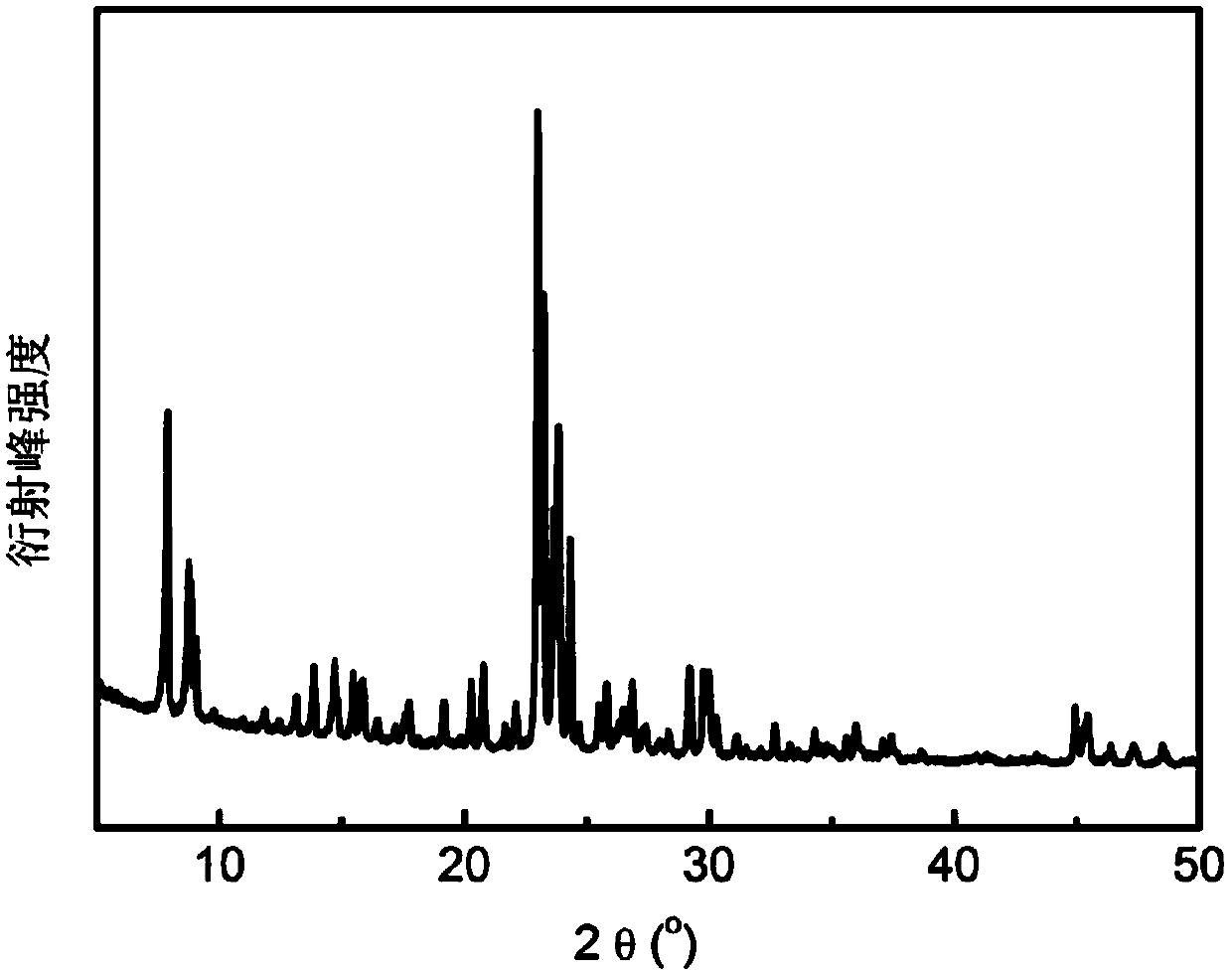

Gradient pore HZSM-5 (hydrogen zeolite socony mobile-5) molecular sieve and preparation method thereof

A molecular sieve and stepped pore technology, applied in nanotechnology, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of long hydrothermal crystallization time, increased process cost, material waste, etc. problems, to overcome poor accessibility, improve greenness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

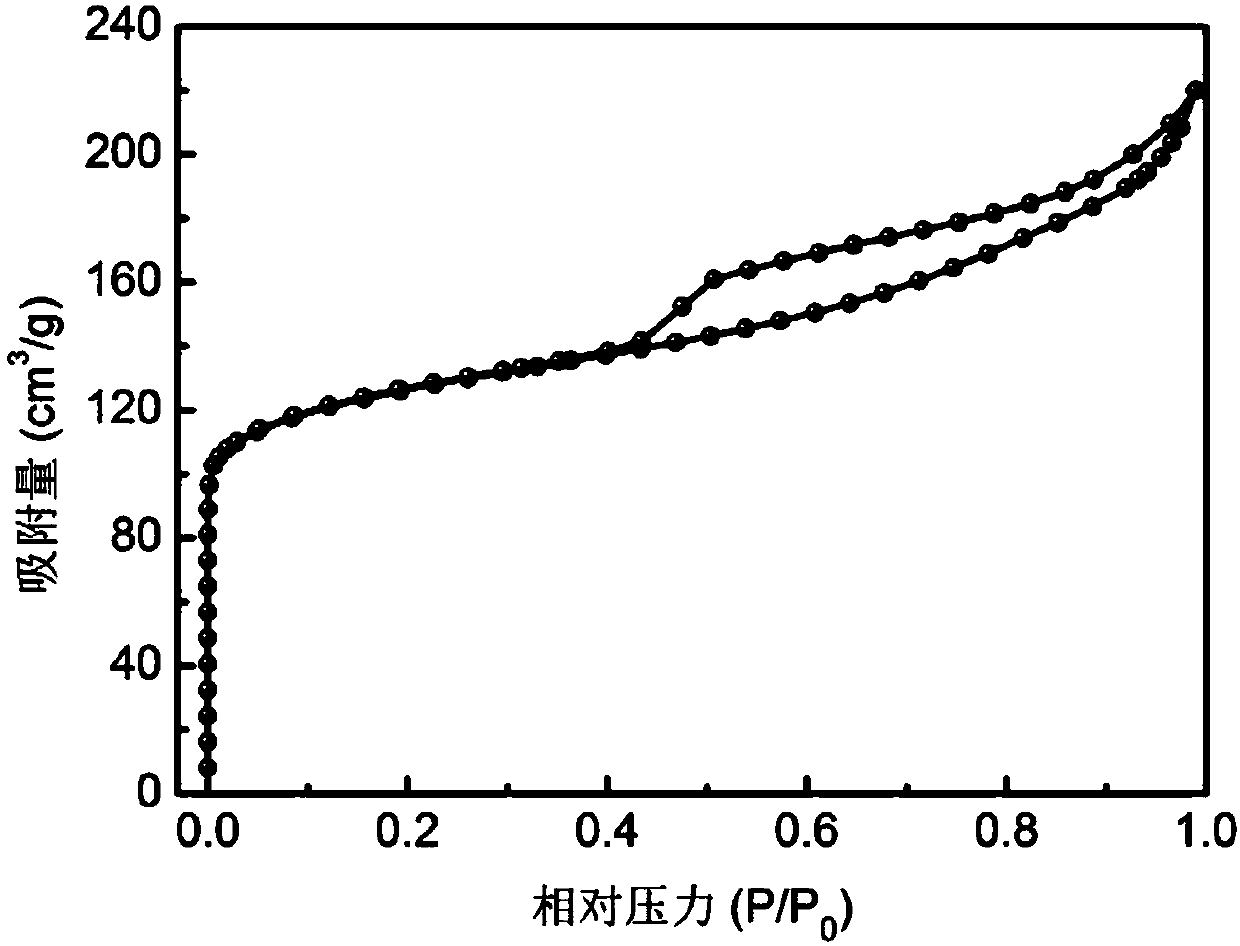

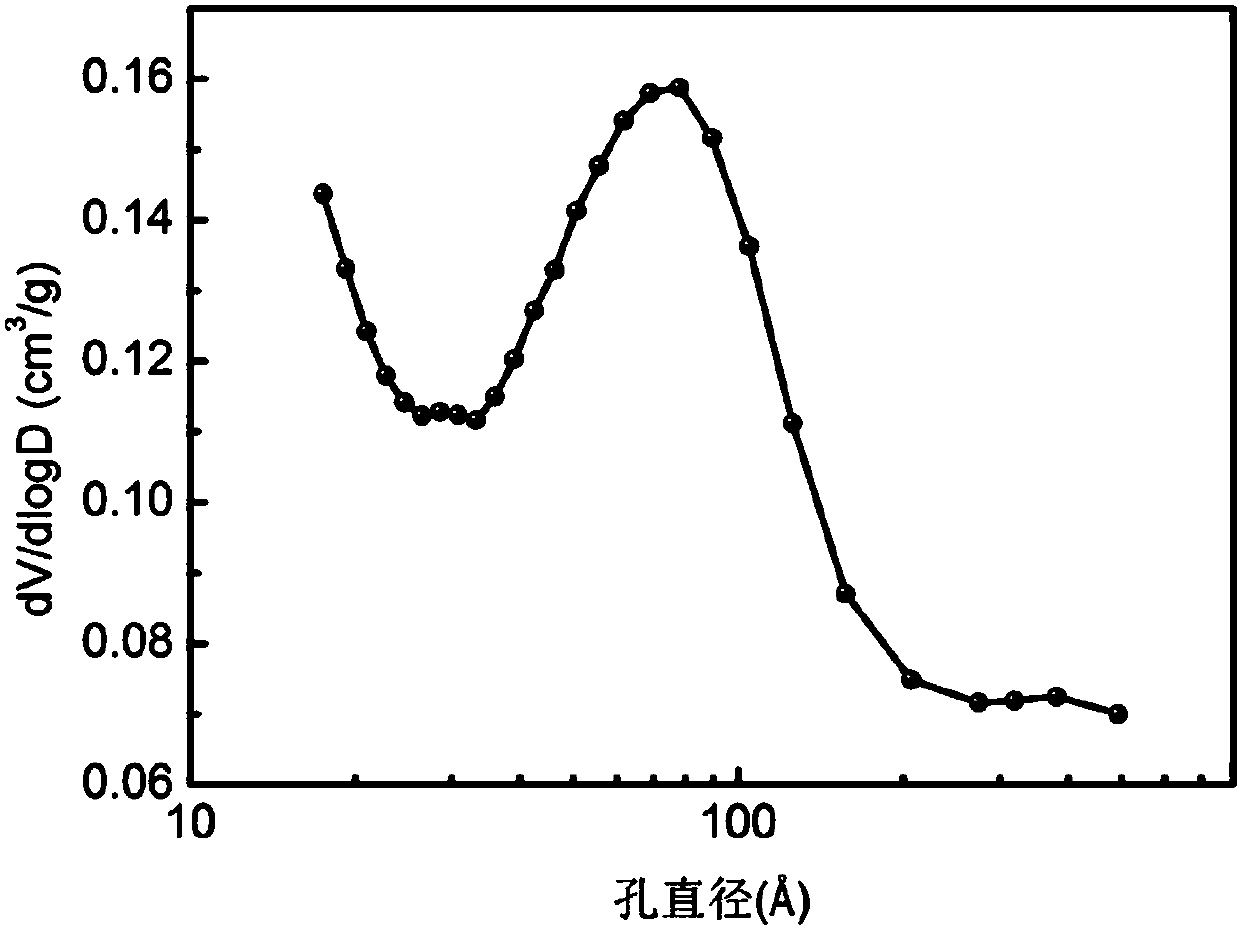

Embodiment 1

[0036] This embodiment provides a kind of stepped pore HZSM-5 molecular sieve, which is prepared by the following steps:

[0037] (1) Synthesis of microporous NaZSM-5 molecular sieve: Weigh 20.00g of kaolin powder and roast at 800°C for 4h, take 0.48g of the above-mentioned roasted kaolin powder, add 30g of deionized water and 0.30g of concentrated sulfuric acid, mix and stir at 60°C 4h; then add 17.24g water glass, 0.05g seed crystal and 19.80g deionized water, stir vigorously for 30min, add sulfuric acid to adjust the pH to gel; age at 60°C for 4h; transfer the mixture into a polytetrafluoroethylene-lined In a stainless steel crystallization kettle, crystallize statically at 180°C for 48 hours. After the crystallization is completed, cool and filter to obtain the filter cake and crystallization mother liquor, wash the filter cake until neutral, and dry at 120°C to obtain a microporous NaZSM-5 molecular sieve ;

[0038] (2) Synthesis of step-pore NaZSM-5 molecular sieve: Mix...

Embodiment 2

[0045] This embodiment provides a kind of stepped pore HZSM-5 molecular sieve, which is prepared by the following steps:

[0046] (1) Synthesis of microporous NaZSM-5 molecular sieve: Weigh 20.00g of kaolin powder and roast at 600°C for 5h, take 0.64g of the above-mentioned roasted kaolin powder, add 30.00g of deionized water and 0.61g of concentrated hydrochloric acid, Mix and stir for 5 hours; then add 16.95g water glass, 0.15g seed crystal and 19.20g deionized water, stir vigorously for 30 minutes, add sulfuric acid to adjust the pH to gel; age at 60°C for 8 hours; transfer the mixture into a polytetrafluoroethylene In a lined stainless steel crystallization kettle, crystallize statically at 170°C for 36 hours; after the crystallization is completed, cool and filter to obtain a filter cake and crystallization mother liquor, wash the filter cake until neutral, and dry at 120°C to obtain a microporous NaZSM- 5 molecular sieves;

[0047] (2) Synthesis of step-pore NaZSM-5 mol...

Embodiment 3

[0051] This embodiment provides a step-pore HZSM-5 molecular sieve, which is prepared by the following steps:

[0052] (1) Synthesis of microporous NaZSM-5 molecular sieve: Weigh 20.00g rectorite powder and roast at 850°C for 4h, take 0.57g of the above-mentioned roasted rectorite powder, add 30.00g deionized water and 0.30g concentrated sulfuric acid, Mix and stir at 60°C for 4h; add 17.22g of water glass, 0.10g of seed crystal and 19.06g of deionized water, stir vigorously for 30min, then add sulfuric acid to adjust the pH to gel; age at 60°C for 4h; move the mixture into a belt In a stainless steel crystallization kettle lined with polytetrafluoroethylene, crystallize statically at 180°C for 36 hours; after the crystallization is complete, cool and filter to obtain the filter cake and crystallization mother liquor, wash the filter cake until neutral, and dry at 120°C to obtain Microporous NaZSM-5 molecular sieve;

[0053] (2) Synthesis of step-pore NaZSM-5 molecular sieve:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore specific surface area | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Mesopore specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com