Cracking-resisting compacting agent for concrete

A concrete and densifier technology, applied in the field of concrete, can solve problems such as difficulty in curing, long retarding time, and reduced concrete strength, and achieve the effect of small increase in project cost, delaying setting time, and increasing early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

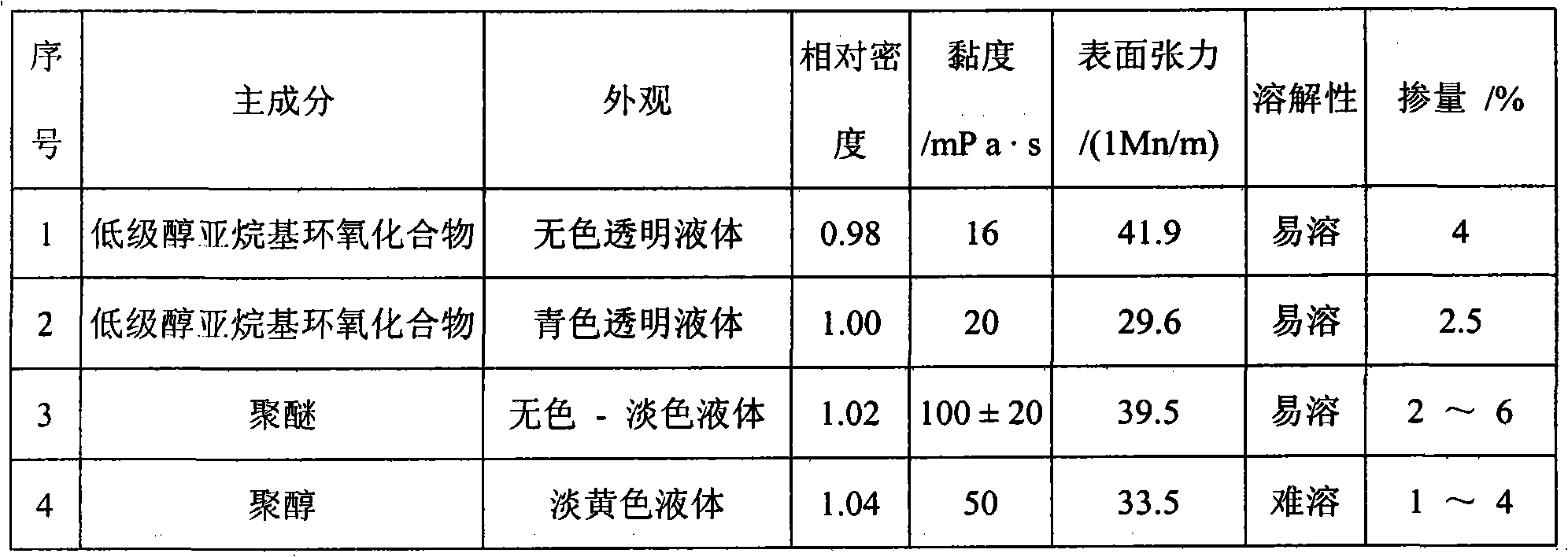

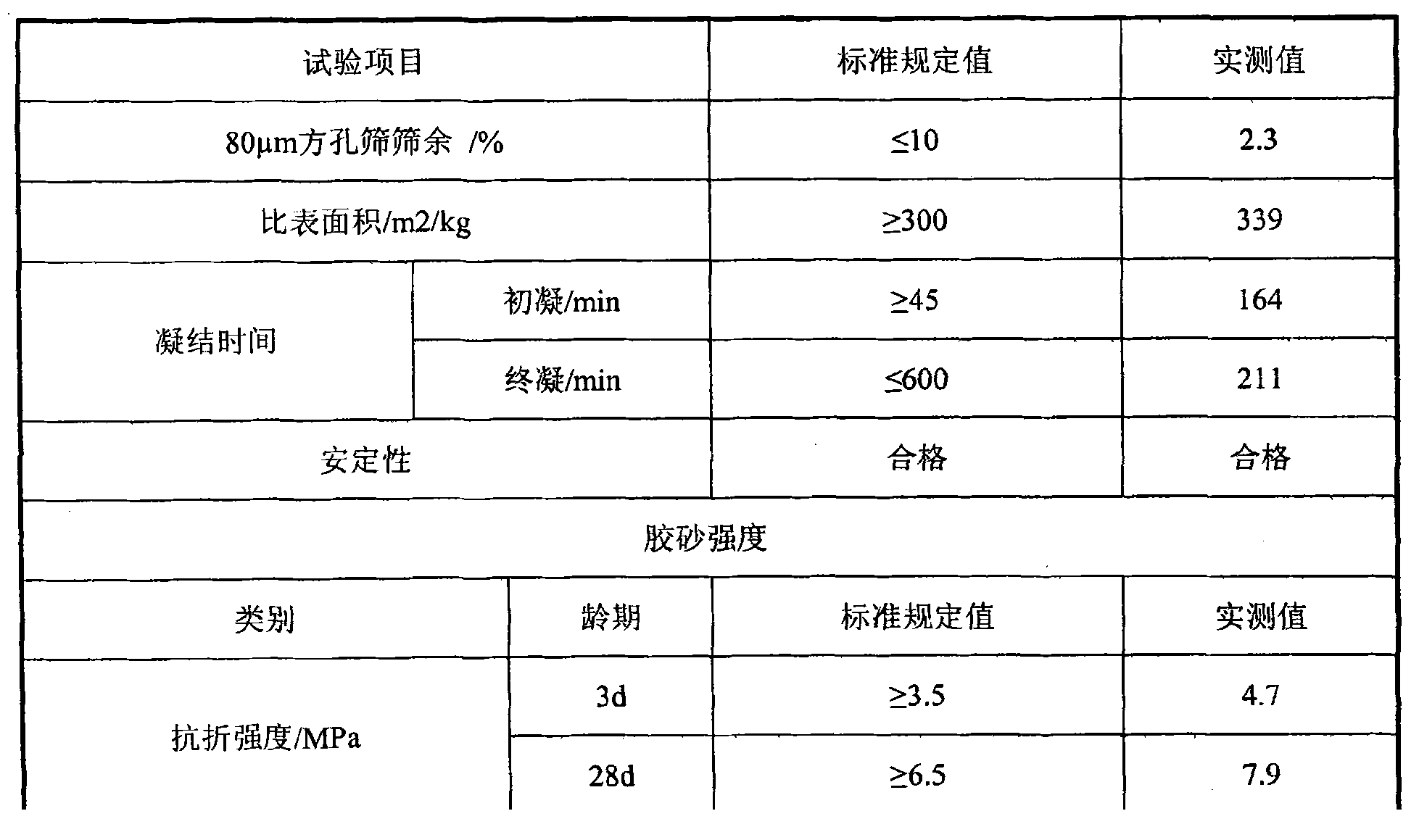

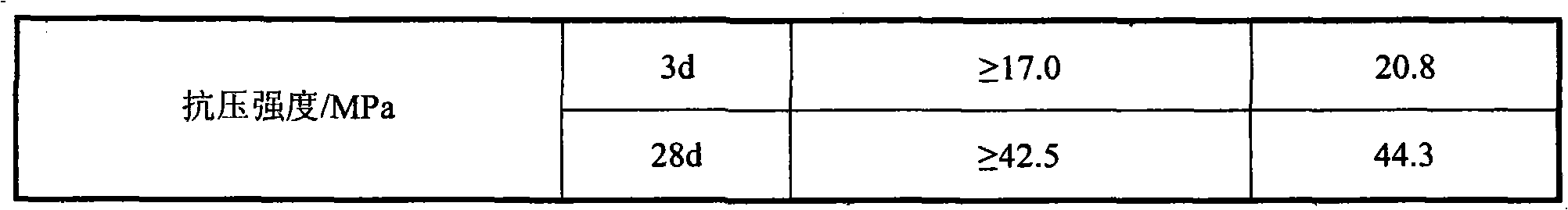

Method used

Image

Examples

Embodiment 1

[0035] (1) Purpose: The L (beam) type, D (pier) type and Z (pile) type concrete mixed with anti-cracking compacting agent were prepared, and the strength and chloride ion penetration resistance test specimens were made, and tested under standard conditions. For curing, the strength value of 7d, 28d and 56d and the electric flux of 28d and 56d were tested respectively; the test results were compared with the optimized concrete without concrete anti-cracking and densifying agent, and the effect of anti-cracking and densifying agent on concrete was analyzed. Strength, compactness and crack resistance.

[0036] (2) Scheme: The technical specifications of the raw materials used in the test are shown in Table 3 to Table 7. The mix ratio of L-type, D-type and Z-type concrete mixed with anti-cracking compacting agent adopts LYC in Table 8, DYC in Table 9 and ZYC in Table 10. Mixing ratio, the dosage of concrete anti-cracking densifier is 1.5%.

[0037] Table 3 physical and mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com