High-strength recycled concrete as well as preparation method and application thereof

A recycled concrete, high-strength technology, applied in the field of building materials, can solve the problems of improving the performance of recycled concrete, the preparation process is not detailed and comprehensive, and the combination method is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing high-strength recycled concrete, comprising the following preparation steps:

[0047] (1) Weighing: Weigh raw materials according to the following parts by weight: 290 parts of cement; 20 parts of fly ash; 70 parts of slag; 20 parts of silica fume; 70 parts of metakaolin; 650 parts of fine aggregate; 600 parts of natural coarse aggregate parts; 510 parts of recycled coarse aggregate; 4.0 parts of water reducing agent; 140 parts of water, spare;

[0048] (2) Regenerated aggregate pre-wetting: pre-wet the regenerated coarse aggregate dried to constant weight, the pre-wet water quality is 90% of the water absorption rate of the regenerated coarse aggregate, and obtain the pre-wet regenerated aggregate;

[0049] (3) Preparation of cementitious materials: Mix cement, fly ash, slag, silica fume and metakaolin evenly to obtain cementitious materials, and then divide them into M1 cementitious materials and M2 cementitious materials by mass, and M1 cementi...

Embodiment 2

[0057] A method for preparing high-strength recycled concrete, comprising the following preparation steps:

[0058] (1) Weighing: Weigh raw materials according to the following parts by weight: 300 parts of cement; 45 parts of fly ash; 45 parts of slag; 30 parts of silica fume; 30 parts of metakaolin; 680 parts of fine aggregate; parts; 480 parts of recycled coarse aggregate; 5.0 parts of water reducer; 150 parts of water, spare;

[0059] (2) Regenerated aggregate pre-wetting: pre-wet the regenerated coarse aggregate dried to constant weight, the pre-wet water quality is 90% of the water absorption rate of the regenerated coarse aggregate, and obtain the pre-wet regenerated aggregate;

[0060] (3) Preparation of cementitious materials: Mix cement, fly ash, slag, silica fume and metakaolin evenly to obtain cementitious materials, and then divide them into M1 cementitious materials and M2 cementitious materials by mass, and M1 cementitious materials account for the total 48% of...

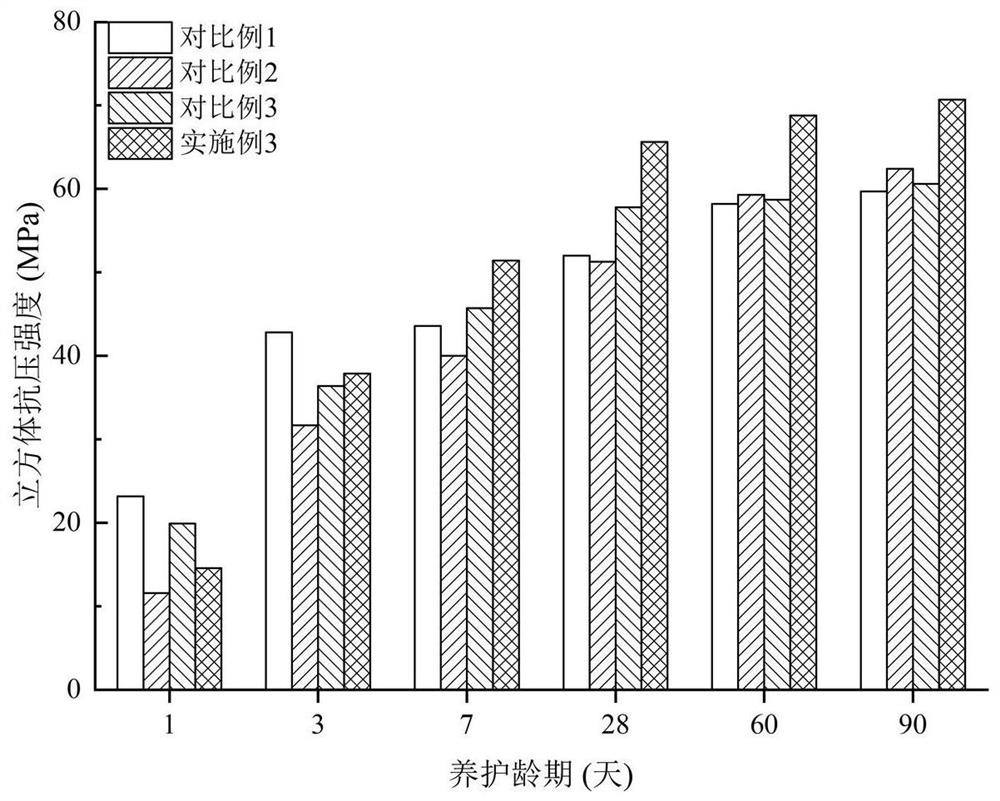

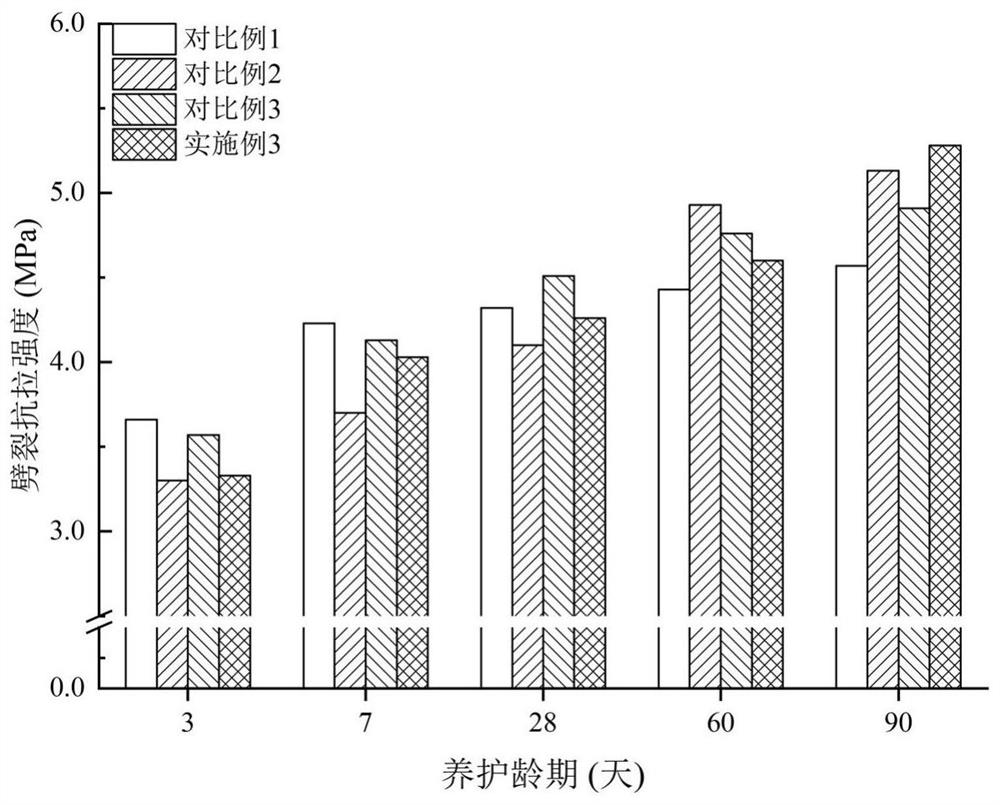

Embodiment 3

[0068] A method for preparing high-strength recycled concrete, comprising the following preparation steps:

[0069] (1) Weighing: Weigh raw materials according to the following parts by weight: 311 parts of cement; 33 parts of fly ash; 33 parts of slag; 33 parts of silica fume; 33 parts of metakaolin; 705 parts of fine aggregate; 560 parts of natural coarse aggregate parts; 498 parts of recycled coarse aggregate; 5.54 parts of water-reducing agent; 155 parts of water, spare;

[0070] (2) Regenerated aggregate pre-wetting: pre-wet the regenerated coarse aggregate dried to constant weight, the pre-wet water quality is 90% of the water absorption rate of the regenerated coarse aggregate, and obtain the pre-wet regenerated aggregate;

[0071] (3) Preparation of cementitious materials: Mix cement, fly ash, slag, silica fume and metakaolin evenly to obtain cementitious materials, and then divide them into M1 cementitious materials and M2 cementitious materials by mass, and M1 cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com