Steel fiber reinforced ultra-high-performance concrete synergistically prepared by multiple solid waste and preparation method of steel fiber reinforced ultra-high performance concrete

An ultra-high-performance, steel fiber technology, applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of difficulty in improving the strength of ultra-high-performance concrete, low overall utilization of steel slag, and large cement consumption , to achieve the effect of improving the comprehensive utilization rate, improving the intensity index, and improving the green degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of steel fiber reinforced ultra-high performance concrete prepared by synergy of multiple solid wastes and a preparation method thereof. The concrete includes 35% to 50% of cementitious material, 35% to 50% of aggregate, and 0% by mass percentage. ~3% water reducing agent, 5%~8% steel fiber and 7%~9% water; among them, the cementitious material is composed of 40%~70% slag, 15%~35% hot-simmered converter steel slag , 5% to 20% of refining slag and 10% to 20% of industrial by-product gypsum, and the aggregate is one or both of quartz sand and drum-process converter steel slag.

[0032] When preparing the concrete, the slag, thermal converter slag, refining slag and industrial by-product gypsum are firstly ground separately, and then mixed to obtain a cementitious material; then the prepared cementitious material, aggregate, and water reducer , steel fiber and water are evenly mixed according to the mass ratio, and then poured into a shape and...

Embodiment 1

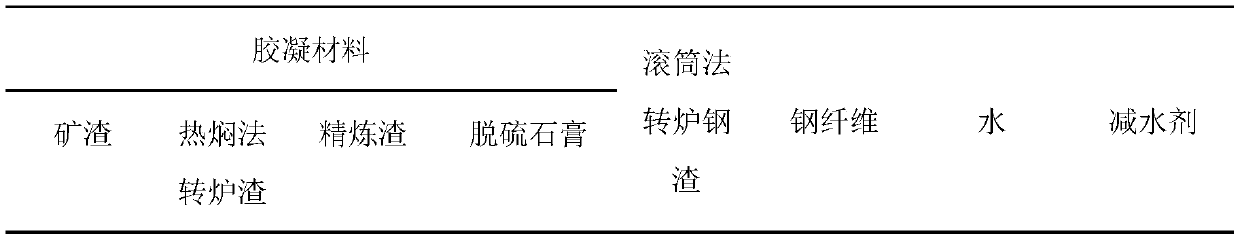

[0035] A kind of multi-solid waste synergistically prepared steel fiber reinforced ultra-high performance concrete, the cementitious material is prepared from the following raw materials: by weight percentage, slag 56.25%, thermal braising method converter slag 18.75%, refining slag 5%, desulfurization gypsum 20%; slag and thermally stewed converter slag are mixed and ground to a specific surface area of 550m 2 / kg, the refining slag is ground to a specific surface area of 564m 2 / kg, desulfurized gypsum is ground to a specific surface area of 400m 2 / kg. In concrete, in terms of weight percentage, cementitious material accounts for 38.1%, aggregate accounts for 47.7%, water reducer accounts for 0.4%, steel fiber accounts for 6.4%, and mixing water accounts for 7.6%. The aggregate is drum method converter steel slag, The water reducer is a solid polycarboxylate high-efficiency water reducer, and the steel fiber is a straight steel fiber with an aspect ratio of 60.

[...

Embodiment 2

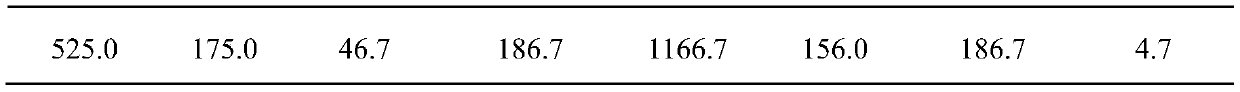

[0041]A kind of multi-solid waste synergistically prepared steel fiber reinforced ultra-high performance concrete, the cementitious material is prepared from the following raw materials: by weight percentage, slag 56.25%, thermal braising method converter slag 18.75%, refining slag 5%, desulfurization gypsum 20%; slag and thermally stewed converter slag are mixed and ground to a specific surface area of 550m 2 / kg, the refining slag is ground to a specific surface area of 564m 2 / kg, desulfurized gypsum is ground to a specific surface area of 400m 2 / kg. In concrete, in terms of weight percentage, cementitious material accounts for 38.1%, aggregate accounts for 47.7%, water reducing agent accounts for 0.2%, steel fiber accounts for 6.4%, mixing water accounts for 7.6%, of which aggregate is quartz sand, water reducing agent The agent is a solid polycarboxylate high-efficiency water reducer, and the steel fiber is a straight steel fiber with an aspect ratio of 60.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com