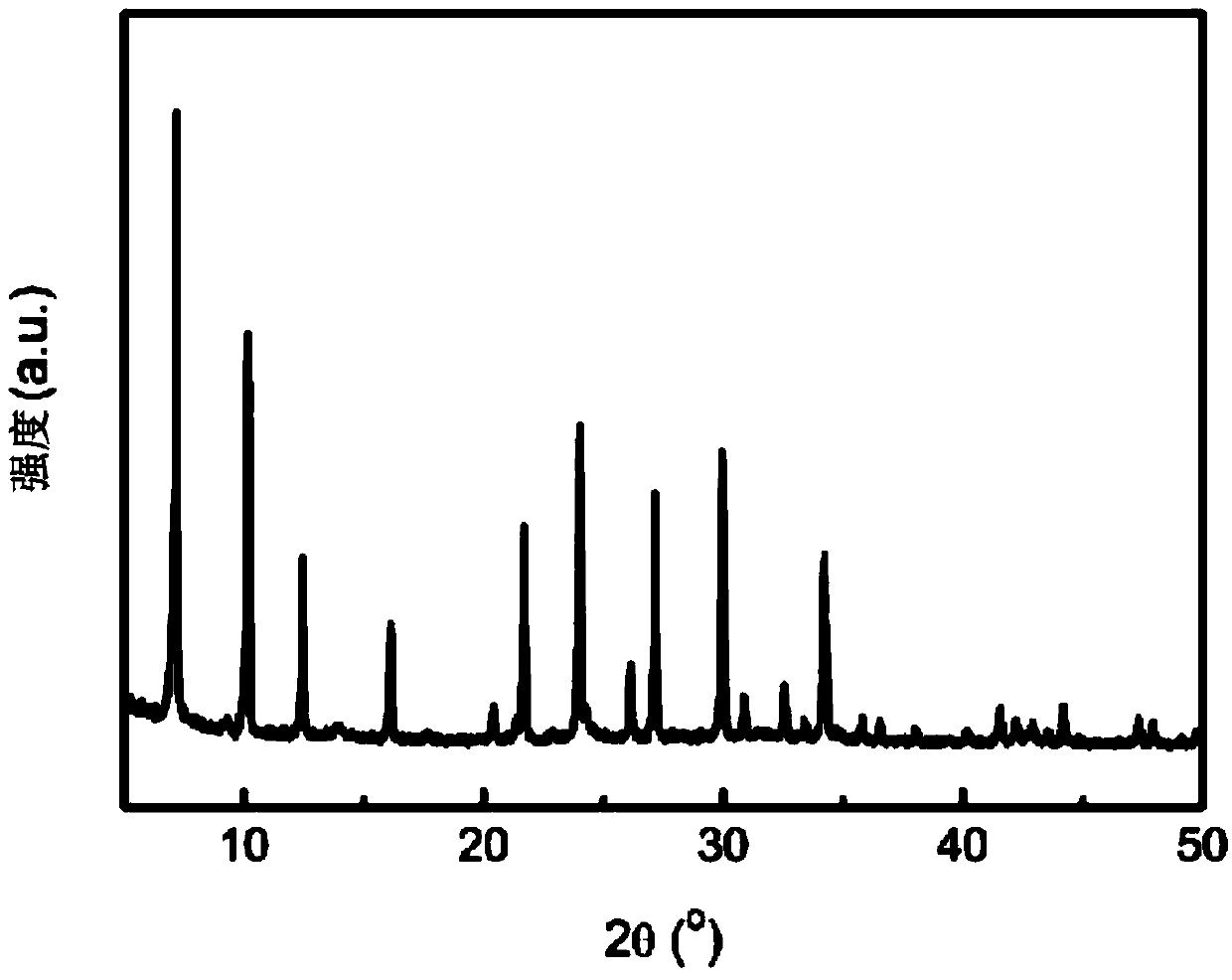

[0042] Weigh 10.44 g of the above dried kaolin powder, add 54.91 g of deionized water, and mix and stir at 40° C. for 12 h. The mixture was poured into a polytetrafluoroethylene-lined stainless steel crystallization kettle, heated to 90°C for static crystallization for 2 h. After the crystallization is completed, cool and filter to remove the mother liquor, wash until neutral, and dry at 120°C to obtain a crystallized product. As determined by XRD, its phase belongs to 4A molecular sieve, the whiteness of 4A molecular sieve...

Embodiment 2

[0044] The pretreatment method of kaolin is with embodiment 1.

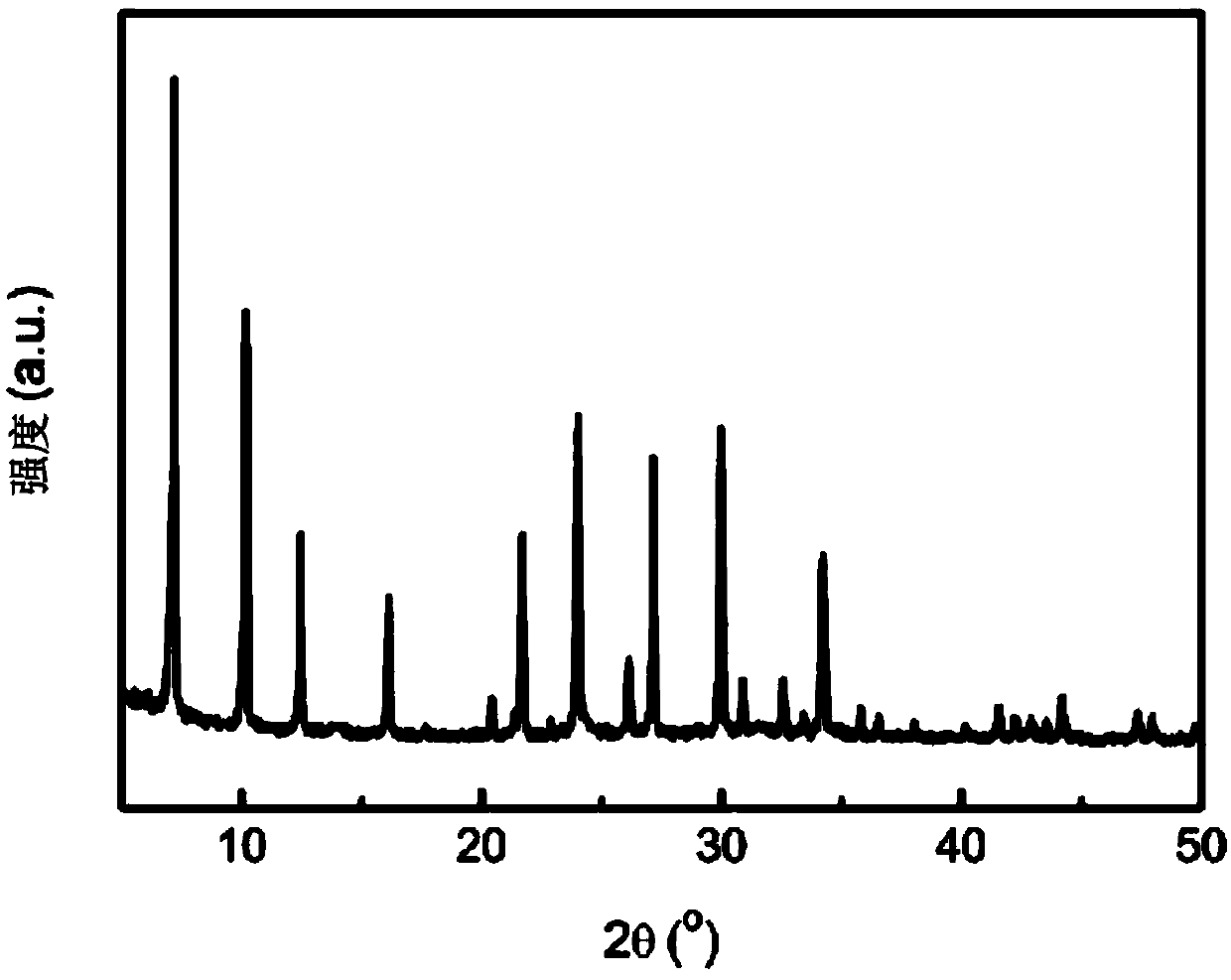

[0045] Weigh 8.70 g of the above dried kaolin powder, add 51.48 g of deionized water, and mix and stir at 20° C. for 4 h. The mixture was poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 100°C for static crystallization for 6h. After the crystallization is completed, cool and filter to remove the mother liquor, wash until neutral, and dry at 120°C to obtain a crystallized product. As determined by XRD, its phase belongs to 4A molecular sieve, the whiteness of 4A molecular sieve in the product is 92, and the calcium ion exchange capacity is 312mg CaCO 3 / g molecular sieve, its XRD spectrum is shown in image 3 .

Embodiment 3

[0047] The pretreatment method of kaolin is with embodiment 1.

[0048] Weigh 16.73 g of the above dried kaolin powder, add 43.93 g of deionized water, and mix and stir at 60° C. for 8 h. The mixture was poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 100°C for static crystallization for 4 hours. After the crystallization is completed, cool and filter to remove the mother liquor, wash until neutral, and dry at 120°C to obtain a crystallized product. According to XRD determination, its phase belongs to 4A molecular sieve, the whiteness of 4A molecular sieve in the product is 94, and the calcium ion exchange capacity is 320mg CaCO 3 / g molecular sieve, its XRD spectrum is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com