Class C40 slag-doped recycled aggregate self-compacting concrete and production method thereof

A technology of self-compacting concrete and recycled aggregate, which is applied in the field of building materials, can solve the problems of high cost, labor shortage, and reduce the production cost of self-compacting concrete. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

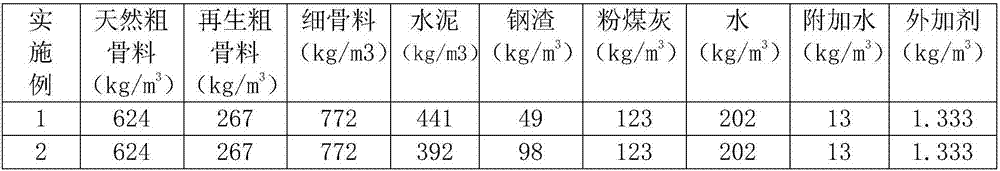

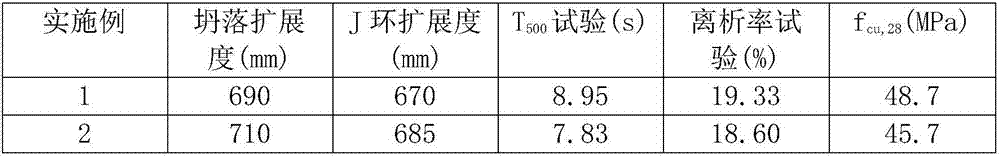

Examples

Embodiment

[0034] (1) Prepare raw materials

[0035] Cement: P·O42.5 ordinary Portland cement, apparent density is 3.20g / cm 3 .

[0036] Fly ash: Grade I fly ash, apparent density is 2.42g / cm 3 .

[0037] Fine aggregate: river sand with a fineness modulus of 2.4 and a bulk density of 1.54g / cm 3 , The apparent density is 2.64g / cm 3 , The moisture content is 0.35%.

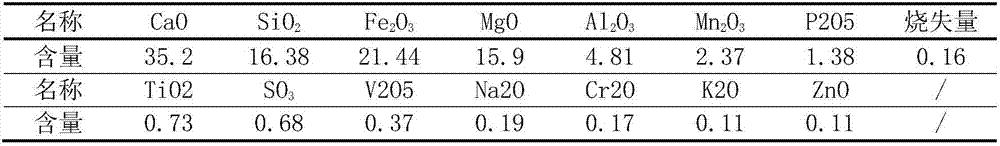

[0038] Steel slag: steel slag that has been placed in the steel plant for more than 6 months after iron removal, ball milling and screening, select steel slag powder with a particle size of less than 0.08mm, with an apparent density of 2.36g / cm 3 The basicity coefficient of steel slag is 1.99, the mass percentage of MgO is 15.9%, and other testing indexes of steel slag are in line with the standard of "Steel Slag Powder Used in Cement and Concrete" GB / T 20491-2006.

[0039] Natural coarse aggregate: 5-20mm crushed stone, apparent density of 2.87g / cm 3 , The bulk density is 1.53g / cm 3 , The water absorption rate is 0.54%.

[0040] Recycle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com