Dry-mixed ceramic tile adhesive mortar

A technology for bonding mortar and ceramic tiles, applied in the field of building materials, can solve problems such as poor performance of composite materials, weak chemical reactivity, and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

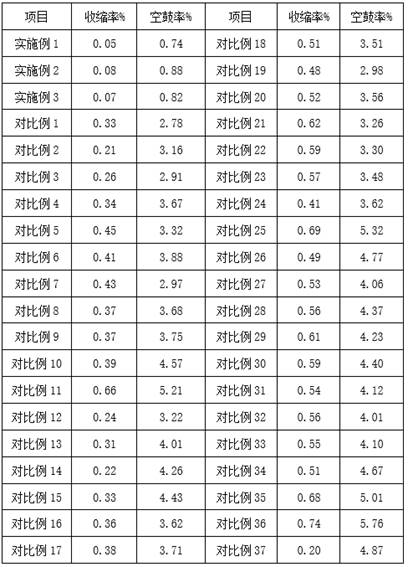

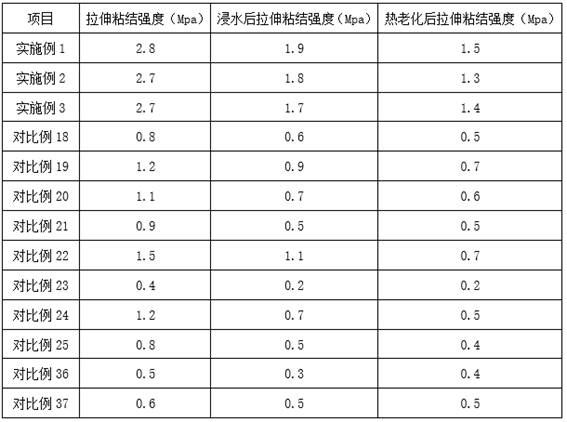

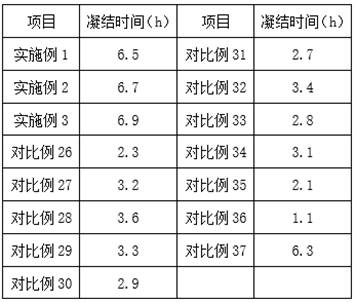

Examples

Embodiment 1

[0046] A dry-mix ceramic tile bonding mortar, the raw materials are: P.O42.5 cement: 325 parts, machine-made sand 675 parts, cellulose ether: 2.5 parts, latex powder: 14 parts, starch ether: 0.4 parts, calcium formate: 5 parts, 2 parts of binder, and 2 parts of modified retarder; among them, the machine-made sand is 55 mesh machine-made sand:95 mesh machine-made sand with a mass ratio of 3:4.

[0047] Wherein, the preparation method of described machine-made sand is:

[0048] 1) Put the peridotite, basalt, quartzite, and silica sand into water to wash away the floating soil impurities between the rocks, put the cleaned particles into the impact crusher respectively, and break them into 1.5cm pieces, and then Put it into water, wash it, clean and remove the dust therein, and set it aside;

[0049] 2) Mix the cleaned particles in step 1 according to 35 parts of peridotite, 40 parts of basalt, 30 parts of quartzite, and 18 parts of silica sand, then add 13 parts of seaweed stone...

Embodiment 2

[0076] A dry-mix ceramic tile bonding mortar, the raw materials are: P.O42.5 cement: 300 parts, machine-made sand: 700 parts, cellulose ether: 3 parts, latex powder: 8 parts, starch ether: 0.3 parts, calcium formate: 10 parts, 1 part of binder, and 1 part of modified retarder; among them, the machine-made sand is 40 mesh machine-made sand:70 mesh machine-made sand with a mass ratio of 3:4.

[0077] Wherein, the preparation method of described machine-made sand is:

[0078] 1) Put the peridotite, basalt, quartzite, and silica sand into water to wash away the floating soil impurities between the rocks, put the cleaned particles into the impact crusher respectively, and break them into 1.5cm pieces, and then Put it into water, wash it, clean and remove the dust therein, and set it aside;

[0079] 2) Mix the cleaned particles in step 1 with 40 parts of peridotite, 35 parts of basalt, 35 parts of quartzite, and 15 parts of silica sand, then add 10 parts of seaweed stone particles ...

Embodiment 3

[0106] A dry-mix ceramic tile bonding mortar, the raw materials are: P.O42.5 cement: 350 parts, machine-made sand 650 parts, cellulose ether: 2 parts, latex powder: 20 parts, starch ether: 0.5 parts, calcium formate: 1 part, 3 parts of binder, and 3 parts of modified retarder; among them, the machine-made sand is 70 mesh machine-made sand:120 mesh machine-made sand with a mass ratio of 3:4.

[0107] Wherein, the preparation method of described machine-made sand is:

[0108] 1) Put the peridotite, basalt, quartzite, and silica sand into water to wash away the floating soil impurities between the rocks, put the cleaned particles into the impact crusher respectively, and break them into 1.5cm pieces, and then Put it into water, wash it, clean and remove the dust therein, and set it aside;

[0109] 2) Mix the cleaned particles in step 1 according to 30 parts of peridotite, 45 parts of basalt, 25 parts of quartzite, and 20 parts of silica sand, then add 15 parts of seaweed stone p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com